Abstract

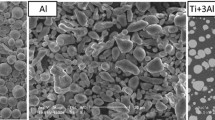

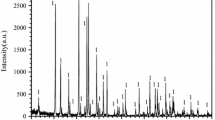

The oxidation behavior of nonstoichiometric Ti2AlCx (x = 0.69) powders synthesized by combustion synthesis was investigated in flowing air by means of simultaneous thermal gravimetric analysis-differential thermal analysis, X-ray diffraction, X-ray photoelectron spectroscopy, and scanning electron microscope/energy dispersive spectroscopy, with an effect of powder size. The oxidation of the fine Ti2AlC powders with the size of about 1 μm starts at 300 °C and completes at 980 °C, while with increasing the powder size around 10 μm the corresponding temperature increases to 400 and 1040 °C, respectively. The oxidation of nonstoichiometric Ti2AlCx (x = 0.69) powders is controlled by surface reaction in 400–600 °C, and mainly diffusion in 600–900 °C, with the corresponding oxidation activation energy of 2.35 eV and 0.12 eV, respectively. In other words, the critical temperature of changing oxidation controlling step is around 600 °C. The oxidation products were mainly rutile-TiO2 and α-Al2O3. The tiny white flocculent particles of α-Al2O3 appeared on the surface of fine Ti2AlC powders and increased with increasing the oxidation temperature.

Similar content being viewed by others

References

M.W. Barsoum: The MN +1AXN phases: A new class of solids: Thermodynamically stable nanolaminates. Prog. Solid State Chem. 28, 201 (2000).

M.W. Barsoum, I.I. Salama, T. Elraghy, J. Golczewski, H.J. Seifert, F. Aldinger, W. Porter, and H. Wang: Thermal and electrical properties of Nb2AlC, (Ti,Nb)2AlC and Ti2AlC. Metall. Mater. Trans. A 33, 2775 (2002).

Y.C. Zhou and X.H. Wang: Deformation of polycrystalline Ti2AlC under compression. Mater. Res. Innovations 5, 87 (2001).

V. Adamaki, T. Minster, T. Thomas, G. Fourlaris, and C.R. Bowen: Study of the mechanical properties of Ti2AlC after thermal shock. Mater. Sci. Eng., A 667, 9 (2016).

M. Radovic, M.W. Barsoum, A. Ganguly, T. Zhen, P. Finkel, S.R. Kalidindi, and E. Laracurzio: On the elastic properties and mechanical damping of Ti3SiC2, Ti3GeC2, Ti3Si0.5Al0.5C2 and Ti2AlC in the 300–1573 K temperature range. Acta Mater. 54, 2757 (2006).

X.H. Wang and Y. Zhou: High-temperature oxidation behavior of Ti2AlC in air. Oxid. Met. 59, 303 (2003).

M.W. Barsoum and M. Radovic: Elastic and mechanical properties of the MAX phases. Annu. Rev. Mater. Res. 41, 195 (2011).

W. Jeitschko, H. Nowotny, and F. Benesovsky: Ternary carbide (H-phase). Monatsh. Chem. 94, 672 (1963).

M.W. Barsoum, D. Brodkin, and T. Elraghy: Layered machinable ceramics for high temperature applications. Scr. Mater. 36, 535 (1997).

M.W. Barsoum, T. Elraghy, and M.F. Ali: Processing and characterization of Ti2AlC, Ti2AlN, and Ti2AlC0.5N0.5. Metall. Mater. Trans. A 31, 1857 (2000).

Y. Bai, X. He, Y. Li, C. Zhu, and S. Zhang: Rapid synthesis of bulk Ti2AlC by self-propagating high temperature combustion synthesis with a pseudo-hot isostatic pressing process. J. Mater. Res. 24, 2528 (2009).

Y. Bai, H. Zhang, X. He, C. Zhu, R. Wang, Y. Sun, G. Chen, and P. Xiao: Growth morphology and microstructural characterization of nonstoichiometric Ti2AlC bulk synthesized by self-propagating high temperature combustion synthesis with pseudo hot isostatic pressing. Int. J. Refract. Met. Hard Mater. 45, 58 (2014).

Y. Bai, X. He, C. Zhu, and G. Chen: Microstructures, electrical, thermal, and mechanical properties of bulk Ti2AlC synthesized by self-propagating high-temperature combustion synthesis with pseudo hot isostatic pressing. J. Am. Ceram. Soc. 95, 358 (2012).

Y. Bai, X. He, R. Wang, Y. Sun, C. Zhu, S. Wang, and G. Chen: High temperature physical and mechanical properties of large-scale Ti2AlC bulk synthesized by self-propagating high temperature combustion synthesis with pseudo hot isostatic pressing. J. Eur. Ceram. Soc. 33, 2435 (2013).

D.J. Tallman, B. Anasori, and M.W. Barsoum: A critical review of the oxidation of Ti2AlC, Ti3AlC2 and Cr2AlC in air. Mater. Res. Lett. 1, 115 (2013).

M.W. Barsoum and T. Elraghy: A progress report on Ti3SiC2, Ti3GeC2, and the H-phases, M2BX. J. Mater. Synth. Process. 5, 197 (1997).

X.H. Wang and Y.C. Zhou: Intermediate-temperature oxidation behavior of Ti2AlC in air. J. Mater. Res. 17, 2974 (2002).

J. Byeon, J. Liu, M. Hopkins, W. Fischer, N. Garimella, K.B. Park, M.P. Brady, M. Radovic, T. Elraghy, and Y.H. Sohn: Microstructure and residual stress of alumina scale formed on Ti2AlC at high temperature in air. Oxid. Met. 68, 97 (2007).

H. Yang, Y.T. Pei, J. Rao, J.T.M. De Hosson, S.B. Li, and G.M. Song: High temperature healing of Ti2AlC: On the origin of inhomogeneous oxide scale. Scr. Mater. 65, 135 (2011).

B. Cui, D.D. Jayaseelan, and W.E. Lee: TEM study of the early stages of Ti2AlC oxidation at 900 °C. Scr. Mater. 67, 830 (2012).

B. Cui, D.D. Jayaseelan, and W.E. Lee: Microstructural evolution during high-temperature oxidation of Ti2AlC ceramics. Acta Mater. 59, 4116 (2011).

H. Yang, Y.T. Pei, J. Rao, and J.T.M. De Hosson: Self-healing performance of Ti2AlC ceramic. J. Mater. Chem. 22, 8304 (2012).

S. Basu, N. Obando, A. Gowdy, I. Karaman, and M. Radovic: Long-term oxidation of Ti2AlC in air and water vapor at 1000–1300 °C temperature range. J. Electrochem. Soc. 159, C90–C96 (2012).

Z. Zhang, S.H. Lim, D.M.Y. Lai, S.Y. Tan, X.Q. Koh, J. Chai, S.J. Wang, H. Jin, and J.S. Pan: Probing the oxidation behavior of Ti2AlC MAX phase powders between 200 and 1000 °C. J. Eur. Ceram. Soc. 37, 43 (2017).

H.Y. Dong, C.K. Yan, S.Q. Chen, and Y.C. Zhou: Solid–liquid reaction synthesis and thermal stability of Ti2SnC powders. J. Mater. Chem. 11, 1402 (2001).

Z.J. Lin, M.S. Li, J.Y. Wang, and Y.C. Zhou: High-temperature oxidation and hot corrosion of Cr2AlC. Acta Mater. 55, 6182 (2007).

S.R. Kulkarni, M. Merlini, N. Phatak, S.K. Saxena, G. Artioli, S. Amini, and M.W. Barsoum: Thermal expansion and stability of Ti2SC in air and inert atmospheres. J. Alloys Compd. 469, 395 (2009).

X.H. Wang and Y.C. Zhou: Oxidation behavior of Ti3AlC2 powders in flowing air. J. Mater. Chem. 12, 2781 (2002).

J.L. Smialek: Environmental resistance of a Ti2AlC-type MAX phase in a high pressure burner rig. J. Eur. Ceram. Soc. 37, 23 (2017).

J.L. Smialek: Kinetic aspects of Ti2AlC MAX phase oxidation. Oxid. Met. 83, 351 (2015).

X.H. Wang and Y.C. Zhou: Stability and selective oxidation of aluminum in nano-laminate Ti3AlC2 upon heating in argon. Chem. Mater. 15, 3716 (2003).

Y. Bai, X. He, R. Wang, S. Wang, and F. Kong: Effect of transition metal (M) and M-C slabs on equilibrium properties of Al-containing MAX carbides: An ab initio study. Comput. Mater. Sci. 91, 28 (2014).

ACKNOWLEDGMENTS

This work was supported by National Natural Science Foundation of China (Grant No. 11302061), the Foundation for Innovative Research Groups of the National Natural Science Foundation of China (Grant No. 11421091), Research Fund for the Doctoral Program of Higher Education of China (Grant No. 20132302120024), China Postdoctoral Science Foundation funded project (Grant No. 2013M531033), and the Fundamental Research Funds for the Central Universities. Dr. Yuelei Bai gratefully acknowledges the financial support from International Postdoctoral Exchange Fellowship Program (Grant No. 20130004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kong, F., Feng, K., Bai, Y. et al. Oxidation behavior of high-purity nonstoichiometric Ti2AlC powders in flowing air. Journal of Materials Research 32, 2747–2754 (2017). https://doi.org/10.1557/jmr.2017.83

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.83