Abstract

Hypericum perforatum (HP) contains valuable and beneficial bioactive compounds that have been used to treat or prevent several illnesses. Encapsulation technology offers protection of the active compounds and facilitates to expose of the biologically active compounds in a controlled mechanism. Microcapsulation of the hydroalcoholic gum arabic and maltodextrin have hot been used as wall materials in the encapsulation of HP extract. Therefore, the optimum microencapsulation parameters of Hypericum perforatum (HP) hydroalcoholic extract were determined using response surface methodology (RSM) for the evaluation of HP extract. Three levels of three independent variables were screened using the one-way ANOVA. Five responses were monitored, including total phenolic content (TPC), 2,2-Diphenyl-1-picrylhydrazyl (DPPH), carr index (CI), hausner ratio (HR), and solubility. Optimum drying conditions for Hypericum perforatum microcapsules (HPMs) were determined: 180 °C for inlet air temperature, 1.04/1 for ratio of maltodextrin to gum arabic (w/w), and 1.98/1 for coating to core material ratio (w/w). TPC, antioxidant activity, CI, HR, and solubility values were specified as 316.531 (mg/g GAE), 81.912%, 6.074, 1.066, and 35.017%, respectively, under the optimized conditions. The major compounds of Hypericum perforatum (hypericin and pseudohypericin) extract were determined as 4.19 μg/g microcapsule and 15.09 μg/g microcapsule, respectively. Scanning electron microscope (SEM) analysis revealed that the mean particle diameter of the HPMs was 20.36 µm. Based on these results, microencapsulation of HPMs by spray drying is a viable technique which protects the bioactive compounds of HP leaves, facilitating its application in the pharmaceutical, cosmetic, and food industries.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The genus Hypericum comprises about 500 species all over the World and widely distributed in North America, Europe, West Asia and North Africa [1]. In Turkey, 109 Hypericum taxa have been reported [2]. Because of the diverse biological activities and medicinal use of the Hypericum species, researchs are focused on the unstudied potential of these species. HP is the best-known plant among them. HP is widely known as St. John’s Wort plant and has been used in the treatment of moderate depression, skin inflammation, minor burns, and wounds [3]. In previous studies, different extracts of HP were encapsulated using various materials and methods [4,5,6].

Plants contain bioactive secondary metabolites such as phenolics, terpenes, Nitrogen containing compounds, Sulfur containing compounds. Especially, phenolic compounds are affected from environmental conditions including oxygen, light, and heat. Microencapsulation technique is applied to overcome this problem. It is used to protect the compounds in the capsule from outer effects (oxygen, light, temperature, etc.) during the storage or processing period [7]. Liquid samples are generally applied in powder form to enhance their stabilities. There are several techniques for microencapsulation, including freze-drying, spray-drying, coacervation, polymerization, fluid bed coating, extrusion coating, and liposome confinement [8, 9]. The most preferred microcapsulation technique is spray-drying due to the advantages of low cost, ease of utilization, high stability of the final product, opportunity for continuous capability, and wide range of carrier material selection [10, 11]. The spray-drying technique is commonly used to obtain dry powders from liquid products [12].

Encapsulation efficiency depends on choosing the right wall materials [13,14,15]. Gum arabic and maltodextrin have been widely used as carriers in spray-drying processes because of their good biocompatibility, safety, high solubility, and optimum viscosity [16,17,18]. Additionally, optimum encapsulation conditions must be determined to ensure maximum efficiency. There are dependent and independent variables that effects the encapsulation efficiency. Therefore, determination of the optimum parameters for the encapsulation process is important in terms of bioavailability. Response Surface Methodology (RSM) is a common method that facilitates finding the optimum experimental conditions. It is useful for the improvement and optimization of the experimental conditions which are influenced by several variables [19,20,21].

Limited studies have been carried out on the encapsulation process of the HP extract which used different methodologies and had different objectives [4, 22,23,24]. Therefore, optimization of the microencapsulation conditions of HP by RSM, microcapsulation of HP by spray-drying method under optimized conditions, HPLC analysis of the microcapsules, determination of the antioxidant activities, total phenolic content (TPC), bioavailability, and morphological properties of the microcapsules were aimed in the current study.

Material and Methods

Materials

HP was picked from Amasya/Turkey during its flowering season in 2018. Identification of HP was performed by Dr. Cengiz Yıldırım and it was deposited at Ondokuz Mayıs University Herbary (OMUB-6640). Gum arabic (Merck.Darmstadt. Germany) and maltodextrin (DE 16.5–19.5. Sigma, St. Louis, MO, USA) were used as carrier materials in the microcapsulation processes of HP extracts. Hypericin, pseudohypericin, and Folin-Ciocalteu were supplied from Merck (Darmstadt, Germany). Ethanol, acetic acid, sodium carbonate (Na2CO3), 1,1-diphenyl-2-picrylhydrazyl (DPPH), potassium chloride (KCl), sodium chloride (NaCl), sodium hydroxide (NaOH) were obtained from Sigma-Aldrich (St. Louis, Missouri, USA). All of the other solvents and reagents were of analytical grade.

Preparation of the Hypericum Extract

The aerial parts of HP were allowed to dry in shade for 3 weeks and then crushed. An ultrasonic wave-assisted extraction (UAE) was applied to extract the active components of HP extract (HPE). Extraction was carried out with ethanol–water (3:7) solvent system at 30 °C using an ultrasonic bath (Çalışkan Lab. Ult 4010, Turkey) for 40 min [25]. The mixtures were then filtered and concentrated under reduced pressure (Buchi R100, Türkiye).

Experimental Design for the RSM and Statistical Analysis

Response surface methodology (RSM) was applied to determine the effect of spray drying parameters. CCD was used for the experimental design. The inlet temperature (120-180C; X1), coating to extract ratio (1/1–4/1; X2), and maltodextrin to gum arabic ratio (1/1–7/1; X3) were varied to maximize TPC, antioxidant power, and solubility by minimizing the HR and CI (Table I). Different coating concentrations (10%, 15%, 20%, and 30%) were used based on a preliminary study [26]. Tatar Turan and Kahyaoglu [26] investigated the effect of an ultrasonic spray nozzle on carbohydrate and protein-based coating materials for blueberry extracts microencapsulation. They employed three levels factorial design with five central points to determine the interaction between ultrasonic power (5–10 W), coating material concentration (10%-30%) and type of coating material. The maximum particle size (38.1 µm) was obtained with 30% coating concentration. In the current study, CCD was applied with five central points, giving a total of 20 combinations. The codes are given in Table I. The results were calculated using nonlinear regression, which fits second-order equations, and the lack of fit test was applied to determine the models. Each response was evaluated to assess the desired working conditions [27]. Optimization of multiple responses was performed with the desirability function. In this method, all independent variables were kept within range by minimizing or maximizing the response values. Analysis of the correlation coefficients, regression, and variance (ANOVA) were performed using Design Expert 10.0 (Statease Inc., Minneapolis. USA).

Encapsulation by Spray Drying

Encapsulation can be defined as a mechanical or physicochemical process which involves trapping active ingredients in the bulk of a less valuable material such as wall materials, external phases, and carrier agents. Recent studies indicate that there has been a growing interest in the encapsulation of bioactive compounds with a focus on the incorporation of active ingredients through drying technologies [28]. Spray drying is a method commonly used to protect active ingredients and heat-sensitive compounds. HPE was microencapsulated according to the optimized conditions in a Mini Spray Dryer Be-290 (Buchi Labor technik. Flawil. Switzerland). The following drying conditions were used: feed pump rate (30%; 9 mL min−1), aspirator rate (100%; 35 m3h−1), and air flow rate (50%; 601 Lh−1). The coating material concentration was adjusted to 10% in the microencapsulation production of HPE. Microencapsulation of HPE was performed at 180 °C inlet air temperature, keeping the ratio of coating to extract as 1.98: 1.10 (w/w %) and using the ratio of maltodextrin to gum arabic as 1.04:1, respectively. First, maltodextrin and gum arabic were dissolved in distilled water (dw) according to the optimized ratios at room temperature, keeping the concentration at 10%, and this solution was used as the coating solution. The coating materials were then homogenized by stirring for 5 min with a magnetic stirrer. HPE was dissolved in the coating solution and stirred for 15 min. for homogenization. At the end of the process, the obtained Hypericum microcapsules were placed in glass jars and stored at 4 °C.

Color Measurement

The color values of HPMs are important as they are parameters related to quality properties. CIELab (L, a* and b*) values of HP microencapsules (HPMs) were measured using a Hunter colorimeter (PCE Instrument, pcecsm 5). Lightness– darkness values symbolized with “L*”and where L = 100 shows lightness, L = 0 shows darkness. In the color measurement system, a* represents greenness (-a*) and redness (+ a*), while b* symbolizes yellowness (+ b*) and blueness (-b*).

Particle Size and Polydispersity Index (PDI)

The microparticle size was analysed from SEM micrograhs by measuring the diameter of 100 particles of images using the Image analysis software ImageJ. The particle size distribution of HPMs was measured using a laser scattering particle size analyzer (PSA 1090 model, USP). It calculates the particle distribution width and mean particle diameter.

Tapped Density and Bulk Density

Bulk density (ρb) refers to weight per unit volume while tapped density (ρt) is defined as the occupied volume after tapping powders. In order to determine the spray-dried HPMs density, HPM powder (1 g) was poured into a 10 mL measuring tape. The bulk density is expressed as the amount of mass per unit volume. It was evaluated as the ratio between the weight of the sample contained in the cylinder and the value occupied (Eq. (1)). The volume of a certain amount of HP microcapsule (HPM) at the end of 125 shaking operations was used to calculate the tapped density based on the Eq. (2).

M shows the powder weight, whereas V represents the powder volume.

Vt is the minimum volume occupied after tapping.

Flowability and Cohesiveness

The flowability of HPMs was studied to analyse the problems caused during storage and transportation. Flowability plays an important role in powder handling. In order to determine the density of the spray-dried extracts, the powder was gently poured into a 10 mL graduate cylinder and the bulk density (ρb) was calculated as the ratio between the weight of the sample contained in the cylinder and the volume occupied. Tapped bulk density (ρt) and loose bulk density (ρb) values were used to determine the Carr index (Cl) (Eq. (3)) and Hausner ratio (HR) (Eq. (4)) values of HPM. The characterization of the flowability and cohesiveness properties of HPM were performed by Cl and HR, respectively.

Reconstitution Properties

What is meant by high solubility, is that the powders could easily and efficiently be reconstituted in water to utilize the bioactive compounds in aqueous systems [29, 30]. Calculation of the solubility of HPMs was carried out in the following way. HPMs (0.1 g) were dissolved in distilled water (24.9 g), the solution was mixed at 25 °C in a water bath and centrifuged at 4500 rpm, for 20 min. The supernatant (10 g) was dried at 105° C and left for obtaining a constant weight [31].

Equation (5) was used for the calculation of the solubility

m represents the dry matter amount (g) and w corresponds the total mass of the microcapsule (g).

Extraction of Bioactive Compounds from HPM

Dissolution of the microcapsules was performed following the previous literature with some modifications [32]. Ethanol/ acetic acid/ water solution (50:8:42 v/v/v; 10 mL) was used to dissolve the microcapsule sample (1 g) and it was vortexed for homogenization. Finally, the mixture was centrifuged (1000 rpm; 5 min.) and then filtered. Analyses of the antioxidant activity, TPC, and HPLC were performed with the supernatant.

Phenolic Content

The chemical, pharmaceutical and food industries show interest in these products due to the functional properties of phenolic compounds. For the TPC analysis,40 µL sample was inserted into test tubes from the stock solutions (1 mg/mL) of HPM and diluted with 2.4 mL of dw. Folin– Ciocalteu (200 µL) and saturated Na2CO3 (600 µL) were added to the composition. Total volume was adjusted to 4 mL with dw and the tubes were vortexed. The tubes were incubated for 2 h in the dark and the absorbance values were recorded at 650 nm [27].

2-Diphenyl-1-picrylhydrazyl (DPPH) Free Radical Scavenging Activity

The modified method of Singh et al. [33] was used to determine the DPPH radical scavenging activity of HPMs. For this purpose, the supernatant (200 µL) and diluted DPPH solution (3.8 mL) were mixed and vortexed for 15 s. The samples were then left 60 min in the dark and measured at 515 nm. The results were given in % of DPPH inhibition according to the following Eq. (6):

A0 represents the absorbance value of the control at 515 nm and A1 is the absorbance of the microcapsules at 515 nm.

HPLC Analysis of the Bioactive Components

The quantitative determination of the HPE and HPMs was carried out by HPLC using hypericin and pseudohypericin standards on an isocratic reverse phase analysis. HPLC analysis conditions were choosen based on the previous literature with some modifications [34]. Microcapsule sample (1 g) was dissolved with 10 mL of ethanol/water/acetic acid (50:42:8 v/v/v) and 10 µL of this solution was analyzed with HPLC (Shimadzu, CTO-10 AS VP) (Intersil C8-3, (GL Sciences) 250 mm × 4.6 mm, 3 µm column. The mobile phase consisted of acetonitrile:methanol:water:phosphoric acid (48:40:10:2) at a flow rate of 1 mL/min with a column temperature of 30 °C, and a total run time of 15 min. The column temperature was adjusted at 60 °C. Hypericin and pseudohypericin contents were evaluated using the peak area of the compounds, which were compared with a reference standard (hypericin, 00190585; pseudohypericin H9416, Sigma Chemical Co., St. Louis, MO, USA).

Bioavailability Analysis

The in vitro digestibility assay of the HPMs was performed following the method developed by Tan et al. [35]. To simulate the oral phase, the sample (1.5 mL) was mixed with 13.5 mL of basal saline (5 mM KCl, 140 mM NaCl) in a centrifuge tube which placed in a water bath. It was shaken for 10 min. and simulated gastric fluid (SGF) (4.5 mL; containing 3.2 g/L pepsin 1 M HCl) was added to the mixture. Then, small amounts of NaOH (1 M) were used to adjust the pH = 2 to stimulate the gastric phase and initiate gastric digestion. The solution was incubated in a shaking water bath (Daihan Maxturdy-18, Seul, South Korea) at 37 °C, 120 strokes/min for 1 h. At the end of the time, a small amount of NaOH (1 M) was added to the solution to adjust the pH = 7.5. Next, 4.5 mL of the simulated intestinal fluid (SIF) (4.76 mg / mL pancreatin and 5.16 mg / mL porcine bile extract PBS, pH 7.5) was added to the mixture. After digestion, the samples were immediately centrifuged at 6000 rpm for 15 min (Hermle Z206A, Wehingen, Germany). The supernatants were collected and stored at -20 °C for further analysis. Supernatants were used for analyses, including TPC and DPPH activity tests [35].

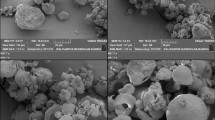

Morphological Characteristics

The external appearance of the HPMs was screened using a scanning electron microscope (SEM). The size of the samples was adjusted to the appropriate size with a sample holder attached to aluminum stubs using two-sided adhesive tape. After the microcapsules were coated with gold– palladium under vacuum, examination of the microcapsules was performed using a SEM (JSM-6400, Jeol Ltd., Tokyo, Japan). Operate conditions of the SEM were at 3 kV and a magnification of 15000X (times).

Results and Discussion

Model Fitting

In the current study, HPMs were prepared by spray drying method. RSM was used for the determination of the optimum conditions of microcapsulation process in order to minimize the experimental runs and times. TPC, antioxidant activity (% DPPH inhibition), CI, HR and solubility data of HPMs were indicated in Table II. Individual model coefficients, significance test of regression model and lack of fit test were evaluated using ANOVA and the results were given in Table III. Experimental results were modeled by operating quadratic, linear, and interaction term functions with the least square regression method. The validity of quadratic, linear and interaction term models for the five responses was evaluated based on their P-values. The model with no significant (P > 0.05) lack-of-fit was suitable for the definition of the response surface. It is observed that, the models developed for CI and HR responses for HPMs were important and there was no lack of fit for all the responses (P > 0.05).

Particle Size and Polydispersity Index (PDI)

The size of the HPMs varied from 14.01–22.04 µm. Meanwhile, the mean diameter over the volume was found to be 20.36 µm. Particle size is an effective parameter on the bulk density, flowability, and coheviness properties [36, 37].

Total Phenolic Content (TPC)

The TPC of HPMs ranged from 4.93 to 550.93 mg/g GAE, and the highest TPC value was attained at 150 °C while the lowest value was obtained at 99.5 °C (Table II). The ratio of maltodextrin to gum arabic affected the TPC significantly (P < 0.05). TPC values indicated an increase with the decrease of coating to extract ratio and increment of gum arabic quantity and inlet temperature, as well. The positive correlation between TPC and gum arabic quantity may be due to the emulsifying ability of gum arabic whose structure was highly brached with several kinds of sugar arrangements [38, 39]. TPC values were calculated as 86.6 mg/g GAE and 4.93 mg/g GAE for the maximum (200.1 °C) and minimum (99.5 °C) temperatures, respectively. TPC of HPMs was calculated as 283.05 mg/g GAE (Table IV) at the optimized conditions (180 °C inlet temperature, 1.047 ratio of maltodextrin to gum arabic, 1.982 ratio of coating to core material). In our previous study, TPC of HPE was determined as 128.82 mg/g GAE [40]. The results of the current study revealed that there was no linear relationship between the inlet temperature and TPC values. Mishra et al. [41] noted that TPC was significantly (P < 0.001) reduced when inlet temperature was increased from 125 °C to 175 °C and they observed a reverse trend above 175 °C. Why there is an increase in the TPC content of the powder when the temperature reachs 175 °C can be attributed to the polymerization as well as synthesis of polyphenols at 200 °C, at which the total phenolic content of the powder rises [41]. Tatar and Kahyaoglu noted that high air inlet temperatures result in low TPC values [26]. The highest TPC value (550.93 mg/g GAE) was observed with 3.5/1 ratio of maltodextrin/gum arabic and 1/1 ratio of coating/core at 150 °C for HPMs (Table II). It is concluded that the TPC values increase with higher amounts of maltodextrin.

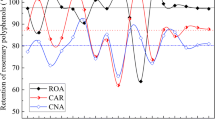

Antioxidant Activity

The antioxidant activity (% inhibition) of HPMs ranged between 15.87% and 81.54%. The effect of independant variables on the antioxidant power of HPMs was not significant (P > 0.05) (Table III). The lowest antioxidant activity was obtained with the highest coating to extract and maltodextrin to gum arabic ratios at 120 °C (Table II). It was observed that the antioxidant activity decreased when the inlet air temperature declined. The ratio of coating to extract was determined as the predominant factor that affected antioxidant activity. Lower values of the coating to extract ratio caused higher antioxidant activity power. In addition, the antioxidant activity increased with the decrease of maltodextrin to gum arabic ratio.

Franceschinis et al. [42] stated significant decreases in antioxidant activity with high temperature in microcapsules during drying process. In another study, the highest antioxidant activity was achieved at 125 °C in the production of blueberry microcapsules (Vaccinium corymbosum L.) [43]. However, maximum antioxidant activity was gained with increasing temperature and decreasing the ratio of coating to extract and the ratio of maltodextrin to gum arabic in the production of HPMs. The highest antioxidant capacity (81.55%) for HPMs was obtained by maintaining a 1/1 ratio both for maltodextrin/gum arabic at 180 °C and the coating/core ratios (Table II). DPPH radical scavenging activity of HPMs was calculated as 81.91 (%) at the optimized conditions (Table IV). DPPH activity results of HP extract were expressed as IC50 value (3.17 ± 0.23 µg/mL) in our previous study [40]. Five (5) concentrations (25, 50, 100, 250, and 1000 µg/mL) of HPE were prepared to calculate the DPPH radical scavenging activity. DPPH activity of HPE was determined as 58.56 (%) at 250 µg/mL concentration [40]. In the current study, DPPH radical scavenging activity of HPMs was computed as 81.91 (%) at 200 µg/mL concentration. It was concluded that HPMs were more effective than HPE in the scavenging of DPPH radicals at lower concentrations (200–250 µg/mL).

Flowability

Flowability is a significant factor in handling properties. The influence of parameters on flowability is generally stated as the Carr index (CI), and a lower CI value means better flowability. The CI values of HPMs ranged between 1.00 and 9.67, which indicates that HPMs have excellent flowability [44]. These values are better than those of yogurt powders (CI: 29.50; i.e. indicating poor flowability) coated with lactose, sucrose, and maltodextrin by spray drying [45, 46].

The maltodextrin to gum arabic ratio and the inlet air temperature along with coating to extract ratio interaction affected the CI value of HPMs, significantly (P < 0.05). In literature, minimum CI values (4.37–15.03) were obtained with lower air inlet temperatures in the production of rosehip microcapsules and instant yogurt powder [45]. Similarly, CI values decrease as the inlet air temperature decreases in the production of HPMs. Not only the air inlet temperature but also the ratio of coating to extract and the ratio of maltodextrin to gum arabic affected the CI values of HPMs. Minimum CI values of HPMs were achieved when the maltodextrin/gum arabic ratio was 3.5/1, and the coating/core ratio was 0.5/1, respectively. The increase in the concentration of maltodextrin provided the best flowability properties in HPMs. The flowability properties of HPMs increased with the decreasing of coating/core ratio.

Hausner Ratio

The Hausner ratio (HR) values were determined to assess the flowability of the HPMs. The lower hausner ratio represents the higher flowability. In the current study, HR values of HPMs were found between 1.01–1.10 indicating excellent flowability [46]. The ratio of maltodextrin to gum arabic, the interaction of inlet temperature and coating to extract ratio affected HR value of HPMs significantly (P < 0.05) (Table III).

The HR values were found to be in the range of 1.07–1.18 of foam dried musk melon powder depending on drying temperature [46]. In another study, liquorice root extract was encapsulated with maltodextrin and gum arabic as wall material and HR of microcapsules were found between 1.29–1.56 [47]. HR values of spray-dried pitaya fruit powder varied from 1.64 to 1.93. Operation parameters such as temperature, core material type, ratio of core to wall might affect HR values of samples. In addition, particle size, van der Waals and electrostatic forces are effective in HR values [48].

It is observed that a higher amount of maltodextrin causes lower flowability. Lower flowability provides an increment in the coating to extract ratio of HPMs.

Solubility

The rehydration ability of microcapsules is very important in terms of the food production process. In order to obtain the ideal powder, it is preferred that the powder sinks and dissolves instead of floating and lump formation, respectively.

The solubility values of HPMs were ranged between 1.68- 35.01 (Table II). The effect of the coating to extract ratio and the inlet air temperature interaction on solubility of HPMs were significant (P < 0.05) (Table III). Additionally solubility values of HPMs increased with the increment of the inlet temperature and decrease of coating to extract ratio.

The solubility of microcapsules is particularly related to temperature, i.e., higher temperatures generally reduce the solubility of microcapsules in spray drying [49, 50]. The states of proteins, pH, and temperature affect the powder solubility [51].

Koç et al. [52] found that the solubility value of the spray-dried yogurt samples was 68% under optimum conditions, which is attributed to the increasing amount of insoluble matter based on the drying temperature in process conditions.

The solubility values were found to be in the range of 23- 26% of foam dried musk melon powder depending on the drying temperature [46]. The solubility values was found to be in the range of 62.73- 68.00% in the production of instant yogurt powder by Atalar and Yazici [45]. In this study solubility values increased as the inlet temperature was decreased.

The solubility values of HPMs were found to be between 1.68 and 35.01. Maximum solubility values were obtained at 150 °C for HPMs. The solubility values determined from the present study are found to be lower than those of other studies [45, 46, 52]. Using high temperatures in the production of microcapsules caused lower solubility. Additionally, the best resolution of HPMs was achieved under the following conditions: coating to extract ratio (2.5/1) and maltodextrin to gum arabic ratio (0.5/1). In general, the decreation of the amount of maltodextrin increased the solubility (Table II).

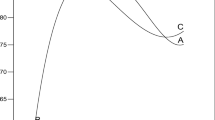

Response Optimization

The aim of this study was to determine the optimum conditions for the microencapsulation of HPE. Optimization of the drying conditions was performed in order to determine the highest TPC, antioxidant activity and solubility values along with the lowest CI and HR values, as well (Fig. 1). The desirability function was used to designate the optimum processing conditions according to the responses. Optimum drying conditions for HPM production were determined as 180 °C for inlet air temperature, 1.04/1 for ratio of maltodextrin to gum arabic (w/w), and 1.98/1 for ratio of coating to core material (w/w). At the optimum conditions, TPC, antioxidant activity, CI, HR, and solubility values were calculated as 316.531 (mg/g GAE), 81.912%, 6.074, 1.066, 35.017%, respectively (Table IV). For produced HPMs, TPC, antioxidant activity, CI, HR, and solubility values were found to be 283.05 (mg/g GAE), 79.27%, 1.93, 1.01, and 12.35 (%), respectively. The percentage error between theroretical and experimental results were given in Table V.

Morphological Characteristics

Figure 2 shows the scanning electron micrographs of HPMs at optimum conditions. The shapes of the microcapsules are generally spherical and there are collapses on their surfaces. Typical morphological features of the particles obtained by the spray dryer are similar to this study [51]. Moreover, microcapsules had highly dented surfaces [53]. This situation probably may be result of degradation of the liquid particles in the drying processes [54, 55]. Vaidya et al. [56] used gum arabic and maltodextrin as coating materials in their study and they observed that microcapsules were spherical and there were collapses on the surface. Collapsing of microcapsules was attributed to the atomization process [57]. Particle shrinkage may occur in the drying and cooling processes during the atomization process [58]. The absence of cracks indicates that the coating materials have good viscoelastic properties during the spray drying stage [59].

In addition, composition and drying kinetics of the microcapsule formulation affect the morphology of the spray dried particles. Bubble nucleation occurs at the beginning of the spray drying process. The formed bubbles rise and burst outward above the surface which occurs in the inflation-deflation cycle. The final morphological features of microparticles affect from this process. Briefly, particle morphology depends on drying conditions, solid content, encapsulating agent and core compound.

Similar results were obtained using maltodextrin or combination of these materials as coating materials with different plant extracts. Eugenol-rich clove extract was encapsulated in various solid lipid carriers by spray drying process. Microcapsules coated with maltodextrin DE10 were more spherical than other microcapsules. The produced particles presented a shriveled aspect generally. Furthermore, Chatterjee and Bhattacharjee encapsulated the eugenolrich clove extracts with maltodextrin and gum arabic by spray dryer and reported that the particles have shriveled morphology [60].

Bioavailability Analysis

TPC of HPMs obtained after in vitro digestion was calculated as 651.8 mg/g GAE. DPPH activity of HPMs was found to be 74.95%. The DPPH scavenging activity of microcapsules exhibited quite a high effect in the stomach and intestinal vitro digestion. It can be concluded that the coating materials are resistant to digestion and the applied ratio of coating/core is very compatible.

HPLC Analysis of the HPMs

HPLC analysis was applied to HPMs and hypericin amount was calculated as 4.19 μg/g microcapsule. In HPE, hypericin amount was 9.57 μg/mL [25]. On the other hand, pseudohypericin amount was found as 15.09 μg/g microcapsule and 7.82 μg/mL, for HPMs and HPE, respectively (25, 40). Decrease of coating core ratio and high temperature application in spray dryer process caused decline in the quantity of bioactive components. Increasing the coating ratio and the amount of maltodextrin provided preservation of bioactive component (pseudohypericin) amount in HPMs.

The removal of water from the microcapsules provided an increase in the pseudohypericin amount. Kalogeropoulos et al. [6] determined the quantity of epicatechin, catechin and quercetin from H. perforatum methanolic extract and they found 118.9%, 8.7% and 5.8%, respectively. The microencapsulation efficiency was investigated after the lyophilization process, and the quantities of catechin, epicatechin, and quercetin in HPMs were found 27.5%, 30%, and 35%, respectively. Microencapsulation is an effective method for protecting bioactive components against oxidation and is suggested for the encapsulation of HP [6].

Colour Analysis of Microcapsules

It is important that the powders have lighter colors and do not affect the natural color of the product. The situation increases its usability in food systems. The difference in coating materials, their ratios, and the colors of the plant extracts cause difference in lightness and darkness. L*, a* and b* values of the microcapsules were used for determination of whiteness, redness and yellowness indexes, respectively. L*, a* and b* values of HPMs were calculated as 73.20, 4.39 and 10.48, respectively. HPMs have lighter color due to higher L* values. + a* and + b* values indicate the redness and yellowness index of HPMs, sequencially. Using hot air in spray dryer decreased the whiteness index (L*) and redness index (a*) values but increased the yellowness index (b*) values of the powders in the study on yogurt powder [45].

High temperature application in spray dryer causes destruction of some natural pigments such as anthocyanins. Thus, it is possible to obtain lighter colored products. Similar results were obtained for blackberry pulp powder [51] and blueberry microcapsule [61].

The application of high temperature and the formation of small particles in the microencapsulation processes cause color changes with the maillard reactions. The change of color can prevented by adjusting the drying conditions and storing the microcapsules under suitable conditions. In addition, the use of maltodextrin and the increment amount of maltodextrin provide lightening of color.

Conclusion

Hypericum perforatum extract was microencapsulated with gum arabic and maltodextrin using the spray drying method. The ratio of maltodextrin to gum arabic showed a significant effect on some responses, including TPC, CI, and HR. Also the interaction of inlet temperature and coating to extract ratio affected most of the responses. TPC values and flowability properties increase with increasing amount of maltodextrin. In addition, TPC values and flowability properties increase with decreasing coating/core ratio. On the other hand, antioxidant activity increases with a reduction in the maltodextrin to gum arabic ratio. The highest antioxidant capacity was obtained at 1/1 for both maltodextrin/gum arabic and coating/core ratios.

The coating to extract ratio and the inlet air temperature interaction effect on the solubility was found significant. The shapes of the microcapsules produced under the optimum conditions are almost spherical, and there are collapses on their surfaces. HPMs obtained after in vitro digestion have extremely high TPC value and DPPH activities. It is observed that the coating materials are very compatible for the coating of HPE. The amount of bioactive components in HPMs was protected by increasing the coating ratio and the amount of maltodextrin. This study reveals that HPMs can be used in pharmaceutical applications with high efficiency.

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

Fugazzotto F, Occhiuto F, García-Pardo MP, Aguilar MAA. Hypericum perforatum L. prevents the acquisition of and promotes resilience against stress-induced reinstatement of the conditioned place preference induced by cocaine. Neurosci Lett. 2021;762:136164.

Duman H, Çakir-Dindar EG. Hypericum alacamdaglariense (Hypericaceae), a new species from Turkey. Phytotaxa. 2020;470(2):176–85.

Wurglics M, Schubert-Zsilavecz M. Hypericum perforatum: A ‘modern’herbal antidepressant. Clin Pharmacokinet. 2006;45(5):449–68.

Estevinho BN, Horciu IL, Blaga AC, Rocha F. Development of controlled delivery functional systems by microencapsulation of different extracts of plants: Hypericum perforatum L., Salvia officinalis L. and Syzygium aromaticum. Food Bioproc Tech. 2021;14(8):1503–17.

Oliveira AI, Pinho C, Fonte P, Sarmento B, Dias AC. Development, characterization, antioxidant and hepatoprotective properties of poly (Ɛ-caprolactone) nanoparticles loaded with a neuroprotective fraction of Hypericum perforatum. Int J Biol Macromol. 2018;110:185–96.

Kalogeropoulos N, Yannakopoulou K, Gioxari A, Chiou A, Makris DP. Polyphenol characterization and encapsulation in β-cyclodextrin of a flavonoid-rich Hypericum perforatum (St John’s wort) extract. LWT-Food Sci Technol. 2010;43(6):882–9.

Koç M, Güngör Ö, Zungur A, Yalçın B, Selek İ, Ertekin F, Ötles S. Microencapsulation of extra virgin olive oil by spray drying: effect of wall materials composition, process conditions, and emulsification method. Food Bioproc Tech. 2015;8(2):301–18.

Bakry AM, Abbas S, Ali B, Majeed H, Abouelwafa MY, Mousa A, Liang L. Microencapsulation of oils: A comprehensive review of benefits, techniques, and applications. CRFSFS. 2016;15(1):143–82.

Madene A, Jacquot M, Scher J, Desobry S. Flavour encapsulation and controlled release–a review. Int J Food Sci Technol. 2006;41(1):1–21.

Jimenez M, Garcia HS, Beristain CI. Spray-drying microencapsulation and oxidative stability of conjugated linoleic acid. Eur Food Res Technol. 2004;219(6):588–92.

Lee YK, Ahn SI, Kwak HS. Optimizing microencapsulation of peanut sprout extract by response surface methodology. Food Hydrocoll. 2013;30(1):307–14.

Arpagaus C, Collenberg A, Rütti D, Assadpour E, Jafari SM. Nano spray drying for encapsulation of pharmaceuticals. Int J Pharm. 2018;546(1–2):194–214.

Selim KA, Alharthi SS, Abu El-Hassan AM, Elneairy NA, Rabee LA, Abdel-Razek AG. The effect of wall material type on the encapsulation efficiency and oxidative stability of fish oils. Molecules. 2021;26(20):6109.

Thakur D, Jain A, Ghoshal G, Shivhare US, Katare OP. Microencapsulation of β-carotene based on casein/guar gum blend using zeta potential-yield stress phenomenon: An approach to enhance photo-stability and retention of functionality. AAPS PharmSci. 2017;18:1447–59.

Lu W, Yang X, Shen J, Li Z, Tan S, Liu W, Cheng Z. Choosing the appropriate wall materials for spray-drying microencapsulation of natural bioactive ingredients: Taking phenolic compounds as examples. Powder Tech. 2021;394:562–74.

Jafari SM, Assadpoor E, He Y, Bhandari B. Encapsulation efficiency of food flavours and oils during spray drying. Dry Technol. 2008;26(7):816–35.

Tolun A, Altintas Z, Artik N. Microencapsulation of grape polyphenols using maltodextrin and gum arabic as two alternative coating materials: Development and characterization. J Biotech. 2016;239:23–33.

Sarabandi K, Jafari SM, Mahoonak AS, Mohammadi A. Application of gum arabic and maltodextrin for encapsulation of eggplant peel extract as a natural antioxidant and color source. Int J Biol Macromol. 2019;140:59–68.

Baş D, Boyacı IH. Modeling and optimization I: Usability of response surface methodology. J Food Eng. 2007;78(3):836–45.

Andres AI, Petron MJ, Lopez AM, Timon ML. Optimization of extraction conditions to improve phenolic content and in vitro antioxidant activity in craft brewers’ spent grain using response surface methodology (RSM). Foods. 2020;9(10):1398.

Weremfo A, Abassah-Oppong S, Adulley F, Dabie K, Seidu-Larry S. Response surface methodology as a tool to optimize the extraction of bioactive compounds from plant sources. J Sci Food Agric. 2023;103(1):26–36.

Amjadi I, Mohajeri M, Borisov A, Hosseini MS. Antiproliferative effects of free and encapsulated Hypericum perforatum L. extract and its potential interaction with doxorubicin for esophageal squamous cell carcinoma. JoP. 2019;22(2):102–8.

Güneş S, Tıhmınlıoğlu F. Hypericum perforatum incorporated chitosan films as potential bioactive wound dressing material. Int J Biol Macromol. 2017;102:933–43.

Pourhojat F, Sohrabi M, Shariati S, Mahdavi H, Asadpour L. Evaluation of poly ε-caprolactone electrospun nanofibers loaded with Hypericum perforatum extract as a wound dressing. Res Chem Intermed. 2017;43:297–320.

Seyrekoğlu F, Temiz H. Effect of extraction conditions on the phenolic content and DPPH radical scavenging activity of Hypericum perforatum L. TURJAF. 2020;8(1):226–9.

Tatar Turan F, Kahyaoglu T. The effect of an ultrasonic spray nozzle on carbohydrate and protein-based coating materials for blueberry extract microencapsulation. J Sci Food Agric. 2021;101(1):120–30.

Tatar F, Kahyaoglu T. Microencapsulation of anchovy (Engraulis encrasicolus L.) oil: Emulsion characterization and optimization by response surface methodology. J Food Process Preserv. 2015;39(6):624–33.

Ray S, Raychaudhuri U, Chakraborty R. An overview of encapsulation of active compounds used in food products by drying technology. Food Biosci. 2016;13:76–83.

Daza LD, Fujita A, Fávaro-Trindade CS, Rodrigues-Ract JN, Granato D, Genovese MI. Effect of spray drying conditions on the physical properties of Cagaita (Eugenia dysenterica DC.) fruit extracts. Food Bioprod Process. 2016;97:20–9.

Tan SP, Tuyen CK, Parks SE, Stathopoulos CE, Roach PD. Effects of the spraydrying temperatures on the physiochemical properties of an encapsulated bitter melon aqueous extract powder. Powder Technol. 2015;281:65–75.

Li J, Ye T, Wu X, Chen J, Wang S, Lin L, Li B. Preparation and characterization of heterogeneous deacetylated konjac glucomannan. Food Hydrocoll. 2014;40:9–15.

Robert P, Gorena T, Romero N, Sepulveda E, Chavez J, Saenz C. Encapsulation of polyphenols and anthocyanins from pomegranate (Punica granatum) by spray drying. Int J Food Sci Technol. 2010;45(7):1386–94.

Singh RP, Chidambara Murthy KN, Jayaprakasha GK. Studies on the antioxidant activity of pomegranate (Punica granatum) peel and seed extracts using in vitro models. J Agric Food Chem. 2002;50(1):81–6.

Sirvent T, Gibson DM. Rapid isocratic HPLC analysis of hypericins. J Liq Chromatogr Relat Technol. 2000;23(2):251–9.

Tan C, Zhang Y, Abbas S, Feng B, Zhang X, Xia S. Modulation of the carotenoid bioaccessibility through liposomal encapsulation. Colloids Surf B: Biointerfaces. 2014;123:692–700.

Santana AA, Kurozawa LE, de Oliveira AR, Park KJ. Influence of process conditions on the physicochemical properties of pequi powder produced by spray drying. Dry Technol. 2013;31:825–36.

Mahdavi SA, Jafari SM, Ghorbani M, Assadpoor E. Spray-drying microencapsulation of anthocyanins by natural biopolymers: A review. Dry Technol. 2014;32:509–18.

Cilek B, Sahin S, Sumnu G, Luca A, Hasirci V. Microencapsulation of phenolic compounds extracted from sour cherry pomace: effect of formulation, ultrasonication time and core to coating ratio. Eur Food Res Technol. 2012;235:587–96.

Mcnamee BF, O’Riordan ED, O’Sullivan M. Emulsification and microencapsulation properties of gum arabic. J Agric Food Chem. 1998;46:4551–5.

Seyrekoglu F, Temiz H, Eser F, Yildirim C. Comparison of the antioxidant activities and major constituents of three Hypericum species (H. perforatum, H. scabrum and H. origanifolium) from Turkey. S Afr J Bot. 2022;146:723–7.

Mishra P, Mishra S, Mahanta CL. Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder. Food Bioprod Process. 2014;92(3):252–8.

Franceschinis L, Salvatori DM, Sosa N, Schebor C. Physical and functional properties of blackberry freeze-and spray-dried powders. Dry Technol. 2014;32(2):197–207.

Tatar Turan F, Cengiz A, Sandıkçı D, Dervisoglu M, Kahyaoglu T. Influence of an ultrasonic nozzle in spray-drying and storage on the properties of blueberry powder and microcapsules. J Sci Food Agric. 2016;96(12):4062–76.

Szulc K, Lenart A. Surface modification of dairy powders: Effects of fluid-bed agglomeration and coating. Int Dairy J. 2013;33(1):55–61.

Atalar I, Yazici F. Effect of different binders on reconstitution behaviors and physical, structural, and morphological properties of fluidized bed agglomerated yoghurt powder. Dry Technol. 2019;37(13):1656–64.

Asokapandian S, Venkatachalam S, Swamy GJ, Kuppusamy K. Optimization of foaming properties and foam mat drying of muskmelon using soy protein. J Food Process Eng. 2016;39(6):692–701.

Basyigit B, Hayoglu I. Liquorice (Glycyrrhiza glabra L.) root sherbet (extract): Microencapsulation and storage stability. Acta Aliment. 2019;48(1):76–85.

Tze NL, Han CP, Yusof YA, Ling CN, Talib RA, Taip FS, Aziz MG. Physicochemical and nutritional properties of spray-dried pitaya fruit powder as natural colorant. Food Sci Biotechnol. 2012;21:675–82.

da Silva Júnior ME, Araújo MVRL, Martins ACS, dos Santos LM, da Silva FLH, Converti A, Maciel MIS. Microencapsulation by spray-drying and freeze-drying of extract of phenolic compounds obtained from ciriguela peel. Sci Rep. 2023;13(1):15222.

Banožić M, Krzywonos M, Aladić K, Pińkowska H, Mucha I, Złocińska A, Jokić S. Physicochemical, structural characterization and evaluation of encapsulated hesperidin from natural sources: Comparison of two encapsulation techniques; spray drying and freeze drying. J Drug Deliv Sci Technol. 2023;90:105098.

Ferrari CC, Germer SPM, Alvim ID, Vissotto FZ, de Aguirre JM. Influence of carrier agents on the physicochemical properties of blackberry powder produced by spray drying. JFST. 2012;47(6):1237–45.

Koç B, Sakin-Yılmazer M, Kaymak-Ertekin F, Balkır P. Physical properties of yoghurt powder produced by spray drying. JFST. 2014;51(7):1377–83.

Yang S, Zhang G, Qi X, Guo W, Wang C, Liu L, He J. Improved protective and controlled releasing effect of flaxseed oil microcapsules with glycosylated casein as wall materials. LWT. 2024;191:115687.

Tripathy S, Srivastav PP. Encapsulation of Centella asiatica leaf extract in liposome: Study on structural stability, degradation kinetics and fate of bioactive compounds during storage. Food Chem Adv. 2023;2:100202.

Jayaprakash P, Maudhuit A, Gaiani C, Desobry S. Encapsulation of bioactive compounds using competitive emerging techniques: Electrospraying, nano spray drying, and electrostatic spray drying. J Food Eng. 2023;339:111260.

Vaidya S, Bhosale R, Singhal RS. Microencapsulation of cinnamon oleoresin by spray drying using different wall materials. Dry Technol. 2006;24(8):983–92.

Younesi M, Peighambardoust SH, Sarabandi K, Akbarmehr A, Ahaninjan M, Soltanzadeh M. Application of structurally modified WPC in combination with maltodextrin for microencapsulation of Roselle (Hibiscus sabdariffa) extract as a natural colorant source for gummy candy. Int J Biol Macromol. 2023;242:124903.

Farinha S, Sá JV, Lino PR, Galésio M, Pires J, Rodrigues MÂ, Henriques J. Spray freeze drying of biologics: a review and applications for inhalation delivery. Pharm Res. 2023;40(5):1115–40.

Jafari SM, He Y, Bhandari B. Role of powder particle size on the encapsulation efficiency of oils during spray drying. Dry Technol. 2007;25(6):1081–9.

Chatterjee D, Bhattacharjee P. Comparative evaluation of the antioxidant efficacy of encapsulated and un-encapsulated eugenol-rich clove extracts in soybean oil: Shelf-life and frying stability of soybean oil. J Food Eng. 2013;117(4):545–50.

Jiménez-Aguilar DM. Color and chemical stability of spray-dried blueberry extract using mesquite gum as wall material. J Food Compos Anal. 2011;24(6):889–94.

Acknowledgements

The authors acknowledge the financial support received from Amasya University Scientific Research Projects (FMB-BAP 17-0273), Turkey.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Seyrekoğlu, F., Temiz, H., Eser, F. et al. Optimization of Hypericum Perforatum Microencapsulation Process by Spray Drying Method. AAPS PharmSciTech 25, 99 (2024). https://doi.org/10.1208/s12249-024-02820-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1208/s12249-024-02820-y