Abstract

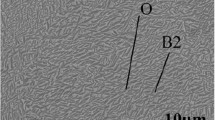

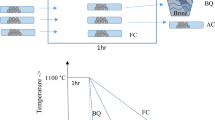

The hot deformation behavior of Ti–6Al–4V alloy with starting fully lamellar microstructure was investigated by conducting isothermal hot compression tests at the temperature of 700–1000 °C and strain rate of 0.001–10 s−1. The deformation activation energy is calculated to be 342 kJ/mol at temperatures from 750 to 850 °C, whereas the higher apparent activation energy of 610 kJ/mol is obtained at a high temperature regime of 900–1000 °C. The relationship between the dynamic softening behavior and deformation parameters was analyzed by power dissipation efficiency η, which shows an increasing trend as the deformation temperature increases and strain rate decreases, respectively. Processing maps were constructed. The instability flow is dominated by the presence of adiabatic shear bands, and the dynamic softening is mainly caused by a combination effect of dynamic recrystallization and dynamic recovery. Moreover, straining is found to have a positive effect on lowering the phase transformation temperature.

Similar content being viewed by others

References

L. Luo, Y. Su, J. Guo, and H. Fu: Formation of titanium hydride in Ti–6Al–4V alloy. J. Alloys Compd. 425, 140–144 (2006).

X. Wang, L. Wang, L. Luo, X. Liu, Y. Tang, X. Li, R. Chen, Y. Su, J. Guo, and H. Fu: Hot deformation behavior and dynamic recrystallization of melt hydrogenated Ti–6Al–4V alloy. J. Alloys Compd. 728, 709–718 (2017).

Z.X. Zhang, S.J. Qu, A.H. Feng, J. Shen, and D.L. Chen: Hot deformation behavior of Ti–6Al–4V alloy: Effect of initial microstructure. J. Alloys Compd. 718, 170–181 (2017).

J. Zhao, H. Ding, Z. Jiang, M. Huang, and H. Hou: Hydrogen-induced hardening of Ti–6Al–4V alloy in β phase field. Mater. Des. 54, 967–972 (2014).

J. Zhao, H. Ding, W. Zhao, and Z. Jiang: Effects of hydrogen on the hot deformation behaviour of Ti–6Al–4V alloy: Experimental and constitutive model studies. J. Alloys Compd. 574, 407–414 (2013).

J. Zhao, H. Ding, Y. Zhong, and C.S. Lee: Effect of thermo hydrogen treatment on lattice defects and microstructure refinement of Ti–6Al–4V alloy. Int. J. Hydrogen Energy 35, 6448–6454 (2010).

W.J. Zhang, H. Ding, M.H. Cai, W.J. Yang and J.Z. Li: Ultra-grain refinement and enhanced low-temperature superplasticity in a friction stir-processed Ti–6Al–4V alloy. Mater. Sci. Eng., A 727, 90–96 (2018).

S. Roy and S. Suwas: The influence of temperature and strain rate on the deformation response and microstructural evolution during hot compression of a titanium alloy Ti–6Al–4V–0.1B. J. Alloys Compd. 548, 110–125 (2013).

C. Cai, X. Gao, Q. Teng, M. Li, K. Pan, B. Song, C. Yan, Q. Wei, and Y. Shi: A novel hybrid selective laser melting/hot isostatic pressing of near-net shaped Ti–6Al–4V alloy using an in situ tooling: Interfacial microstructure evolution and enhanced mechanical properties. Mater. Sci. Eng., A 717, 95–104 (2018).

T. Seshacharyulu, S.C. Medeiros, W.G. Frazier, and Y.V.R.K. Prasad: Hot working of commercial Ti–6Al–4V with an equiaxed α–β microstructure: Materials modeling considerations. Mater. Sci. Eng., A 284, 184–194 (2000).

T. Seshacharyulu, S.C. Medeiros, W.G. Frazier, and Y.V.R.K. Prasad: Microstructural mechanisms during hot working of commercial grade Ti–6Al–4V with lamellar starting structure. Mater. Sci. Eng., A 325, 112–125 (2002).

S.L. Semiatin, V. Seetharaman, and I. Weiss: Flow behavior and globularization kinetics during hot working of Ti–6Al–4V with a colony alpha microstructure. Mater. Sci. Eng., A 263, 257–271 (1999).

E.B. Shell and S.L. Semiatin: Effect of initial microstructure on plastic flow and dynamic globularization during hot working of Ti–6Al–4V. Metall. Mater. Trans. A 30, 3219–3229 (1999).

J.H. Kim, S.L. Semiatin, and C.S. Lee: Constitutive analysis of the high-temperature deformation of Ti–6Al–4V with a transformed microstructure. Acta Mater. 51, 5613–5626 (2003).

Z. Du, S. Jiang, and K. Zhang: The hot deformation behavior and processing map of Ti–47.5Al–Cr–V alloy. Mater. Des. 86, 464–473 (2015).

J. Zhao, H. Ding, Z. Jiang, D. Wei, and K. Linghu: Effects of hydrogen on the critical conditions for dynamic recrystallization of titanium alloy during hot deformation. Metall. Mater. Trans. A 45, 4932–4945 (2014).

X. Peng, H. Guo, Z. Shi, C. Qin, and Z. Zhao: Constitutive equations for high temperature flow stress of TC4-DT alloy incorporating strain, strain rate and temperature. Mater. Des. 50, 198–206 (2013).

Y. Kim, Y-B. Song, S.H. Lee, and Y-s. Kwon: Characterization of the hot deformation behavior and microstructural evolution of Ti–6Al–4V sintered preforms using materials modeling techniques. J. Alloys Compd. 676, 15–25 (2016).

J. Zhao, H. Ding, W. Zhao, M. Huang, D. Wei, and Z. Jiang: Modelling of the hot deformation behaviour of a titanium alloy using constitutive equations and artificial neural network. Comput. Mater. Sci. 92, 47–56 (2014).

C. Shi, W. Mao, and X.G. Chen: Evolution of activation energy during hot deformation of AA7150 aluminum alloy. Mater. Sci. Eng., A 571, 83–91 (2013).

Y.Q. Ning, B.C. Xie, H.Q. Liang, H. Li, X.M. Yang, and H.Z. Guo: Dynamic softening behavior of TC18 titanium alloy during hot deformation. Mater. Des. 71, 68–77 (2015).

Q. Chao, P.D. Hodgson, and H. Beladi: Ultrafine grain formation in a Ti–6Al–4V alloy by thermomechanical processing of a martensitic microstructure. Metall. Mater. Trans. A 45, 2659–2671 (2014).

X. Peng, H. Guo, Z. Shi, C. Qin, Z. Zhao, and Z. Yao: Study on the hot deformation behavior of TC4-DT alloy with equiaxed α + β starting structure based on processing map. Mater. Sci. Eng., A 605, 80–88 (2014).

J. Luo, M. Li, H. Li, and W. Yu: Effect of the strain on the deformation behavior of isothermally compressed Ti–6Al–4V alloy. Mater. Sci. Eng., A 505, 88–95 (2009).

N-K. Park, J-T. Yeom, and Y-S. Na: Characterization of deformation stability in hot forging of conventional Ti–6Al–4V using processing maps. J. Mater. Process. Technol. 130, 540–545 (2002).

T. Seshacharyulu, S.C. Medeiros, J.T. Morgan, J.C. Malas, W.G. Frazier, and Y.V.R.K. Prasad: Hot deformation mechanisms in ELI Grade Ti–6A1–4V. Scr. Mater. 41, 283–288 (1999).

A. Momeni and S.M. Abbasi: Effect of hot working on flow behavior of Ti–6Al–4V alloy in single phase and two phase regions. Mater. Des. 31, 3599–3604 (2010).

C. Poletti, F. Warchomicka, and H.P. Degischer: Local deformation of Ti–6Al–4V modified 1 wt% B and 0.1 wt% C. Mater. Sci. Eng., A 527, 1109–1116 (2010).

I. Sen and U. Ramamurty: High-temperature (1023 K to 1273 K [750 °C to 1000 °C]) plastic deformation behavior of B-modified Ti–6Al–4V alloys: Temperature and strain rate effects. Metall. Mater. Trans. A 41, 2959–2969 (2010).

S.V. Raj and G.M. Pharr: A compilation and analysis of data for the stress dependence of the subgrain size. Mater. Sci. Eng., A 81, 217–237 (1986).

D-X. Wen, Y.C. Lin, H-B. Li, X-M. Chen, J. Deng, and L-T. Li: Hot deformation behavior and processing map of a typical Ni-based superalloy. Mater. Sci. Eng., A 591, 183–192 (2014).

Y. Liu, Y. Ning, Z. Yao, and H. Guo: Hot deformation behavior of Ti–6.0Al–7.0Nb biomedical alloy by using processing map. J. Alloys Compd. 587, 183–189 (2014).

H. Chen, X. Liu, G. Liu, X. Tang, J. Luo, Y. Feng, J. Li, and H. Fu: Hot deformation behavior and processing map of Ti–6Al–3Nb–2Zr–1Mo titanium alloy. Rare Met. Mater. Eng. 45, 901–906 (2016).

J. Koike, Y. Shimoyama, I. Ohnuma, T. Okamura, R. Kainuma, K. Ishida, and K. Maruyama: Stress-induced phase transformation during superplastic deformation in two-phase Ti–Al–Fe alloy. Acta Mater. 48, 2059–2069 (2000).

W.J. Zhang, H. Ding, P.H.R. Pereira, Y. Huang, and T.G. Langdon: Grain refinement and superplastic flow in a fully lamellar Ti–6Al–4V alloy processed by high-pressure torsion. Mater. Sci. Eng., A 732, 398–405 (2018).

X. Li, S. Lu, K. Wang, M.W. Fu, and C. Cao: Analysis and comparison of the instability regimes in the processing maps generated using different instability criteria for Ti–6.5Al–3.5Mo–1.5Zr–0.3Si alloy. Mater. Sci. Eng., A 576, 259–266 (2013).

ACKNOWLEDGMENT

The present work is financially supported by the National Natural Science Foundation of China under Grant No. 51334006.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, W., Ding, H., Zhao, J. et al. Hot deformation behavior and processing maps of Ti–6Al–4V alloy with starting fully lamellar structure. Journal of Materials Research 33, 3677–3688 (2018). https://doi.org/10.1557/jmr.2018.331

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.331