Abstract

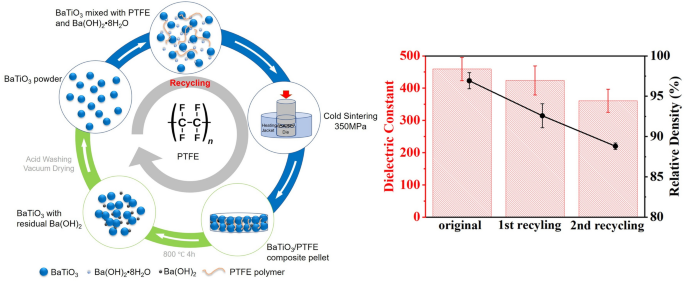

Cold sintering is an emerging technology that significantly reduces sintering temperatures by approximately an order of magnitude, down to about 100–200°C. This reduction of processing temperature enables the co-sintering and integration of dissimilar materials, such as ceramics and polymers, into unprecedented composites, where the low-energy consumption densification provides an opportunity for recycling. Here, we cold sintered barium titanate (BaTiO3)-polytetrafluoroethylene (PTFE) ceramic-polymer composites, demonstrating that nano-sized PTFE polymer powders facilitate co-sintering and enable the recycling of ceramic composites. This approach offers an opportunity for reusing and re-processing ceramic components, thereby promoting sustainability through waste reduction and energy savings.

Graphical abstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

X. Hao, A review on the dielectric materials for high energy-storage application. J. Adv. Dielectr. 3, 1330001 (2013)

M. Acosta et al., BaTiO3-based piezoelectrics: fundamentals, current status, and perspectives. Appl. Phys. Rev. 4, 041305 (2017)

C. Pan et al., Fabrication and characterization of AlN/PTFE composites with low dielectric constant and high thermal stability for electronic packaging. Mater. Sci. Mater. Electron. 27, 286–292 (2016)

Y. Bai et al., High-dielectric-constant ceramic-powder polymer composites. Appl. Phys. Lett. 76, 3804–3806 (2000)

S. Schwarzer, A. Roosen, Tape casting of piezo ceramic/polymer composites. J. Eur. Ceram. Soc. 19, 1007–1010 (1999)

S.-M. Chang et al., Optimization of piezoelectric polymer composites and 3D printing parameters for flexible tactile sensors. Addit. Manuf. 67, 103470 (2023)

J. Guo et al., Cold sintering process of composites: bridging the processing temperature gap of ceramic and polymer materials. Adv. Funct. Mater. 26, 7115–7121 (2016)

M.N. Rahaman, Sintering of ceramics (CRC Press, Boca Raton, 2007)

F. Andreola et al., Recycling of industrial wastes in ceramic manufacturing: state of art and glass case studies. Ceram. Int. 42, 13333–13338 (2016)

M. Pelino, Recycling of zinc-hydrometallurgy wastes in glass and glass ceramic materials. Waste Manag. 20, 561–568 (2000)

C. Manière et al., A spark plasma sintering densification modeling approach: from polymer, metals to ceramics. J. Mater. Sci. 53, 7869–7876 (2018)

A. Ndayishimiye et al., Hydrothermal sintering for densification of silica. Evidence for the role of water. J. Eur. Ceram. Soc. 38, 1860–1870 (2018)

C. Pithan, D. Hennings, R. Waser, Progress in the synthesis of nanocrystalline BaTiO3 powders for MLCC. Int. J. Appl. Ceram. 2, 1–14 (2005)

S.H. Wemple, M. Didomenico Jr., I. Camlibel, Dielectric and optical properties of melt-grown BaTiO3. J. Phys. Chem. Solids 29, 1797–1803 (1968)

H. Takahashi et al., Piezoelectric properties of BaTiO3 ceramics with high performance fabricated by microwave sintering. Jpn. J. Appl. Phys. 45, 7405 (2006)

T. Sada et al., High permittivity BaTiO3 and BaTiO3-polymer nanocomposites enabled by cold sintering with a new transient chemistry: Ba(OH)2⋅8H2O. J. Eur. Ceram. Soc. 41, 409–417 (2021)

Z.-M. Dang et al., Fabrication and dielectric characterization of advanced BaTiO3/polyimide nanocomposite films with high thermal stability. Adv. Funct. Mater. 18, 1509–1517 (2008)

D. Völtzke et al., Surface modification of pre-sintered BaTiO3 particles. Mater. Chem. Phys. 73, 274–280 (2002)

T. Sada et al., Highly reliable BaTiO3-polyphenylene oxide nanocomposite dielectrics via cold sintering. Adv. Mater. Interfaces 8, 2100963 (2021)

M.N. Almadhoun, U.S. Bhansali, H.N. Alshareef, Nanocomposites of ferroelectric polymers with surface-hydroxylated BaTiO3 nanoparticles for energy storage applications. J. Mater. Chem. 22, 11196–11200 (2012)

D.A. Purser, Recent developments in understanding the toxicity of PTFE thermal decomposition products. Fire Mater. 16, 67–75 (1992)

O. Pekonen et al., Numerical testing of dielectric mixing rules by FDTD method. J. Electromagn. Waves Appl. 13, 67–87 (1999)

V. Buscaglia, C.A. Randall, Size and scaling effects in barium titanate: an overview. J. Eur. Ceram. Soc. 40, 3744–3758 (2020)

T.-T. Fang, H.-L. Hsieh, F.-S. Shiau, Effects of pore morphology and grain size on the dielectric properties and tetragonal-cubic phase transition of high-purity barium titanate. J. Am. Ceram. Soc. 76, 1205–1211 (1993)

R.P.S.M. Lobo, N.D.S. Mohallem, R.L. Moreira, Grain-size effects on diffuse phase transitions of sol–gel prepared barium titanate ceramics. J. Am. Ceram. Soc. 78, 1343–1346 (1995)

M. Wintersgill et al., The temperature variation of the dielectric constant of ‘pure’ CaF2, SrF2, BaF2, and MgO. J. Appl. Phys. 50, 8259–8261 (1979)

Ch. Rayssi et al., Frequency and temperature-dependence of dielectric permittivity and electric modulus studies of the solid solution Ca0.85Er0.1Ti1−xCo4x/3O3 (0≤ x ≤ 0.1). RSC Adv. 8, 17139–17150 (2018)

K. Yang et al., Fluoro-polymer@BaTiO3 hybrid nanoparticles prepared via RAFT polymerization: toward ferroelectric polymer nanocomposites with high dielectric constant and low dielectric loss for energy storage application. Chem. Mater. 25, 2327–2338 (2013)

G. Busca et al., Solid-state and surface spectroscopic characterization of BaTiO3 fine powders. Chem. Mater. 6, 955–961 (1994)

J. Mihály et al., FTIR and FT-Raman spectroscopic study on polymer based high pressure digestion vessels. Croat. Chem. Acta 79, 497–501 (2006)

Acknowledgements

The authors acknowledge the support of the National Science Foundation FMSG (2134643).

Funding

This work was supported by the National Science Foundation FMSG (2134643).

Author information

Authors and Affiliations

Contributions

JZ: Conceptualization, Methodology, Formal analysis, Investigation, Visualization, Writing—original draft. EDG: Conceptualization, Writing—review & editing, Supervision, Funding acquisition. HS: Conceptualization, Writing—review & editing, Supervision, Funding acquisition.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, J., Gomez, E.D. & Sun, H. Nano-sized polymer-assisted cold sintering and recycling of ceramic composites. MRS Communications (2024). https://doi.org/10.1557/s43579-024-00524-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1557/s43579-024-00524-9