Abstract

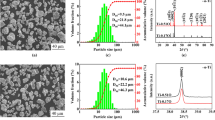

A series of (HfN)1−x(TaN)x, ceramics with x representing the starting powder blend compositions of 0.0, 18.8, 28.1, and 46.7 at.%, have been fabricated by vacuum plasma spraying. During the plasma spraying, the mixture lost approximately 25 at.% nitrogen facilitating the precipitation of metallic and metal-rich nitride phases. These specimens underwent static air oxidation exposure up to 1700 °C. In general, it was found that the addition of tantalum nitrides to the hafnium nitrides resulted in poorer oxidation behavior. However, the 18.8 at.% specimen deviated from this trend and had the lowest observed mass change. This specimen formed a dark-colored oxide scale, indexed as Hf6Ta2O17, which acted as a passivation layer. Within the scale, hafnium oxynitride phases were observed. A transformation pathway in forming these rhombohedral oxynitride phases is proposed by the filling in of oxygen in the light element interstitial locations of the rhombohedral ε-Hf3N2 and ζ-Hf4N3 structures.

Similar content being viewed by others

References

E. Wuchina, E. Opila, M. Opeka, W. Fahrenholtz, and I. Talmy: UHTCS: Ultra-high temperature ceramic materials for extreme enviornment applications. Electrochem. Soc. Interface 16(4), 30–36 (2007).

A.J. Perry: The refractories HfC and HfN—A survey. Powder Metall. Int. 19(1), 29–35 (1987).

B.O. Johansson, U. Helmersson, M.K. Hibbs, and J.E. Sundgren: Reactively magnetron sputtered Hf-N films I. Composition and structure. J. Appl. Phys. 58(8), 3104–3111 (1985).

A. Zerr, G. Miehe, and R. Riedel: Synthesis of cubic zirconium and hafnium nitride having Th3P4 structure. Nat. Mater. 2, 185–189 (2003).

K. Balani, G. Gonzalez, and A. Agarwal: Synthesis, microstructure characterization, and mechanical property evaluation of vacuum plasma sprayed tantalum carbide. J. Am. Ceram. Soc. 89(4), 1419–1425 (2006).

M. Desmaison-Brut, L. Themalin, F. Valin, and M. Boncoeur: Mechanical proprties of hot-isostatically-pressed titanium nitride. Eur.Ceram. 3, 258–262 (1989).

L. Limeng, Y. Feng, and Z. Yu: Microstructure and mechanical properties of spark plasma sintered TaC0.7 ceramics. J. Am. Ceram. Soc. 93(10), 2945–2947 (2010).

C.M. Carney, T.A. Parthasarathy, and M.K. Cinibulk: Oxidation resistance of hafnium diboride ceramics with additions of silicon carbide and tungsten boride or tungsten carbide. J. Am. Ceram. Soc. 94(8), 2600–2607 (2011).

S. Shimada: Interfacial reaction on oxidation of carbides with formation of carbon. Solid State Ionics 141–142, 99–104 (2001).

S. Shimada: A thermoanalytical study of the oxidation of ZrC and HfC powders with formation of carbon. Solid State Ionics 149(3–4), 319–326 (2002).

S. Shimada: Microstructural observation of ZrO2 scales formed by oxidation of ZrC single crystals with formation of carbon. Solid State Ionics 101–103, 749–753 (1997).

S. Shimada and M. Inagaki: A kinetic study of oxidation of niobium carbide. Solid State Ionics 63–65, 312–317 (1993).

S. Shimada, K. Nakajima, and M. Inagaki: Oxidation of single crystals of hafium carbide in a temperature range of 600° to 900°C. J. Am. Ceram. Soc. 80(7), 1749–1756 (1997).

T.A. Parthasarathy, R.A. Rapp, M. Opeka, and R.J. Kerans: A Model for the Oxidation of ZrB2, HfB2 and TiB2. Acta Materialia 55(17), 5999–6010 (2007).

D.P. Brady, F.N. Fuss, and D. Gerstenberg: Thermal oxidation and resistivity of tantalum nitride films. Thin Solid Films 66(3), 287–302 (1980).

T.A. Parthasarathy, R.A. Rapp, M. Opeka, and R.J. Kerans: Effects of phase change and oxygen permeability in oxide scales on oxidation kinetics of ZrB2 and HfB2. J. Am. Ceram. Soc. 92(5), 1079–1086 (2009).

M. Desmaison, N. Alexandre, and J. Desmaison: Comparison of the oxidation behavior of two dense hot isostatically pressed tantalum carbide (TaC and Ta2C) materials. J. Eur. Ceram. Soc. 17(11), 1325–1334 (1997).

M. Desmaison-Brut and J. Montintin: Mechanical properties and oxidation behavior of HIPed hafnium nitride ceramics. J. Eur. Ceram. Soc. 13(4), 379–386 (1994).

M. Opeka, I. Talmy, E. Wuchina, J. Zaykoski, and S. Causey: Mechanical, thermal, and oxidation properties of refractory hafnium and zirconium compounds. J. Eur. Ceram. Soc. 19(13–14), 2405–2414 (1999).

E. Wuchina: Oxidation of Hf based nitrides and borides. Electrochem. Soc., Proc. 16, 240–252 (2004).

H. Okamoto: Hf-O (hafnium-oxygen). ASM Int. 29, 124 (2008).

D. Shin, R. Arroyave, and Z. Liu: Thermodynamic modeling of the Hf-Si-O system. Comput. Coupling Phase Diagrams Thermochem. 30(4), 375–386 (2008).

B.C. Schulz, B. Wang, R.A. Morris, D. Butts, and G.B. Thompson: Influence of hafnium carbide on vacuum plasma spray processed tantalum carbide microstructures. J. Eur. Ceram. Soc. 33(6), 1219–1224 (2013).

L. Trignan-Piot, M. Berardo, J. Gastaldi, and S. Giorgio: Influence of plasma spraying parameters on the carbon content and porosity of TaC coatings. Surf. Coat. Technol. 79(1–3), 113–118 (1996).

C.B. Williams and D.B. Carter: Transmission Electron Microscopy: A Textbook for Materials Science (Springer Science, New York, 1996).

R.A. Morris, B. Wang, G.B. Thompson, and D. Butts: Variation in tantalum carbide microstructures with changing carbon content. J. Appl. Ceram. Technol. 89(3), 540–551 (2012).

R.A. Morris, B. Wang, L. Matson, and G.B. Thompson: Microstructural formations and phase transformations pathways in hot isostatically pressed tantalum carbides. Acta Mater. 60(1), 139–148 (2012).

ASM International: Handbook of Thermal Spray Technology (ASM International, Materials Park, OH, USA, 2004).

International Centre for Diffraction Data: 00-038-1478 (Alpha Hf), 2012.

International Centre for Diffraction Data: 04-004-6450 (HfN0.67), 2013.

International Centre for Diffraction Data: 04-004-6451 (HfN0.75), 2013.

International Centre for Diffraction Data: 00-025-1410 (HfN), 2013.

International Centre for Diffraction Data: 00-004-0788 (Cubic Ta), 2012.

International Centre for Diffraction Data: 01-089-4764 (Ta2N), 2012.

International Centre for Diffraction Data: 00-039-1485 (Hex TaN), 2012.

International Centre for Diffraction Data: 00-049-1283 (Cubic TaN), 2012.

International Centre for Diffraction Data: 00-006-0318 (Mono HfO2), 2013.

International Centre for Diffraction Data: 00-008-0342 (Tetra HfO2), 2013.

International Centre for Diffraction Data: 00-021-0904 (Ortho HfO2), 2013.

International Centre for Diffraction Data: 00-053-0550 (Cubic HfO2), 2013.

International Centre for Diffraction Data: 00-050-1171 (Cubic Hf2ON2), 2013.

International Centre for Diffraction Data: 00-050-1173 (Rhom Hf7O8N4), 2013.

International Centre for Diffraction Data: 33-1391 (Mono Ta2O5), 2012.

International Centre for Diffraction Data: 33-1390 (Tri Ta2O5), 2012.

International Centre for Diffraction Data: 21-1199 (Tetra Ta2O5), 2012.

International Centre for Diffraction Data: 25-0922 (Ortho Ta2O5), 2012.

International Centre for Diffraction Data: 18-1304 (Hex Ta2O5), 2012.

International Centre for Diffraction Data: 00-044-0998 (Ortho Hf6Ta2O17), 2015.

E.R. Weibel: Stereological Methods (Academic Press/Harcourt Brace Javanovich, New York, NY, 1989).

V.V. Klechkovskaya, Z.G. Pinkser, and V.I. Khikova: Nonstiochiometry, Diffusion and Electrical Conductivity in Binary Metal Oxides. Kristallografiya 17, 506 (1972).

A. Reisman, F. Holtzberg, M. Berkenblit, and M. Berry: Reactions of the group VB pentoxides with alkali oxides and carbonates. III. Thermal and X-Ray phase diagrams of the system K2O or K2CO3 with Ta2O5. J. Am. Chem. Soc. 78(18), 4514–4520 (1956).

G.L. Humphrey: Heats of formation of tantalum, niobium and zirconium oxides, and tantalum carbide. J. Am. Chem. Soc. 76(4), 978–980 (1954).

G.L. Humphrey: Heats of formation of hafnium oxide and hafnium nitride. J. Am. Chem. Soc. 75(12), 2806–2807 (1953).

E. Rudy: The Crystal structures of Hf3N2 and Hf4N3. Metall. Mater. Trans. 1(5), 1249–1252 (1970).

E. Rudy: Part V. Compendium of Phase Diagram Data (USAF, Wright-Patterson Air Force Base, Ohio, 1969).

ACKNOWLEDGMENT

The authors thank Dr. Eric Wuchina for technical discussions. This work has been approved for public release 14-MDA-7794.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schulz, B.C., Butts, D. & Thompson, G.B. Oxidation behavior of vacuum plasma-sprayed hafnium–tantalum nitrides. Journal of Materials Research 30, 2949–2957 (2015). https://doi.org/10.1557/jmr.2015.191

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2015.191