Abstract

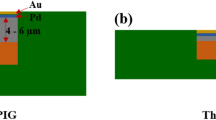

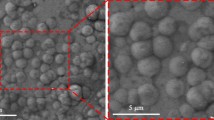

To reinforce the reliability issue brought by excessive interfacial reaction with the dimensional scale-down of electronic device, an electroless Ni–P–ZrO2 (17.5 at.% of P) composite coating was developed as the under bump metallization (UBM) for lead-free solder interconnect. ZrO2 nanoparticles were proved to be homogeneously distributed and helped improve wetting ability of the layer. Both Sn–3.5Ag/Ni–P–ZrO2 and Sn–3.5Ag/Ni–P solder joints were prepared and aged at various conditions to study the interfacial reaction. Growth of intermetallic compounds (IMCs) without serious spalling in solder/Ni–P–ZrO2 joint was slowed down because of the barrier property of incorporation of ZrO2 nanoparticles, which blocked the diffusion of Ni and Cu atoms. Based on the IMC growth, the activation energy of solder/Ni–P–ZrO2 was estimated to be higher than that of plain solder joint. The top-view of IMCs demonstrated a much finer grain size compared with that of solder/Ni–P joint. A reactive diffusion-induced compound formation mechanism was proposed to address the microstructural evolution in detail. Moreover, solder/Ni–P–ZrO2 joint demonstrated higher shear strength than did solder/Ni–P joint for different aging durations. The fracture surface of solder/Ni–P joint after shear test showed ductile transition failure, with big dimples and plastic deformation.

Similar content being viewed by others

References

K.N. Tu and K. Zeng: Tin–lead (SnPb) solder reaction in flip chip technology. Mater. Sci. Eng., R 34, 1 (2001).

M.L. Huang, S. Ye, and N. Zhao: Current-induced interfacial reactions in Ni/Sn–3Ag–0.5Cu/Au/Pd(P)/Ni–P flip chip interconnect. J. Mater. Res. 26, 3009 (2011).

D.M. Jang and J. Yu: Tungsten alloying of the Ni(P) films and the reliability of Sn–3.5Ag/NiWP solder joints. J. Mater. Res. 26, 889 (2011).

P.L. Liu and J.K. Shang: Fracture of SnBi/Ni(P) interfaces. J. Mater. Res. 20, 818 (2005).

J.W. Jang, P.G. Kim, K.N. Tu, D.R. Frear, and P. Thompson: Solder reaction-assisted crystallization of electroless Ni–P under bump metallization in low cost flip chip technology. J. Appl. Phys. 85, 8456 (1999).

C.Y. Liu, C. Chen, A.K. Mal, and K.N. Tu: Direct correlation between mechanical failure and metallurgical reaction in flip chip solder joints. J. Appl. Phys. 85, 3882 (1999).

P.G. Kim, J.W. Jang, T.Y. Lee, and K.N. Tu: Interfacial reaction and wetting behavior in eutectic SnPb solder on Ni/Ti thin films and Ni foils. J. Appl. Phys. 86, 6746 (1999).

A.K. Gain, Y.C. Chan, and K.C. Yung: Microstructure, thermal analysis and hardness of a Sn–Ag–Cu–1 wt% nano-TiO2 composite solder on flexible ball grid array substrates. Microelectron. Reliab. 51, 975 (2011).

Y. Yang, J.N. Balaraju, Y.Z. Huang, H. Liu, and Z. Chen: Interface reaction between an electroless Ni-co-P metallization and Sn-3.5Ag lead-free solder with improved joint reliability. Acta Mater. 71, 69 (2014).

Y. Yang, J.N. Balaraju, S.C. Chong, H. Xu, C.Q. Liu, V.V. Silberschmidt, and C. Chen: Significantly retarded interfacial reaction between an electroless Ni-W-P metallization and lead-free Sn-3.5Ag solder. J. Alloys Compd. 565, 11 (2013).

J. Shen and Y.C. Chan: Research advances in nano-composite solders. Microelectron. Reliab. 49, 223 (2009).

R. Zhao, L.M. Ma, Y. Zuo, S.H. Liu, and F. Guo: Retarding electromigration in lead-free solder joints by alloying and composite approaches. J. Electron. Mater. 42, 280 (2013).

X. Hu, Y.C. Chan, K.L. Zhang, and K.C. Yung: Effect of graphene doping on microstructural and mechanical properties of Sn–8Zn–3Bi solder joints together with electromigration analysis. J. Alloys Compd. 580, 162 (2013).

C.Y. Liu, K.N. Tu, T.T. Sheng, C.H. Tung, D.R. Frear, and P. Elenius: Electron microscopy study of interfacial reaction between eutectic SnPb and Cu/Ni(V)/Al thin film metallization. J. Appl. Phys. 87, 750 (2000).

C.F. Tseng and J.G. Duh: The influence of Pd on growth behavior of a quaternary (Cu,Ni,Pd)6Sn5 compound in Sn–3.0Ag–0.5Cu/Au/Pd/Ni–P solder joint during a liquid state reaction. J. Mater. Sci. 48, 857 (2013).

X. Gu, Y.C. Chan, D. Yang, and B.Y. Wu: The shearing behavior and microstructure of Sn-4Ag-0.5Cu solder joints on a Ni-P-carbon nanotubes composite coating. J. Alloys Compd. 468, 553 (2009).

A.K. Gain, T. Fouzder, Y.C. Chan, and Y.C. Yung: Microstructure, kinetic analysis and hardness of Sn–Ag–Cu–1 wt% nano-ZrO2 composite solder on OSP-Cu pads. J. Alloys Compd. 509, 3319 (2011).

G.O. Mallory and J.B. Hajdu: Electroless Plating: Fundamentals and Applications, 1st ed. (William Andrew, 1900).

Joint Committee on Powder Diffraction Standards Diffraction Data File, No. 37–1484 (International Centre for Diffraction Data (ICDD, formerly JCPDS), Newtown Square, PA, 2011).

K.M. Martorano, M.A. Martorano, and S.D. Brandi: Optimal conditions for the wetting balance test. J. Mater. Process. Technol. 209, 3089 (2009).

J.J. Guo, A.P. Xian, and J.K. Shang: Degradation of solderability of electroless nickel by phosphide particles. Surf. Coat. Technol. 202, 268 (2007).

Z. Chen, M. He, and G.J. Qi: Morphology and kinetic study of the interfacial reaction between the Sn-3.5Ag solder and electroless Ni-P metallization. J. Electron. Mater. 33, 1465 (2004).

H.K. Kim and K.N. Tu: Kinetic analysis of the soldering reaction between eutectic SnPb alloy and Cu accompanied by ripening. Phys. Rev. B 53, 16027 (1996).

S. Chada, W. Laub, R.A. Fournelle, and D.S. Guan: An improved numerical method for predicting intermetallic layer thickness developed during the formation of solder joints on Cu substrates. J. Electron. Mater. 28, 1194 (1999).

Y.D. Lu, X.Q. He, Y.F. En, X. Wang, and Z.Q. Zhuang: Polarity effect of electromigration on intermetallic compound formation in SnPb solder joints. Acta Mater. 57, 2560 (2009).

X. Hu, S. Xu, Y. Yang, Z. Chen, and Y.C. Chan: Effect of TiO2 nanoparticle addition on electroless Ni — P under bump metallization for lead-free solder interconnection. Mater. Sci. Eng., A 600, 67 (2014).

J.W. Yoon and S.B. Jung: Growth kinetics of Ni3Sn4 and Ni3P layer between Sn–3.5Ag solder and electroless Ni–P substrate. J. Alloys. Compd. 105, 376 (2004).

P.L. Tu, Y.C. Chan, K.C. Hung, and J.K.L. Lai: Growth kinetics of intermetallic compounds in chip scale package solder joints. Scr. Mater. 44, 317 (2001).

Y.C. Sohn, J. Yu, S.K. Kang, D.Y. Shih, and T.Y. Lee: Spalling of intermetallic compounds during the reaction between lead-free solders and electroless Ni-P metallization. J. Mater. Res. 19, 2428 (2004).

S.W. Kim, J.W. Yoon, and S.B. Jeng: Interfacial reactions and shear strengths between Sn-Ag-based Pb-free solder balls and Au/EN/Cu metallization. J. Electron. Mater. 33, 1182 (2004).

ACKNOWLEDGMENTS

The authors would like to acknowledge the financial support provided by the Research Grants Council, Hong Kong, ref. no. 9041636 (A study of nanostructured electronic interconnects-preparation, characterization and integration), City University of Hong Kong research project: 7002848 (A study of functionalized CNT/graphene reinforced composite electronic interconnects: preparation, characterization and integration for green nanoelectronic applications), the Center for Electronic Packaging and Assemblies, Failure Analysis and Reliability Engineering (EPA Center) of City University of Hong Kong, Chartermate International Ltd. for help the electroplating process.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, X., Chan, Y.C. Reinforced solder joint performance by incorporation of ZrO2 nanoparticles in electroless Ni–P composite layer. Journal of Materials Research 29, 2657–2666 (2014). https://doi.org/10.1557/jmr.2014.310

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.310