Abstract

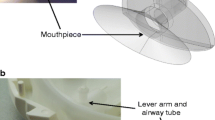

The design of a dry powder inhaler device has significant influence on aerosol performance; however, such influence may be different between the drug-only and carrier-based formulations. The present study aims to examine the potential difference on the dispersion between these distinct types of formulations, using Aerolizer® as a model inhaler with the original or modified (cross-grid) designs. A coupled CFD-discrete element method analysis was employed to determine the flow characteristics and particle impaction. Micronized salbutamol sulphate as a drug-only formulation and three lactose carrier-based formulations with various drug-to-carrier weight ratios 1:5, 1:10 and 1:100 were used. The in vitro aerosolization performance was assessed by a next-generation impactor operating at 100 L/min. Using the original device, FPFloaded was reduced from 47.5 ± 3.8% for the drug-only formulation to 31.8 ± 0.7%, 32.1 ± 0.7% and 12.9 ± 1.0% for the 1:5, 1:10 and 1:100 formulations, respectively. With the cross-grid design, powder-mouthpiece impaction was increased, which caused not only powder deagglomeration but also significant drug retention (doubling or more) in the mouthpiece, and the net result is a significant decrease in FPFloaded to 36.8 ± 1.2%, 20.9 ± 2.6% and 21.9 ± 1.5% for the drug-only, 1:5 and 1:10 formulations, respectively. In contrast, the FPFloaded of the 1:100 formulation remained the same at 12.1 ± 1.3%, indicating the increased mouthpiece drug retention was compensated by increased drug detachment from carriers caused by increased powder-mouthpiece impaction. In conclusion, this study has elucidated different effects and the mechanism on the aerosolization of varied dry powder inhaler formulations due to the grid design.

Similar content being viewed by others

References

Chan JG, Wong J, Zhou QT, et al. Advances in device and formulation technologies for pulmonary drug delivery. AAPS PharmSciTech. 2014;15(4):882–97.

Zhou QT, Tang P, Leung SSY, et al. Emerging inhalation aerosol devices and strategies: where are we headed? Advanced drug delivery reviews. 2014;75:3–17.

Donovan MJ, Kim SH, Raman V, et al. Dry powder inhaler device influence on carrier particle performance. Journal of pharmaceutical sciences. 2012;101(3):1097–107.

de Boer AH, Chan HK, Price R. A critical view on lactose-based drug formulation and device studies for dry powder inhalation: which are relevant and what interactions to expect? Adv Drug Deliv Rev. 2012;64(3):257–74.

Coates MS, Fletcher DF, Chan HK, et al. Effect of design on the performance of a dry powder inhaler using computational fluid dynamics. Part 1: grid structure and mouthpiece length. Journal of pharmaceutical sciences. 2004;93(11):2863–76.

Tong ZB, Zheng B, Yang RY, et al. CFD-DEM investigation of the dispersion mechanisms in commercial dry powder inhalers. Powder Technology. 2013;240:19–24.

Lin Y-W, Wong J, Qu L, et al. Powder production and particle engineering for dry powder inhaler formulations. Current pharmaceutical design. 2015;21(27):3902–16.

Pilcer G, Wauthoz N, Amighi K. Lactose characteristics and the generation of the aerosol. Adv Drug Deliv Rev. 2012;64(3):233–56.

Zhou QT, Armstrong B, Larson I, et al. Understanding the influence of powder flowability, fluidization and de-agglomeration characteristics on the aerosolization of pharmaceutical model powders. European Journal of Pharmaceutical Sciences. 2010;40(5):412–21.

Zhou QT, Morton DA. Drug–lactose binding aspects in adhesive mixtures: controlling performance in dry powder inhaler formulations by altering lactose carrier surfaces. Advanced drug delivery reviews. 2012;64(3):275–84.

de Boer AH, Chan HK, Price R. A critical view on lactose-based drug formulation and device studies for dry powder inhalation: which are relevant and what interactions to expect? Advanced drug delivery reviews. 2012;64(3):257–74.

Zhou QT, Tong Z, Tang P, et al. Effect of device design on the aerosolization of a carrier-based dry powder inhaler—a case study on Aerolizer® Foradile®. The AAPS journal. 2013;15(2):511–22.

Shur J, Lee S, Adams W, et al. Effect of device design on the in vitro performance and comparability for capsule-based dry powder inhalers. The AAPS journal. 2012;14(4):667–76.

Byron PR, Hindle M, Lange CF, et al. In vivo–in vitro correlations: predicting pulmonary drug deposition from pharmaceutical aerosols. Journal of aerosol medicine and pulmonary drug delivery. 2010;23(S2):S-59–69.

Ruzycki CA, Javaheri E, Finlay WH. The use of computational fluid dynamics in inhaler design. Expert Opinion on Drug Delivery. 2013;10(3):307–23.

Tong Z, Yu A, Chan H-K, et al. Discrete modelling of powder dispersion in dry powder inhalers—a brief review. Current pharmaceutical design. 2015;21(27):3966–73.

Yang J, Wu CY, Adams M. Numerical modelling of agglomeration and deagglomeration in dry powder inhalers: a review. Curr Pharm Des. 2015;21(40):5915–22.

Tong ZB, Yang RY, Chu KW, et al. Numerical study of the effects of particle size and polydispersity on the agglomerate dispersion in a cyclonic flow. Chemical Engineering Journal. 2010;164(2–3):432–41.

Zhu HP, Zhou ZY, Yang RY, et al. Discrete particle simulation of particulate systems: theoretical developments. Chemical Engineering Science. 2007;62(13):3378–96.

Tong Z, Kamiya H, Yu A, Chan H-K, Yang R. Multi-scale modelling of powder dispersion in a carrier-based inhalation system. Pharm Res. 2014:1–11

Coates MS, Fletcher DF, Chan HK, et al. The role of capsule on the performance of a dry powder inhaler using computational and experimental analyses. Pharm Res. 2005;22(6):923–32.

Tong ZB, Yang RY, Yu AB, et al. Numerical modelling of the breakage of loose agglomerates of fine particles. Powder Technology. 2009;196:213–21.

Acknowledgments

This study was financially supported by the Australian Research Council (grant DP110105161). The authors would like to thank Mr Mauro Citterio from Plastiape S.p.A for the supply of modified inhalers.

Author information

Authors and Affiliations

Corresponding author

Additional information

Cassandra Ming Shan Leung and Zhenbo Tong share first authorship as these authors contributed equally.

Rights and permissions

About this article

Cite this article

Leung, C.M.S., Tong, Z., Zhou, Q.(. et al. Understanding the Different Effects of Inhaler Design on the Aerosol Performance of Drug-Only and Carrier-Based DPI Formulations. Part 1: Grid Structure. AAPS J 18, 1159–1167 (2016). https://doi.org/10.1208/s12248-016-9922-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12248-016-9922-1