Abstract

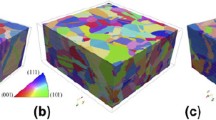

We investigated the connectivity of high-energy random grain boundaries through fractal analyses of specimens with different grain boundary (GB) microstructures in BFe10-1-1 copper-nickel alloy. It was found that the profile of maximum random boundary network possesses a fractal nature and more than one fractal dimension can exist. The fraction of special boundaries and grain size homogeneity can play an important role on GB character distribution. Here, GB microstructures are combined with quantitative materials structure-property relationship models to predict intergranular corrosion properties. The experimental results are accurately consistent with the theoretical predictions.

Similar content being viewed by others

References

S. Bechtle, M. Kumar, B.P. Somerday, M.E. Launey, and R.O. Ritchie: Grain-boundary engineering markedly reduces susceptibility to intergran-ular hydrogen embrittlement in metallic materials. Acta Mater. 57, 4148 (2009).

S. Tokita, H. Kokawa, Y.S. Sato, and H.T. Fujii: In situ EBSD observation of grain boundary character distribution evolution during thermomechanical process used for grain boundary engineering of 304 austenitic stainless steel. Mater. Charact 100, 365 (2017).

B. S. Kumar, B.S. Prasad, V. Kain, and J. Reddy: Methods for making alloy 600resistant to sensitization and intergranular corrosion. Corns. Sci. 70, 55 (2013).

T.D. Burleigh and D.H. Waldeck: Effect of alloying on the resistance of Cu-10% Ni alloys to seawater impingement. Corrosion 55, 800 (1999).

C. Hu, S. Xia, H. Li, T. Liu, B. Zhou, W. Chen, and N. Wang: Improving the intergranular corrosion resistance of 304 stainless steel by grain boundary network control. Corros. Sci. 53, 1880 (2011).

T. Watanabe: An approach to grain boundary design for strong and ductile polycrystals. Res. Mech. 11, 47 (1984).

A.Y. Chen, W.F. Hu, D. Wang, Y.K. Zhu, P. Wang, J.H. Yang, X.Y. Wang, J. F. Gu, and J. Lu: Improving the intergranular corrosion resistance of austenitic stainless steel by high density twinned structure. Scr. Mater. 130, 264 (2017).

K. Deepak, S. Mandal, C.N. Athreya, D-H Kim, B. de Boer, and V. Subramanya Sarma: Implication of grain boundary engineering on high temperature hot corrosion of alloy 617. Corros. Sci. 106, 293 (2016).

M. Michiuchi, H. Kokawa, Z.J. Wang, Y.S. Sato, and K. Sakai: Twin-induced grainboundary engineering for 316 austenitic stainless steel. Acta Mater. 54, 5179 (2006).

A. Drach, I. Tsukrov, J. DeCew, J. Aufrecht, A. Grohbauer, and U. Hofmann: Field studies of corrosion behaviour of copper alloys in natural seawater. Corros. Sci. 76, 453 (2013).

A.L. Ma, S.L. Jiang, Y.G. Zheng, and W. Ke: Corrosion product film formed on the 90/10 copper-nickel tube in natural seawater: composition/structure and formation mechanism. Corros. Sci. 91, 245 (2015).

O.O. Ekerenam, A. Ma, Y. Zheng, and W. Emori: Electrochemical behavior of three 90Cu-10Ni tubes from different manufacturers after immersion in 3.5% NaCI solution. J. Mater. Eng. Perform. 26, 1701 (2017).

V. Randle: “Special” boundaries and grain boundary plane engineering. Scr. Mater. 54, 1011 (2006).

G. Gottstein and L.S. Shvindlerman: Grain boundary junction engineering. Scr. Mater. 54, 1065 (2006).

S. Kobayashi, T. Maruyama, S. Tsurekawa, and T. Watanabe: Grain boundary engineering based on fractal analysis for control of segregation-induced intergranular brittle fracture in polycrystalline nickel. Acta Mater. 60, 6200 (2012).

S. Kobayashi, R. Kobayashi, and T. Watanabe: Control of grain boundary connectivity based on fractal analysis for improvement of intergranular corrosion resistance in SUS316L austenitic stainless steel. Acta Mater. 102, 397 (2016).

D.G. Brandon: The structure of high-angle grain boundaries. Acta Metall. 14, 1479 (1966).

T. Watanabe and Grain boundary engineering: Historical perspective and future prospects. J. Mater. Sci. 46, 4095 (2011).

P. Fortier, W.A. Miller, and K.T. Aust: Effects of symmetry, texture and topology on triple junction character distribution in polycrystalline materials. Acta Metall. Mater. 43, 339 (1995).

B.B. Mandelbrot, D.E. Passoja, and A.J. Paullay: Fractal character of fracture surfaces of metals. Nature 70, 721 (1984).

S. Kobayashi, S. Tsurekawa, and T. Watanabe: A new approach to grain boundary engineering for nanocrystalline materials. Beilstein J. Nanotechnol. 7, 1829 (2016).

B. Dubuc, J.F. Quiniou, C. Roques-Carmes, C. Tricot, and S.W. Zucker: Evaluating the fractal dimension of profiles. Phys. Rev. A 39, 1500 (1989).

E. Charkaluk, M. Bigerelle, and A. Iost: Fractals and fracture. Eng. Fract Mech. 61, 119 (1998).

D.B. Bober, J. Lind, R.P. Mulay, T.J. Rupert, and M. Kumar: The formation and characterization of large twin related domains. Acta Mater. 129, 500 (2017).

C.A. Schuh, R.W. Minich, and M. Kumar: Connectivity and percolation in simulated grain-boundary networks. Philos. Mag. 83, 711 (2003).

F. Cao, J. Wei, J. Dong, and W. Ke: The corrosion inhibition effect of phytic acid on 20SiMn steel in simulated carbonated concrete pore solution. Corros. Sci. 100, 365 (2015).

V. Subramanian, P. Chandramohan, M.P. Srinivasan, S. Velmurugan, and S.V. Narasimhan: Corrosion of cupronickel alloy in permanganate under acidic condition. Corros. Sci. 49, 620 (2007).

V. Randle, Y. Hu, and M. Coleman: Grain boundary reorientation in copper. J. Mater. Sci. 43, 3782 (2008).

ACKNOWLEDGMENTS

The authors are grateful to Biao Wen for providing the image processing software for fractal analysis. This work was supported by the National Key Research and Development Program of China (No. 2016YFB0301400).

Author information

Authors and Affiliations

Corresponding authors

Supplementary materials

Supplementary materials

The supplementary material for this article can be found at https://doi.org/10.1557/mrc.2018.211.

Rights and permissions

About this article

Cite this article

Zhang, Y., Feng, X., Song, C. et al. Quantification of grain boundary connectivity for predicting intergranular corrosion resistance in BFe10-1-1 copper-nickel alloy. MRS Communications 9, 251–257 (2019). https://doi.org/10.1557/mrc.2018.211

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/mrc.2018.211