Abstract

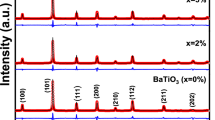

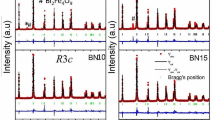

As a new functional material, multiferroic materials have attracted much attention in recent years. In this paper, BaFe12O19 (BaM) ceramics were prepared by the sol–gel method sintered at different temperatures. The effect of sintering temperature on microstructure, surface morphology, dielectric properties, ferroelectric properties and magnetic properties of BaM ceramics were systematically studied. XRD results show that the main diffraction peaks are attributed to BaM ceramics. SEM results show that the grain size of ceramics increases from 0.82 to 1.15 μm with the sintering temperature increase from 1150 to 1300 °C. At room temperature, when the sintering temperature is 1150 °C, the residual polarization, saturation magnetization and residual magnetization of ceramics reach the maximum, which are 0.064 μC/cm2, 67.145 emu/g, 34.722 emu/g, respectively. The changes of dielectric and ferroelectric properties under applied magnetic field indicate that BaM ceramics have certain magnetoelectric response, which provides a new direction for the development and application of BaM devices.

Graphical abstract

The effect of sintering temperature on the multiferroic properties of hexagonal barium ferrite (BaM) ceramics was studied. The ferroelectric and magnetic hysteresis loops of the ceramics indicate the room temperature multiferroic properties of the prepared ceramics. The effect of leakage current on ferroelectric properties of ceramics was also studied. It lays a foundation for the study of single-phase multiferroic materials at room temperature.

Similar content being viewed by others

Data availability

The datasets and material generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

R.L. Gao, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, W. Cai, G. Chen, X.L. Deng, X.L. Cao, X.D. Luo, C.L. Fu, Nanoscale 10(26), 11750–11759 (2018). https://doi.org/10.1039/C8NR02368A

H. Wu, H. Ao, W.C. Li, Z.X. Zeng, R.L. Gao, C.L. Fu, G. Chen, X.L. Deng, Z.H. Wang, X. Lei, W. Cai, Mater. Today Chem. 21, 100511 (2021). https://doi.org/10.1016/j.mtchem.2021.100511

R.L. Gao, L. Bai, Z.Y. Xu, Q.M. Zhang, Z.H. Wang, W. Cai, G. Chen, X.L. Deng, C.L. Fu, Adv. Electron. Mater. 4(6), 1800030 (2018). https://doi.org/10.1002/aelm.201800030

H. Wu, Z.X. Zeng, S.L. Xing, M.S. Lan, W.C. Li, Q. Zhang, H. Ao, C. Zhou, R.C. Xu, R.L. Gao, X.L. Deng, Adv. Eng. Mater. (2021). https://doi.org/10.1002/adem.202100410

R.L. Gao, H.W. Yang, J.R. Sun, Y.G. Zhao, B.G. Shen, Appl. Phys. Lett. 104, 031906 (2014). https://doi.org/10.1063/1.4862793

C.Y. Li, R.C. Xu, R.L. Gao, Z.H. Wang, G. Chen, X.L. Deng, W. Cai, C.L. Fu, Q.T. Li, Mater. Chem. Phys. 249, 123144 (2020). https://doi.org/10.1016/j.matchemphys.2020.123144

T. Kimura, T. Goto, H. Shintani, K. Ishizaka, T. Arima, Y. Tokura, Nature 426, 55–58 (2003). https://doi.org/10.1038/nature02018

N. Hur, S. Park, P.A. Sharma, J.S. Ahn, S. Guha, S.-W. Cheong, Nature 429, 392–395 (2004). https://doi.org/10.1038/nature02572

J.W. Kim, S.Y. Haam, Y.S. Oh, K.H. Kim, P. Natl, Proc. Natl. Acad. Sci 106, 15573–15576 (2009). https://doi.org/10.1073/pnas.0907589106

J.M. Liu, S. Dong, J. Adv. Dielectr 5, 1530003 (2015). https://doi.org/10.1142/S2010135X15300030

S. Prathap, W. Madhuri, J. Magn. Magn. Mater 430, 114–122 (2017). https://doi.org/10.1016/j.jmmm.2016.12.116

A. Shayan, M. Abdellahi, F. Shahmohammadian, S. Jabbarzare, A. Khandan, H. Ghayour, J. Alloys Compd 708, 538–546 (2017). https://doi.org/10.1016/j.jallcom.2017.02.305

G.L. Tan, X.N. Chen, J. Magn. Magn. Mater 327, 87–90 (2013). https://doi.org/10.1016/j.jmmm.2012.09.047

S. Díaz-Castañón, L.J.L. Sánchez, E. Estevez-Rams, F. Leccabue, B.E. Watts, J. Magn. Magn. Mater 185, 194–198 (1998). https://doi.org/10.1016/S0304-8853(98)00013-4

R.J. Tang, H. Zhou, W.L. You, H. Yang, Appl. Phys. Lett 109, 082903 (2016). https://doi.org/10.1063/1.4961615

T. Kaur, J. Sharma, S. Kumar, A.K. Srivastava, Cryst. Res. Technol 52, 1700098 (2017). https://doi.org/10.1002/crat.201700098

S. Anjum, M. Sattar, Z. Mustafa, J. Mater. Sci. Mater. Electron 32, 232–245 (2021). https://doi.org/10.1007/s10854-020-04759-9

G.B. Teh, Y.C. Wong, R.D. Tilley, J. Magn. Magn. Mater 323, 2318–2322 (2011). https://doi.org/10.1016/j.jmmm.2011.04.014

Y. Liu, M.G.B. Drew, J.P. Wang, M.L. Zhang, Y. Liu, J. Magn. Magn. Mater 22, 366–374 (2010). https://doi.org/10.1016/j.jmmm.2009.09.062

R.C. Pullar, Prog. Mater. Sci 57, 1191–1334 (2012). https://doi.org/10.1016/j.pmatsci.2012.04.001

A. Ashrafizadeh, A. Ghasemi, A. Paesano Jr., X. Liu, A. Morisako, J. Meteorol. Soc. Jpn. 34, 489–492 (2010). https://doi.org/10.3379/msjmag.1006R004

X. Li, G.L. Tan, J. Alloys Compd 858, 157722 (2021). https://doi.org/10.1016/j.jallcom.2020.157722

P. Ren, J.G. Guan, X.D. Cheng, Mater. Chem. Phys 98, 90–94 (2006). https://doi.org/10.1016/j.matchemphys.2005.08.070

G. Benito, M.P. Morales, J. Requena, V. Raposo, M. Vázquez, J.S. Moya, J. Magn. Magn. Mater 234, 65 (2001). https://doi.org/10.1016/S0304-8853(01)00288-8

S. Mandizadeh, F. Soofivand, M. Salavati-Niasari, Adv. Powder. Technol 26, 1348 (2015). https://doi.org/10.1016/j.apt.2015.07.009

A. Ataie, S. Heshmati-Manesh, H. Kazempour, J. Mater. Sci 37, 2125 (2002). https://doi.org/10.1023/A:1015254221872

G.Z. Shen, X.U. Zheng, L.I. Yi, J. Mater. Sci. Eng 23, 521 (2005). https://doi.org/10.3969/j.issn.1673-2812.2005.05.012

R.L. Gao, X.F. Qin, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, C.L. Fu, G. Chen, X.L. Deng, W. Cai, Mater. Chem. Phys. 232, 428–437 (2019). https://doi.org/10.1016/j.matchemphys.2019.05.016

H. Wu, W.C. Li, H. Ao, Z.X. Zeng, X.F. Qin, S.L. Xing, C. Zhou, R.L. Gao, X.L. Deng, W. Cai, G. Chen, Z.H. Wang, X. Lei, C.L. Fu, J. Alloys Compd. 896, 162932 (2021). https://doi.org/10.1016/j.jallcom.2021.162932

R.L. Ga, Z.H. Wang, G. Chen, X.L. Deng, W. Cai, C.L. Fu, Ceram. Int. 44, S84–S87 (2018). https://doi.org/10.1016/j.ceramint.2018.08.234

X.F. Qin, H. Wu, C.Y. Chen, H. Ao, W.C. Li, R.L. Gao, W. Cai, G. Chen, X.L. Deng, Z.H. Wang, X. Lei, C.L. Fu, J. Alloys Compd. 890, 161869 (2021). https://doi.org/10.1016/j.jallcom.2021.161869

R.C. Xu, Z.H. Wang, R.L. Gao, S.L. Zhang, Q.W. Zhang, Z.D. Li, C.Y. Li, G. Chen, X.L. Deng, W. Cai, C.L. Fu, J. Mater. Sci. Mater. Electron. 29, 16226–16237 (2018). https://doi.org/10.1007/s10854-018-9712-x

H. Wu, R.C. Xu, C. Zhou, S.L. Xing, Z.X. Zeng, H. Ao, W.C. Li, X.F. Qin, R.L. Gao, J. Phys. Chem. Solids 160, 110314 (2022). https://doi.org/10.1016/j.jpcs.2021.110314

R.C. Xu, S.L. Zhang, F.Q. Wang, Q.W. Zhang, Z.D. Li, Z.H. Wang, R.L. Gao, C.L. Fu, J. Electron. Mater. 48(1), 386–400 (2019). https://doi.org/10.1007/s11664-018-6718-3

Y.Z. Xue, R.C. Xu, Z.H. Wang, R.L. Gao, C.Y. Li, G. Chen, X.L. Deng, W. Cai, C.L. Fu, J. Electron. Mater. 48(8), 4806–4817 (2019). https://doi.org/10.1007/s11664-019-07261-z

R.L. Gao, Q.Z. Leng, Z.H. Wang, G. Chen, C.L. Fu, X.L. Deng, W. Cai, Mater. Res. Express 6, 026308 (2018). https://doi.org/10.1088/2053-1591/aaeefc

S. Giordano, Y. Dusch, N. Tiercelin, P. Pernod, V. Preobrazhensky, J. Phys. D 46, 325002 (2013). https://doi.org/10.1088/0022-3727/46/32/325002

B. Raneesh, H. Soumya, J. Philip, S. Thomas, K. Nandakumar, J. Alloys Compd 611, 381 (2014). https://doi.org/10.1016/j.jallcom.2014.05.155

N.S. Negi, R. Kumar, H. Sharma, J. Shah, R.K. Kotnala, J. Magn. Magn. Mater 456, 292 (2018). https://doi.org/10.1016/j.jmmm.2017.12.095

R.L. Gao, X.F. Qin, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, C.L. Fu, G. Chen, X.L. Deng, W. Cai, J. Alloys Compd 795, 501 (2019). https://doi.org/10.1016/j.jallcom.2019.05.013

G.L. Tan, W. Li, J. Am. Ceram. Soc 98, 1812 (2015). https://doi.org/10.1111/jace.13530

G.L. Tan, Y. Huang, H.H. Sheng, PLoS ONE 11, e0167084 (2016). https://doi.org/10.1371/journal.pone.0167084

W. Cai, J.C. Gao, C.L. Fu, L.W. Tang, J. Alloys Compd 487, 668 (2009). https://doi.org/10.1016/j.jallcom.2009.08.034

R.L. Gao, Q.M. Zhang, Z.Y. Xu, Z.H. Wang, G. Chen, X.L. Deng, C.L. Fu, W. Cai, Composites B 166, 204 (2019). https://doi.org/10.1016/j.compositesb.2018.12.010

F.Q. Wang, W. Cai, C.L. Fu, R.L. Gao, Z.H. Wang, G. Chen, X.L. Deng, J. Mater. Sci-Mater. El 30, 2177 (2019). https://doi.org/10.1007/s10854-018-0489-8

A.R. Abraham, B. Raneesh, S. Joseph, P.A. Mohammed, P.M.G. Nambissan, D. Das, D. Rouxel, O.S. Oluwafemi, S. Thomas, N. Kalarikkal, Phys. Chem. Chem. Phys 21, 8709 (2019). https://doi.org/10.1039/C8CP04946G

H.B. Sharma, K.N. Devi, V. Gupta, J.H. Lee, S.S. Bobby, J. Alloy. Compd 599, 32 (2014). https://doi.org/10.1016/j.jallcom.2014.02.024

B.C. Brightlin, S. Balamurugan, J. Supercond. Nov. Magn 30, 215 (2017). https://doi.org/10.1007/s10948-016-3703-z

K. Polley, R. Kundu, J. Bera, Int. J. Environ. Anal. Chem (2021). https://doi.org/10.1080/03067319.2021.1887165

R. Pattanayak, R. Subhajit, T. Dash, S. Mohapatra, R. Muduli, S. Panigrahi, Physica. B 485, 67 (2016). https://doi.org/10.1016/j.physb.2017.02.013

M. Drofenik, I. Ban, G. Ferk, D. Makovec, A. Žnidaršič, Z. Jagličić, D. Lisjak, J. Am. Ceram. Soc 93, 1602 (2010). https://doi.org/10.1111/j.1551-2916.2010.03620.x

J.C.F. Gandarilla, S. Dı́az-Castañón, N.S. Almodovar, J. Magn. Magn. Mater 222, 271 (2000). https://doi.org/10.1016/S0304-8853(00)00431-5

S.E. Jacobo, L. Civale, M.A. Blesa, J. Magn. Magn. Mater. 260, 37 (2003). https://doi.org/10.1016/S0304-8853(01)00924-6

J. Ding, W.F. Miao, P.G. McCormick, R. Street, J. Alloy. Compd. 281, 32 (1998). https://doi.org/10.1016/S0925-8388(98)00766-X

L. Rezlescu, E. Rezlescu, P.D. Popa, N. Rezlescu, J. Magn. Magn. Mater. 193, 288 (1999). https://doi.org/10.1016/S0304-8853(98)00442-9

Acknowledgments

The present work has been supported by the Scientific and Technological Research Program of Chongqing Municipal Education Commission (KJZD-M201901501), the Chongqing Research Program of Basic Research and Frontier Technology (cstc2019jcyj-msxmX0071, cstc2021jcyj-msxmX0008, cstc2021jcyj-msxmX0039, cstc2021jcyj-msxmX0599), the Program for Creative Research Groups in University of Chongqing (CXQT19031), the Natural Science Foundation of Chongqing (cstc2020jcyj-zdxmX0008, cstc2020jcyj-msxmX0030), the Leading Talents of Scientific and Technological Innovation in Chongqing (CSTCCXLJRC201919), the special project of Chongqing technology innovation and application development (cstc2020jscx-msxmX0218), the Research Foundation of Chongqing University of Science and Technology (No. Ckrc2019020), the special project for technological innovation and application development of Chongqing Science and technology enterprises (cstc2021kqjscx-phxmX0008), the Postgraduate Technology Innovation Project of the Chongqing University of Science and Technology (Grant No. 2021187), and the Postgraduate technology innovation project of Chongqing University of Science & Technology (YKJCX2120525, YKJCX2120510, YKJCX2120531, YKJCX2120201).

Author information

Authors and Affiliations

Contributions

ML: Conceptualization, Methodology, Investigation, Writing—original draft. ZZ: Validation, Formal analysis, Visualization. QZ: Validation, Formal analysis, Visualization, Writing—review and editing. GS: Validation, Formal analysis,—review and editing. HW: Resources, Writing—review and editing. HA: Resources, Writing—review and editing. XD, RG: Formal analysis, Writing—review and editing. WC, ZW: Writing—review and editing. CF: Resources, Writing—review and editing, Supervision, Data curation. XL: Resources, Writing—review and editing, Supervision, Data curation. GC: Writing—review and editing.

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

No human and/or animal studies are involved. Manuscript is approved by all authors for publication.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lan, M., Zeng, Z., Zhang, Q. et al. Effect of sintering temperature on magnetoelectric properties of barium ferrite ceramics. Journal of Materials Research 37, 2837–2847 (2022). https://doi.org/10.1557/s43578-022-00679-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00679-y