Abstract

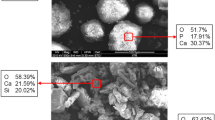

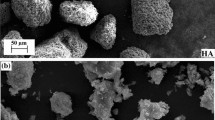

This research presents the basic in vitro assessment of bare Ti6Al4V alloy, hydroxyapatite (HA), and calcium silicate (CS)-reinforced HA coatings. The weight percentage of CS reinforcement in HA was varied as the HA–x%CS (x = 0, 10, and 20 wt %). The phase compositions, coating’s microstructure, chemical properties, microhardness, porosity, surface roughness, and in vitro studies were performed. The HA–10%CS and HA–20%CS coatings displayed the crack-free morphology, whereas microcracks were observed over the surface of pure HA coating. With the progressive increment of CS content in HA, crystallinity, surface roughness, porosity, microhardness, and Young’s modulus for HA–10%CS and HA–20%CS coatings increased compared to pure HA coating. The HA–10%CS and HA–20%CS coatings were more conducive and displayed superior hemocompatibility than HA. The HA–10%CS and HA–20%CS coatings exhibited no adverse effects on the erythrocytes, and the hemolysis rate (HR) was within the domain of safe value (< 5%) for implant materials. The findings of this study indicate that surface modification of Ti6Al4V alloy with HA–10%CS and HA–20%CS coatings is a promising approach to improve the performance for bio-implant applications.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

M. Talha, C.K. Behera, O.P. Sinha, A review on nickel-free nitrogen containing austenitic stainless steels for biomedical applications. Mater. Sci. Eng. C 33, 3563–3575 (2013). https://doi.org/10.1016/j.msec.2013.06.002

G. Singh, T.R. Ablyaz, E.S. Shlykov, K.R. Muratov, A.S. Bhui, S.S. Sidhu, Enhancing corrosion and wear resistance of Ti6Al4V alloy using CNTs mixed electro-discharge process. Micromachines (2020). https://doi.org/10.3390/MI11090850

A.S. Bhui, G. Singh, S.S. Sidhu, P.S. Bains, Experimental investigation of optimal ed machining parameters for Ti-6Al-4V biomaterial. Facta Univ. Ser. Mech. Eng. 16, 337–345 (2018). https://doi.org/10.22190/FUME180824033B

G. Singh, S.S. Sidhu, P.S. Bains, M. Singh, A.S. Bhui, On surface modification of Ti alloy by electro discharge coating using hydroxyapatite powder mixed dielectric with graphite tool. J. Bio- Tribo-Corros. (2020). https://doi.org/10.1007/s40735-020-00389-0

R. Balokhonov, V. Romanova, A. Panin, S. Martynov, M. Kazachenok, Numerical study of stress–strain localization in the titanium surface modified by an electron beam treatment. Facta Univ. Ser. Mech. Eng. 14, 329–334 (2016). https://doi.org/10.22190/FUME1603329B

R. Kumari, J. Dutta, Studies on corrosion resistance and bio-activity of plasma spray deposited hydroxylapatite (HA) based TiO2 and ZrO2 dispersed composite coatings on titanium alloy (Ti-6Al-4V) and the same after post spray heat treatment. Appl. Surf. Sci. 420, 935–943 (2017). https://doi.org/10.1016/j.apsusc.2017.05.208

J. Singh, S.S. Chatha, H. Singh, Synthesis and characterization of plasma sprayed functional gradient bioceramic coating for medical implant applications. Ceram. Int. 47, 9143–9155 (2021). https://doi.org/10.1016/j.ceramint.2020.12.039

J. Singh, S. Singh, H. Singh, Characterization and corrosion behavior of functional gradient hydroxyapatite coating. J. Therm. Spray Technol. (2018). https://doi.org/10.1007/s11666-018-0802-3

X. Zhang, W. Chaimayo, C. Yang, J. Yao, B.L. Miller, M.Z. Yates, Surface & coatings technology silver-hydroxyapatite composite coatings with enhanced antimicrobial activities through heat treatment. Surf. Coat. Technol. 325, 39–45 (2017). https://doi.org/10.1016/j.surfcoat.2017.06.013

Y. Yang, Y. Wang, W. Tian, D. Ran Yan, J. Xin Zhang, L. Wang, Influence of composite powders’ microstructure on the microstructure and properties of Al2O3–TiO2 coatings fabricated by plasma spraying. Mater. Design 65, 814–822 (2015). https://doi.org/10.1016/j.matdes.2014.09.078

V.F. Shamray, V.P. Sirotinkin, V.I. Kalita, V.S. Komlev, S.M. Barinov, A.Y. Fedotov, A.S. Gordeev, Study of the crystal structure of hydroxyapatite in plasma coating. Surf. Coat. Technol. 372, 201–208 (2019). https://doi.org/10.1016/j.surfcoat.2019.05.037

E. Canas, M.J. Orts, A.R. Boccaccini, E. Sanchez, Microstructural and in vitro characterization of 45S5 bioactive glass coatings deposited by solution precursor plasma spraying (SPPS). Surf. Coat. Technol. 371, 151–160 (2019). https://doi.org/10.1016/j.surfcoat.2018.12.057

S. Yang, H.C. Man, W. Xing, X. Zheng, Adhesion strength of plasma-sprayed hydroxyapatite coatings on laser gas-nitrided pure titanium. Surf. Coat. Technol. 203, 3116–3122 (2009). https://doi.org/10.1016/j.surfcoat.2009.03.034

X. Zhao, X. Liu, J. You, Z. Chen, C. Ding, Bioactivity and cytocompatibility of plasma-sprayed titania coating treated by sulfuric acid treatment. Surf. Coat. Technol. 202, 3221–3226 (2008). https://doi.org/10.1016/j.surfcoat.2007.11.026

V. Koshuro, A. Fomin, I. Rodionov, Composition, structure and mechanical properties of metal oxide coatings produced on titanium using plasma spraying and modified by micro-arc oxidation. Ceram. Int. 44, 12593–12599 (2018). https://doi.org/10.1016/j.ceramint.2018.04.056

A. Singh, G. Singh, V. Chawla, Characterization and mechanical behavior of reinforced hydroxyapatite coatings deposited by vacuum plasma spray on SS-316L alloy. J. Mech. Behav. Biomed. Mater. 79, 273–282 (2018). https://doi.org/10.1016/j.jmbbm.2018.01.005

R. Kumari, J. Dutta, Materials Characterization Microstructure and surface mechanical properties of plasma spray deposited and post spray heat treated hydroxyapatite (HA) based composite coating on titanium alloy (Ti-6Al-4V) substrate. Mater. Charact. 131, 12–20 (2017). https://doi.org/10.1016/j.matchar.2017.06.011

J. Singh, S. Singh, H. Singh, Effect of Various Additives on Mechanical and Biological Properties of Hydroxyapatite Coating, (2017), pp. 290–293

S. Singh, C. Prakash, H. Singh, Deposition of HA–TiO2 by plasma spray on β-phase Ti–35Nb–7Ta–5Zr alloy for hip stem: characterization, mechanical properties, corrosion, and in-vitro bioactivity. Surf. Coat. Technol. 398, 126072 (2020). https://doi.org/10.1016/j.surfcoat.2020.126072

G. Singh, H. Singh, B. Singh, Characterization and corrosion resistance of plasma sprayed HA and HA–SiO2 coatings on Ti–6Al–4V. Surf. Coat. Technol. 228, 242–247 (2013). https://doi.org/10.1016/j.surfcoat.2013.04.036

M. Mittal, S.K. Nath, S. Prakash, Improvement in mechanical properties of plasma sprayed hydroxyapatite coatings by Al2O3 reinforcement. Mater. Sci. Eng. C 33, 2838–2845 (2013). https://doi.org/10.1016/j.msec.2013.03.005

M. Mirzaee, M. Vaezi, Y. Palizdar, Synthesis and characterization of silver doped hydroxyapatite nanocomposite coatings and evaluation of their antibacterial and corrosion resistance properties in simulated body fluid. Mater. Sci. Eng. C 69, 675–684 (2016). https://doi.org/10.1016/j.msec.2016.07.057

B. Singh, G. Singh, B.S. Sidhu, Analysis of corrosion behaviour and surface properties of plasma-sprayed composite coating of hydroxyapatite—tantalum on biodegradable Mg alloy ZK60. J. Compos. Mater. (2019). https://doi.org/10.1177/0021998319839127

B. Singh, G. Singh, B. Singh, In vitro investigation of Nb-Ta alloy coating deposited on CoCr alloy for biomedical implants. Surf. Coat. Technol. 377, 124932 (2019). https://doi.org/10.1016/j.surfcoat.2019.124932

B. Singh, G. Singh, B.S. Sidhu, Investigation of the in vitro corrosion behavior and biocompatibility of niobium (Nb)–reinforced hydroxyapatite (HA) coating on CoCr alloy for medical implants. J. Mater. Res. 34, 1–14 (2019). https://doi.org/10.1557/jmr.2019.94

S. Liu, H. Li, Y. Su, Q. Guo, L. Zhang, Preparation and properties of in-situ growth of carbon nanotubes reinforced hydroxyapatite coating for carbon/carbon composites. Mater. Sci. Eng. C 70, 805–811 (2017). https://doi.org/10.1016/j.msec.2016.09.060

H. Chen, E. Zhang, K. Yang, Microstructure, corrosion properties and bio-compatibility of calcium zinc phosphate coating on pure iron for biomedical application. Mater. Sci. Eng. C 34, 201–206 (2014). https://doi.org/10.1016/j.msec.2013.09.010

H. Hu, Y. Qiao, F. Meng, X. Liu, C. Ding, Enhanced apatite-forming ability and cytocompatibility of porous and nanostructured TiO2/CaSiO3 coating on titanium. Colloids Surf. B 101, 83–90 (2013). https://doi.org/10.1016/j.colsurfb.2012.06.021

X. Liu, C. Ding, Characterization of plasma sprayed wollastonite powder and coatings. Surf. Coat. Technol. 153, 173–177 (2002). https://doi.org/10.1016/S0257-8972(01)01666-8

X. Liu, C. Ding, Z. Wang, Apatite formed on the surface of plasma-sprayed wollastonite coating immersed in simulated body fluid. Biomaterials 22, 2007–2012 (2001). https://doi.org/10.1016/S0142-9612(00)00386-0

W. Xue, X. Liu, X. Zheng, C. Ding, In vivo evaluation of plasma-sprayed wollastonite coating. Biomaterials 26, 3455–3460 (2005). https://doi.org/10.1016/j.biomaterials.2004.09.027

X. Liu, C. Ding, P.K. Chu, Mechanism of apatite formation on wollastonite coatings in simulated body fluids. Biomaterials 25, 1755–1761 (2004). https://doi.org/10.1016/j.biomaterials.2003.08.024

J. Singh, S.S. Chatha, H. Singh, Microstructural and in-vitro characteristics of functional calcium silicate topcoat on hydroxyapatite coating for bio-implant applications. Prog. Biomater. (2022). https://doi.org/10.1007/s40204-022-00183-w

P. Tian, H. Hu, H. Wang, X. Liu, C. Ding, TiO2/CaF2 composite coating on titanium for biomedical application. Mater. Lett. 117, 98–100 (2014). https://doi.org/10.1016/j.matlet.2013.12.006

M. Yusuf, A. Bakar, N. Muhamad, M. Rafi, Incorporation of wollastonite bioactive ceramic with titanium for medical applications: an overview. Mater. Sci. Eng. C 97, 884–895 (2019). https://doi.org/10.1016/j.msec.2018.12.056

H.H. Beheri, K.R. Mohamed, G.T. El-bassyouni, Mechanical and microstructure of reinforced hydroxyapatite/calcium silicate nano-composites materials. Mater. Des. 44, 461–468 (2013). https://doi.org/10.1016/j.matdes.2012.08.020

K. Lin, M. Zhang, W. Zhai, H. Qu, J. Changw, Fabrication and characterization of hydroxyapatite/wollastonite composite bioceramics with controllable properties for hard tissue repair. J. Am. Ceram. Soc. 105, 99–105 (2011). https://doi.org/10.1111/j.1551-2916.2010.04046.x

A. Encinas-romero, S.R. Paya, Mechanical and bioactive behavior of hydroxyapatite—wollastonite sintered composites. Int. J. Appl. Ceram. Technol. 7, 164–177 (2010). https://doi.org/10.1111/j.1744-7402.2009.02377.x

P. Feng, P. Wei, P. Li, C. Gao, C. Shuai, S. Peng, Calcium silicate ceramic scaffolds toughened with hydroxyapatite whiskers for bone tissue engineering (Elsevier, Amsterdam, 2014). https://doi.org/10.1016/j.matchar.2014.08.017

S. Kunjalukkal, F. Gervaso, M. Carrozzo, F. Scalera, A. Sannino, A. Licciulli, Wollastonite/hydroxyapatite scaffolds with improved mechanical, bioactive and biodegradable properties for bone tissue engineering. Ceram. Int. 39, 619–627 (2013). https://doi.org/10.1016/j.ceramint.2012.06.073

K. Lin, J. Chang, X. Liu, C. Ning, Synthesis and characterization of nanocomposite powders composed of hydroxyapatite nanoparticles and wollastonite nanowires. Appl. Ceram. Technol. 183, 178–183 (2010). https://doi.org/10.1111/j.1744-7402.2009.02474.x

R. Morsy, R. Abuelkhair, T. Elnimr, A facile route to the synthesis of hydroxyapatite/wollastonite composite powders by a two-step. Silicon (2015). https://doi.org/10.1007/s12633-015-9339-y

A. Encinas-romero, S. Aguayo-salinas, F.F. Castillo, Synthesis and characterization of hydroxyapatite—wollastonite composite powders by sol–gel processing. Appl. Ceram. Technol. 5, 401–411 (2008). https://doi.org/10.1111/j.1744-7402.2008.02212.x

A.P. Solonenko, A.I. Blesman, D.A. Polonyankin, Materials characterization poorly crystallized hydroxyapatite and calcium silicate hydrate composites: synthesis, characterization and soaking in simulated body fluid. Mater. Charact. 161, 110158 (2020). https://doi.org/10.1016/j.matchar.2020.110158

Y. Huang, H. Zhang, H. Qiao, X. Nian, X. Zhang, Anticorrosive effects and in vitro cytocompatibility of calcium silicate/zinc-doped hydroxyapatite composite coatings on titanium. Appl. Surf. Sci. 357, 1776–1784 (2015). https://doi.org/10.1016/j.apsusc.2015.10.034

B. Singh, G. Singh, B. Singh, N. Bhatia, In-vitro assessment of HA–Nb coating on Mg alloy ZK60 for biomedical applications. Mater. Chem. Phys. 231, 138–149 (2019). https://doi.org/10.1016/j.matchemphys.2019.04.037

D.Q. Pham, C.C. Berndt, U. Gbureck, H. Zreiqat, V.K. Truong, A.S.M. Ang, Mechanical and chemical properties of Baghdadite coatings manufactured by atmospheric plasma spraying. Surf. Coat. Technol. 378, 124945 (2019). https://doi.org/10.1016/j.surfcoat.2019.124945

X. Chen, B. Zhang, Y. Gong, P. Zhou, H. Li, Mechanical properties of nanodiamond-reinforced hydroxyapatite composite coatings deposited by suspension plasma spraying. Appl. Surf. Sci. 439, 60–65 (2018). https://doi.org/10.1016/j.apsusc.2018.01.014

X. Liu, D. He, Z. Zhou, G. Wang, Z. Wang, X. Guo, Effect of post-heat treatment on the microstructure of micro-plasma sprayed hydroxyapatite coatings. Surf. Coat. Technol. 367, 225–230 (2019). https://doi.org/10.1016/j.surfcoat.2019.03.056

X. Liu, C. Ding, Phase compositions and microstructure of plasma sprayed wollastonite coating. Surf. Coat. Technol. 141, 269–274 (2001). https://doi.org/10.1016/S0257-8972(01)01169-0

W. Wang, J. Liang, X. Guo, F. Xuan, H. Hong, Mechanical properties and dissolution behavior of plasma sprayed wollastonite coatings deposited at different substrate temperatures. J. Therm. Spray Technol. 21, 496–504 (2012). https://doi.org/10.1007/s11666-011-9699-9

S. Mohajernia, S. Pour-Ali, S. Hejazi, M. Saremi, A.R. Kiani-Rashid, Hydroxyapatite coating containing multi-walled carbon nanotubes on AZ31 magnesium: mechanical-electrochemical degradation in a physiological environment. Ceram. Int. 44, 8297–8305 (2018). https://doi.org/10.1016/j.ceramint.2018.02.015

G. Singh, S. Singh, S. Prakash, Surface characterization of plasma sprayed pure and reinforced hydroxyapatite coating on Ti6Al4V alloy. Surf. Coat. Technol. 205, 4814–4820 (2011). https://doi.org/10.1016/j.surfcoat.2011.04.064

Acknowledgments

The authors gratefully acknowledge the financial support provided to this research by the University Grant Commission, New Delhi, India, under Grant Number RGNF-2013-14-SC-PUN-52049. The authors additionally thank Clarion pharmaceutical ltd., India and wolkem, ltd., India, for providing the HA and CS powders.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interest or personal relationships that could have influenced the work reported in this paper.

Rights and permissions

About this article

Cite this article

Singh, J., Chatha, S.S. & Singh, H. In vitro assessment of plasma-sprayed reinforced hydroxyapatite coatings deposited on Ti6Al4V alloy for bio-implant applications. Journal of Materials Research 37, 2623–2634 (2022). https://doi.org/10.1557/s43578-022-00549-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-022-00549-7