Abstract

Background

In recent years, solar photovoltaic technology has experienced significant advances in both materials and systems, leading to improvements in efficiency, cost, and energy storage capacity. These advances have made solar photovoltaic technology a more viable option for renewable energy generation and energy storage. However, intermittent is a major limitation of solar energy, and energy storage systems are the preferred solution to these challenges where electric power generation is applicable. Hence, the type of energy storage system depends on the technology used for electrical generation. Furthermore, the growing need for renewable energy sources and the necessity for long-term energy solutions have fueled research into novel materials for solar photovoltaic systems. Researchers have concentrated on increasing the efficiency of solar cells by creating novel materials that can collect and convert sunlight into power.

Main body of the abstract

This study provides an overview of the recent research and development of materials for solar photovoltaic devices. The use of renewable energy sources, such as solar power, is becoming increasingly important to address the growing energy demand and mitigate the impact of climate change. Hence, the development of materials with superior properties, such as higher efficiency, lower cost, and improved durability, can significantly enhance the performance of solar panels and enable the creation of new, more efficient photovoltaic devices. This review discusses recent progress in the field of materials for solar photovoltaic devices. The challenges and opportunities associated with these materials are also explored, including scalability, stability, and economic feasibility.

Conclusion

The development of novel materials for solar photovoltaic devices holds great potential to revolutionize the field of renewable energy. With ongoing research and technological advancements, scientists and engineers have been able to design materials with superior properties such as higher efficiency, lower cost, and improved durability. These materials can be used to enhance the performance of existing solar panels and enable the creation of new, more efficient photovoltaic devices. The adoption of these materials could have significant implications for the transition toward a more sustainable and environmentally friendly energy system. However, there are still challenges to be addressed, such as scalability, stability, potential environmental effects, and economic feasibility, before these materials can be widely implemented. Nonetheless, the progress made in this field is promising and continued reports on the research and development of materials for solar photovoltaic devices are crucial for achieving a sustainable future. The adoption of novel materials in solar photovoltaic devices could lead to a more sustainable and environmentally friendly energy system, but further research and development are needed to overcome current limitations and enable large-scale implementation.

Similar content being viewed by others

1 Background

Energy and environmental problems are at the top of the list of challenges in the world, attributed to the need to replace the combustion exhaust of fossil fuels, which has resulted in environmental contamination and the greenhouse effect as opposed to renewable energy sources [1]. This replacement will be achieved while keeping pace with the increasing consumption of energy resulting from an increase in population and rising demand from developing countries since the use of non-renewable energy sources would not meet the energy demand because they are an exhaustible and limited source of energy [2]. Thus, the search for clean and sustainable renewable energy resources has become an urgent priority. Researchers regard solar energy as one of the alternative sustainable energy resources that is low-cost, non-exhaustible, and abundantly available, giving solid and increasing output efficiencies compared to other sources of energy solutions and energy sources of renewable energy [3]. The sun radiates at 3.8 1023 kW, intercepting the Earth at 1.8 1014 kW, while the remaining energy is scattered, reflected, and taken in by clouds [4]. 1.7 × 1022 J of the energy from the sun in 1.5 days is equal to the energy produced from three trillion barrels of oil reserves on Earth [5]. The total annual energy used by the world in 1 year is 4 s.6 × 1020 J, and the sun provides this energy in 1 h [5]. The solar photovoltaic (SPV) industry heavily depends on solar radiation distribution and intensity. Solar radiation amounts to 3.8 million EJ/year, which is approximately 10,000 times more than the current energy needs [6]. Solar energy is used whether in solar thermal applications where solar energy is the source of heat or indirectly as a source of electricity in concentrated solar power plants, photo-assisted fuel cells, generating electricity in SPVs, hydrocarbons from CO2 reduction, and fuels such as hydrogen [7].

Each technology harvests sunlight rays and converts them into different end forms. For instance, solar energy can be naturally converted into solar fuel through the process of photosynthesis. Also, through photosynthesis, plants store energy from the sun, where protons and electrons are produced, which can be further metabolized to produce H2 and CH4. Thus, 11% of solar energy is utilized in the natural photosynthesis of biomass [8]. Photovoltaics convert photons into electrons to get electrical energy, while in solar thermal applications, the photons are absorbed and their energy is converted into tangible heat [9]. This heat is used to heat a working fluid that can be directly collected and used for space and water heating [10].

However, the energy converted may be too low for consumption, and production efficiency can be improved by producing fuel from water and carbon dioxide through artificial bio-inspired nanoscale assemblies, connecting natural photosynthetic pathways in novel configurations, and using genetic engineering to facilitate biomass production [11]. One of the major challenges for photovoltaic (PV) systems remains matching intermittent energy production with dynamic power demand [12, 13]. A solution to this challenge is to add a storage element to these intermittent power sources [14, 15].

Furthermore, intermittent sources like SPV are allowed to address timely load demands and add flexibility to storage devices like batteries [16, 17]. Nonetheless, compared with the photosynthesis process, which has conversion efficiencies of 5–10%, photovoltaic cells have better solar conversion efficiencies of approximately 22.5% [6, 18]. There are other technologies used for enhancing the efficiency of PV systems encountered by temperature changes, which include floating tracking concentrating cooling systems (FTCC), hybrid solar photovoltaic/thermal systems (PV/T) cooled by water spraying, hybrid solar photovoltaic/thermoelectric (PV/TE) systems cooled by a heat sink, hybrid solar photovoltaic/thermal systems cooled by forced water circulation, improving the performance of solar panels through the use of phase change materials, and solar panels with water immersion cooling techniques [19, 20]. SPV panels with transparent covering (photonic crystal cooling), hybrid solar photovoltaic/thermal systems (PV/T) having forced air circulation, and SPV panels with thermoelectric cooling [21]

This review discusses the latest advancements in the field of novel materials for solar photovoltaic devices, including emerging technologies such as perovskite solar cells. It evaluates the efficiency and durability of different generations of materials in solar photovoltaic devices and compares them with traditional materials. It investigates the scalability and cost-effectiveness of producing novel materials for solar photovoltaic devices and identifies the key challenges and opportunities associated with the development and implementation of novel materials in solar photovoltaic devices, such as stability, toxicity, and economic feasibility. Hence, proposing strategies to overcome current limitations and promote the large-scale implementation of novel materials in solar photovoltaic devices, including manufacturing processes and material characterization techniques, while assessing the potential environmental impact of using novel materials in solar photovoltaic devices, including the sustainability and carbon footprint of the production process.

2 Main text

2.1 Solar photovoltaic systems

Solar energy is used in two different ways: one through the solar thermal route using solar collectors, heaters, dryers, etc., and the other through the solar electricity route using SPV, as shown in Fig. 1. A SPV system consists of arrays and combinations of PV panels, a charge controller for direct current (DC) and alternating current (AC); (DC to DC), a DC-to-AC inverter, a power meter, a breaker, and a battery or an array of batteries depending on the size of the system [22, 23].

This technology converts sunlight directly into electricity, with no interface for conversion. It is pollutant-free during operation, rugged and simple in design, diminishes global warming issues, is modular, has a lower operational cost, offers minimal maintenance, can generate power from microwatts to megawatts, and has the highest power density compared to the other renewable energy technologies [24, 25]. A high rate of 100 megawatts (MW) of capacity installed per day in 2013 has been used to illustrate the rise in research interest in PV systems, with a record of 177 gigawatts (GW) of overall PV capacity taking place in 2015 [26, 27]. However, according to Nadia et al. [19], solar photovoltaic systems have considerable limitations, including high prices as compared to fossil fuel energy resources, low efficiency, and intermittent operation. Hence, the solar tracker systems shown in Fig. 2 were designed to mitigate some of these challenges by keeping the solar devices at the optimal angle to track the sun’s position for maximum power production.

Various environmental pressures and characteristics, such as angle of photon incidence, panel orientation, photovoltaic module conductivity, the material of solar cells, and time to measure the direction of the sun, can all impact the output of solar panel cells; therefore, before using tracker systems, a large number of measurement results are necessary [29]. There are active and passive tracking systems. Active tracking systems move the solar panel toward the sun using motors and gear trains, while passive tracking systems rely on a low-boiling-point compressed gas fluid through canisters generated by solar heat [30]. The disadvantages of passive solar tracking systems are their reliance on weather conditions and the selection of the right gas and glass to develop an efficient passive solar tracking system since the glass absorption levels depend on the color, strength, and chemical properties of the glass. While active solar is high maintenance and reduces power output if the panel is not directly under the sun [31]. There are also single- and double-axis solar trackers and closed- and open-loop solar trackers. Some trackers use electro-optical units, while others use microprocessor units [32]. However, the initial cost and running cost of the tracking system, coupled with the cost of energy generated by a PV tracking system, are greater than the cost of energy generated by a fixed system, making their tracking system’s economic advantages unclear. Thus, most recent research on tracking systems has concentrated solely on the optimization of tracking technologies, with little attention devoted to all other critical elements influencing cost and efficiency, PV cell materials, temperature, solar radiation levels, transport, auxiliary equipment, and storage techniques [6]. Hence, the future outlook on tracking systems includes developing innovative ways for tracking the sun cost-effectively and efficiently. Jamroen et al. [32] proposed the design and execution of a low-cost dual-axis solar tracking system based on digital logic design and pseudo-azimuthal mounting systems. Their findings reveal that the suggested tracking system improves electrical energy efficiency by 44.89% on average with power costs of 0.2 $/kWh and 0.3 $/kWh, which is relatively low when compared to other tracking methods. Chowdhury et al. [35], on an 8-bit microcontroller architecture, developed a stand-alone low-cost yet high-precision dual-axis closed-loop sun-tracking system based on the sun position algorithm. Their simulation results showed a very high prediction rate and a very low mean square error, which was concluded to be better than neutral and fuzzy network principles as photovoltaic energy sources.

2.1.1 Photovoltaic energy sources

Photovoltaic energy sources are used as grid-connected systems and stand-alone systems. Their applications include battery charging, water pumping, home power supplies, refrigeration, street lighting, swimming pools, hybrid vehicles, heating systems, telecommunications, satellite power systems, military space, and hydrogen production [28, 29]. SPV and storage systems are classified into grid-tied or grid-direct PV systems, off-grid PV systems, and grid/hybrid or grid interaction systems with energy storage [30, 31]. The grid-tied solar PV system does not have a battery bank for storage, but a grid-tied inverter is used to convert the DC generated into AC; hence, power can be generated and utilized only during the daytime, which may also be a limiting factor [31, 32]. However, the disadvantage of only using the system during the day can be overcome by using a battery bank to store the generated power during the daytime, but this new setup will eventually increase the cost of the system [6, 34]. Hence, just using this system during the day makes the grid-tied SPV system very cost-effective, simple to design, easily manageable, and requires less maintenance. Furthermore, solar panels mostly produce more electricity than is required by the loads. Hence, this excess electricity can be given back to the grid instead of being stored in batteries [35, 36].

The off-grid PV system, on the other hand, uses a battery for the storage of the generated electricity during the daytime, which can be used in the future or during any emergency. This is beneficial when the load cannot be easily connected to the grid [37, 38]. This system not only gives sufficient energy to a household, but it can also power places that are far away from the grid; hence, these systems use more components and are comparatively more expensive than grid-direct systems. Grid-connected PV systems run in parallel and are linked to the electric utility grid [39, 40]. The power conditioning unit (PCU) or inverter is the main component of grid-connected PV systems, converting the DC power produced by the PV array into AC power that meets the voltage and power quality requirements of the utility grid for either direct use of appliances or sending to the utility grid to earn feed-in tariff compensation [41, 42]. Grid-connected PV systems without backup energy storage (ES) are environmentally friendly, while systems with backup ES are usually interconnected with the utility grid [43, 44].

Essential characteristics of PV technology are the operating range of 1 kW up to 300 MW, which can be used as fuel on residential, commercial, and utility scales. The efficiency of PV cells is about 12–16% for crystalline silicon, 11–14% for thin film, and 6–7% for organic cells [44]. There is no direct environmental impact due to the lack of CO2, CO, and NOx emissions. These systems have low operating and maintenance costs. The few drawbacks are higher installation costs, fluctuating output power due to the variation in weather patterns, and the need for mechanical and electronic tracking devices and backup storage for maximum efficiency. Installation costs can vary from 600 to 1300 USD/kW, while operation and maintenance annual costs vary from 0.004 and 0.07 USD/kWh (ac) for utility-scale generation and grid-connected residential systems, respectively [21].

3 Solar photovoltaic materials

Solar photovoltaic materials shown in Fig. 3, when exposed to light, absorb the light and transform the energy of the light photons into electrical energy. Commercially available photovoltaic systems are based on inorganic materials, which require costly and energy-intensive processing techniques.

Moreover, some of those materials, like CdTe, are toxic and have a limited natural abundance. These problems are preventable by using organic photovoltaics. Nonetheless, the effectiveness of organic-based photovoltaic cells is still far below that of solely inorganic-based photovoltaic systems. Photovoltaic devices usually employ semiconductor materials to generate energy, with silicon-based solar cells being the most popular. Photovoltaic (PV) cells or modules made of crystalline silicon (c-Si), whether single-crystalline (sc-Si) or multi-crystalline (c-Si) (mcSi). PV modules, which are fundamental components, can function in harsh outdoor environments and deliver high energy density to electronic loads. These are the most common forms of solar cells, accounting for over 90% of the PV industry. PV modules must have an efficiency of at least 14%, a price of less than 0.4 USD/Wp, and a service life of at least 15 years [22]. Now, wafer-based crystalline silicon technologies have best satisfied the criteria because of their high efficiency, cheap cost, and extended service life, and they are projected to dominate future PV power generation due to the abundance of materials. The greatest known energy conversion efficiency for research on crystalline silicon PV cells is 25%, although ordinary industrial cells are restricted to 15–18%. Optimizing these cells is a hard undertaking; hence, novel solutions to break past the efficiency barrier of 25% are wafer-slicing technologies and equipment for ultrathin (50 m) wafer technologies, and equipment for direct slicing ultrathin wafers with negligible kerf loss, solar cell and module manufacturing technologies and equipment based on ultrathin wafers. High-quality polycrystalline ingot technologies that outperform monocrystalline cells, contact-forming processes, and materials that are less expensive than screen-printed and burned silver paste are used. To reduce overall PV system costs, low-concentration, and high-efficiency module technologies are used [22, 23].

Crystalline silicon solar cells are spectrally selective absorbers that are semiconductor devices. The percentage of incident solar irradiance absorbed by the cell is the absorption factor of a PV cell. Under operational settings, this absorption factor is one of the key criteria controlling cell temperature. The absorption factor may be calculated experimentally using reflection and transmission data. According to Santbergen et al. [23], using a two-dimensional (2D) computational model that agrees with experimental results, the AM1.5 absorption factor of a typical encapsulated c-Si photovoltaic cell can reach 90.5%. The existence of an appropriate steepness texture at the front of the c-Si wafer was used to obtain such a high absorption factor. As a result, by limiting reflecting losses over the solar spectrum, c-Si cell AM1.5 absorption may potentially be improved to 93.0%. Notably, there is widespread use of c-Si bifacial PV devices compared to their monofacial counterparts due to their potential to achieve a higher annual energy yield. Factors that promote these devices are the bifacial PV performance measurement method/standard for indoor characterization and comprehensive simulation models for outdoor performance characterization [24]. Non-commercial 3D tools such as PC3D, an open-source numerical analysis program for simulating the internal operation of silicon solar cells, have been reported to provide accurate simulation results that are only ≈1.7% different from their commercial counterparts [25]. In recent studies, Sun et al. [27] studied the high-efficiency silicon heterojunction solar cells, which were reported to be the next generation of crystalline silicon cells. The authors reported that increasing the efficiency limits can be achieved by increasing the short-circuit current while maintaining its high open-circuit voltage, and for mass production, there should be minimal consumption of indium and silver. Ibarra et al. [6] stated that high water quality is now commonplace for crystalline silicon (c-Si)-based solar cells, meaning that the cell's efficiency potential is largely dictated by the effectiveness of its carrier-selective contacts based on highly doped-silicon, which can introduce negative side effects such as parasitic absorption. According to Chee et al. [37], carrier-selective crystalline silicon heterojunction (SHJ) solar cells have already achieved remarkable lab-scale efficiencies, with SiOx/heavily doped polycrystalline silicon (n + -/p + -poly-Si) creating the most attractive polysilicon-on-oxide (POLO) junctions.

As a result, industry trends will shift away from p-Si passivated emitter and rear polysilicon (PERPoly) designs and toward TOPCon architectures. Costals et al. [38] described how vanadium oxide films provide excellent surface passivation with effective lifetime values of up to 800 s and solar cells with efficiencies greater than 18%, shedding light on the possibilities of transition metal oxides deposited using the atomic layer deposition technique. To solve the challenge of realizing a high aspect ratio (AR) of the metal fingers in a bifacial (BF) copper-plated crystalline silicon solar cell, Han et al. [31] created a new type of hybrid-shaped Cu finger device, electromagnetically fabricated in a 2-step deposition BF plating process, which shows a front-side efficiency of 22.1% and a BF factor of 0.99. Finally, using a grading technique to increase the efficiency of c-Si solar cells, Pham et al. [32] attained a conversion efficiency of 22%.

Other materials currently in use are low-cost solar cells based on hybrid polymer semiconductor materials containing a light-harvesting material, which absorbs photons with energy equal to or greater than the energy of the band gap (Eg). This leads to the creation of excitons (bound electron–hole pairs) ranging from 5 to 15 nm in most organic semiconductors, which diffuse in the material and may either undergo dissociation to the separate charge carriers or recombination with the emission of energy [32]. To improve the dissociation of excitons and enhance the efficiency of the PV cell, the photoactive material is combined with a strong acceptor of electrons of high electron affinity. Then, the separated electrons and holes migrate through different materials in the internal electric field generated across the device and are accommodated by the appropriate collecting electrodes. Organic particle–polymer (PCBM-P3HT) solar cells’ conversion efficiencies are much lower than those obtained for semiconductor devices [6]. Recent research on hybrid cells discusses performance analysis and the parameter optimization of hybrid PV cells [34, 35], while porous organic polymer cells have received current research attention for drug delivery and biomedical applications [36,37,38].

Thin films (TF) only represent 10% of the global PV market. However, researchers around the world are exploring other options to produce electricity more efficiently using solar cells; hence, R&D for developing new materials is currently going on. A strategic approach to tuning absorbance, grain size rearrangement, conductivity, morphology, topography, and stoichiometric compositions for absorber layer solar cell applications is the incorporation of foreign dopants in the CdSe host lattice. Chasta et al. [18] using the thermal-evaporation approach, thin films of CdSe:Cu alloys with 1%, 3%, and 5% Cu contents were grown and annealed at 350 °C. Because of their efficiency, simplicity of manufacturing, and low cost, hybrid organic–inorganic halides are regarded as excellent materials when utilized as the absorber layer in perovskite solar cells (PSCs). According to Marí-Guaita et al. [39], its lower efficiency using MASnI3 as an absorber is more stable, which could be improved by enhancing the bandgap alignment of MaSnI3 [39]. Tarbi et al. [40] stated that the physical parameters of the absorption coefficients are more related to the variation of pressure than the temperature variation and deformation of a double-junction solar cell (Jsc) equal to 47.03 mA/cm2, and this results in a shift from maximum current density to low voltages while retaining its maximum value of 36.03 mW/m2. According to Chaudhry et al. [49], improving the optical absorption and current density in an active layer, under the standard AM-1.5 solar spectra, is achieved through the inclusion of semiconductor nanoparticles (NPs). The efficiencies were raised by 10% for the aluminum nanoparticles (NPs) design and by 21% and 30% for solar cells with and without anti-reflective thin film coating, respectively. In another study, Al- and Cu-doped ZnO nanostructured films were deposited using a sputtering technique, and doping resulted in enhanced conductivity as well as improved mobility in Al–ZnO and Cu–ZnO films in comparison with pure ZnO films, resulting in efficiencies of 0.492% and 0.559% for Al–ZnO- and Cu–ZnO-based solar cells, respectively.

Dye-sensitized solar cells (DSC) shown in Fig. 4 are an alternative concept to present-day p–n junction photovoltaic devices for optoelectronics applications. DSC is made up of a cathode, a photoactive layer, an electrolyte, and an anode [53]. The functional layers for flexible DSC, notably the electrodes that also serve as active layer substrates, must be flexible. In contrast to typical systems in which the semiconductor performs both light absorption and charge carrier transport, light is absorbed by a sensitizer attached to the surface of a wide-band semiconductor in this system [54]. The dye sensitizer absorbs incoming sunlight and uses the energy to initiate a vectorial electron transfer process. Around 10% of overall solar-to-current conversion efficiencies (IPCE) have been achieved [55]. However, DSC has no practical conversion efficiency breakthrough and suffers from low mechanical stability and problematic sealing, but enhancing the properties of the sensitizers, metal oxide/semiconductor film, substrate, redox electrolyte, and counter electrode (CE) accelerates DSC applications [56].

The N3 dye was reported to be stable as a pure solid in the air up to 280 °C, where decarboxylation occurs. It lasts 108 redox cycles under long-term light with no obvious loss of function. Metal oxides, such as TiO2, SnO2, ZnO2, In2O3, CeO3, and NbO3, have been employed as photoanodes to investigate materials for effective photoanodes [57]. Hence, the breakthrough in DSC was the use of a high-surface-area nanoporous TiO2 layer, and the outstanding stability is the very rapid deactivation of its excited state via charge injection into the TiO2, which occurs in the femtosecond time domain [58].

TiO2 became the preferred semiconductor because of its low cost, non-toxicity, and abundance. Although the N3/N3 + pair exhibits reversible electrochemical activity in various organic solvents, showing that the lifespan of N3 + is at least several seconds under these conditions, the oxidized form of N3 + , the dye created by electron injection, is significantly less stable [59]. However, when maintained in the oxidized state, the dye degrades through the loss of sulfur. To avoid this undesirable side reaction, regeneration of the N3 in the photovoltaic cell should occur quickly, i.e., within nanoseconds or microseconds [60]. Cell failure may occur due to the circumstances of the dye renewal. Recent advances in the field of sensitizers for these devices have resulted in dyes that absorb over the visible spectrum, resulting in better efficiencies. The DSC may be based on a huge internal interface prepared in a simple laboratory environment without strict demands on the purity of the materials or the absence of a built-in electric field. DSC offers low production costs and, interestingly, much lower investment costs compared with conventional PV technologies. It offers flexibility, lightweight, and design opportunities, such as transparency and multicolor options (building integration, consumer products, etc.). There is feedstock availability to reach the terawatt scale, and there is also a short energy payback time (< 1 year), where the enhanced performance is under real outdoor conditions, which are relatively better than competitors at diffuse light and higher temperatures [61].

In high-efficiency DSCs, ruthenium (Ru) complex dyes and organic solvent-based electrolytes such as N719, N3, and black dye are commonly utilized. Ru dyes, on the other hand, are costly and require a complicated chemical method. Its products, such as ruthenium oxide (RuO4), are also very poisonous and volatile. Organic solvents are also poisonous, ecologically dangerous, and explosive, and their low surface tension can cause leakage difficulties [48, 50, 52]. Hence, organic solvents and Ru-based complex dyes may need to be replaced to realize low-cost, biocompatible, and environmentally benign devices. Water and natural dyes derived from plants could be excellent alternatives, according to Kim et al. [56]. Yadav et al. [60] assembled TiO2 nanorod (NR)-based hibiscus dye with different counter electrodes such as carbon, graphite, and gold. The authors measured efficiencies of 0.07%, 0.10%, and 0.23%, respectively. The key to the breakthrough for DSCs in 1991 was the use of a mesoporous TiO2 electrode with a high internal surface area to support the monolayer of a sensitizer and the increase in surface area by using mesoporous electrodes [42]. The standard DSC dye was tris (2,2′-bipyridyl-4,4′-carboxylate) ruthenium (II) (N3 dye), and the carboxylate group in the dye attaches the semiconductor oxide substrate by chemisorption; hence, when the photon is absorbed, the excited state of the dye molecule will relax by electron injection to the semiconductor conduction band. Since 1993, the photovoltaic performance of N3 dye has been irreplaceable by other dye complexes [42]. Bandara et al. [43] mentioned that recent developments comprising textile DSCs are being looked at for their sustainability, flexibility, pliability, and lightweight properties, as well as the possibility of using large-scale industrial manufacturing methods (e.g., weaving and screen printing) [62].

A conducting polymer such as pyrrole was electrochemically polymerized on a porous nanocrystalline TiO2 electrode, which was sensitized by N3 dye. Polypyrrole successfully worked as a whole transport layer, connecting dye molecules anchored on TiO2 to the counter electrode. Conducting polyaniline has also been used in solid-state solar cells sensitized with methylene blue.

Light-emitting diodes based on halide perovskites have limited practical uses [63]. Additional drawbacks of the technique include a lack of knowledge of the influence of the electric field on mobile ions present in perovskite materials, a drop in external quantum efficiency at high current density, and limited device lifetimes [63, 64]. Nonetheless, the technology has advanced rapidly in recent years, and it can currently provide external quantum efficiencies of more than 21%, equivalent to silicon solar cells [64]. Perovskite solar cells (PSCs) were created in the same way as other SPV materials like organic photovoltaics, dye-sensitized solar cells, and vacuum-processed PVs such as CdTe and CIGSOne. PSCs have a high open-circuit voltage (VOC), which distinguishes them from all other photovoltaics (PVs). The loss in VOC induced by non-radiative recombination in the case of PSCs is significantly low, even as low as that reported for vacuum-processed Si. By enhancing the high open-circuit voltage VOC, all-inorganic and tin-based perovskites have the potential to exceed the Shockley–Queisser (S–Q) limitations [65]. Luo et al. [80] used a (FAPbI3)0.95(MAPbBr3)0.05 perovskite to produce a VOC of 1.11 V and an efficiency of 21.73% using a new fluorinated iron (III) porphine dopant for PTAA. Unlike Wu et al. [81], who achieved a 1.59 eV hybrid perovskite, the Jen group obtained a VOC of 1.21 V and a high efficiency of 22.31%.

Carbon nanotubes (CNTs) have demonstrated a significant potential for enhancing polymer material characteristics. CNTs have better electrical and thermal conductivity, they are highly stiff, robust, and tough. Combining CNTs with brittle materials allows one to convey some of the CNTs' appealing mechanical qualities to the resultant composites, making CNT a good choice for reinforcement in polymeric materials. Zhu et al. [109] used carbon nanotubes (CNTs) with single walls to strengthen the epoxy Epon 862 matrix. The molecular dynamics method is used to investigate three periodic systems: a long CNT-reinforced Epon 862 composite, a short CNT-reinforced Epon 862 composite, and the Epon 862 matrix itself. The stress–strain relationships and elastic Young's moduli along the longitudinal direction (parallel to CNT) are simulated, and the results are compared to those obtained using the rule-of-mixture. Their findings reveal that when longitudinal strain rises, the Young's modulus of CNT increases whereas that of the Epon 862 composite or matrix drops. Furthermore, a long CNT may significantly increase the Epon 862 composite's Young's modulus (approximately 10 times stiffer), which is consistent with the prediction based on the rule-of-mixture at low strain level. Even a short CNT can improve the Young's modulus of the Epon 862 composite, with a 20% increase when compared to the Epon 862 matrix. Sui et al. [110] made CNT/NR composites after CNTs were treated in an acid bath and then ball-milled using HRH bonding methods. The thermal properties, vulcanization properties, and mechanical properties of CNT/NR composites were studied. When compared to CB, the absorption of CNTs into NR was quicker and consumed less energy. CNT/NR composites' over-curing reversion was reduced. The dispersion of CNTs in the rubber matrix and the interaction between CNTs and the matrix enhanced after acid treatment and ball milling. When compared to plain NR and CB/NR composites, the addition of treated CNTs improved the performance of the CNT/reinforced NR composites. Medupin et al. [111] used multi-walled carbon nanotube (WMCNT) reinforced natural rubber (NR) polymer nanocomposite (PNC) for prosthetic foot applications. On an open two-roll mill, the components were mixed according to the ASTM D-3182 standard during vulcanization. The nanocomposites (NCs) were cured in an electrically heated hydraulic press for 10 min at a temperature of 1502 °C and a pressure of 0.2 MPa. Mechanical testing found that NR/ MWCNT-3 had the maximum tensile and dynamic loading capability (449.79 MPa). It also had better filler dispersion, which increased crystallinity and cross-linking. The newly created prosthetic material is also said to have better wear resistance than conventional prosthetic materials as shown in Fig. 5. The developed nanocomposite from MWCNTs for reinforced natural rubber is suited for the construction of the anthropomorphic prosthetic foot.

4 Efficiency, stability, and scalability of solar photovoltaic materials

4.1 Economic feasibility

The economic feasibility of solar photovoltaic devices refers to their cost-effectiveness compared to other sources of energy. In the past, solar panels were relatively expensive, and their high cost made them less attractive to many consumers. However, in recent years, the cost of solar panels has dropped significantly, making them much more affordable. Recent advances in SPV technologies have driven this cost reduction in manufacturing technology and economies of scale. Additionally, many governments around the world offer incentives and subsidies to encourage the use of renewable energy sources like solar power, further increasing their economic feasibility. Angmo et al. [77] prepared polymer solar cell modules directly on thin flexible barrier polyethylene terephthalate foil, which is a cost-effective alternative to ITO-based devices with potential applications in information, communications, and mobile technology (ICT) where low humidity (50%) and lower temperatures (65 °C) are expected and operational lifetimes over one year are estimated.

4.2 PV device efficiencies

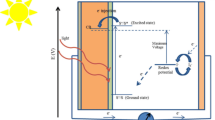

Several procedures are required to generate electricity from PVs. Strongly bonded holes and electron pairs, known as photo-produced excitons, are formed by incoming light and separated at the interface between the donor and acceptor. Materials with a greater electron affinity take electrons, while materials with a low electronization potential admit holes. The produced electrons and holes are then carried through the p-type and n-type material phases, respectively, toward both electrodes, resulting in an external photocurrent flow. Hence, the efficiency of power conversion in organic solar cells is determined by the combination of the following steps: dissociation of electron–hole pairs at the p-n interface; exciton formation following incoming solar light absorption; charge collection at the electrodes; and transport of electrons and holes to both electrodes. The first-generation solar cell has a recorded performance of around 15–20%, as displayed in Fig. 6. The second-generation solar cell is made of amorphous silicon, CdTe, and CIGS and has a 4–15% efficiency. Because second-generation technologies do not rely on silicon wafers, they are less expensive than first-generation technologies.

Hence, first-generation solar cells have higher reported efficiencies than thin-film solar cells, but they are more expensive due to the use of pure silicon in the production process. Thin-film solar cells, on the other hand, use less material, take less time, and are less expensive. Solar cells of the first generation are non-toxic and bountiful in nature. Second-generation solar cells have a lower per-watt price and efficiency when compared to other technologies. Organic materials and polymers are used in the third-generation solar cell. As compared to other varieties, the third-generation solar cell is more efficient and less expensive. The process for producing third-generation cells is simple and unique, but it has yet to be verified. The third-generation new kind of solar cell technology, the perovskite solar cell, has a record efficiency of more than 25% [78]. Nevertheless, UV light, oxygen, and moisture can all contribute to the poor stability of polycrystalline perovskite materials, the most pressing issue that must be addressed before the application of perovskite photovoltaic technology is the long-term stability of PSCs [79].

4.3 Stability of photovoltaics

The stability of solar photovoltaic devices refers to their ability to maintain their efficiency and reliability over time. In the past, solar panels had a reputation for being unreliable due to their sensitivity to weather and the environment. However, modern solar panels are much more stable and durable than earlier versions. They can withstand extreme temperatures and harsh weather conditions, making them suitable for use in a wide range of environments. Additionally, advances in solar panel technology have made them more efficient, which means they produce more energy for longer periods. However, increasing the long-term stability of perovskite solar cells is currently one of the most crucial concerns. According to Lee et al. [94], nanoscale metal–organic frameworks (MOFs) with chemically, moistly, and thermally stable nanostructures have better PSCs’ stability as well as higher device performance, which has increased the interest of the perovskite photovoltaic community in recent times. This can be attributed to MOF’s flexible structure, considerable pore volume, high surface area, high concentration of active metal sites, controllable topology, and tuneable pore diameters [81]. MOFs are used to improve device stability in applications such as gas separation and storage, optoelectronics, and catalysis devices [67, 82, 83]. Furthermore, to improve operational stability in hybrid perovskite solar cells, a thorough understanding of photodegradation and thermal degradation processes is required [84]. Additionally, interfacial engineering with hydrophobic materials, or the 2D/3D concept, has significantly improved long-term stability.

4.4 Scalability of photovoltaics

Furthermore, the ability of solar photovoltaic devices to meet rising energy demands is referred to as their scalability. Solar panels can be installed on a wide range of structures, from homes to commercial and industrial structures. They can also be scaled up for utility-scale power generation, allowing solar energy to power entire communities. Furthermore, advancements in solar panel manufacturing have increased their efficiency, allowing them to be more scalable in terms of the amount of energy they can produce from a given surface area. The challenges for scaling up perovskite solar cells include developing scalable deposition strategies for the uniform coating of all device layers over large-area substrates, including the perovskite photoactive layer, electron-transport layer (ETL), hole-transport layer (HTL), and electrodes. Other challenges include developing procedures for fabrication and achieving better control of film formation across the device stack at large scales by improving the precursor chemistry to match the processing methods. Nonetheless, despite the challenges, in 2019, a stable solid-state perovskite solar cell with a certified power conversion efficiency (PCE) of 25.2% was recorded [75]. Although small-area cells are extremely efficient, scaling-up technology is required for commercialization. Scalable Technologies is now focused on high-efficiency module production and large-area perovskite coating, where dimethyl sulfoxide or N, N-dimethylformamide (DMF), which are perovskite precursor solutions used for spin coating and scalable depositions, may not be feasible due to sluggish evaporation and significant interactions with Lewis acid precursors. For producing a homogeneous perovskite coating over a large area substrate, Park [87] suggested using acetonitrile or 2-methoxyethanol solvents, while Li et al. [89] mentioned blade coating, meniscus coating, slot-die coating, spray coating, screen-printing, inkjet printing, and electrodeposition as scalable solution deposition processes for perovskite development. Altinkaya et al. [90] reported that tin oxide (SnO2) is a scalable alternative to mesoporous titanium dioxide (TiO2)/compact TiO2 stacks as electron-selective layers (ESLs) due to its wide bandgap, high carrier mobility, high optical transmission, decent chemical stability, and suitable band alignment with perovskites.

Finally, the scalability, stability, and economic feasibility of solar photovoltaic devices have all improved significantly in recent years. Advances in technology and manufacturing have made solar panels more efficient and affordable, while incentives and subsidies have encouraged their use. As a result, solar energy is becoming an increasingly popular source of renewable energy capable of meeting growing energy demands sustainably and reliably.

5 Environmental effects of solar photovoltaics

PV systems are recognized as clean and long-term energy sources. Although PV systems may generate little pollution while in operation, the environmental effects of such systems observed from manufacture through disposal must not be disregarded. The environmental problems of PV systems include the generation of hazardous chemicals, the pollution of water resources, and the emission of air pollutants during the production process, and the impact of PV installations on land utilization. According to Tawalbeh et al. [68], by improving PV design, recycling solar cell materials to reduce GHG emissions by up to 42%, creating novel materials with improved properties, improving cell lifespans, avoiding hazardous components, recycling, and making careful site selection, the negative environmental impacts of PV systems may be considerably reduced. These mitigation actions will reduce greenhouse gas (GHG) emissions, restrict solid waste accumulation, and save essential water resources. PV systems have a carbon footprint of 14–73 CO2-eq/kWh, which is 10 to 53 orders of magnitude lower than the emissions observed from oil burning (742 CO2-eq/kWh from oil). The carbon footprint of the PV system might be lowered by using novel production materials. When compared to traditional solid oxide fuel cells (SOFCs), Smith et al. [69] proposed the use of these novel material combinations leads to a reduction in embodied materials and toxicological impact, but a higher electrical energy consumption during manufacturing. Their findings provide support for the drive to reduce the operating temperatures of SOFCs using unique material designs, resulting in a lower overall environmental impact due to the lower operational energy from the constituents of the selected material. Blanco et al. [70] reported that thin-film silicon and dye-sensitized cells lead the way in terms of total environmental impact, followed by thin-film chalcogenide, organic, and silicon. Chetyrkina et al. [71] analyzed the constituents of perovskite cells for their environmental hazards: lead, tin, or bismuth iodide on the one hand, and methylammonium, formamidinium, or cesium iodide on the other. The authors stated that bismuth iodide was the least hazardous in the first round of cell testing. Cesium and formamidinium iodides were less harmful to cells than methylammonium iodide. This study argued that their reports show that perovskite cells will fully phase out silicon-based cells since the former is not as toxic as the latter [72].

6 Summary and outlook

Covalent organic frameworks (COFs) have been reported to exhibit covalent bond-supported crystallinity as well as capture and mass transport characteristics [90]. Organic semiconductors are gaining popularity in research, and materials for organic electronics are currently intensively researched for other purposes, such as organic photovoltaics, large-area devices, and thin-film transistors, benefiting from the emergence of non-fullerene acceptors (NFAs) and the organic light-emitting diode (OLED) [91]. There have also been reports of issues arising from applications such as displays on flexible substrates, OLED lighting, huge area displays, and printable or solution processible greater area solar cells. Inorganic halide templates in carbon nanotubes of 1.2 nm, which are currently the smallest halide perovskite structures, have been reported to function as solar cells [92]. While other research has developed strategies to increase the durability of perovskites by using computer models based on density functional theory (DFT) to determine which molecules would be best at bridging the perovskite layer and the charge transport layers since the interface between the perovskite layer and the next layers is a critical location of vulnerability in perovskite solar cells. The results showed that inverted perovskite solar cells containing 1,3-bis(diphenylphosphine)propane, or DPPP, had the best performance because the cell's total power conversion efficiency remained high for around 3,500 h [93].

There are also environmental problems with PV systems, from production through installation and disposal [94]. Moreso, because perovskites are unstable, they must be protected with transparent polymers. Perovskite decomposes into chemicals that may pose environmental and human health hazards when this protection deteriorates [95]. Hence, PV solar systems have a carbon footprint of 14–73 g CO2-eq/kWh, which is lower than gas (607.6 CO2-eq/kWh), oil (742.1 CO2-eq/kWh), and coal-fired (975.3 g CO2-eq/kWh) power plants. New materials and/or recycled silicon material can reduce GHG emissions by up to 50% [96]. Floating PV systems and self-cleaning installations offer the benefit of using less water during the cleaning process. Except during installation, the PV modules have little noise and visual impact [97]. The life cycle analysis revealed that PV systems cannot be considered zero-emission technology due to the potential environmental effects imposed by land use, air quality, water use, the inclusion of hazardous materials, and possible noise/visual pollution; however, these effects can be mitigated by novel technologies such as hybrid power systems and/or floating PV systems [98,99,100]. Overall, future materials for solar photovoltaic devices must balance efficiency, cost, durability, toxicity, availability, and integration to provide a sustainable and cost-effective source of renewable energy [100,101,102,103,104,105,106,107,108].

7 Conclusion

Recent advancements in solar photovoltaic (PV) materials and systems have resulted in considerable efficiency, cost, and durability improvements. PV has become a more realistic choice for a wide range of applications, including power production, water pumping, and space exploration, as a result of these advancements. The creation of high-efficiency crystalline silicon (c-Si) solar cells has been one of the most significant recent developments in PV technology. C-Si solar cells can currently convert more than 20% of the sun's energy into electricity.

This is a huge advance over early c-Si solar cells, which could only convert roughly 10% of the sun's energy into power. The creation of thin-film solar cells is another significant recent advancement in PV technology. Thin-film solar cells are constructed from substantially thinner materials than c-Si solar cells. As a result, they are lighter and less expensive to produce. Thin-film solar cells are also more flexible than c-Si solar cells, allowing them to be used in a broader range of applications. In addition to advancements in PV materials, substantial advancements in PV systems have occurred. PV systems today feature a number of components that aid in efficiency, durability, and dependability.

Solar trackers, inverters, and batteries are among the components. PV has become a more realistic choice for a wide range of applications due to advancements in PV materials and systems. PV is currently used to power homes and businesses, as well as to pump water and power satellites and other spacecraft. PV technology is expected to become more commonly employed in the future as it improves.

Other recent advances in solar PV materials and systems include the development of new materials, such as perovskites, that have the potential to achieve even higher efficiencies than c-Si solar cells, the development of new manufacturing processes that can lower the cost of PV modules, and the development of new PV applications, such as solar-powered cars and homes. These advancements make solar PV a more appealing alternative for a broader range of applications. As the cost of PV continues to fall, solar PV is anticipated to become the major form of renewable energy in the future.

Availability of data and material

Not applicable.

Abbreviations

- SPV:

-

Solar photovoltaic

- PV:

-

Photovoltaic

- FTCC:

-

Floating tracking concentrating cooling system

- HPV/TS:

-

Hybrid solar photovoltaic/thermal system

- PV/TE:

-

Hybrid solar photovoltaic/thermoelectric

- PV/T:

-

Hybrid solar photovoltaic/thermal

- DC:

-

Direct current

- AC:

-

Alternating current

- MW:

-

Mega Watts

- GW:

-

Giga Watts

- PCU:

-

Power conditioning unit

- ES:

-

Energy storage

- 2D:

-

Two-dimensional

- 3D:

-

Three-dimensional)

- SHJ:

-

Silicon heterojunction

- POLO:

-

Polysilicon-on-oxide

- BF:

-

Bifacial

- TF:

-

Thin films

- PSCs:

-

Perovskite solar cells

- VOC:

-

Open-circuit voltage

- Jsc:

-

Junction solar cell

- NPs:

-

Nanoparticles

- DSC:

-

Dye-sensitized solar cells

- CE:

-

Counter electrode

- Ru:

-

Ruthenium

- S–Q:

-

Shockley–Queisser

- ICT:

-

Information and communications and mobile technology

- UV:

-

Ultraviolet

- MOFs:

-

Metal–organic frameworks

- ETL:

-

Electron-transport layer

- HTL:

-

Hole-transport layer

- PCE:

-

Power conversion efficiency

- DMF:

-

N-dimethylformamide

- ESLs:

-

Electron-selective layers

- SOFCs:

-

Solid oxide fuel cells

- COFs:

-

Covalent organic frameworks

- NFAs:

-

Non-fullerene acceptors

- OLED:

-

Organic light-emitting diode

- DFT:

-

Density functional theory

- DPPP:

-

1,3 Bis(diphenylphosphino)propane

- GHG:

-

Greenhouse gas

References

Gong J, Liang J, Sumathy K (2012) Review on dye-sensitized solar cells (DSSCs): fundamental concepts and novel materials. Renew Sustain Energy Rev 16(8):5848–5860

Dubacheva GV, Liang CK, Bassani DM (2012) Functional monolayers from carbon nanostructures–fullerenes, carbon nanotubes, and graphene–as novel materials for solar energy conversion. Coord Chem Rev 256(21–22):2628–2639

Lim EL, Yap CC, Jumali MHH, Teridi MAM, Teh CH (2018) A mini review: can graphene be a novel material for perovskite solar cell applications? Nano-micro Lett 10:1–12

Ohshita Y, Suzuki H, Kojima N, Tanaka T, Honda T, Inagaki M, Yamaguchi M (2011) Novel material for super high efficiency multi-junction solar cells. J Cryst Growth 318(1):328–331

Chen J, Cao Y (2009) Development of novel conjugated donor polymers for high-efficiency bulk-heterojunction photovoltaic devices. Acc Chem Res 42(11):1709–1718

Hayat MB, Ali D, Monyake KC, Alagha L, Ahmed N (2019) Solar energy—a look into power generation, challenges, and a solar-powered future. Int J Energy Res 43(3):1049–1067

Casper F, Graf T, Chadov S, Balke B, Felser C (2012) Half-Heusler compounds: novel materials for energy and spintronic applications. Semicond Sci Technol 27(6):063001

Mozer AJ, Sariciftci NS (2006) Conjugated polymer photovoltaic devices and materials. C R Chim 9(5–6):568–577

Kannan N, Vakeesan D (2016) Solar energy for future world: a review. Renew Sustain Energy Rev 62:1092–1105

Meinel AB, Meinel MP (1977) Applied solar energy: an introduction. NASA STI/Recon Tech Report A 77:33445

Gordon J, Gordon JM (eds) (2001) Solar energy: the state of the art: ISES position papers

Chen CJ (2011) Physics of solar energy. Wiley

Sayigh AAM (ed) (2012) Solar energy engineering. Elsevier

Gong J, Li C, Wasielewski MR (2019) Advances in solar energy conversion. Chem Soc Rev 48(7):1862–1864

Fang B, Xing Z, Sun D, Li Z, Zhou W (2022) Hollow semiconductor photocatalysts for solar energy conversion. Adv Powder Mater 1(2):100021

Rabaia MKH, Abdelkareem MA, Sayed ET, Elsaid K, Chae KJ, Wilberforce T, Olabi AG (2021) Environmental impacts of solar energy systems: a review. Sci Total Environ 754:141989

Sodiqjon K, Begyor S, Aleksandr K, Farrukh D, Mukhtasar M, Akbarjon A (2022) Prospective aspects of using solar energy. J New Century Innovat 18(1):142–148

Chasta G, Suthar D, Thakur A, Kannan MD, Dhaka MS (2022) Comprehensive investigation on influence of copper doping on physical properties of CdSe thin films for solar cell applications. Mater Res Bull 152:111845

Ding T, Zhou Y, Ong WL, Ho GW (2021) Hybrid solar-driven interfacial evaporation systems: beyond water production towards high solar energy utilization. Mater Today 42:178–191

Hoeven MVD (2015) Technology roadmap: solar photovoltaic energy. International Energy Agency, Paris, France

Siecker J, Kusakana K, Numbi EB (2017) A review of solar photovoltaic systems cooling technologies. Renew Sustain Energy Rev 79:192–203

Saga T (2010) Advances in crystalline silicon solar cell technology for industrial mass production. NPG Asia Mater 2(3):96–102

Santbergen R, van Zolingen RC (2008) The absorption factor of crystalline silicon PV cells: a numerical and experimental study. Sol Energy Mater Sol Cells 92(4):432–444

Liang TS, Pravettoni M, Deline C, Stein JS, Kopecek R, Singh JP, Luo W, Wang Y, Aberle AG, Khoo YS (2019) A review of crystalline silicon bifacial photovoltaic performance characterisation and simulation. Energy Environ Sci 12(1):116–148

Zhao J, Xu Z, Law MK, Heidari H, Abdellatif SO, Imran MA, Ghannam R (2021) Simulation of crystalline silicon photovoltaic cells for wearable applications. IEEE Access 9:20868–20877

Benda V, Černá L (2020) PV cells and modules–State of the art, limits and trends. Heliyon 6(12):e05666

Sun Z, Chen X, He Y, Li J, Wang J, Yan H, Zhang Y (2022) Toward efficiency limits of crystalline silicon solar cells: recent progress in high-efficiency silicon heterojunction solar cells. Adv Energy Mater 12(23):2200015

Nadia AR, Isa NAM, Desa MKM (2018) Advances in solar photovoltaic tracking systems: a review. Renew Sustain Energy Rev 82:2548–2569

Hightower M, Pierce SA (2008) The energy challenge. Nature 452(7185):285–286

Chong KK, Wong CW (2009) General formula for on-axis sun-tracking system and its application in improving tracking accuracy of solar collector. Sol Energy 83(3):298–305

Nsengiyumva W, Chen SG, Hu L, Chen X (2018) Recent advancements and challenges in solar tracking systems (STS): a review. Renew Sustain Energy Rev 81:250–279

Jamroen C, Komkum P, Kohsri S, Himananto W, Panupintu S, Unkat S (2020) A low-cost dual-axis solar tracking system based on digital logic design: Design and implementation. Sustain Energy Technol Assessm 37:100618

Ibarra Michel J, Dréon J, Boccard M, Bullock J, Macco B (2023) Carrier-selective contacts using metal compounds for crystalline silicon solar cells. Progress Photovoltaics Res Appl 31(4):380–413

Jamroen C, Komkum P, Kohsri S, Himananto W, Panupintu S, Unkat S (2020) A low-cost dual-axis solar tracking system based on digital logic design: design and implementation. Sustain Energy Technol Assess 37:100618

Chowdhury ME, Khandakar A, Hossain B, Abouhasera R (2019) A low-cost closed-loop solar tracking system based on the sun position algorithm. J Sensors

Chee KW, Ghosh BK, Saad I, Hong Y, Xia QH, Gao P, Ye J, Ding ZJ (2022) Recent advancements in carrier-selective contacts for high-efficiency crystalline silicon solar cells: Industrially evolving approach. Nano Energy 95:106899

Costals ER, Masmitjà G, Almache E, Pusay B, Tiwari K, Saucedo E, Raj CJ, Kim BC, Puigdollers J, Martin I, Voz C (2022) Atomic layer deposition of vanadium oxide films for crystalline silicon solar cells. Mater Adv 3(1):337–345

Han C, Yang G, Procel P, O’Connor D, Zhao Y, Gopalakrishnan A, Zhang X, Zeman M, Mazzarella L, Isabella O (2022) Controllable simultaneous bifacial Cu-plating for high-efficiency crystalline silicon solar cells. Solar RRL 6(6):2100810

Pham DP, Yi J (2022) Dopant-grading proposal for polysilicon passivating contact in crystalline silicon solar cells. J Power Sources 522:231005

.Skompska, M. (2010) Hybrid conjugated polymer/semiconductor photovoltaic cells. Synth Met 160(1–2):1–15

Singh A, Sharma A, Rajput S, Bose A, Hu X (2022) An investigation on hybrid particle swarm optimization algorithms for parameter optimization of PV cells. Electronics 11(6):909

Cotfas DT, Cotfas PA, Mahmoudinezhad S, Louzazni M (2022) Critical factors and parameters for hybrid photovoltaic-thermoelectric systems; review. Appl Therm Eng, p 118977

Tang Y, Varyambath A, Ding Y, Chen B, Huang X, Zhang Y, Yu DG, Kim I, Song W (2022) Porous organic polymers for drug delivery: hierarchical pore structures, variable morphologies, and biological properties. Biomater Sci

Kim JH, Kang DW, Yun H, Kang M, Singh N, Kim JS, Hong CS (2022) Post-synthetic modifications in porous organic polymers for biomedical and related applications. Chem Soc Rev 51(1):43–56

Zhu Y, Xu P, Zhang X, Wu D (2022) Emerging porous organic polymers for biomedical applications. Chem Soc Rev 51(4):1377–1414

Marí-Guaita J, Bouich A, Shafi MA, Bouich A, Marí B (2022) Investigation on the stability and efficiency of MAPbI3 and MASnI3 thin films for solar cells. Phys Status Solidi 219(5):2100664

Tarbi A, Chtouki T, Bouich A, Elkouari Y, Erguig H, Migalska-Zalas A, Aissat A (2022) InP/InGaAsP thin films based solar cells: lattice mismatch impact on efficiency. Opt Mater 131:112704

Chaudhry FA, Escandell L, López-Fraguas E, Vergaz R, Sánchez-Pena JM, García-Cámara B (2022) Light absorption enhancement in thin film GaAs solar cells using dielectric nanoparticles. Sci Rep 12(1):9240

O’regan B, Grätzel M (1991) A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 353(6346):737–740

Bandara TMWJ, Hansadi JMC, Bella F (2022) A review of textile dye-sensitized solar cells for wearable electronics. Ionics 28(6):2563–2583

Shahzad N, Perveen T, Pugliese D, Haq S, Fatima N, Salman SM, Tagliaferro A, Shahzad MI (2022) Counter electrode materials based on carbon nanotubes for dye-sensitized solar cells. Renew Sustain Energy Rev 159:112196

Alizadeh A, Roudgar-Amoli M, Bonyad-Shekalgourabi SM, Shariatinia Z, Mahmoudi M, Saadat F (2022) Dye sensitized solar cells go beyond using perovskite and spinel inorganic materials: a review. Renew Sustain Energy Rev 157:112047

Venkatesan S, Lin WH, Hsu TH, Teng H, Lee YL (2022) Indoor dye-sensitized solar cells with efficiencies surpassing 26% using polymeric counter electrodes. ACS Sustain Chem Eng 10(7):2473–2483

Devadiga D, Selvakumar M, Shetty P, Santosh MS (2022) The integration of flexible dye-sensitized solar cells and storage devices towards wearable self-charging power systems: a review. Renew Sustain Energy Rev 159:112252

Kim JH, Kim DH, So JH, Koo HJ (2022) Toward eco-friendly dye-sensitized solar cells (DSSCs): natural dyes and aqueous electrolytes. Energies 15(1):219

De Freitas ES, Da Silva PB, Chorilli M, Batista AA, Lopes EDO, da Silva MM, Leite CQF, Pavan FR (2014) Nanostructured lipid systems as a strategy to improve the in vitro cytotoxicity of ruthenium (II) compounds. Molecules 19(5):5999–6008

Dragutan I, Dragutan V, Demonceau A (2017) Special issue on ruthenium complexes. Molecules 22(2):255

Tojo G, Fernández M, Tojo G, Fernández M (2007) Ruthenium tetroxide and other ruthenium compounds. Oxidation of primary alcohols to carboxylic acids: a guide to current common practice, pp 61–78

Yadav SC, Sharma A, Devan RS, Shirage PM (2022) Role of different counter electrodes on performance of TiO2 based dye-sensitized solar cell (DSSC) fabricated with dye extracted from Hibiscus Sabdariffa as sensitizer. Opt Mater 124:112066

Grätzel M (2003) Dye-sensitized solar cells. J Photochem Photobiol, C 4(2):145–153

Hagfeldt A, Boschloo G, Sun L, Kloo L, Pettersson H (2010) Dye-sensitized solar cells. Chem Rev 110(11):6595–6663

Wei D (2010) Dye sensitized solar cells. Int J Mol Sci 11(3):1103–1113

Kalyanasundaram K (2010) Dye-sensitized solar cells. CRC Press

Nazeeruddin MK, Baranoff E, Grätzel M (2011) Dye-sensitized solar cells: a brief overview. Sol Energy 85(6):1172–1178

Chiba Y, Islam A, Watanabe Y, Komiya R, Koide N, Han L (2006) Dye-sensitized solar cells with conversion efficiency of 111%. Jpn J Appl Phys 45(7L):L638

Hardin BE, Snaith HJ, McGehee MD (2012) The renaissance of dye-sensitized solar cells. Nat Photonics 6(3):162–169

Tawalbeh M, Al-Othman A, Kafiah F, Abdelsalam E, Almomani F, Alkasrawi M (2021) Environmental impacts of solar photovoltaic systems: a critical review of recent progress and future outlook. Sci Total Environ 759:143528

Smith L, Ibn-Mohammed T, Yang F, Reaney IM, Sinclair DC, Koh SL (2019) Comparative environmental profile assessments of commercial and novel material structures for solid oxide fuel cells. Appl Energy 235:1300–1313

Blanco CF, Cucurachi S, Peijnenburg WJ, Beames A, Vijver MG (2020) Are technological developments improving the environmental sustainability of photovoltaic electricity? Energ Technol 8(11):1901064

Chetyrkina MR, Kameneva L, Mishchenko DV, Klimanova EN, Sashenkova TE, Allayarova UY, Kostyuk SV, Frolova LA, Aldoshin SM, Troshin PA (2023) Lead, tin, bismuth or organics: assessment of potential environmental and human health hazards originating from mature perovskite PV technology. Sol Energy Mater Sol Cells 252:112177

Li C, Wang X, Bi E, Jiang F, Park SM, Li Y, Chen L, Wang Z, Zeng L, Chen H, Liu Y (2023) Rational design of Lewis base molecules for stable and efficient inverted perovskite solar cells. Science 379(6633):690–694

Ning Z, Fu Y, Tian H (2010) Improvement of dye-sensitized solar cells: what we know and what we need to know. Energy Environ Sci 3(9):1170–1181

Law M, Greene LE, Johnson JC, Saykally R, Yang P (2005) Nanowire dye-sensitized solar cells. Nat Mater 4(6):455–459

Kashtiban RJ, Patrick CE, Ramasse Q, Walton RI, Sloan J (2022) Picoperovskites: the smallest conceivable isolated halide perovskite structures formed within carbon nanotubes. Adv Mater, 2208575

Tan S, Huang T, Yavuz I, Wang R, Yoon TW, Xu M, Xing Q, Park K, Lee DK, Chen CH, Zheng R (2022) Stability-limiting heterointerfaces of perovskite photovoltaics. Nature 605(7909):268–273

Lin R, Xu J, Wei M, Wang Y, Qin Z, Liu Z, Wu J, Xiao K, Chen B, Park SM, Chen G (2022) All-perovskite tandem solar cells with improved grain surface passivation. Nature 603(7899):73–78

Li H, Zhou J, Tan L, Li M, Jiang C, Wang S, Zhao X, Liu Y, Zhang Y, Ye Y, Tress W (2022) Sequential vacuum-evaporated perovskite solar cells with more than 24% efficiency. Sci Adv 8(28):eabo7422

DuBose JT, Kamat PV (2022) Efficacy of perovskite photocatalysis: challenges to overcome. ACS Energy Lett 7(6):1994–2011

Luo J, Lin F, Xia J, Yang H, Zhang R, Malik HA, Shu H, Wan Z, Han K, Wang R, Yao X (2021) An efficient and hydrophobic molecular doping in perovskite solar cells. Nano Energy 82:105751

Wu S, Zhang J, Li Z, Liu D, Qin M, Cheung SH, Lu X, Lei D, So SK, Zhu Z, Jen AKY (2020) Modulation of defects and interfaces through alkylammonium interlayer for efficient inverted perovskite solar cells. Joule 4(6):1248–1262

Friederich P, Fediai A, Kaiser S, Konrad M, Jung N, Wenzel W (2019) Toward design of novel materials for organic electronics. Adv Mater 31(26):1808256

Yang Y, Börjesson K (2022) Electroactive covalent organic frameworks: a new choice for organic electronics. Trends Chem 4(1):60–75

Tareen AK, Khan K, Rehman S, Iqbal M, Yu J, Zhou Z, Yin J, Zhang H (2022) Recent development in emerging phosphorene based novel materials: progress, challenges, prospects and their fascinating sensing applications. Prog Solid State Chem 65:100336

Mahato N, Sharma K, Sinha M, Baral ER, Koteswararao R, Dhyani A, Cho MH, Cho S (2020) Bio-sorbents, industrially important chemicals and novel materials from citrus processing waste as a sustainable and renewable bioresource: a review. J Adv Res 23:61–82

Verduci R, Romano V, Brunetti G, Yaghoobi Nia N, Di Carlo A, D’Angelo G, Ciminelli C (2022) Solar energy in space applications: review and technology perspectives. Adv Energy Mater 12(29):2200125

Park NG (2020) Research direction toward scalable, stable, and high efficiency perovskite solar cells. Adv Energy Mater 10(13):1903106

Green M, Dunlop E, Hohl-Ebinger J, Yoshita M, Kopidakis N, Hao X (2021) Solar cell efficiency tables (version 57). Prog Photovoltaics Res Appl 29(1):3–15

Li Z, Klein TR, Kim DH, Yang M, Berry JJ, Van Hest MF, Zhu K (2018) Scalable fabrication of perovskite solar cells. Nat Rev Mater 3(4):1–20

Altinkaya C, Aydin E, Ugur E, Isikgor FH, Subbiah AS, De Bastiani M, Liu J, Babayigit A, Allen TG, Laquai F, Yildiz A (2021) Tin oxide electron-selective layers for efficient, stable, and scalable perovskite solar cells. Adv Mater 33(15):2005504

Angmo D, Gevorgyan SA, Larsen-Olsen TT, Søndergaard RR, Hösel M, Jørgensen M, Gupta R, Kulkarni GU, Krebs FC (2013) Scalability and stability of very thin, roll-to-roll processed, large area, indium-tin-oxide free polymer solar cell modules. Org Electron 14(3):984–994

Kim M, Jeong J, Lu H, Lee TK, Eickemeyer FT, Liu Y, Choi IW, Choi SJ, Jo Y, Kim HB, Mo SI (2022) Conformal quantum dot–SnO2 layers as electron transporters for efficient perovskite solar cells. Science 375(6578):302–306

Wang HP, Li S, Liu X, Shi Z, Fang X, He JH (2021) Low-dimensional metal halide Perovskite photodetectors. Adv Mater 33(7):2003309

Lee CC, Chen CI, Liao YT, Wu KCW, Chueh CC (2019) Enhancing efficiency and stability of photovoltaic cells by using perovskite/Zr-MOF heterojunction including bilayer and hybrid structures. Adv Sci 6(5):1801715

Exposing unsaturated Cu1-O2 sites in nanoscale Cu-MOF for efficient electrocatalytic hydrogen evolution

Zou YH, Huang YB, Si DH, Yin Q, Wu QJ, Weng Z, Cao R (2021) Porous metal–organic framework liquids for enhanced CO2 adsorption and catalytic conversion. Angew Chem 133(38):21083–21088

Ehrling S, Reynolds EM, Bon V, Senkovska I, Gorelik TE, Evans JD, Rauche M, Mendt M, Weiss MS, Pöppl A, Brunner E (2021) Adaptive response of a metal–organic framework through reversible disorder–disorder transitions. Nat Chem 13(6):568–574

Nicks J, Sasitharan K, Prasad RR, Ashworth DJ, Foster JA (2021) Metal–organic framework nanosheets: programmable 2D materials for catalysis, sensing, electronics, and separation applications. Adv Func Mater 31(42):2103723

Juarez-Perez EJ, Ono LK, Maeda M, Jiang Y, Hawash Z, Qi Y (2018) Photodecomposition and thermal decomposition in methylammonium halide lead perovskites and inferred design principles to increase photovoltaic device stability. J Mater Chem A 6(20):9604–9612

Ueoka N, Oku T (2018) Stability characterization of PbI2-added CH3NH3PbI3–x Cl x photovoltaic devices. ACS Appl Mater Interfaces 10(51):44443–44451

Rajvikram M, Leoponraj S (2018) A method to attain power optimality and efficiency in solar panel. Beni-Suef Univ J Basic Appl Sci 7(4):705–708

Abouelregal AE, Akgöz B, Civalek Ö (2023) Magneto-thermoelastic interactions in an unbounded orthotropic viscoelastic solid under the Hall current effect by the fourth-order Moore–Gibson–Thompson equation. Comput Math Appl 141:102–115

Civalek Ö, Uzun B, Yaylı MÖ (2022) An effective analytical method for buckling solutions of a restrained FGM nonlocal beam. Comput Appl Math 41(2):67

Jalaei MH, Thai HT, Civalek Ӧ (2022) On viscoelastic transient response of magnetically imperfect functionally graded nanobeams. Int J Eng Sci 172:103629

Numanoğlu HM, Ersoy H, Akgöz B, Civalek Ö (2022) A new eigenvalue problem solver for thermo-mechanical vibration of Timoshenko nanobeams by an innovative nonlocal finite element method. Math Methods Appl Sci 45(5):2592–2614

Abouelregal AE, Ersoy H, Civalek Ö (2021) Solution of Moore–Gibson–Thompson equation of an unbounded medium with a cylindrical hole. Mathematics 9(13):1536

Akgöz B, Civalek Ö (2022) Buckling analysis of functionally graded tapered microbeams via Rayleigh-Ritz method. Mathematics 10(23):4429

Dastjerdi S, Akgöz B, Civalek Ö (2020) On the effect of viscoelasticity on behavior of gyroscopes. Int J Eng Sci 149:103236

Ashery MH, Elnouby M, EL-Maghraby EM, Elsehly EM (2023) Structural control of V2O5 nanoparticles via a thermal decomposition method for prospective photocatalytic applications. Beni-Suef Univ J Basic Appl Sci 12(1):1–15

Zhu R, Pan E, Roy AK (2007) Molecular dynamics study of the stress–strain behavior of carbon-nanotube reinforced Epon 862 composites. Mater Sci Eng, A 447(1–2):51–57

Sui G, Zhong W, Yang X, Zhao S (2007) Processing and material characteristics of a carbon-nanotube-reinforced natural rubber. Macromol Mater Eng 292(9):1020–1026

Medupin RO, Abubakre OK, Abdulkareem AS, Muriana RA, Abdulrahman AS (2019) Carbon nanotube reinforced natural rubber nanocomposite for anthropomorphic prosthetic foot purpose. Sci Rep 9(1):1–11

Acknowledgements

The authors acknowledge the Surface Engineering Research Laboratory (SERL)

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

Authors declare that there are no conflicting interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dada, M., Popoola, P. Recent advances in solar photovoltaic materials and systems for energy storage applications: a review. Beni-Suef Univ J Basic Appl Sci 12, 66 (2023). https://doi.org/10.1186/s43088-023-00405-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s43088-023-00405-5