Abstract

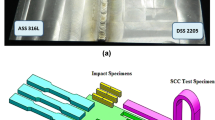

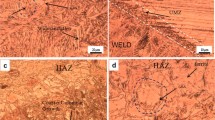

In this work, examination of joint properties of ferritic and dual-phase stainless steel dissimilar welds was carried out by using E2209 duplex and E309LMo austenitic electrodes. The results of E2209 weld showed dual-phase microstructure of ferrite and austenite in the form of grain boundary austenite, Widmanstatten and intragranular austenite, whereas E309LMo weld showed acicular ferrite in the cores of subgrain of austenite. Electron backscatter diffraction was used to study the evolution of the microstructure and micro-texture. The significant variations in the feature of weldments illustrated the presence of a very strong texture. Ferritoscope measurement revealed higher ferrite content in the E2209 weld. Tensile strength, hardness, and absorbed energy of weld metal were dominated by E2209 weld. The modified Strauss test indicated intergranular corrosion attack in the AISI 430 ferritic side heat affected zone. Higher pitting resistance showed by E2209 weld than E309LMo weld. While higher galvanic corrosion observed in the E309LMo weld and AISI 430 ferritic base metal couple.

Similar content being viewed by others

References

T. Oshima, Y. Habara, and K. Kuroda: Efforts to save nickel in austenitic stainless steels. ISIJ Int. 47, 359 (2007).

G. Mallaiah, A. Kumar, P.R. Reddy, and G.M. Reddy: Influence of grain refining elements on mechanical properties of AISI 430 ferritic stainless steel weldments—Taguchi approach. Mater. Des. 36, 443 (2012).

J. Verma and R.V. Taiwade: Effect of austenitic and austeno-ferritic electrodes on 2205 duplex and 316L austenitic stainless steel dissimilar welds. J. Mater. Eng. Perform. 25, 4706 (2016).

K.R. Gadelrab, G. Li, M. Chiesa, and T. Souier: Local characterization of austenite and ferrite phases in duplex stainless steel using MFM and nanoindentation. J. Mater. Res. 27, 1573 (2012).

R. Kaçar and M. Acarer: Microstructure-property relationship in explosively welded duplex stainless steel–steel. Mater. Sci. Eng., B 363, 290 (2003).

P. Sathiya, S. Aravindan, and A.N. Haq: Effect of friction welding parameters on mechanical and metallurgical properties of ferritic stainless steel. Int. J. Adv. Des. Manuf. Technol. 31, 1076 (2007).

H. Krafft: Alloy 430 ferritic stainless steel welds fail due to stress-corrosion cracking in heat-recovery steam generator. Practical Fail. Anal. 2, 39 (2002).

K.D. Ramkumar, A. Chandrasekhar, A.K. Singh, S. Ahuja, and N. Arivazhagan: Effect of filler metals on the structure-property relationships of continuous and pulsed current GTA welds of AISI 430 and AISI 904L. Metallogr. Microstruct. Anal. 4, 525 (2015).

M. Moine, N. Mary, B. Normand, L. Peguet, A. Gaugain, and H.N. Evin: Tribo electrochemical behavior of ferrite and ferrite–martensite stainless steels in chloride and sulfate media. Wear 41, 292 (2012).

M. Rahmani, A. Eghlimi, and M. Shamanian: Evaluation of microstructure and mechanical properties in dissimilar austenitic/super duplex stainless steel joint. J. Mater. Eng. Perform. 23, 3745 (2014).

A.K. Lakshminarayanan, K. Shanmugam, and V. Balasubramanian: Effect of autogenous arc welding processes on tensile and impact properties of ferritic stainless steel joints. J. Iron Steel Res. Int. 16, 6216 (2009).

V. Singh: Physical Metallurgy (Standard Publications Distributers, NaiSarak, Delhi, 2008).

J. Verma, R.V. Taiwade, R.K. Khatirkar, S.G. Sapate, and A.D. Gaikwad: Microstructure, mechanical and intergranular corrosion behavior of dissimilar DSS 2205 and ASS 316L shielded metal arc welds. Trans. Indian Inst. Met. 70, 225 (2017).

J. Verma and R.V. Taiwade: Effect of welding processes and conditions on the microstructure, mechanical properties and corrosion resistance of duplex stainless steel weldments—A review. J. Manuf. Process. 25, 124 (2017).

S. Aguilar, R. Tabares, and C. Serna: Microstructural transformations of dissimilar austenite-ferrite stainless steels welded joints. J. Mater. Phys. Chem. 1, 65 (2013).

K.D. Ramkumar, P.S.G. Kumar, V.S. Radhakrishna, K. Kothari, R. Sridhar, N. Arivazhagan, and P. Kuppan: Studies on microstructure and mechanical properties of keyhole mode Nd:YAG laser welded Inconel 625 and duplex stainless steel, SAF 2205. J. Mater. Res. 30, 3288 (2015).

J. Verma, R.V. Taiwade, R.K. Khatirkar, and A. Kumar: A comparative study on the effect of electrode on microstructure and mechanical properties of dissimilar welds of 2205 austeno–ferritic and 316L austenitic stainless steel. Mater. Trans. 57, 494 (2016).

Standard practice for preparation of metallographic specimens (ASTM E3-95, Philadelphia, PA, USA, 2001).

Standard test methods for tension testing of metallic materials (ASTM E8-04, Philadelphia, PA, USA, 2004).

Standard practice for detecting susceptibility to intergranular attack in austenitic stainless steels (ASTM A262-91, Philadelphia, PA, USA, 1991).

Standard practice for preparation notched impact testing of metallic material (ASTM E23-04, Philadelphia, PA, USA, 2004).

J.C. Lippold and D.J. Kotecki: Welding Metallurgy and Weldability of Stainless Steel (John Wiley & Sons, New Delhi, India, 2005).

F. Mas, G. Martin, P. Lhuissier, Y. Bréchet, C. Tassin, F. Roch, P. Todeschini, and A. Simar: Heterogeneities in local plastic flow behavior in a dissimilar weld between low-alloy steel and stainless steel. Mater. Sci. Eng., B 667, 156 (2016).

A. Eghlimi, M. Shamanian, M. Eskandarian, A. Zabolian, M. Nezakat, and J.A. Szpunar: Evaluation of microstructure and texture across the welded interface of super duplex stainless steel and high strength low alloy steel. Surf. Coat. Technol. 264, 150 (2015).

M. Mukherjeey and T.K. Pal: Influence of heat input on martensite formation and impact property of ferritic-austenitic dissimilar weld metals. J. Mater. Sci. Technol. 28, 343 (2012).

A. Eghlimi, M. Shamanian, and K. Raeissi: Effect of current type on microstructure and corrosion resistance of super duplex stainless steel claddings produced by the gas tungsten arc welding process. Surf. Coat. Technol. 244, 45 (2014).

Y. Yang, B. Yan, J. Li, and J. Wang: The effect of large heat input on the microstructure and corrosion behaviour of simulated heat affected zone in 2205 duplex stainless steel. Corros. Sci. 53, 3756 (2011).

A. Eghlimi, M. Shamanian, M. Eskandarian, A. Zabolian, and J.A. Szpunar: Characterization of microstructure and texture across dissimilar super duplex/austenitic stainless steel weldment joint by austenitic filler metal. Mater. Charact. 106, 208 (2015).

M. Shamanian, M. Mohammadnezhad, M. Amini, A. Zabolian, and J.A. Szpunar: Electron backscatter diffraction analysis of joints between AISI 316L austenitic/UNS S32750 dual-phase stainless steel. J. Mater. Eng. Perform. 24, 3118 (2015).

M. Shamanian, A. Eghlimi, M. Eskandarian, and J.A. Szpunar: Interface microstructure across cladding of super duplex stainless steel with austenitic stainless steel buffer layer. Surf. Coat. Technol. 259, 532 (2014).

A. Joshi and D.F. Stein: Chemistry of grain boundary and its relation to intergranular corrosion of austenitic stainless steel. Corrosion 28, 321 (1972).

W.T. Tsai and J.R. Chen: Galvanic corrosion between the constituent phases in duplex stainless steel. Corros. Sci. 49, 3659 (2007).

H. Alinejad, B. Korojy, and G.R. Ebrahimi: Microstructure and flow behavior of cast 2304 duplex stainless steel at elevated temperatures. J. Mater. Res. 31, 3939 (2016).

ACKNOWLEDGMENTS

The authors express their sincere thank to Director, VNIT Nagpur for providing facilities and constant encouragement to publish this paper. The authors express their acknowledgment to Dr. Nilesh Gurao, IIT Kanpur for their valuable inputs. The authors are grateful to Texture Laboratory at Advanced Center for Material Science, IIT Kanpur.

Author information

Authors and Affiliations

Corresponding author

Supplementary Material

Rights and permissions

About this article

Cite this article

Verma, J., Taiwade, R.V. & Sonkusare, R. Effects of austenitic and duplex electrodes on microstructure, mechanical properties, pitting, and galvanic corrosion resistance of ferritic and dual-phase stainless steel dissimilar joints. Journal of Materials Research 32, 3066–3077 (2017). https://doi.org/10.1557/jmr.2017.269

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.269