Abstract

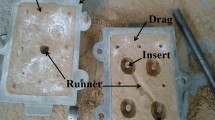

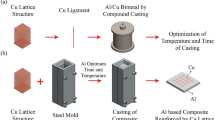

The effect of aluminizing and Cu electroplating of the steel insert in fabrication of Al-matrix bimetal on the microstructure and mechanical properties of the interface layer was investigated. Compound casting process was used to fabricate Al-matrix bimetals reinforced with coated steel insert. The microstructures at the interface region were studied using light optical and scanning electron microscopes and energy dispersive X-ray spectroscopy. The interfacial shear strengths of the fabricated bimetals were compared using push-out test. The results showed that electroplating with copper and aluminizing of steel insert in aluminum matrix led to significant improvement of metallurgical bonding between the steel and aluminum cast matrix. Cu-coated insert contained a thicker and uniform reaction layer formed at the interface between the steel insert and aluminum matrix compared to aluminized coated insert. The results of push-out tests indicated higher interfacial shear strength for the bimetal with Cu-coated insert despite possessing a larger thickness.

Similar content being viewed by others

References

J.C. Vaila, M. Peronnet, F. Barbeau, F. Bosselet, and J. Bouix: Interface chemistry in aluminum alloy castings reinforced with iron base insert. Composites, Part A 33, 1417 (2002).

A. Bouayad, C. Gerometta, M. Radouani, and A. Saka: Interface characterization in aluminum alloy casting reinforced with SG iron insert. J. Adv. Res. Mech. Eng. 1, 226 (2010).

K.J.M. Papis, B. Hallstedt, J.F. Löffler, and P.J. Uggowitzer: Interface formation in aluminum–aluminum compound casting. Acta Mater. 56, 3036 (2008).

E. Hajjari, M. Divandari, S.H. Razavi, T. Homma, and S. Kamado: Microstructure characteristics and mechanical properties of Al 413/Mg joint in compound casting process. Metall. Mater. Trans. A 43, 4667 (2012).

G.R. Zare, M. Divandari, and H. Arabi: Investigation on interface of Al/Cu couples in compound casting. J. Mater. Sci. Technol. 29, 190 (2013).

E.M. Khoonsari, F. Jalilian, F. Paray, D. Emadi, and R.A.L. Drew: Interaction of 308 stainless steel insert with A319 aluminum casting alloy. J. Mater. Sci. Technol. 26, 833 (2010).

J. Bruckner: Cold metal transfer has a future joining steel to aluminum. Weld. J. 84, 38 (2005).

S. Pontevichi, F. Bosselet, F. Barbeau, M. Peronnet, and J.C. Viala: Solid-liquid phase equilibria in the Al–Fe–Si system at 727 °C. J. Phase Equilib. Diffus. 25, 528 (2004).

E. Aguado, A. Baquedano, U. Uribe, A.I. Fernández-Calvo, and A. Niklas: Comparative study of different interfaces of steel inserts in aluminum castings. Mater. Sci. Forum 765, 711 (2013).

K.H. Choe, K.S. Park, B.H. Kang, G.S. Cho, K.Y. Kim, K.W. Lee, M.H. Kim, A. Ikenaga, and S. Koroyasu: Study of the interface between steel insert and aluminum casting in EPC. J. Mater. Sci. Technol. 24, 60 (2008).

B. Lemmens, B. Caklu, J. de Strycker, and K. Verbeken: The effect of Si on the intermetallics formation during hot dip aluminizing. J. Adv. Mater. Res. 922, 429 (2014).

C.J. Wang and S.M. Chen: The high-temperature oxidation behavior of hot-dipping Al–Si coating on low carbon steel. Surf. Coat. Technol. 200, 6601 (2006).

F.C. Yin, M.X. Zhao, Y.X. Liu, W. Han, and Z. Li: Effect of Si on growth kinetics of intermetallic compounds during reaction between solid iron and molten aluminum. Trans. Nonferrous Met. Soc. China 23, 556 (2013).

T.S. Shih and S.H. Tu: Interaction of steel with pure Al, Al–7Si and A356 alloys. Mater. Sci. Eng., A 454–455, 349 (2007).

W.J. Cheng and C.J. Wang: Microstructural evaluation of intermetallic layer in hot-dipped aluminide mild steel with silicon addition. Surf. Coat. Technol. 205, 4726 (2011).

U.R. Kattner: Binary Alloy Phase Diagrams, 2nd ed. (ASM International, Materials Park, Ohio, 1990).

G. Ghosh: Aluminium–iron–silicon, Light Metal Systems: Phase Diagrams, Crystallographic and Thermodynamic Data. Landolt–Börnstein, New Series IV, Vol. 11A2 (Springer Verlag, Berlin, 2005).

G. Ghosh: Cost 507. Final Report Group B, The European Commission, 1998.

G. Ghosh: Ternary Alloys, Vol. 5 (VCH publisher, Weinheim, Germany, 1992).

V.J. Raghavan: Al–Fe–Si aluminum–iron–silicon, section II: Phase diagram evaluations. J. Phase Equilib. Diffus. 23, 362 (2002).

M.V. Akdeniz and A.O. Mekhrabov: The effect of substitutional impurities on evolution of Fe–Al diffusion layer. Acta Mater. 46, 1185 (1998).

W. Fragner, B. Zberg, R. Sonnleitner, P.J. Uggowitzer, and J.F. Löffler: Interface reactions of Al and binary Al-alloys on mild steel substrates in controlled atmosphere. Mater. Sci. Forum 519–521, 1157 (2006).

O. Dezellus, B. Digonnet, and M. Sacerdote-peronnet: Mechanical testing of steel/aluminum-silicon interface by push-out. Int. J. Adhes. Adhes. 27, 417 (2007).

O. Dezellus, L. Milani, F. Bosselet, M. Sacerdote-Peronnet, and J.C. Viala: Mechanical testing of titanium/aluminum-silicon interface by push out. J. Mater. Sci. 43, 1749 (2008).

G.H. Awan and F.U. Hasan: The morphology of coating/substrate interface in hot-dip-aluminized steel. Mater. Sci. Eng., A 472, 157 (2008).

S. Madhavan, M. Kamaraj, and L. Vijayaraghavan: Microstructure and mechanical properties of cold metal transfer welded aluminum/dual phase steel. Sci. Technol. Weld. Joining 21, 194 (2016).

J.A. Taylor: Iron containing intermetallic phases in Al–Si based casting. Procedia Mater. Sci. 1, 19 (2012).

L. Backerud, G. Chai, and J. Tamminen: Solidification Characteristics of Aluminum Alloys. Vol. 2: Foundry Alloys (AFS/Scanaluminium, Stockholm, Sweden, 1990).

C. Wei-Jen and W. Chaur-Jeng: Observation of high-temperature phase transformation in the Si-modified aluminide coating on mild steel using EBSD. Mater. Charact. 61, 467 (2010).

H. Springer, A. Kostka, E.J. Payton, D. Raabe, A. Kaysser-Pyzalla, and G. Eggeler: On the formation and growth of intermetallic phases during interdiffusion between low-carbon steel and aluminum alloys. Acta Mater. 59, 1586 (2011).

H.R. Shahverdi, M.R. Ghomashchi, S.G. Shabestari, and J. Hejazi: Microstructure analysis of interfacial reaction between molten aluminum and solid iron. J. Mater. Process. Technol. 124, 345 (2002).

W. Zhang, D. Sun, L. Han, W. Gao, and X. Qiu: Characterization of intermetallic compound in dissimilar material resistance spot welded joint of high strength steel and aluminum alloy. ISIJ Int. 51, 1870 (2011).

L. Backerud, E. Krol, and J. Tamminen: Solidification Characteristics of Aluminum Alloys. Vol. 1: Wrought Alloys (Skanaluminium/Universitetsforlaget AS, Stockholm, Sweden, 1986).

L. Backerud: Kinetic aspects of the solidification of binary and ternary alloy systems. Jernkontorets Ann. 152, 109 (1968).

Q. Wang, X.S. Leng, T.H. Yang, and J.C. Yan: Effect of Fe–Al intermetallic compounds on interfacial bonding of clad material. Trans. Nonferrous Met. Soc. China 24, 279 (2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salimi, M., Malekan, M., Nami, B. et al. Microstructure characteristics and mechanical properties of the interface layer of coated steel insert-aluminum bimetals. Journal of Materials Research 32, 874–882 (2017). https://doi.org/10.1557/jmr.2017.32

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.32