Abstract

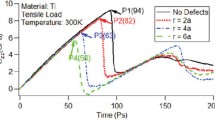

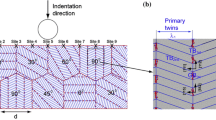

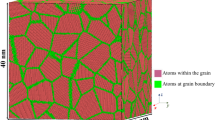

Adding nanotwins to a metal could be a way to effectively improve its strength without suppressing its tensile ductility, which suggests that their unique nanostructure may alter microstructure evolution and deformation mechanisms. In this work, we perform a molecular dynamics-based tension simulation of two-dimension (2D) polycrystalline copper (Cu) with embedded nanotwins under uniaxial stress conditions. The results of MD-simulation reveal that the spacing of the twin boundaries had a significant effect on the mechanical properties of nanotwinned materials. Specifically, an irregular relationship is found between the twin boundary spacing (\(D_{T}\)) and the strength of the material. It exhibits that the peak stress reached a maximum at \(D_{T}\) = 12.5 nm and decreased thereafter with increasing average \(D_{T}\). However, flow stress reaches a maximum at a critical value of \(D_{T}\) = 7 nm. According to the analysis of microstructure evolution, the presence of nanotwins hinder the motion of partial dislocations and stacking faults, and the stress-concentrated region leads to the transition from coherent twin boundaries to incoherency. The stress-concentrated region locates in the step of incoherent would release the intrinsic stacking faults responsible for the formation of hierarchical contraction nanotwins stacking faults which efficiently improves the strength of Cu. In addition, as the tension proceeds, some samples begin to display the secondary twinning. This work will be helpful for further investigation the nucleation and evolution of 2D nanotwinned metals and for formulating effective strength criteria for 2D nanotwinned metals.

Graphic Abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

L. Lu, Y. Shen, X. Chen, L. Qian, K. Lu, Science 304, 422 (2004)

X. Zhang, H. Wang, X. Chen, L. Lu, K. Lu, R. Hoagland, A. Misra, Appl. Phys. Lett. 88, 173116 (2006)

A. Cao, Y. Wei, J. Appl. Phys. 102, 083511 (2007)

D. Xu, V. Sriram, V. Ozolins, J.-M. Yang, K. Tu, G.R. Stafford, C. Beauchamp, I. Zienert, H. Geisler, P. Hofmann, Microelectron. Eng. 85, 2155 (2008)

S. Li, Q. Zhu, B. Zheng, J. Yuan, X. Wang, Mater. Sci. Eng. A 758, 1 (2019)

D. Jang, X. Li, H. Gao, J.R. Greer, Nat. Nanotechnol. 7, 594 (2012)

Z. Cheng, H. Zhou, Q. Lu, H. Gao, L. Lu, Science 362, eaau1925 (2018)

X. Li, M. Dao, C. Eberl, A.M. Hodge, H. Gao, MRS Bullet. 41, 298 (2016)

O. Anderoglu, A. Misra, H. Wang, F. Ronning, M. Hundley, X. Zhang, Appl. Phys. Lett. 93, 083108 (2008)

D. Bufford, H. Wang, X. Zhang, Acta Mater. 59, 93 (2011)

B. Cui, K. Han, Y. Xin, D. Waryoba, A. Mbaruku, Acta Mater. 55, 4429 (2007)

Y. Zhang, N. Tao, K. Lu, Scripta Mater. 60, 211 (2009)

H.J. Kim, S.I. Hong, Met. Mater. Int. 25, 94 (2019)

J.W. Huang, Y.P. Yi, S. Huang, F. Dong, W. Guo, D. Tong, H. He, Met. Mater. Int. 27, 815 (2021)

G.H. Lee, J.H. Kim, H.G. Beom, Met. Mater. Int. 27, 584 (2021)

J. Park, S. Park, X.F. Han, K.W. Yi, Met. Mater. Int. 22, 118 (2016)

O. Anderoglu, A. Misra, J. Wang, R. Hoagland, J. Hirth, X. Zhang, Int. J. Plasticity 26, 875 (2010)

L. Lu, X. Chen, X. Huang, K. Lu, Science 323, 607 (2009)

T. Varol, A. Canakci, Met. Mater. Int. 21, 704 (2015)

M.A. Meyers, A. Mishra, D.J. Benson, Prog. Mater. Sci. 51, 427 (2006)

A.H. Chokshi, A. Rosen, J. Karch, H. Gleiter, Scripta Metall. 23, 1679 (1989)

Z. Shan, E.A. Stach, J.M.K. Wiezorek, J.A. Knapp, D.M. Follstaedt, S.X. Mao, Science 305, 654 (2004)

H. Van Swygenhoven, M. Spaczer, A. Caro, D. Farkas, Phys. Rev. B 60, 22 (1999)

V. Yamakov, D. Wolf, S.R. Phillpot, H. Gleiter, Acta Mater. 50, 5005 (2002)

X. Li, Y. Wei, L. Lu, K. Lu, H. Gao, Nature 464, 8 (2010)

A. Singh, L. Tang, M. Dao, L. Lu, S. Suresh, Acta Mater. 59, 2437 (2011)

Q. Pan, H. Zhou, Q. Lu, H. Gao, L. Lu, Nature 551, 214 (2017)

Y. Mishin, M. Mehl, D. Papaconstantopoulos, A. Voter, J. Kress, Phys. Rev. B 63, 224106 (2001)

S. Plimpton, J. Comput. Phys. 117, 1 (1995)

N.S. Martys, R.D. Mountain, Phys. Rev. E 59, 3733 (1999)

D.J. Evans, B.L. Holian, J. Chem. Phys. 83, 4069 (1985)

A. Stukowski, V.V. Bulatov, A. Arsenlis, Model. Simul. Mater. Sci. Eng. 20, 085007 (2012)

A. Stukowski, Model. Simul. Mater. Sci. Eng. 18, 015012 (2009)

J.D. Honeycutt, H.C. Andersen, J. Phys. Chem. 91, 4950 (1987)

M. Bagheripoor, R. Klassen, Mech. Mater. 143, 103311 (2020)

Q. Peng, Y. Sun, B. Ge, H. Fu, Q. Zu, X. Tang, J. Huang, Acta Mater. 169, 36 (2019)

F. Yuan, X. Wu, J. Appl. Phys. 113, 203516 (2013)

Acknowledgements

The authors would like to deeply appreciate the support from the National Natural Sciences Foundation of China (11572191, 51701117, and 51779139) and Shanghai science and technology committee foundation (17411962200).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qi, Y., He, T. & Feng, M. Molecular Dynamics-Based Tension Simulation of Plastic Deformation of 2D Nanotwinned Copper Under Uniaxial Stress Conditions: Evolution of Dislocations and Secondary Twinning. Met. Mater. Int. 28, 1611–1619 (2022). https://doi.org/10.1007/s12540-021-01041-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01041-3