Abstract

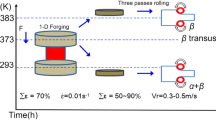

In the paper, 2.5 vol% (TiB + TiC)/Ti composite has been fabricated by in situ casting route. 1-D forging and subsequent multistep rolling in (α + β) phase field are conducted on the as-cast composite and, accordingly, the matrix microstructure is significantly refined, and the distribution uniformity of reinforcements is greatly improved. The tensile properties of the composites with different processing states are tested at room temperature (RT), 600 and 700 °C. The results indicate that thermomechanical processing (TMP) can drastically improve strength and elongation of the as-cast composite both at RT and 600 °C. As tensile temperature increases to 700 °C, the UTSs of the composites gradually reduce while the elongations of the composites are enhanced remarkably after TMP. The degradation in UTS can be related to the matrix softening and interfacial debonding at 700 °C.

Similar content being viewed by others

References

S.C. Tjong and Y.W. Mai: Processing-structure-property aspects of particulate-and whisker-reinforced titanium matrix composites. Compos. Sci. Technol. 68, 583 (2008).

K. Morsi, V.V. Patel, and K.S. Moon: Current activated pressure-assisted sintering (CAPAS) and nanoindentation mapping of dual matrix composites. J. Mater. Sci. 43, 4050 (2008).

S. Gorsse and D.B. Miracle: Mechanical properties of Ti–6Al–4V/TiB composites with randomly oriented and aligned TiB reinforcements. Acta Mater. 51, 2427 (2003).

D. Hill, R. Banerjee, and D. Huber: Formation of equiaxed alpha in TiB reinforced Ti alloy composites. Scr. Mater. 52, 387 (2005).

O.M. Ivasishin, R.V. Teliovych, and V.G. Ivanchenko: Processing, microstructure, texture, and tensile properties of the Ti–6Al–4V–1.55B eutectic alloy. Metall. Mater. Trans. A 39, 411 (2008).

L.J. Huang, L. Geng, and H.X. Peng: In situ (TiBw + TiCp)/Ti6Al4V composites with a network reinforcement distribution. Mater. Sci. Eng., A 527, 6726 (2010).

C.F. Yolton: The pre-alloyed powder metallurgy of Titanium with boron and carbon additions. JOM 56, 56–59 (2004).

S.C. Tjong and Z.Y. Ma: Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng., R 29, 67 (2000).

W.J. Lu, D. Zhang, and X.N. Zhang: Microstructure and tensile properties of in situ (TiB + TiC)/Ti6242 (TiB: TiC = 1:1) composites prepared by common casting technique. Mater. Sci. Eng., A 311, 142 (2001).

V. Imayev, R. Gaisin, and E. Gaisina: Effect of hot forging on microstructure and tensile properties of Ti–TiB based composites produced by casting. Mater. Sci. Eng., A 609, 39 (2014).

H.A. Rastegari, S. Asgari, and S.M. Abbasi: Producing Ti–6Al–4V/TiC composite with good ductility by vacuum induction melting furnace and hot rolling process. Mater. Des. 32, 5010 (2011).

T. Wang, H.Z. Guo, and Y.W. Wang: Influence of processing parameters on microstructure and tensile properties of TG6 titanium alloy. Mater. Sci. Eng., A 528, 736 (2010).

X. Li, S.Q. Lu, and M.W. Fu: The optimal determination of forging process parameters for Ti–6.5Al–3.5Mo–1.5Zr–0.3Si alloy with thick lamellar microstructure in two phase field based on P-map. J. Mater. Process. Technol. 210, 37 (2010).

J.Q. Qi, H.W. Wang, and C.M. Zou: Influence of matrix characteristics on tensile properties of in situ synthesized TiC/TA15 composite. Mater. Sci. Eng., A 553, 60 (2012).

C.J. Zhang, F.T. Kong, and S.L. Xiao: Evolution of microstructure and tensile properties of in situ titanium matrix composites with volume fraction of (TiB + TiC) reinforcements. Mater. Sci. Eng., A 548, 152 (2012).

I. Sen, S. Tamirisakandala, and D.B. Miracle: Microstructural effects on the mechanical behavior of B-modified Ti–6Al–4V alloys. Acta Mater. 55, 4988 (2007).

S. Tamirisakandala, R.B. Bhat, and J.S. Tiley: Grain refinement of cast titanium alloys via trace boron addition. Scr. Mater. 53, 1424 (2005).

Z.Q. Chen, Y.G. Li, and D. Hu: Role of alloying elements in microstructures of beta titanium alloys with carbon additions. Mater. Sci. Technol. 19, 1397 (2003).

P. Nandwana, J.Y. Hwang, M.Y. Koo, J. Tiley, S.H. Hong, and R. Banerjee: Formation of equiaxed alpha and titanium nitride precipitates in spark plasma sintered TiB/Ti–6Al–4V composites. Mater. Lett. 83, 203 (2012).

L.G. Huang, F.T. Kong, and Y.Y. Chen: Microstructure and tensile properties of Ti–6Al–4V–0.1B alloys of direct rolling in the near β phase region. Mater. Sci. Eng., A 560, 145 (2013).

R. Srinivasan, M.D. Bennett, and S. Tamirsakandala: Rolling of plates and sheets from as-cast Ti–6Al–4V–0.1B. J. Mater. Eng. Perform. 18, 394 (2008).

F.C. Ma, W.J. Lu, and J.N. Qin: Effect of forging and heat treatment on the microstructure of in situ TiC/Ti–1100 composites. J. Alloys Compd. 428, 336 (2007).

M.J. Bermingham, S.D. McDonald, and K. Nogita: Effects of boron on microstructure in cast titanium alloys. Scr. Mater. 59, 539 (2008).

G. Lütjering: Influence of processing on microstructure and mechanical properties of (α + β) titanium alloys. Mater. Sci. Eng., A 243, 38 (1998).

D.R. Ni, L. Geng, and J. Zhang: Effect of B4C particle size on microstructure of in situ titanium matrix composites prepared by reactive processing of Ti–B4C system. Scr. Mater. 55, 429 (2006).

H.Z. Ye and X.Y. Liu: Review of recent studies in magnesium matrix composites. J. Mater. Sci. 39, 6154 (2004).

P. Guo, Y.Q. Zhao, and W.D. Zeng: The effect of microstructure on the mechanical properties of TC4–DT titanium alloys. Mater. Sci. Eng., A 563, 107 (2014).

Z.G. Zhang, J.N. Qin, and Z.W. Zhang: Microstructure effect on mechanical properties of in situ synthesized titanium matrix composites reinforced with TiB and La2O3. Mater. Lett. 64, 361 (2010).

L. Xiao, W.J. Lü, and J.N. Qin: High-temperature tensile properties of in situ-synthesized titanium matrix composites with strong dependence on strain rates. J. Mater. Res. 23, 3068 (2008).

ACKNOWLEDGMENTS

The authors gratefully thank the financial support from the National Natural Science Foundation of China (Nos. 51504163 and 51505323), The State Key Laboratory for Advanced Metal and Materials foundation (No. 2014-ZD06), the talent funded projects of Taiyuan University of technology (Nos. tyut-rc201342a and tyut-rc201343a) and the Special/Youth Foundation of Taiyuan University of Technology (No. 2013T001-T004).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, C., Zhang, S., Lin, P. et al. Thermomechanical processing of (TiB + TiC)/Ti matrix composites and effects on microstructure and tensile properties. Journal of Materials Research 31, 1244–1253 (2016). https://doi.org/10.1557/jmr.2016.143

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.143