Abstract

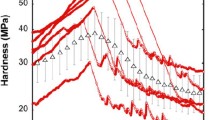

Nanoindentation has been used to measure the elastic modulus of 5 and 18 μm thick high-purity vapor deposited polycrystalline lithium films at 31 °C. Over indentation depths ranging from 150 to 1100 nm, the modulus is found to vary with film thickness from 9.8 GPa ± 11.9% to 8.2 GPa ± 14.5%. These results are well within the range of lithium’s orientation dependent elastic modulus, which spans approximately 3.1 to 21.4 GPa. The measured values may also indicate (111) and (100) texture for the 5 and 18 μm thick films, respectively. The potential effects of pileup and surface contamination are found to be negligible if any at all. Small but discernible changes in damping capability near the free surface may provide insight into the subsurface defect structure and the potential for localized heating. Numerous experimental challenges are addressed and key metrics are used to validate the measured elastic modulus.

Similar content being viewed by others

References

S. Yu, R.D. Schmidt, R. Garcia-Mendez, E. Herbert, N.J. Dudney, J.B. Wolfenstine, and D.J. Siegel: Elastic properties of the solid electrolyte Li7La3Zr2O12 (LLZO). Chem. Mater. 28, 197 (2015).

E.J. Cheng, A. Sharafi, and J. Sakamoto: Intergranular Li metal propagation through polycrystalline Li6.25Al0.25La3Zr2O12 ceramic electrolyte. Electrochim. Acta 223, 85 (2017).

E.G. Herbert, S.A. Hackney, N.J. Dudney, V. Thole, and P.S. Phani: Nanoindentation of high purity vapor deposited lithium films: A mechanistic rationalization of diffusion-mediated flow. J. Mater. Res. 33, 1347–1360 (2018).

E.G. Herbert, S.A. Hackney, N.J. Dudney, V. Thole, and P.S. Phani: Nanoindentation of high purity vapor deposited lithium films: A mechanistic rationalization of the transition from diffusion to dislocation-mediated flow. J. Mater. Res. 33, 1361–1368 (2018).

W.C. Oliver and G.M. Pharr: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564 (1992).

W.C. Oliver and G.M. Pharr: Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19, 3 (2004).

J.L. Hay, P. Agee, and E.G. Herbert: Continuous stiffness measurement during instrumented indentation testing. Exp. Tech. 34, 86 (2010).

J.L. Hay and G.M. Pharr: Instrumented Indentation Testing, Vol. 232 (ASM International, Materials Park, OH, 2000).

G.M. Pharr, W.C. Oliver, and F. Brotzen: On the generality of the relationship among contact stiffness, contact area, and elastic modulus during indentation. J. Mater. Res. 7, 613 (1992).

G.M. Pharr and A. Bolshakov: Understanding nanoindentation unloading curves. J. Mater. Res. 17, 2660 (2002).

E.G. Herbert, P.S. Phani, and K.E. Johanns: Nanoindentation of viscoelastic solids: A critical assessment of experimental methods. Curr. Opin. Solid State Mater. Sci. 19, 334 (2015).

G.M. Pharr, J.H. Strader, and W.C. Oliver: Critical issues in making small-depth mechanical property measurements by nanoindentation with continuous stiffness measurement. J. Mater. Res. 24, 653 (2009).

B. Merle, V. Maier-Kiener, and G.M. Pharr: Influence of modulus-to-hardness ratio and harmonic parameters on continuous stiffness measurement during nanoindentation. Acta Mater. 134, 167 (2017).

A.H.W. Ngan and B. Tang: Viscoelastic effects during unloading in depth-sensing indentation. J. Mater. Res. 17, 2604 (2002).

G. Feng and A.H.W. Ngan: Effects of creep and thermal drift on modulus measurement using depth-sensing indentation. J. Mater. Res. 17, 660 (2002).

Y.T. Cheng, W. Ni, and C.M. Cheng: Nonlinear analysis of oscillatory indentation in elastic and viscoelastic solids. Phys. Rev. Lett. 97, 075506 (2006).

Y.T. Cheng, W. Ni, and C.M. Cheng: Determining the instantaneous modulus of viscoelastic solids using instrumented indentation measurements. J. Mater. Res. 20, 3061 (2005).

A.H.W. Ngan and B. Tang: Response of power-law-viscoelastic and time-dependent materials to rate jumps. J. Mater. Res. 24, 853 (2009).

Z.L. Zhou, T.H. Hui, B. Tang, and A.H.W. Ngan: Accurate measurement of stiffness of leukemia cells and leukocytes using an optical trap by a rate-jump method. RSC Adv. 4, 8453 (2014).

E.G. Herbert, W.C. Oliver, and G.M. Pharr: Nanoindentation and the dynamic characterization of viscoelastic solids. J. Phys. D: Appl. Phys. 41, 074021 (2008).

R. Saha and W.D. Nix: Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Mater. 50, 23 (2002).

J.L. Hay and B. Crawford: Measuring substrate-independent modulus of thin films. J. Mater. Res. 26, 727 (2011).

H.C. Nash and C.S. Smith: Single-crystal elastic constants of lithium. J. Phys. Chem. Solids 9, 113–118 (1959).

T. Slotwinski and J. Trivisonno: Temperature dependence of the elastic constants of single crystal lithium. J. Phys. Chem. Solids 30, 1276–1279 (1968).

C. Xu, Z. Ahmad, A. Aryanfar, V. Viswanathan, and J.R. Greer: Enhanced strength and temperature dependence of mechanical properties of Li at small scales and its implications for Li metal anodes. Proc. Natl. Acad. Sci. U.S.A. 114, 57 (2017).

R. Schultz: Lithium: Measurement of Young’s Modulus and Yield Strength; Technical Report FERMILAB-TM-2191; Fermi National Accelerator Laboratory: Batavia, IL, 2002.

J.J. Vlassak and W.D. Nix: Measuring the elastic properties of anisotropic materials by means of indentation experiments. J. Mech. Phys. Solid. 42, 1223 (1994).

K. Zavadil and N. Armstrong: Surface chemistries of lithium: Detailed characterization of the reactions with O2 and H2O using XPS, EELS, and microgravimetry. Surf. Sci. 230, 47 (1990).

L. Chongmo and M. Hillert: A metallographic study of diffusion-induced grain boundary migration in the Fe–Zn system. Acta Metall. 29, 1949 (1981).

C.G. Andrés, F. Caballero, C. Capdevila, and D.S. Martín: Revealing austenite grain boundaries by thermal etching: Advantages and disadvantages. Mater. Charact. 49, 121 (2002).

ACKNOWLEDGMENTS

This research was sponsored jointly by the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy’s Advanced Battery Materials Research program (managed by Tien Duong) and by TARDEC, the U.S. Army Tank Automotive Research Development and Engineering Center. E.G.H. is grateful for start-up funding from the Department of Materials Science and Engineering at Michigan Technological University.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper has been selected as an Invited Feature Paper.

Rights and permissions

About this article

Cite this article

Herbert, E.G., Hackney, S.A., Dudney, N.J. et al. Nanoindentation of high-purity vapor deposited lithium films: The elastic modulus. Journal of Materials Research 33, 1335–1346 (2018). https://doi.org/10.1557/jmr.2018.83

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.83