Abstract

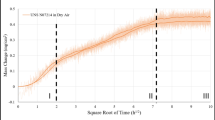

Aluminum-mercury alloys prepared by a thermal processing route were exposed to humid air environments under controlled temperature and humidity. The mass changes and energetics associated with the ensuing reaction were monitored by thermal analysis techniques, and it was found that a surprising inverse relationship exists between reaction rate and temperature under constant mass flow rate of water vapor. Additionally, at constant temperature there exists a water mass flow rate threshold below which no reaction occurs. The presence of mercury in the alloy at a gravimetric loading of 120 ppm or less produces no measurable reaction with humid air under the conditions employed, while higher mercury loadings result in the formation of voluminous low-density alumina filaments. Increasing the surface area of a bulk alloy sample through mechanical attrition reduces the rate and extent of reaction, contrary to the behavior of typical surface-moderated reactions. These findings demonstrate that “homogeneously” distributed Hg in Al, as produced by our thermal processing route, generally retains its strongly activating behavior in air. Furthermore, the systematic variation in Hg composition and reaction conditions has quantified the thresholds required for sustaining air-reactivity of such materials.

Graphical abstract

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to legal or ethical reasons.

References

J. Petrovic, Reaction of aluminum with water to produce hydrogen, a study of issues related to the use of aluminum for on-board vehicular hydrogen storage, version 1.0., U.S. Department of Energy (2008)

I. Oluwole, Aluminium anode activation research—a review. Int. J. Sci. Technol. 2, 561–566 (2012)

A. Malek, T. Thomas, E. Prasad, Evidence of nano-galvanic couple formation on in-situ formed nano-aluminum amalgam surfaces for passivation-bypassed water splitting. Int. J. Hydrog. Energy 43, 10878–10886 (2018)

S. Xu, X.-H. Yang, S.-S. Tang, J. Liu, Liquid metal activated hydrogen production from waste aluminum for power supply and its life cycle assessment. Int. J. Hydrog. Energy 44, 17505–17514 (2019)

O.V. Kravchenko, K.N. Semenenko, B.M. Bulychev, K.B. Kalmykov, Activation of aluminum metal and its reaction with water. J. Alloys Compd. 397, 58–62 (2005)

S. Xu, X. Zhao, J. Liu, Liquid metal activated aluminum-water reaction for direct hydrogen generation at room temperature. Renew. Sustain. Energy Rev. 92, 17–37 (2018)

J. Bessone, The activation of aluminium by mercury ions. Corros. Sci. 48, 4243–4256 (2006)

M.R. Pinnell, J.E. Bennett, Voluminous oxidation of aluminium by continuous dissolution in a wetting mercury film. J. Mater. Sci. 7, 1016–1026 (1972)

E. Senel, K. Nisancioglu, Anodic activation of aluminium containing small amounts of gallium. Corros. Sci. 88, 280–290 (2014)

R.C. Furneaux, G.E. Thompson, G.C. Wood, An electronoptical study of the conversion coating formed on aluminium in a chromate/fluoride solution. Corros. Sci. 19, 63–71 (1979)

A. Cossa, Sull’Amalgama dell’Alluminio (On the Amalgam of Aluminum). Il Nuovo Cimento 3, 228 (1870)

H. Wislicenus, Über die faserähnlichegewachsene Tonerde (Fasertonerde) und ihre Oberflächenwirkungen (Adsorption). Kolloid-Zeitschrift 2, 11–20 (1908)

J.H.L. Watson, A. Vallejo-Freire, P. DeSouza Santos, J. Parsons, The fine structure and properties of fibrous alumina. Kolloid-Zeitschrift 154, 4–15 (1957)

W. Vedder, D.A. Vermilea, Aluminum + water reaction. Trans. Faraday Soc. 65, 561–584 (1969)

L.A. Bruce, G.W. West, Comment on “Voluminous oxidation of aluminium by continuous dissolution in a wetting mercury film.” J. Mater. Sci. 9, 335–338 (1974)

X.-N. Huang, C.-J. Lv, Y.-X. Huang, S. Liu, C. Wang, D. Chen, Effects of amalgam on hydrogen generation by hydrolysis of aluminum with water. Int. J. Hydrog. Energy 36, 15119–15124 (2011)

I.E. Smith, Hydrogen generation by means of the aluminum/water reaction. J. Hydronaut. 6, 106–109 (1972)

W. Chesworth, Use of aluminum-amalgam in mineral synthesis at low temperatures and 1 atmosphere total pressure. Clays Clay. Miner. 19, 337–339 (1971)

E.J. Markel, E. Reddick, L.A. Napper, J.W. Van Zee, Aerogel monoliths produced by direct oxidation of aluminum. J. Non-Cryst. Solids 180, 32–39 (1994)

R. Fitch, F. Luzzio, The aluminum amalgam reduction of 2-nitroalkanols promoted by ultrasound. Tetrahedron Lett. 35, 6013 (1994)

J.C. Anderson, H.A. Chapman, Aluminum amalgam for the reduction of sensitive β-nitroamines to 1,2-diamines. Synthesis 19, 3309–3315 (2006)

P. Villars, ASM Alloy Phase Diagram Database, ASM International, 2006–2018. https://matdata.asminternational.org/apd/index.aspx.

L.F. Kozin, S. Hansen, Mercury Handbook: Chemistry, Applications and Environmental Impact. RSC Publishing (2013). www.RSC.org/books.

G. Jangg, E. Lugscheider, Die Löslichkeit von Quecksilber in verschiedenen Metallen. Monatsh. Chem. 104, 1269–1275 (1973)

C. Gumiński, Review selected properties of simple amalgams. J. Mater. Sci. 24, 2661–2676 (1989)

W. Rostaker, J.M. McCaughey, H. Markus, Embrittlement by Liquid Metals (Reinhold Pub. Co., New York, 1960)

J.E. Bennett, M.R. Pinnell, Reactions between mercury-wetted aluminium and liquid water. J. Mater. Sci. 8, 1189–1193 (1973)

R.W. Rice, D.V. Sarode, Mercury-catalyzed dissolution of aluminum in nitric acid. Ind. Eng. Chem. Res. 40, 1872–1878 (2001)

Acknowledgments

Sandia National Laboratories is a multi-mission laboratory managed and operated by National Technology and Engineering Solutions of Sandia, LLC., a wholly owned subsidiary of Honeywell International, Inc., for the U.S. Department of Energy’s National Nuclear Security Administration under contract DE-NA0003525. The views expressed in this article do not necessarily represent the views of the U.S. Department of Energy or the United States Government.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Coker, E.N., Small, L.J., Hahn, N.T. et al. Near-ambient oxidation of melt-processed aluminum-mercury alloy compounds under air with controlled humidity. Journal of Materials Research 37, 1771–1779 (2022). https://doi.org/10.1557/s43578-022-00577-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00577-3