Abstract

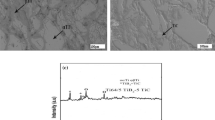

Fatigue behaviour of titanium reinforced with TiB particles fabricated by ‘plasma transferred arc solid freeform fabrication’ (PTA-SFFF) technique was investigated. Rotation bending fatigue tests were conducted following the MPIF 56 standard using the staircase method approach. Experimental data is used to calculate the fatigue strength and construct S-N curves, where the results were compared to a powder metallurgy FC0205 as a benchmark material. The titanium samples were found to exhibit superior fatigue behaviour in comparison to the reference FC0205 material, performing well above 1/3 of its ultimate tensile strength with a 90% survival fatigue strength of 244 +/- 98.3 MPa versus 141 +/- 17.4 MPa. Fatigue failure mechanisms of samples were identified by examination of the fracture surfaces through scanning electron microscopy (SEM) as well as using transmission-electron microscopy (TEM) and focused ion beam (FIB) analysis techniques. Fatigue crack propagation was either arrested or deflected when propagation occurred within the vicinity of the TiB intermetallics. Fracture surfaces of the titanium matrix displayed evidence of striations while the TiB intermetallic experience cleavage fracture.

Similar content being viewed by others

References

M.J.J. Donachie, in Titan. - A Tech. Guid., 2nd ed. (ASM International, Materials Park, 2000), pp. 1–3.

G. Lütjering and J.C. Williams, Titanium : Engineering Materials and Processes, 2nd ed. (Springer, New York, 2007).

S.A. Niknam, R. Khettabi, and V. Songmene, in Mach. Titan. Alloy., edited by J.P. Davim (Springer-Verlag Berlin Heidelberg, New York, 2014), pp. 1–10.

P. Kumar and K.S.R. Chandran, Metall. Mater. Trans. A 48, 2301 (2017).

S. Jinks, J. Scanlan, and S. Wiseall, in Collab. Prod. Serv. Life Cycle Manag. a Sustain. World, edited by R. Curran, S.Y. Chou, and A. Trappey (Springer-Verlag London Limited, London, 2008), pp. 225–232.

D. Marini, D. Cunningham, and J.R. Corney, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. (2017).

L. Bolzoni, E.M. Ruiz-Navas, and E. Gordo, Mater. Sci. Eng. A 687, 47 (2017).

Y. Cao, F. Zeng, B. Liu, Y. Liu, J. Lu, Z. Gan, and H. Tang, Mater. Sci. Eng. A 654, 418 (2016).

R.M. German, Powder Metallurgy and Particulate Materals Processing: The Processes, Materials, Products, Properties and Applications (Metal Powder Industries Federation, Princeton, New Jersey, 2005).

Standard Test Methods for Metal Powders and Powder Metallurgy Products (Metal Powder Industries Federation, Princeton, 2002).

G.N. Grayson, G.B. Schaffer, and J.R. Griffiths, Mater. Sci. Eng. A 434, 1 (2006).

S. Biamino, A. Penna, U. Ackelid, S. Sabbadini, O. Tassa, P. Fino, M. Pavese, P. Gennaro, and C. Badini, Intermetallics 19, 776 (2011).

P. Edwards, A. O’Conner, and M. Ramulu, J. Manuf. Sci. Eng. 135, (2013).

P. Edwards and M. Ramulu, Mater. Sci. Eng. A 598, 327 (2014).

S. Leuders, M. Thöne, A. Riemer, T. Niendorf, T. Tröster, H.A. Richard, and H.J. Maier, Int. J. Fatigue 48, 300 (2013).

D. Greitemeier, F. Palm, F. Syassen, and T. Melz, Int. J. Fatigue 94, 211 (2017).

C. Cai, B. Song, C. Qiu, L. Li, P. Xue, Q. Wei, J. Zhou, H. Nan, H. Chen, and Y. Shi, J. Alloys Compd. 710, 364 (2017).

A.P.I. Popoola, L. Phume, S. Pityana, and V.S. Aigbodion, Surf. Coatings Technol. 285, 161 (2016).

S. Li, K. Kondoh, H. Imai, B. Chen, L. Jia, and J. Umeda, Mater. Sci. Eng. A 628, 75 (2015).

K.S. Ravi Chandran, K.B. Panda, and S.S. Sahay, Jom 56, 42 (2004).

B.J. Kooi, Y.T. Pei, and J.T.M. De Hosson, Acta Mater. 51, 831 (2003).

F. Weng, H. Yu, C. Chen, J. Liu, L. Zhao, J. Dai, and Z. Zhao, J. Alloys Compd. 692, 989 (2017).

S. Pouzet, P. Peyre, C. Gorny, O. Castelnau, T. Baudin, F. Brisset, C. Colin, and P. Gadaud, Mater. Sci. Eng. A 677, 171 (2016).

R. Banerjee, P.C. Collins, and H.L. Fraser, Adv. Eng. Mater. 4, 847 (2002).

S. Nag and R. Banerjee, in ASM Handb. (ASM International, Materials Park, 2012), pp. 6–17.

ASTM B962-15 Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle (ASTM International, West Conshohocken, 2015).

Standard Test Method 56: Method for Determination of Rotating Beam Fatigue Endurance Limit of Powder Metallurgy (PM) Materials (Metal Powder Industries Federation, Princeton, 2016).

ASTM E8/E8M-16a Standard Test Methods for Tension Testing of Metallic Materials (ASTM International, West Conshohocken, 2016).

ASM Handbook Volume 3, Alloy Phase Diagrams - B (Boron) Binary Alloy Phase Diagrams (ASM International, Materials Park, 2016).

ASM Handbook Volume 2, Properties and Selection: Nonferrous Alloys and Special Purpose Materials (ASM International, Materials Park, 1995).

B.F. Decker and J.S. Kasper, Acta Crystallogr. 7, 77 (1954).

H. Rutz, T. Murphy, and T. Cimino, in PM-EC ’96 World Congr. (PM International, Washington, 1996), pp. 1–20.

K. Farokhzadeh and A. Edrisy, Mater. Sci. Eng. A 620, 435 (2014).

M. Lewandowska and K.J. Kurzydlowski, J. Mater. Sci. 43, 7299 (2008).

Y. Estrin and A. Vinogradov, Acta Mater. 61, 782 (2013).

A. Azushima, R. Kopp, A. Korhonen, D.Y. Yang, F. Micari, F.G.D. Lahoti, P. Groche, J. Yanagimoto, N. Tsujii, A. Rosochowskij, and A. Yanagidaa, CIRP Ann. 57, 716 (2008).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Boudreau, D.B., DiCecco, LA., Gali, O.A. et al. Fatigue Behaviour of Additive Manufactured Ti-TiB. MRS Advances 3, 3641–3653 (2018). https://doi.org/10.1557/adv.2018.618

Published:

Issue Date:

DOI: https://doi.org/10.1557/adv.2018.618