Abstract

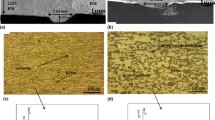

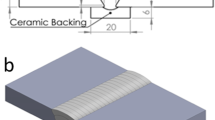

This study addresses the effect of different types of austenitic and austeno-ferritic electrodes (E309L, E309LMo and E2209) on the relationship between weldability, microstructure, mechanical properties and corrosion resistance of shielded metal arc welded duplex/austenitic (2205/316L) stainless steel dissimilar joints using the combined techniques of optical, scanning electron microscope, energy-dispersive spectrometer and electrochemical. The results indicated that the change in electrode composition led to microstructural variations in the welds with the development of different complex phases such as vermicular ferrite, lathy ferrite, widmanstatten and intragranular austenite. Mechanical properties of welded joints were diverged based on compositions and solidification modes; it was observed that ferritic mode solidified weld dominated property wise. However, the pitting corrosion resistance of all welds showed different behavior in chloride solution; moreover, weld with E2209 was superior, whereas E309L exhibited lower resistance. Higher degree of sensitization was observed in E2209 weld, while lesser in E309L weld. Optimum ferrite content was achieved in all welds.

Similar content being viewed by others

References

B.P. Logan, A.I. Toumpis, A.M. Galloway, N.A. McPherson, and S.J. Hambling, Dissimilar Friction Stir Welding of Duplex Stainless Steel to Low Alloy Structural Steel, Sci. Technol. Weld. Join., 2016, 21, p 11–19

S. Wang, Q. Ma, and Y. Li, Characterization of Microstructure, Mechanical Properties and Corrosion Resistance of Dissimilar Welded Joint Between 2205 Duplex Stainless Steel and 16MnR, Mater. Des., 2011, 32, p 831–837

J. Olsson and M. Snis, Duplex—A New Generation of Stainless Steels for Desalination Plants, Desalin, 2007, 205, p 104–113

J. Labanowski, Stress Corrosion Cracking Susceptibility of Dissimilar Stainless Steels Welded Joints, J. Achiev. Mater. Manuf. Eng., 2007, 20, p 255–258

N.R. Baddoo, Stainless Steel in Construction: A Review of Research, Applications, Challenges and Opportunities, J. Const. Steel. Res., 2008, 64, p 1199–1206

B. Deng, Y. Jiang, J. Gong, C. Zhong, J. Gao and J. Li, Critical Pitting and Repassivation Temperatures for Duplex Stainless Steel in Chloride Solutions, Electrochim. Acta, 2008, 53, p 5220–5225

T. Ihsan-ul-Haq, P.J. Hyun, and H.S. Kwon, Development of High Mn-N Duplex Stainless Steel for Automobile Structural Components, Corros. Sci., 2008, 50, p 404–410

Y.A. Albrimi, A. Eddib, J. Douch, Y. Berghoute, M. Hamdani, and R.M. Souto, Electrochemical Behaviour of AISI, 316 Austenitic Stainless Steel in Acidic Media Containing Chloride Ions, Int. J. Electrochem. Sci., 2011, 6, p 4614–4627

B. Gideon, L. Ward, and G. Biddle, Duplex Stainless Steel Welds and their Susceptibility to Intergranular Corrosion, J. Miner. Mater. Charact. Eng., 2008, 7, p 247–263

P. Vasantharaja, M. Vasudevan, and P. Palanichamy, Effect of Welding Processes on the Residual Stress and Distortion in Type 316LN Stainless Steel Weld Joints, J. Manuf. Process., 2015, 19, p 187–193

G.S. Sidhu and S.S. Chatha, Role of Shielded Metal Arc Welding Consumables on Pipe Weld Joint, Int. J. Emerg. Technol. Adv. Eng., 2012, 2, p 746–750

R. Neissi, M. Shamanian, and M. Hajihashemi, The Effect of Constant and Pulsed Current Gas Tungsten Arc Welding on Joint Properties of 2205 Duplex Stainless Steel to 316L Austenitic Stainless Steel, J. Mater. Eng. Perform., 2016, 25, p 2017–2028

U. Kamachi Mudali, B.M. Ananda Rao, K. Shanmugam et al., Corrosion and Microstructural Aspects of Dissimilar Joints of Titanium and Type 304L Stainless Steel, J. Nucl. Mater., 2003, 321, p 40–48

K.D. Ramkumar, A. Singh, S. Raghuvanshi et al., Metallurgical and Mechanical Characterization of Dissimilar Welds of Austenitic Stainless Steel and Super-Duplex Stainless Steel—A Comparative Study, J. Manuf. Process., 2015, 19, p 212–232

K.D. Ramkumar, N. Arivazhagan, and S. Narayanan, Effect of Filler Materials on the Performance of Gas Tungsten Arc Welded AISI, 304 and Monel 400, Mater. Des., 2012, 40, p 70–79

M. Sadeghian, M. Shamanian, and A. Shafye, Effect of Heat Input on Microstructure and Mechanical Properties of Dissimilar Joints Between Super Duplex Stainless Steel and High Strength Low Alloy Steel, Mater. Des., 2014, 60, p 678–684

C.J. Múnez, M.V. Utrilla, A. Ureña, and E. Otero, Influence of the Filler Material on Pitting Corrosion in Welded Duplex Stainless Steel 2205, Weld. Int., 2010, 24, p 105–110

K. Bettahar, M. Bouabdallah, R. Badji et al., Microstructure and Mechanical Behavior in Dissimilar 13Cr/2205 Stainless Steel Welded Pipes, Mater. Des., 2015, 85, p 221–229

P.B. Srinivasan, V. Muthupandi, W. Dietzel, and V. Sivan, An Assessment of Impact Strength and Corrosion Behavior of Shielded Metal Arc Welded Dissimilar Weldments Between UNS 31803 and IS 2062 Steels, Mater. Des., 2006, 27, p 182–191

M. Rahmani, A. Eghlimi, and M. Shamanian, Evaluation of Microstructure and Mechanical Properties in Dissimilar Austenitic/Super Duplex Stainless Steel Joint, J. Mater. Eng. Perform., 2014, 23(10), p 3745–3753

J. Verma, R.V. Taiwade, R.K. Khatirkar, S.G. Sapate, and A.D. Gaikwad, Microstructure, Mechanical and Intergranular Corrosion Behavior of Dissimilar DSS 2205 and ASS 316L Shielded Metal Arc Welds, Trans. Indian. Inst. Metal, 2016, p 1–13. doi:10.1007/s12666-016-0878-8

ASTM E 3-95, Standard Practice for Preparation of Metallographic Specimens Philadelphia, PA, USA, 2001

ASM, Handbook of Metallography and Microstructures, Materials Park, OH, 2004

ANSI/AWS A4.2, Standard Procedures for Calibrating Magnetic Instruments to Measure the Delta Ferrite Content of Austenitic and Duplex Ferritic-Austenitic Stainless Steel Weld Metal, PA, 1997

ASTM E 8-04, Standard Practice for Preparation Tension Testing of Metallic Materials, Philadelphia, PA, USA, 2004

ASTM E23-04, Standard Practice for Preparation Notched Impact Testing of Metallic Material, PA, USA, 2004

J. Gong, Y.M. Jiang, B. Deng, J.L. Xu, J.P. Hu, and J. Li, Evaluation of Intergranular Corrosion Susceptibility of UNS S31803 Duplex Stainless Steel with an Optimized Double Loop Electrochemical Potentiokinetic Reactivation Method, Electrochim. Acta, 2010, 55, p 5077–5083

A.P. Majidi and M.A. Streicher, Potentiodynamic Reactivation Method for Detecting Sensitization in AISI, 304 And 304L Stainless Steels, Corrosion, 1984, 40, p 393–408

R.V. Taiwade, A.P. Patil, R.D. Ghugal et al., Effect of Welding Passes on Heat Affected Zone and Tensile Properties of AISI, 304 Stainless Steel and Chrome-Manganese Austenitic Stainless Steel, ISIJ Int., 2013, 53, p 102–109

J.C. Lippold and D.J. Kotecki, Welding Metallurgy and Weldability of Stainless Steels, Wiley, New York, 2005

J.C. Lippold, W.A.I.I.I. Baeslack, III, and I. Varol, Heat-Affected Zone Liquation Cracking in Austenitic and Duplex Stainless Steels, Weld. J., 1988, 71, p 1S

V. Muthupandi, P.B. Srinivasan, S.K. Seshadri, and S. Sundaresan, Effect of Weld Metal Chemistry and Heat Input on the Structure and Properties of Duplex Stainless Steel Welds, Mater. Sci. Eng. A, 2003, 358, p 9–16

R. Kacar, Effect of Solidification Mode and Morphology of Microstructure on the Hydrogen Content of Duplex Stainless Steel Weld Metal, Mater. Des., 2004, 25, p 1–9

A.J. Ramirez, S.D. Brandi, and J.C. Lippold, Secondary Austenite and Chromium Nitride Precipitation in Simulated Heat Affected Zones of Duplex Stainless Steels, Sci. Technol. Weld. Join., 2004, 9, p 301–313

J.A. Brooks, J.C. Williams, and A.W. Thompson, Microstructural Origin of the Skeletal Ferrite Morphology of Austenitic Stainless Steel Welds, Metall. Trans. A, 1983, 14A, p 1271–1281

R. Saluja and K.M. Moeed, Metallurgical Behaviour of AISI, 304 Steel Butt Welds Under Segregation, Int. J. Mech. Eng. Technol., 2014, 5, p 36–43

Y.H. Kim, D.G. Kim, J.H. Sung, I.S. Kim, D.E. Ko et al., Influences of Cr/Ni Equivalent Ratios of Filler Wires on Pitting Corrosion and Ductility-Dip Cracking of AISI, 316L Weld Metals, Met. Mater. Int., 2011, 17, p 151–155

F.W. Fourie and F.P.A. Robinson, Literature Review on the Influence of Weld-Heat Inputs on the Mechanical and Corrosion Properties of Duplex Stainless Steels, J. S. Atr. Inst. Min. Metall., 1990, 90, p 59–65

K. Yıldızlı, Investigation on the Microstructure and Toughness Properties of Austenitic and Duplex Stainless Steels Weldments Under Cryogenic Conditions, Mater. Des., 2015, 77, p 83–94

R. Badji, M. Bouabdallah, B. Bacroix, C. Kahloun, B. Belkessa, and H. Maza, Phase Transformation and Mechanical Behavior in Annealed 2205 Duplex Stainless Steel Welds, Mater. Charact., 2008, 59, p 447–453

A. Eghlimi, M. Shamanian, and K. Raeissi, Dilution and Ferrite Number Prediction in Pulsed Current Cladding of Super-Duplex Stainless Steel Using RSM, J. Mater. Eng. Perform., 2013, 22, p 3657–3666

V. Shankar, T.P.S. Gill, S.L. Mannan, and S. Sundaresan, Solidification Cracking in Austenitic Stainless Steel Welds, Sadhana, 2003, 28, p 359–382

D. Harish Kumar, A. Somireddy, and K. Gururaj, A Review on Critical Aspects of 316LN Austenitic Stainless Steel Weldability, Int. J. Mater. Sci. Appl., 2012, 1, p 1–7

M. Keskitalo, K. Mantyjarvi, and J. Sundqvist, Laser Welding of Duplex Stainless Steel with Nitrogen as Shielding Gas, J. Mater. Process. Technol., 2015, 216, p 381–384

A. Moteshakker, I. Danaee, S. Moeinifar, and A. Ashrafi, Hardness and Tensile Properties of Dissimilar Welds Joints Between SAF 2205 and AISI, 316L, Sci. Technol. Weld. Join., 2015, 21, p 1–10

S. Geng, J. Sun, L. Guo, and H. Wang, Evolution of Microstructure and Corrosion Behavior in 2205 Duplex Stainless Steel GTA-Welding Joint, J. Manuf. Process., 2015, 19, p 32–37

J. Verma, R.V. Taiwade et al., A Comparative Study on the Effect of Electrode on Microstructure and Mechanical Properties of Dissimilar Welds of 2205 Austeno-Ferritic and 316L Austenitic Stainless Steel, Mater. Trans., 2016, 57, p 494–500

B. Chakrabarti, H. Das, S. Das, and T.K. Pal, Effect of Process Parameters on Clad Quality of Duplex Stainless Steel Using GMAW Process, Trans. Ind. Inst. Met., 2013, 66, p 221–230

Y. Yang, B. Yan, J. Li, and J. Wang, The Effect of Large Heat Input on the Microstructure and Corrosion Behaviour of Simulated Heat Affected Zone in 2205 Duplex Stainless Steel, Corros. Sci., 2011, 53, p 3756–3763

K.H. Lo, C.T. Kwok, and W.K. Chan, Characterisation of Duplex Stainless Steel Subjected to Long-Term Annealing in the Sigma Phase Formation Temperature Range by the DLEPR Test, Corros. Sci., 2011, 53, p 3697–3703

J. Moon, H.Y. Ha, and T.H. Lee, Corrosion Behavior in High Heat Input Welded Heat-Affected Zone of Ni-Free High-Nitrogen Fe–18Cr–10Mn–N Austenitic Stainless Steel, Mater. Charact., 2013, 82, p 113–119

N. Ebrahimi, M.H. Moayed, and A. Davoodi, Critical Pitting Temperature Dependence of 2205 Duplex Stainless Steel on Dichromate Ion Concentration in Chloride Medium, Corros. Sci., 2011, 53, p 1278–1287

P.H. Potgieter, P.A. Olubambi, and L. Cornish, Influence of Nickel Additions on the Corrosion Behaviour of Low Nitrogen 22% Cr Series Duplex Stainless Steels, Corros. Sci., 2008, 50, p 2572–2579

API Technical Report 938-C, Use of Duplex Stainless Steels in the Oil Refining Industry 2nd ed., American Petrol Institute, April, 2011

P.B. Srinivasan, V. Muthupandi, W. Dietzel, and V. Sivan, Microstructure and Corrosion Behavior of Shielded Metal Arc-Welded Dissimilar Joints Comprising Duplex Stainless Steel and Low Alloy Steel, J. Mater. Eng. Perform., 2006, 15, p 759–764

S. Bakour, A. Guenbour, A. Bellaouchou et al., Effect of Welding on the Corrosion Behaviour of a Highly Alloyed Austenitic Stainless Steel UNS N06027 in Polluted Phosphoric Acid Media, Int. J. Electrochem. Sci., 2012, 7, p 10530–10543

Acknowledgment

The authors would like to thank Director, VNIT, Nagpur, for providing necessary facilities and constant encouragement to publish this paper. The authors are also thankful to Mr. Ashvin Gaikwad, Weldfast Electrodes, Nagpur, for providing the welding facilities and electrodes. The authors would also like to thank Mrs. Varsha Patankar (Technical staff, Testing of Materials Laboratory, Department of Metallurgical and Materials Engineering) for her help in conducting mechanical testing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Verma, J., Taiwade, R.V. Effect of Austenitic and Austeno-Ferritic Electrodes on 2205 Duplex and 316L Austenitic Stainless Steel Dissimilar Welds. J. of Materi Eng and Perform 25, 4706–4717 (2016). https://doi.org/10.1007/s11665-016-2329-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2329-4