Abstract

Metamaterials and metasurfaces of artificial micro-/nano- structures functioning from microwave, terahertz, to infrared regime have enabled numerous applications from bioimaging, cancer detection and immunoassay to on-body health monitoring systems in the past few decades. Recently, the trend of turning metasurface devices flexible and stretchable has arisen in that the flexibility and stretchability not only makes the device more biocompatible and wearable, but also provides unique control and manipulation of the structural and geometrical reconfiguration of the metasurface in a creative manner, resulting in an extraordinary tunability for biomedical sensing and detection purposes. In this Review, we summarize recent advances in the design and fabrication techniques of stretchable reconfigurable metasurfaces and their applications to date thereof, and put forward a perspective for future development of stretchable reconfigurable metamaterials and metasurfaces.

Similar content being viewed by others

Introduction

Metamaterials are artificial materials that possess unique electromagnetic properties well exceeding those of naturally occurring materials, such as the ability to achieve a negative index of refraction for cloaking applications. In 1968, Veselago first conceived and experimentally demonstrated the possibility of negative permittivity and negative permeability, previously considered impossible in natural materials [1]. In 1999, Pendry et al. proposed using a regularly structured split ring resonator (SRR) in order to achieve negative permeability and negative permittivity simultaneously [2] in the microwave regime. The viability of Pendry’s idea was subsequently confirmed in 2000 by Smith et al., who successfully experimentally demonstrated [3] verified the negative refractive index for the first time [4].

The two-dimensional form of metamaterial is termed metasurface. Due to its planar nature and ease of fabrication, it possesses unique optical properties that contribute to the mechanical flexibility and thus great potential of wearable devices. In recent years, metasurfaces have been the focus of intense research and study due to their potential for applications in various fields such as state-of-the-art optical, microwave, and plasmonic devices. In addition, the ability to manipulate the phase and amplitude of light at the sub-wavelength scale, as well as the compatibility with conventional semiconductor and integrated circuit fabrication techniques, have made metasurfaces ideal candidates for the development of novel optical components and devices. For example, some metasurfaces may exhibit strong scattering effects due to the patterning of meta-particles [5]. Namely, by embedding metal in the substrate, a tunable and reconfigurable photonic metasurface can be realized [6]. All of the above principles have been translated into practical applications. As for the applications of metasurfaces, there are many similar research areas, such as the Frequency Selective Surface (FSS) introduced by Munk’s team in 1974 [7], wavefront modulation engineering based on the special electromagnetic properties [8,9,10], perfect absorbers [11,12,13], electromagnetic invisibility cloaks [14,15,16,17,18], perfect lenses, metalens and superlenses [19,20,21,22,23]. Due to these special structures and unique properties, metamaterials and metasurfaces are widely used in various kinds of practical applications such as biosensing [24, 25], cancer detection [26], immunoassay [27, 28], imaging [29] especially bioimaging [30,31,32], communication and electromagnetic wave control [33,34,35,36,37,38,39].

In fact, major applications of metamaterials and metasurfaces have been focusing on devices functioning in terahertz regime, such as metamaterial perfect absorbers, from an electromagnetic and mechanical perspective. Tao et al. presented a metamaterial perfect absorber with strong resonance at terahertz frequencies in 2008 [40], and then built the impressive stand-up metamaterial in 2011 [41], which paved the ways for many potential reconfigurable metamaterial applications. In 2016, Ee et al. built a tunable metasurface on a stretchable substrate [6]. In the subsequent year, they implemented this research to develop practical metasurface holography [42]. Alternative typical tuning mechanisms include utilizing 2D materials [43,44,45,46], vanadium dioxide [47,48,49,50], and topological materials [51,52,53,54,55] for precise modulation of terahertz waves. Indeed, diverse applications exhibit unique characteristics; nevertheless, the demand for enhanced flexibility, reconfigurability, or stretchability has propelled remarkable advancements in these domains in recent years.

With the development of materials science and advances in fabrication techniques, people have developed higher demands on the performance of metamaterials, such as more biocompatible, flexible, stretchable, biocompatible and wearable, which drive the innovative development in the field of metasurfaces. To meet these increasing demands for flexibility and scalability, many novel devices have been creatively designed and fabricated over the past decades. For example, the “island-bridge” strategy that interconnects discrete rigid devices with knots introduces stretchability and scalability; the auxetic stretchable electronics with designed pattern and structure that allows native material to achieve negative Poisson’s ratio; the origami/kirigami structure [24, 34,35,36, 56,57,58,59] inspired by traditional Asian paper folding and cutting art, the bionic structure inspired by animals[60], the tunable structure such as MEMS-driven metasurfaces [61,62,63], the epidermal electronics system [64].

There have already been many excellent reviews on the specific areas such as electromagnetic wave perfect absorbers [65, 66], electromagnetic [67,68,69], bioimaging [70], the classification and applications of metamaterials [71,72,73,74], the fundamental principle [75, 76] and reviews focusing on the flexible and reconfigurable metasurfaces [77,78,79,80,81]. In this Review, we provide a comprehensive overview of the mechanism of metasurface reconfiguration, the development of related fabrication techniques and some innovative points in future trends of metamaterials and their applications. Also, we highlight the challenges and future directions in this rapidly growing field.

Tuning mechanisms of flexible metasurfaces

In their early stages, metamaterials operate mostly in the microwave range [2, 4, 82]. As the operating frequency of the metasurfaces rises into the terahertz regime, the corresponding subatomic wavelengths become shorter. The structures of metasurfaces thus become more refined and miniaturized than before, and the actuation mechanism for the reconfiguration of metasurfaces also becomes more diverse and complicate. In addition, reconfigurable metasurfaces have made many breakthroughs compared to ordinary metasurfaces, such as combining multiple functions in a single device and achieving dynamic tunability of working parameters [37, 83, 84].

To meet the need for flexibility and stretchability in practical applications, many different structures based on different mechanisms have been proposed. There are many different types of common mechanical tuning mechanisms, such as micro-electro-mechanism systems (MEMS) [62, 63, 85,86,87], origami/kirigami and chiral structures [56,57,58,59, 88,89,90,91]. In addition, some novel tuning mechanisms such as photoactuation[92,93,94,95], electroactuation [9, 96] and magnetoactuation [97, 98] also play important roles in the tuning function of metasurfaces. Different tuning mechanisms have their own characteristics in the achieving of the tuning and reconfiguration function of metasurfaces, such as exploiting the physical properties of the material itself, exploiting the special properties of the artificially designed structure, and so on. It is worth mentioning that the operating frequency range can be further extended to infrared and even visible light, which also have numerous applications, similar to the reconfigurable and tunable metamaterials. The optical response of metasurfaces is in most cases strongly influenced by the deformation of the substrate due to its flexible or tunable properties. The realization of the flexibility and stretchability of reconfigurable metasurfaces is partly due to the wide application of flexible substrates.

In this section, we summarize how the reconfigurable metasurfaces with different functions are actuated using different tuning mechanisms, and representative examples are listed in Fig. 1 to illustrate this point.

Schematic diagram of metamaterials and metasurfaces from the negative refraction theory to their applications (Stretchable absorber, e-skins, immunoassay, bioimaging, cancer detection, metalens and cloaking) [6, 19, 26, 99,100,101,102,103,104]. Copyright 2004, Taylor & Francis. Copyright 2020, John Wiley and Sons. Copyright 2015, Springer Nature. Copyright 2015, John Wiley and Sons. Copyright 2017, Springer Nature. Copyright 2021, De Gruyter. Copyright American Chemical Society, 2016. Copyright 2021, Optica Publishing Group. Copyright 2020, MDPI

Mechanical tuning

There are several traditional mechanical tuning methods for reconfiguration. Micro-electro-mechanical systems (MEMS), with their advantages of compact structure, low power consumption and efficient performance, have been widely used for metasurface tuning in various fields [136,137,138]. Microscale MEMS devices are typically made for sensing, control, and actuation. The use of MEMS devices could ultimately achieve the purposes such as achieving motion, flexibility or tunability at macroscopic level. Researchers have also proposed many mature solutions for both in-plane and out-of-plane metasurface reconfiguration using mature MEMS technology, ultimately leading to many different types of reconfigurable metasurface devices [139]. The use of MEMS-actuated metasurfaces enables simple and efficient implementation of the tuning and reconfigurable functions. Over the past decades, researchers have used MEMS to build many reconfigurable devices in different wavelengths such as microwave and terahertz fields, to achieve functions such as perfect absorbers [12, 140], sensors [138], modulators and filters [62], and detectors [141].

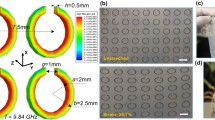

After presenting their research of terahertz metamaterial absorber [40], Tao et al. showed the mechanism of how MEMS based technology actuate the metasurfaces with tight configurability in 2009 [142]. This presented their discovery of reconfigurable terahertz metamaterials, which have the potential to realize novel electromagnetic functionalities such as reconfigurable cloaks, absorbers, and thermal detectors. They use different materials to build the basic pattern, the split resonator rings and the microcantilevers. Due to the different coefficients of thermal expansion of different materials, once the above metasurfaces are treated by rapid thermal annealing (RTA), the different out-of-plane angles produced by the two materials will cause the cantilever to tilt. Researchers often achieve the desired functionality by flexibly changing the angles, which will be discussed later. Many advances have been made in the field of mechanical tuning and the use of MEMS cantilevers. For example, in 2014, Pitchappa et al. doubled the tunable range and greatly improved the switching contrast in the terahertz region by adjusting the structure and number of cantilevers [143]. Then, in 2015, Pitchappa et al. demonstrated their subwavelength MEMS cantilevers for dynamic manipulation of terahertz waves [136]. Their design can achieve different modulation depths depending on the length and the out-of-plane angle of the microcantilevers. The actual effect is very close to the simulation. Later in 2017, Pitchappa et al. performed experiments on thermal tuning of cantilevers [144]. Unlike the previous designs, the new design optimizes the mechanical and thermal properties, allowing bidirectional reconfiguration in the temperature range of 77 to 400 K. Common mechanical tuning devices are shown in Fig. 2.

Mechanical tuning devices. a Single-material kirigami structure sheet under biaxial tension. Reproduced with permission from [105], copyright John Wiley and Sons, 2022. b Miura-ori chiral metamaterials with split-ring resonators. Reproduced with permission from [106], copyright John Wiley and Sons, 2017. c Reconfigurable SRR structure based on kirigami and its cantilevers structure. Reproduced with permission from [107], copyright Springer Nature, 2018. d Metasurface on stretched polydimethylsiloxane (PDMS) substrate. Reproduced with permission from [6], copyright American Chemical Society, 2016. e Illustrations of the stretchable device while applying a biaxial stretching force. Reproduced with permission from [108], copyright John Wiley and Sons, 2019. f Diagram of a bilayer metasurface covered with Al-PI. Reproduced with permission from [100], copyright John Wiley and Sons, 2020

Additionally, Tao et al. successfully fabricated and demonstrated their MEMS-based reconfigurable metamaterials at the terahertz frequencies in 2011 [85]. They designed some more complicated materials that allow some meta-atoms to stay remain while allowing others to move in orthogonal directions. They offer a novel design for tunable or reconfigurable metasurfaces since their design is principally realized by adjusting the cantilever beams structure or the distribution of meta-atoms. Similarly, Han et al. conceived, and fabricated two different types of MEMS based tunable reconfigurable metamaterials [62, 137] with different parameters and properties in 2014. They designed efficient tunable terahertz filter and modulator with a simple structure. By adjusting the SRR arm-gap and air-gap, the proposed metamaterials can accomplish the goal of obtaining variable transmission coefficients under various voltage-controlled switching ON or OFF states. Alves et al. built terahertz sensor in a different approach. In addition to the ultra-high absorbance at terahertz band, they also achieved the function of converting terahertz to infrared by fabricating double metasurface on a common ground [138]. Alves used thermal insulating legs instead of the bi-material legs in order to meet different requirements for thermal functions, while simplifying the fabrication processes. In addition, Manjappa et al. developed a multiple-input-output (MIO) state with voltage-controlled ON and OFF states for logic operations at terahertz frequencies based on reconfigurable MEMS metasurfaces [63]. The new structure of the MIO state shows the possibility and potential of reconfigurable metasurface development in the digital and computing field in the future.

In addition to the mature MEMS technique, there are two widely used techniques called origami and kirigami. These techniques are derived from the traditional Asian paper folding and cutting art. There are already many novel structure designs of stretchable reconfigurable metasurfaces and metamaterials inspired by origami [145] or kirigami [146, 147].

Origami and Kirigami are actually very different from each other in that they have different structures, working principles, and energy storage mechanisms. In contrast, kirigami achieves its stretchable and reconfigurable functions mostly by cutting apart parts connected by knots. In 2021, Jiang’s team investigated mechanical metamaterials based on origami and kirigami. In addition, they classified the mechanical metamaterials into three categories based on the method of folding or cutting the thin film materials: origami only, kirigami only, and origami and kirigami combination [59].

In order to improve the stretchability and reconfigurability of metamaterials and metasurfaces to meet the novel requirements of practical devices, origami/kirigami-based structures have been widely used in many fields [56, 58]. There are many application areas for stretchable and reconfigurable metasurfaces and metamaterials, such as flexible sensors and detectors, reconfigurable antenna [23, 25, 32], etc.

Using origami/kirigami structures, Liu et al. fabricated a novel capacity pressure sensor with wide sensing range based on the origami [14] in 2021. In addition to the different structure, they experimented with mixing different types and dose of dielectric materials, such as carbon nanotubes (CNTs) and BaTiO3(BTO), into the polydimethylsiloxane (PDMS) substrate. Eventually, they found the right combination that allowed them to achieve a wide range of pressure and reconfiguration function.

In addition to designing structures using origami/kirigami alone, researchers have created a variety of unique devices that combine various devices with such structures to improve performance or achieve novel functions. For example, Zhu et al. proposed their design of a complex micro-origami structure that can be controlled and rapidly deformed in 2020 [113]. They combine the device with MEMS functionality, elastic-plastic materials, and origami structures to achieve functions that cannot be achieved by ordinary origami structures alone. Recently, Zheng et al. break the limitation of the unidirectional shortcoming of traditional origami with the proposed bidirectional 3D origami metasurface [148], which has more degrees of freedom and provides a highly efficient approach to 3D photonic devices.

It is worth mentioning that the Miura origami [149], a widely used origami structure introduced by Miura in 1980, provides new design ideas for reconfigurable structures due to its negative Poisson’s ratio and multiple degrees of freedom. In 2012, Nishiyama showed how to make the Miura structure and early applications of the Miura structure in the field of mapping and space exploration [150]. In addition, the Miura Origami structure has been widely used in the field of electromagnetic control for decades. By taking advantage of its reconfigurable and deployable characteristics, it can achieve the flexible tuning of electromagnetic devices and other functions. For example, Wang et al. proposed a reconfigurable metamaterial for tunable chirality by folding the plate with SRRs into different enantiomers [106]. Similarly, Zhang et al. designed and fabricated a metasurface to reduce the radar cross section based on different origami structures including the Miura-origami [151].

Kirigami has several applications in a wide range of industries. In order to apply the metasurfaces to conformal devices, kirigami structures are used to improve the stretchability and reconfigurability of the metasurfaces. To illustrate, Jing et al. used the kirigami approach to transform the two-dimensional metasurface structure into a three-dimensional structure with better reconfigurable properties [107]. Jiang et al. designed an adaptive conformal electronic skin inspired by snake skin and kirigami structure, which can well exploit the stretchability, flexibility and conformability of kirigami structure [105].

We believe that mechanical tuning mechanisms such as MEMS and origami/kirigami will continue to play an important role in the disciplines of stretchable and reconfigurable metasurfaces. The potential of metasurfaces will be realized by merging metasurface design with more specially designed origami structures, such as Miura origami. For instance, frequency tunable FSS or perfect absorbers in the field of electromagnetic waves, or the tunable antenna [34,35,36, 57] in the field of communications.

Photoactuated tuning

By virtue of its capacity to transmit both information and energy, light has found wide-ranging applications in the fields of communication and energy conversion. Over the past few years, a growing number of researchers have turned their attention to light-driven tunable and reconfigurable metasurfaces, owing to their distinctive modes of actuation and tremendous potential in the realms of electromagnetic and communication engineering. The light-driven tunable mechanism confers upon these metasurfaces the ability to exhibit diverse performance parameters or functions in response to a variety of control beams and other stimuli. The photon-based control methods employed typically operate on distinct principles. Figure 3 offers some examples of photoactuated tuning devices.

Photoactuation devices. a Illustration of principle for soft opto-mechanical reconfigurable device. Reproduced with permission from [109], copyright Elsevier, 2021. b Diagram of working principle for the Ge2Sb2Te5 (GST) based metasurface. Reproduced with permission from [110], copyright John Wiley and Sons, 2020. c Schematic of photon-induced metasurface in the silicon wafer. Reproduced with permission from [111], copyright John Wiley and Sons, 2019. d Diagram of holographic metasurface gas sensor platform. Reproduced with permission from [112], copyright AAAS, 2021

First, light can serve as a means to manipulate specifically-engineered material structures in order to achieve controlled switching states or targeted deformation patterns within the device. In this way, these devices exhibit photon-driven tunable functionalities. For example, reconfigurable deformation of a bilayer material can be achieved using thermal energy transferred by infrared light [94]. Similarly, Pau et al. proposed the reconfigurable artificial iris based on flexible metamaterial has achieved ultra-broadband optical absorption [109].

Second, in addition to the aforementioned devices, the performance characteristics of existing metasurfaces or metamaterials can also be adjusted to specific wavelengths of light beam transmission, absorption, or polarization, through the utilization of photoactuated tuning and apparent deformation structures. By exploiting the ability of sapphire-based metamaterials to change their transmission coefficient for terahertz waves with infrared light for this attribute [152], Gu et al. developed a new function for tunable transparency. Shcherbakov et al. proposed their optical metasurfaces that can realize ultrafast all-optical tuning through the specific structure and material design, which has great potential for the active control of light propagation [153].

Finally, the use of photosensitive substrates enables light-modulated planar metasurfaces. By irradiating thin silicon wafers with femtosecond lasers, dynamic metasurfaces and the ability to spatially modulate them can theoretically be efficiently applied in areas such as streaming holograms and variable focal length lenses [152]. Many related devices have been used in areas such as hologram and imaging gas detection [112]. In the future, improving the flexibility and stretchability of these rigid metasurfaces will be a popular trend.

Electroactuated tuning

Similar to the MEMS based reconfigurable structures proposed by Tao et al., Ma et al. also used a cantilever beam composed of two materials to design a reconfigurable metasurface [96]. However, the latter uses voltage rather than thermal properties to adjust the deformation of the cantilever beam. There are also many planned electrically powered reconfigurable devices [154, 155].

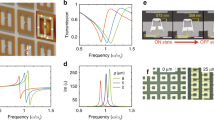

The use of electrically-controlled deformation offers advantages of both efficiency and precision. Indeed, when combined with structures such as origami, electrical actuation permits the attainment of perfect equilibrium between external forces, deformation, and electrical actuation. Furthermore, in addition to its use in directly controlling the deformation of structures, electrical modulation can also enable manipulation of the optical properties of metasurfaces [156, 157]. For example, by applying a voltage to both sides of the metasurface, the structure or properties of the meta-atoms themselves are changed, and the tuning of the optical properties of the metasurfaces becomes controllable. Some dielectrics, such as liquid metal or liquid crystal, can also be controlled by electrical methods, making these materials useful in the design of electrically controlled devices. For example, Bosch et al. created a varifocal lens by electrically driven tuning of the dielectric properties [115]. Vassos et al. achieved the dynamic phase shift with their tunable piezoelectrically actuated metasurfaces [158]. Kwon et al. also proposed their Nano Electro Mechanical System (NEMS) tunable metasurface based on voltage-controlled dielectric [117]. Some examples of electroactuation devices are shown in Fig. 4.

Electroactuation devices. a Schematic of voltage-controlled cantilever. Reproduced with permission from [96], copyright Springer Nature, 2014. b Illustration of electrothermal micro-origami. Reproduced with permission from [113], copyright John Wiley and Sons, 2020. c Diagram of omega-ring metamaterial arrays controlled by MEMS. Reproduced with permission from [114], copyright AIP Publishing, 2014. d The electrically actuated varifocal lens. Reproduced with permission from [115], copyright American Chemical Society, 2021. e Schematic of electrically-controlled digital metasurface. Reproduced with permission from [116], copyright Springer Nature, 2020. f Schematic illustration of NEMS-tuning metasurface. Reproduced with permission from [117], copyright American Chemical Society, 2021

Magnetoactuated tuning

In addition to metasurfaces based on the control and regulation mechanisms mentioned above, there is another type of reconfigurable metasurface that is often controlled by magnetic fields. Magnetically actuated, or magnetoactuated tuning methods generally exploit the sensitivity of certain materials to magnetic fields to provide tunability for metasurfaces. The structure of magnetically actuated metasurfaces typically varies with the intensity of the electromagnet field [119, 120].

Magnetic tuning shares commonalities with several of the other conditioning mechanisms mentioned above. For example, during the fabricating process, metal materials and structures that are sensitive to magnetic fields can be appropriately designed so that they can be easily adjusted from within using the magnetic field in the device’s operating environment. In addition, it is possible to directly use a magnetic fluid or similar materials, whether on a macroscopic or microscopic scale, to achieve a function in which the shape structure, strength, and other properties of the material change with the change in magnetic field strength. In particular, electric and magnetic fields can be combined to use Lorentz forces to produce a recoverable deformation of a flexible material in the desired direction and size [97].

In summary, whether it be thermal, electrical, or electromagnetic, there are numerous studies, tests, and potentially mature applications. Different mechanical mechanisms or other actuation methods make sense, no matter how the configuration of metasurfaces and metamaterials is realized. The various actuation methods have different specific characteristics from the point of the view of concepts and applications, but they also share some similarities. In practical applications, several mechanisms usually work together to achieve the best modulation effect. By combining different structures or designs with different actuation mechanisms, disadvantages such as inefficient control or manufacturing complexity that arise when one mechanism is driven alone can be overcome. Here, typical magnetoactuated tuning devices and schematics are listed in Fig. 5.

Magnetoactuated Tuning devices. a Deformation of array under the magnetic-actuation. Reproduced with permission from [118], copyright John Wiley and Sons, 2020. b Illustration of electrothermal deformation in static magnetic field. Reproduced with permission from [97], copyright AIP Publishing, 2015. c Schematic illustration of 3D deformed patterns under different magnetic field actuation. Reproduced with permission from [119], copyright AIP Publishing, 2022. d Schematic of magnetic plasmonic metasurface. Reproduced with permission from [98],copyright American Chemical Society, 2020. e Deformation of MR fluid–filled lattice. Reproduced with permission from [120], copyright AAAS, 2018. f Schematic of magnetophotonic metasurface that can manipulate the light intensity. Reproduced with permission from [121], copyright Elsevier, 2018

Fabrication of flexible and stretchable metasurfaces

After discussing the origin and development, the working principle of metasurfaces and metamaterials, and the various mechanisms that make them reconfigurable, this section summarizes various fabrication techniques applied to different types of flexible and stretchable metasurfaces.

Micro/nano fabrication technologies

When it comes to the fabrication, there are many traditional fabrication technologies such as deep-ultraviolet lithography, electron lithography, laser direct writing lithography and so forth. In general, fabrication technologies can be divided into two categories: subtractive manufacturing and additive manufacturing, according to the subtraction or addition of materials during the manufacturing processes.

Subtractive manufacturing

In terms of subtractive manufacturing, the most conventional micro- and nano-manufacturing technology is lithography. Lithography can be divided into mask lithography, laser direct writing lithography and so on according to the working method. Besides, it can be divided into ultraviolet lithography, deep ultraviolet lithography and extreme ultraviolet lithography according to the wavelength of ultraviolet rays. Lithography plays a significant role in the fabrication of metasurfaces. The corresponding lithography technology applied in the fabrication of specific metasurface is different because there are different specific requirements in different application fields. Usually, metasurfaces are composed of arrays of periodic or aperiodic arrays meta-atoms on the substrate, which can be rapidly fabricated using lithography technology. For example, J.-S. Park et al. successfully fabricated 45 metalenses (Fresnel lens) at a time on a 4 in. fused-silica wafer with deep-ultraviolet projection lithograph [122]. Jiao et al. fabricated passivated aluminum nanopillars by etch on wafer to achieve their design of flexible immunosensors [159]. However, lithography technologies mentioned above have difficult in the fabrication of metasurfaces consist of large-scale pattern or metasurfaces based on flexible or stretchable substrates.

In order to improve the fabrication efficiency of large-scale pattern metasurfaces that are based on flexible substrates, various novel fabrication technologies such as nanoimprint lithography (NIL) had been proposed over the past several decades. The NIL was firstly introduced by SY Chou et al. in 1996 [160]. Similar to the cupper paddle print technique derived from ancient China, the NIL possesses many advantages like high efficiency, high resolution and relatively low costs. To date, NIL has been employed in the fabrication of numerous practical devices, such as sensors based on metasurface [28], silicon meta-lens [161] and various others [162]. Besides, NIL can be divided into three types according to imprint contact types: plate-to-plate (P2P) NIL [163], roll-to-plate (R2P) NIL [164], and roll-to-roll (R2R) NIL [165,166,167]. Different kinds of metasurfaces can be fabricated by combining different materials with different fabrication technologies. For example, NIL can transplant flexible materials to fabrication flexible or stretchable electronics rapidly [168, 169].

Besides the utilization of NIL technology, various other fabrication methods have been employed in the production of flexible metasurfaces in recent years. Z. Liu et al. fabricated their design of hybrid terahertz metamaterials based on the silk substrate via water lithograph in 2019 [170]. Nanochannel-guided lithography (NCL) can be used to fabricate nanochannels on substrate for future usage as small period gratings [171]. Both the water lithography based on silk or other substrates and the NCL have great inspiration for the design and development of flexible metasurface. Commonly used top-down fabrication techniques are shown in Fig. 6.

Top-down fabrication techniques (photolithography, e-beam lithography (EBL), nanoimprinting). a Schematic illustration of fabrication processes with deep ultraviolet (DUV) lithography and dry etch. Reproduced with permission from [122], copyright American Chemical Society, 2019. b Schematic of high-index dielectric metasurface. Reproduced with permission from [123], copyright John Wiley and Sons, 2018. c Schematic diagram of the fabrication processes for flexible PDMS-based microdevices. Reproduced with permission from [81], copyright AIP Publishing, 2015. d Schematic illustration of the fabrication process for multi-scale hierarchical structure. Reproduced with permission from [124], copyright American Chemical Society, 2017. e Full processes of PDMS mold fabrication with direct etch and soft UV-NIL. Reproduced with permission from [125], copyright Elsevier, 2022

Additive manufacturing

When it comes to additive manufacturing, there already have many technologies have been applied in the fabrication of flexible and stretchable metasurfaces. For example, ink-jet printing [172] and 3D printing technique [173] that can directly print the pattern layer-by-layer on different kinds of flexible and stretchable substrates. Dip-Pen nanolithography (DPN) and two-photon polymerization (2PP) that enable printing periodical pattern array in a quiet short time are used in the direct fabrication of micro 3D structure in large scale.

From the point of view of device structure, since metasurfaces are composed of many meta-atoms, this means that it is important to manufacture meta-atoms. In addition, the relative position of the meta-atom and substrate differs in the choice of manufacturing technology. For instance, the frequency selective surface needs split resonator rings in different size to gain the peak of absorbance at different frequency, which usually takes 30-3000 μm to attain the regime of terahertz. Typically, a metasurface is consisted of periodical or non-periodical patterns array in micro- or nano-scale. It is important to fabricate patterns array as a whole object, which means fabricate one pattern one time will take extremely long time to finish a whole metasurface. As a result, the corresponding subatomic wavelength becomes lower, which makes the structures are more detailed than previously and raises the bar for fabrication technology.

Nowadays, whether it is inkjet printing or 3D printing, the manufacturing accuracy has been greatly improved, and micro- and nano-scale printing can be rapidly realized on various materials. Kashiwagi et al. took good usage of inkjet print in fabrication of flexible and stackable materials working in terahertz region [172]. Ahn et al. fabricated their origami structures design in a planar by 3D print technique and then fold then into 3D structures [174]. Dip-pen nanolithography was firstly carried out by Mirkin et al. in 1999 [127]. Polymer pen lithography (PPL) was firstly conceived by Huo, F. et al. in 2008 [126]. Both Dip-pen and PPL can fabricate large scale micro/nano pattern in a quiet short time. Latterly, Bunea et al. described the PPL from Configurations and Parameters layers [129]. Similarly, two-photon polymerization (2PP) even multi-photon polymerization technique have been widely used in large scale manufacturing of nano-structure because of its high efficiency. Geng et al. used 2PP to complete ultrafast 3D micro nano-fabrication [175].

Flexible metasurfaces and metamaterials could already be quickly and accurately fabricated using a variety of ways. However, which technology to choose relies on the type of functioning mechanism that metasurfaces or metamaterials are based on. This implies that different metasurfaces or metamaterials device designs in different sectors match to different fabrication technologies, demanding a detailed analysis of the relevant circumstances. Commonly used bottom-up fabrication techniques are shown in Fig. 7.

Bottom-up fabrication technologies (3D printing, self-assembly, soft lithography including Dip-Pen nanolithography (DPN)). a Schematic of how polymer pen lithography works. Reproduced with permission from [126], copyright AAAS, 2008. b Schematic of working principle of DPN. Reproduced with permission from [127], copyright AAAS, 1999. c Schematic of specific setup of two-photon polymerization (2PP) fabrication during experimental. Reproduced with permission from [128], copyright John Wiley and Sons, 2019. d Schematic illustration of the micro structure print by two-photon polymerization. Reproduced with permission from [129], copyright MDPI, 2021

Flexible metasurfaces

Fabricating a common metasurface on a rigid substrate is similar to fabricating chips on a silicon wafer. The structure and pattern need to be designed in advance. Engineers can then select the most appropriate additive or subtractive manufacturing method based on the pre-designed dimensions of the structure or pattern. This enables the fabrication of corresponding metasurface devices on specific substrate materials. Most traditional metasurfaces are based on rigid substrate such as wafers or metal plates. Those devices are relatively easy to design and fabricate. Comprehending the operational mechanisms of flexible metasurfaces across diverse application domains, as well as their specific composition and structure, is fundamental to comprehending their creation and fabrication. Indeed, the technology employed in fabrication is closely contingent on the size and structure of the constituent meta-atoms comprising the metasurfaces, as well as the functional principles governing their operation.

Subtractive manufacturing techniques not only have been used in rigid substrates, but also can be devoted into the fabrication of flexible metasurfaces. Metasurfaces can be constructed on a variety of substrates, with the choice of substrate depending on the intended usage scenario. For instance, a rigid substrate such as silicon may be suitable for applications operating in a more typical setting, while a flexible polymer like PDMS may be preferred for fabricating flexible devices. Except for traditional rigid substrates such as silicon wafer or metal plates, there are many other materials can be used as the substrate of flexible metasurfaces, such as polyethylene terephthalate (PET), polyethylene naphthalate (PEN), polyimide, and PDMS. The flexibility and stretchability of metal materials are commonly increased with the decreasing of the grain size, whether the meta-atoms made from rigid or flexible materials. The mechanical performance of metal materials will significantly increase, especially when they are finely processed to be micro- or nano-structured.

As for the corresponding fabrication technology, additively fabrication techniques such as 3D print, dip-pen lithograph and 2PP technology can easily fabricate patterns on both rigid and flexible planar substrates. Soft lithograph is another widely used technology for flexible substrate based metasurfaces and metamaterials. To illustrate, David et al. fabricated the metal-only modulated metasurface antennas with the help of additively manufacturing technology [176]. Dong Qin et al. summarized related techniques in their protocol in 2010 [177].

Intrinsically stretchable metasurfaces

The process of fabricating flexible and stretchable metasurfaces may differ across certain application domains. As noted previously, the fabrication of flexible metasurfaces can be achieved through various direct methods. However, intrinsically stretchable metasurfaces may require additional steps in their production. Furthermore, some flexible metasurfaces feature only flexible substrates, while others may incorporate dielectrics such as liquid metal, thus imposing diverse requirements on the underlying fabrication technologies.

In contrast to metasurfaces where only substrates are flexible and meta-atoms are rigid and those that achieve tensile properties through structure. There are inherently flexible metasurfaces whose substrates and conductive patterns are made of flexible or stretchable materials. Those intrinsically stretchable metasurfaces can be a better solution of implantable devices to reduce problems like mismatch and rejection reaction for patients.

For instance, Wang et al. designed an intrinsically stretchable electronic for the monition of dynamically moving organs [178]. They took styrene-ethylene-butylene-styrene (SEBS) elastomer as stretchable substrate, liquid metal as stretchable conductive and nanocomposite as the electrodes. With the natural flexibility of those basic materials, the proposed electronic has ultrahigh deformability, which means that this electronic can be completely attached to a non-planar surface. By integrating these layers together, the fabrication of the intrinsically stretchable electronic chip is completed. There are many novel designs of intrinsically stretchable metasurfaces inspired by nature or body. To illustrate, Fan et al. successfully created a skin-like, ultrathin metasurface in a stretchable structure [100]. Zhang et al. devised a flexible, all-dielectric metasurface which they fabricated on a PET substrate using lithographic techniques [179].

Applications

Flexible and stretchable reconfigurable metasurfaces are typically developed based on a range of principles and design methodologies, including those related to electromagnetism and mechanisms. Consequently, these metasurfaces find applications across several different, yet inherently related fields, such as bioimaging, bio-detection, and communication, among others. In the subsequent subsections, we outline several representative fields with examples of practical applications in everyday life.

Bioimaging

Metasurfaces have their wide usage in bio-medical field. Bioimaging is one of those examples. Taking advantages of the controlling ability of electromagnetic waves, metasurfaces could be used as the imaging devices in different scales. Through analyzing the metasurfaces’ transmission, reflection and scattering ratio for lights, the intensity, phase and polarization of lights can be obtained. Optical bioimaging can be carried out by using this information. Metasurfaces have improving the quality and efficiency of bioimaging because of those unique optical properties and optic-controlling abilities mentioned above.

Metasurfaces have a long history in imaging and can be used at different scales, regardless of physical scale or electromagnetic spectrum. In some large-scale imaging fields, mature techniques such as millimeter wave, X-ray and magnetic resonance are widely used. Bioimaging has its wide usage in the whole spectrum from radio-frequency, micro-wave to terahertz, infrared frequency and optical, and bioimaging often uses fluorescence, ultrasound, X-ray and magnetic resonance as imaging sources. Gollub et al. demonstrated their imaging method in human-scale based on millimeter wave [103]. Dawood Alsaedi et al. also designed a metasurface biomedical imaging device on thin film working in the microwave regime in 2021 [30]. Additionally, applications of terahertz and millimeter waves in imaging have been noticed by researchers for recent years because of their great potential for biomonitoring and imaging, etc. The main reason is that the wave radiation in the terahertz band is non-ionized, and it can also deeply detect non-metallic and other materials that are opaque to terahertz, so that it can achieve high resolution and other imaging effects without harming human body. Meanwhile, the wavelength and imaging resolution for various frequency ranges vary.

Imaging and sensing from a nanophotonics perspective are rising research fields. The fundamental principle is similar to a perfect absorber used for the absorbing of transmit waves. For example, the terahertz scale has garnered interests among researchers due to its high efficiency and resolution in the field of imaging, particularly in the area of bioimaging. Escorcia et al. demonstrated their design of a terahertz imager [180] that can detect metallic objects through envelope, and the imager is temperature sensitive because the using of PN diode. On the basis of predecessors, Zhou et al. designed and manufactured a multispectral imaging array device in the terahertz frequency domain that can easily tune and work on multiple discrete THz bands to match different characteristics of the samples to be imaged to obtain color images [181]. To improve the efficiency while processing large data, Zhang et al. took advantages of the principle of furrier transform and proposed the image processing by their reconfigurable metasurface [182].

In bioimaging, real-time imaging methods are frequently utilized to non-invasively visualize biological processes while minimizing patient contact as much as possible. In the practical applications of bioimaging, it is necessary to ensure that the equipment does not cause any uncontrollable harm to patients and operators during operation. For example, the intensity of the lights used during detection cannot be too large, and the contrast agents employed must not be harmful to human body. Many researchers have created matching equipment for implantable needs in addition to the detection and imaging tools used externally. Implantable means the devices cannot be sensitive and harmful to human body, and should be flexible and stretchable enough to fit in the soft inner body environment. For example, Tao et al. presented their devices made of magnesium and silk protein that could degrade at a controlled rate and were completely implantable and resorbable [183]. Several applications in the field of bioimaging are shown in Fig. 8.

Metamaterials and metasurfaces used in bioimaging field. a Image of beetles imaged with metalens multispectral chirality. Reproduced with permission from [88], copyright American Chemical Society, 2016. b Schematic of the tunable metamaterial for Magnetic Resonance Imaging (MRI). Reproduced with permission from [130], copyright John Wiley and Sons, 2022. c Schematic of human-scale computational imaging with metasurface. Reproduced with permission from [103], copyright Springer Nature, 2017

Bioimaging has made great progress for recent decades. Except for expanding the application scale, combining different research fields is another rising topic. To improve the efficiency of human body’s real-time imaging and data processing, Li et al. combined the machine-learning with the metasurface and fabricated the bioimager in 2019 [184]. A recent review by Padilla et al. has provide a comprehensive overview of the history and the influence of metamaterials and metasurfaces on imaging field [185].

Immunoassay

Except for bioimaging, immunoassay is an important biomedical field. Several immunoassay devices have previously been developed and put to use in practical uses [186, 187]. Researchers have become increasingly interested in this combination of immunoassay and metasurfaces in recent decades. With the help of metasurfaces’ unique properties in electromagnetic, the efficiency and accuracy of detection in immunoassay were highly improved. For instance, Amin et al. proposed a graphene metasurface in sensing of virus in terahertz region [188]. Iwanaga designed an all-dielectric metasurface biosensor to detect antibody or antigen in 2020 [189]. Their biosensor highly improved the sensitivity and the accuracy in detection. Tightly the next year, Iwanaga et al. designed another high sensitivity and high throughout detection method for detection of nucleic acid target based on metasurface fluorescence biosensors [131]. Their novel methods are far less complicated than conventional spectroscopic approaches, which require frequency scan.

Except for high sensitivity, the flexibility of detection devices has also been adhered by researchers. In order to make immunoassay surface flexible, researchers have developed a variety of methods. Z. Yu et al. proposed a sensor design that is flexible, incredibly responsive and pressure-sensitive, using paper as the electrode material [190]. Jiao et al. fabricated passivated aluminum nanopillars by etching the wafer to achieve their design of flexible immunosensors [159]. Typical immunoassay applications are shown in Fig. 9.

Metasurfaces used for immunoassay (a) Schematic diagram of graphene-gold metasurface structure ultrasensitive plasmonic for ultrasensitive Plasmonic detection. Reproduced with permission from [102], copyright John Wiley and Sons, 2015. b Schematic of metasurface sensor chip for immunoassay. Reproduced with permission from [131], copyright MDPI, 2021. c Photograph and SEM image of large-area flexible metasurface for tumor markers detection. Reproduced with permission from [28], copyright Elsevier, 2020

Cancer detection

Metasurfaces also have wide usage in cancer detection [191, 192]. Early detection plays an important role in the prevention and treatment of cancer. Thus, in recent years, the control effect of metasurfaces on light at micro/nano-scales has been used by researchers to design and fabricate a varieties of cancer detection devices. There are many advances in the application of metasurfaces in cancer detection fields. Li et al. explored the immunodetection of tumor marks based on complementary plasmonic metasurfaces [27]. Patel et al. have designed a series of high efficiency metasurface sensors for cancer detection based on graphene [133].

There is another kind of metasurface called plasmonic metasurface, which have been widely used in sensing of human tumor markers recently. For example, Zhan et al. built their biosensor for lung cancer cells to cut down the cost of early cancer detection and make it a rapid process [26]. In 2019, Zhu et al. they proposed the portable tumor biosensors based on plasmonic metasurface to accomplish rapid detection of carcinoembryonic antigen (CEA) [193]. Later in 2020, they designed another low-cost plasmonic metasurface sensor for detection of tumor markers in human serum [28] based on former work. With the inventive integration of 3D nanorods into the plasma metasurface, Rakhshani was able to realize the high-quality factor and sensitivity, as well as the broad angle perfect absorb and tunable functions [194]. Their work highly simplified the detection system and reduced the cost of detection devices. Schematic diagram of representative metasurfaces for cancer detection are shown in Fig. 10.

Metasurfaces used for cancer detection. a Schematic of metasurface biosensor for lung cancer cells detection. Reproduced with permission from [26], copyright De Gruyter, 2021. b Schematic and SEM image of metasurfaces for label-free assays of SNPs. Reproduced with permission from [132], copyright Elsevier, 2018. c Different meta-atoms for metasurface-based cancer detection sensors. Reproduced with permission from [133], copyright Elsevier, 2022

Electronic skin

Electronic skin has been developed for many decades, and it has led to numerous practical applications in people’s daily lives. For instance, electronic skin can be employed to monitor real-time physiological parameters of the human body, such as temperature and heart rate. The main feature of electronic skin is that it is similar to human or animal skin. Electronic skin should be flexible, stretchable, conformal and self-healable. Additionally, the electronic skin has many capabilities that human skins do not possess, such as electromagnetic wave emission. The main advantage of electronic skin is that it could be applied to patients’ skin conformally, which means the electronic skin could actually exist like real skin while working as a detection or monitoring device. After treating processes, the electronic skin could be departed from the skin easily without any harming.

In certain fields, electronic skin has been integrated with flexible metasurfaces to exploit their capability in manipulating electromagnetic waves and achieving cloaking effects in visual or other specific frequency ranges. Otherwise, we noticed that the electronic skin used as tactile and prosthetics has risen researchers interests recent decades. The sensibility for pressure and temperature can be used in disabled people’s prosthetics to help them feeling. Those novel prosthetics can also integrate sensors, imaging and other functions for a wider usage. For example, Kim et al. designed an electrodes for a higher comfortable performance [195]. Electronic skin related devices and applications are shown in Fig. 11.

Electronic skins related applications. a Epidermal electronics work at undeformed and stretched states. Reproduced with permission from [64], copyright AAAS, 2011. b Optical micrograph of flexible PCB and surface-mounted electronic components. Reproduced with permission from [134], copyright AAAS, 2018. c A battery-free epidermal electronic device work in wet state. Reproduced with permission from [135], copyright John Wiley and Sons, 2018

It is noteworthy to mention that there exists a type of electronic skin known as Epidermal Electronic Systems (EES), which is specifically designed for applications in biomedical detection and bioimaging. EES comprises integrated circuits that serve various detection functions, and it represents a novel approach to bio-detection that is based on the utilization of metasurfaces. The EES is firstly proposed by Rogers’ team in 2011 [64], they designed the metasurface which could adhere and keep conformal to patients’ skin, in order to dismiss the comfortable and inconvenience brought by the interface of conductive gels between skin and the cold electrodes. Comparing with the devices used in detection and imaging before, the EES takes little space and makes the same difference as them. Then in 2012, S. Wang et al. explain the mechanism of the EES [196]. In 2013, Woon-Hong Yeo et al. proposed the EES which could be printed onto skin directly while integrating sensors of temperature, strain and electrophysiological signals [197]. The EES can even keep high efficiency on the challenging part like knees and elbows. Besides, the EES have commons with traditional integrated circuits and can integrate kinds of circuit like light-emitting diodes (LED) display and temp-sensor in a small scale. Otherwise, there are several advanced functions developed in the EES, such as self-powered sensors and highly breathable and surface-hydrophobic devices that used in long-time monitoring. To illustrate, Zhang et al. listed electronics that are friendly for skin used in real-time health and fitness monitoring in 2019 [198].

In conclusion, the past decade has witnessed significant advancements in the development of electronic skin, which has emerged as highly integrated subject that combines various research fields, such as deep learning, wearable electronics, human-machine interfaces, and others.

Conclusions

In conclusion, the development of metasurfaces, from a fundamental concept to their applications in the field of medicine, shows people a typical representative and extraordinary proof of scientific innovation and highly interdisciplinary cooperation. Since the concept of metamaterials and metasurfaces was proposed, many scientists and engineers have built on them to design and manufacture new devices capable of controlling electromagnetic waves and other physical phenomena. In this process, the development of materials science and the need for practical applications have promoted the birth and progress of flexible reconfigurable metasurfaces. Since then, flexible metasurfaces have made breakthroughs in optics, communications, and other fields, and have now entered new fields of medical applications. With the help of flexible reconfigurable metasurfaces, great progress has been made in bioimaging technologies that can reduce the pain of patients during medical examinations, more efficient and convenient means of virus antibody and cancer detection, and electronic skin that can help people with disabilities provide more convenience in the future. Flexible reconfigurable metasurfaces have the potential to revolutionize the way we approach all aspects of healthcare in the future.

Availability of data and materials

All data generated or analysed during this study are included in this published article.

References

Veselago V. Experimental demonstration of negative index of refraction. Sov Phys Usp. 1968;10:509.

Pendry JB, Holden AJ, Robbins DJ, Stewart W. Magnetism from conductors and enhanced nonlinear phenomena. IEEE Trans Microwave Theory Tech. 1999;47(11):2075–84.

Smith DR, Padilla WJ, Vier D, Nemat-Nasser SC, Schultz S. Composite medium with simultaneously negative permeability and permittivity. Phys Rev Lett. 2000;84(18):4184.

Shelby RA, Smith DR, Schultz S. Experimental verification of a negative index of refraction. Science. 2001;292(5514):77–9.

Chen K, Feng Y, Yang Z, Cui L, Zhao J, Zhu B, Jiang T. Geometric phase coded metasurface: from polarization dependent directive electromagnetic wave scattering to diffusion-like scattering. Sci Rep. 2016;6(1):1–10.

Ee H-S, Agarwal R. Tunable metasurface and flat optical zoom lens on a stretchable substrate. Nano Lett. 2016;16(4):2818–23.

Munk B, Luebbers R, Fulton R. Transmission through a two-layer array of loaded slots. IEEE Trans Antennas Propag. 1974;22(6):804–9.

Xie Y, Wang W, Chen H, Konneker A, Popa B-I, Cummer SA. Wavefront modulation and subwavelength diffractive acoustics with an acoustic metasurface. Nat Commun. 2014;5(1):1–5.

Salary MM, Jafar-Zanjani S, Mosallaei H. Electrically tunable harmonics in time-modulated metasurfaces for wavefront engineering. New J Phys. 2018;20(12):123023.

Jin B, Zhang C, Engelbrecht S, Pimenov A, Wu J, Xu Q, et al. Low loss and magnetic field-tunable superconducting terahertz metamaterial. Opt Express. 2010;18(16):17504–9.

Cheng X, Huang R, Xu J, Xu X. Broadband terahertz near-perfect absorbers. ACS Appl Mater Interfaces. 2020;12(29):33352–60.

Chen S, Chen Z, Liu J, Cheng J, Zhou Y, Xiao L, Chen K. Ultra-narrow band mid-infrared perfect absorber based on hybrid dielectric metasurface. Nanomaterials. 2019;9(10): 1350.

Iwaszczuk K, Strikwerda AC, Fan K, Zhang X, Averitt RD, Jepsen PU. Flexible metamaterial absorbers for stealth applications at terahertz frequencies. Opt Express. 2012;20(1):635–43.

Huang C, Yang J, Wu X, Song J, Pu M, Wang C, Luo X. Reconfigurable metasurface cloak for dynamical electromagnetic illusions. ACS Photonics. 2017;5(5):1718–25.

Orazbayev B, Estakhri NM, Beruete M, Alù A. Terahertz carpet cloak based on a ring resonator metasurface. Phys Rev B. 2015;91(19):195444.

Rajput A, Srivastava KV. Design of a two-dimensional metamaterial cloak with minimum scattering using a quadratic transformation function. J Appl Phys. 2014;116(12):124501.

Zhou F, Bao Y, Cao W, Stuart CT, Gu J, Zhang W, Sun C. Hiding a realistic object using a broadband terahertz invisibility cloak. Sci Rep. 2011;1(1):1–5.

Ma HF, Cui TJ. Three-dimensional broadband ground-plane cloak made of metamaterials. Nat Commun. 2010;1(1):1–6.

Pendry JB. Negative refraction. Contemp Phys. 2004;45(3):191–202.

Fang N, Lee H, Sun C, Zhang X. Sub-diffraction-limited optical imaging with a silver superlens. Science. 2005;308(5721):534–7.

Pendry JB. Negative refraction makes a perfect lens. Phys Rev Lett. 2000;85(18): 3966.

Paniagua-Dominguez R, Yu YF, Khaidarov E, Choi S, Leong V, Bakker RM, et al. A metalens with a near-unity numerical aperture. Nano Lett. 2018;18(3):2124–32.

Dong T, Li S, Manjappa M, Yang P, Zhou J, Kong D, et al. Nonlinear THz-Nano metasurfaces. Adv Funct Mater. 2021;31(24):2100463.

Liu X, Li C, Wang Z, Li Y, Huang J, Yu H. Wide-range flexible capacitive pressure sensors based on origami structure. IEEE Sens J. 2021;21(8):9798–807.

Cheng R, Xu L, Yu X, Zou L, Shen Y, Deng X. High-sensitivity biosensor for identification of protein based on terahertz Fano resonance metasurfaces. Opt Commun. 2020;473: 125850.

Zhang C, Xue T, Zhang J, Liu L, Xie J, Wang G, et al. Terahertz toroidal metasurface biosensor for sensitive distinction of lung cancer cells. Nanophotonics. 2022;11(1):101–9.

Li F, Shen J, Guan C, Xie Y, Wang Z, Lin S, et al. Exploring near-field sensing efficiency of complementary plasmonic metasurfaces for immunodetection of tumor markers. Biosens Bioelectron. 2022;203: 114038.

Zhu J, Wang Z, Lin S, Jiang S, Liu X, Guo S. Low-cost flexible plasmonic nanobump metasurfaces for label-free sensing of serum tumor marker. Biosens Bioelectron. 2020;150: 111905.

Watts CM, Shrekenhamer D, Montoya J, Lipworth G, Hunt J, Sleasman T, et al. Terahertz compressive imaging with metamaterial spatial light modulators. Nat Photonics. 2014;8(8):605–9.

Alsaedi D, El Badawe M, Ramahi OM. A Metasurface for Biomedical Imaging Applications. Singapore: 2021 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting (APS/URSI). 2021, pp. 589–90. https://doi.org/10.1109/APS/URSI47566.2021.9704530.

Zhang S, Wong CL, Zeng S, Bi R, Tai K, Dholakia K, Olivo M. Metasurfaces for biomedical applications: imaging and sensing from a nanophotonics perspective. Nanophotonics. 2021;10(1):259–93.

Woodward RM, Wallace VP, Pye RJ, Cole BE, Arnone DD, Linfield EH, Pepper M. Terahertz pulse imaging of ex vivo basal cell carcinoma. J Invest Dermatology. 2003;120(1):72–8.

Hu J, Luo GQ, Hao ZC. A wideband quad-polarization reconfigurable metasurface antenna. IEEE Access. 2017;6:6130–7.

Khan MR, Zekios CL, Bhardwaj S, Georgakopoulos SV. Origami-enabled frequency reconfigurable dipole antenna. Atlanta: 2019 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting; 2019, pp. 901–2. https://doi.org/10.1109/APUSNCURSINRSM.2019.8889002.

Russo NE, Zekios CL, Georgakopoulos SV, An HS, Mishra AK, Shepherd RF. Design and fabrication of an origami multimode ring antenna. Boulder: 2021 United States National Committee of URSI National Radio Science Meeting (USNC-URSI NRSM); 2021, pp. 246–7. https://doi.org/10.23919/USNC-URSINRSM51531.2021.9336435.

Yao S, Bonan Y, Shafiq Y, Georgakopoulos SV. Rigid origami based reconfigurable conical spiral antenna. Boston: 2018 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting. 2018, pp. 179–80. https://doi.org/10.1109/APUSNCURSINRSM.2018.8608655.

Huang C, Zhang C, Yang J, Sun B, Zhao B, Luo X. Reconfigurable metasurface for multifunctional control of electromagnetic waves. Adv Opt Mater. 2017;5(22):1700485.

Watts CM, Liu X, Padilla WJ. Metamaterial electromagnetic wave absorbers. Adv Mater. 2012;24(23):OP98–120.

Xiong R-h, Peng X-q, Li J-s. Graphene-metasurface for wide-incident-angle terahertz absorption. Front Inform Technol Electron Eng. 2021;22(3):334–40.

Tao H, Landy NI, Bingham CM, Zhang X, Averitt RD, Padilla WJ. A metamaterial absorber for the terahertz regime: design, fabrication and characterization. Opt Express. 2008;16(10):7181–8.

Fan K, Strikwerda AC, Tao H, Zhang X, Averitt RD. Stand-up magnetic metamaterials at terahertz frequencies. Opt Express. 2011;19(13):12619–27.

Malek SC, Ee H-S, Agarwal R. Strain multiplexed metasurface holograms on a stretchable substrate. Nano Lett. 2017;17(6):3641–5.

Arezoomandan S, Gopalan P, Tian K, Chanana A, Nahata A, Tiwari A, Sensale-Rodriguez B. Tunable terahertz metamaterials employing layered 2-D materials beyond graphene. IEEE J Sel Top Quantum Electron. 2016;23(1):188–94.

Thareja V, Esfandyarpour M, Kik PG, Brongersma ML. Anisotropic metasurfaces as tunable SERS substrates for 2D materials. ACS Photonics. 2019;6(8):1996–2004.

Ju L, Geng B, Horng J, Girit C, Martin M, Hao Z, et al. Graphene plasmonics for tunable terahertz metamaterials. Nat Nanotechnol. 2011;6(10):630–4.

Cao Y, Gan S, Geng Z, Liu J, Yang Y, Bao Q, Chen H. Optically tuned terahertz modulator based on annealed multilayer MoS2. Sci Rep. 2016;6(1): 22899.

Wu G, Jiao X, Wang Y, Zhao Z, Wang Y, Liu J. Ultra-wideband tunable metamaterial perfect absorber based on vanadium dioxide. Opt Express. 2021;29(2):2703–11.

Wang S, Kang L, Werner DH. Hybrid resonators and highly tunable terahertz metamaterials enabled by vanadium dioxide (VO2). Sci Rep. 2017;7(1):1–8.

Xiao L, Ma H, Liu J, Zhao W, Jia Y, Zhao Q, et al. Fast adaptive thermal camouflage based on flexible VO2/graphene/CNT thin films. Nano Lett. 2015;15(12):8365–70.

Qi H, Tang B. An active tunable terahertz functional metamaterial based on hybrid-graphene vanadium dioxide. Phys Chem Chem Phys. 2023;25(11):7825–31.

He X, Cao W. Tunable terahertz hybrid metamaterials supported by 3D Dirac semimetals. Opt Mater Express. 2023;13(2):413–22.

Giorgianni F, Chiadroni E, Rovere A, Cestelli-Guidi M, Perucchi A, Bellaveglia M, et al. Strong nonlinear terahertz response induced by Dirac surface states in Bi2Se3 topological insulator. Nat Commun. 2016;7(1): 11421.

Wang J, Sui X, Duan W, Liu F, Huang B. Density-independent plasmons for terahertz-stable topological metamaterials. Proc Natl Acad Sci. 2021;118(19):e2023029118.

Wang G, Cao W, He X. 3D Dirac semimetal elliptical fiber supported THz tunable hybrid plasmonic waveguides. IEEE J Sel Top Quantum Electron. 2023;29(5: Terahertz Photonics):1–7.

Cheng Y, Cao W, Wang G, He X, Lin F, Liu F. 3D Dirac semimetal supported thermal tunable terahertz hybrid plasmonic waveguides. Opt Express. 2023;31(11):17201–14.

Chen S, Chen J, Zhang X, Li Z-Y, Li J. Kirigami/origami: unfolding the new regime of advanced 3D microfabrication/nanofabrication with folding. Light Sci Appl. 2020;9(1):1–19.

Kaddour AS, Velez CA, Georgakopoulos SV. A deployable and reconfigurable origami reflectarray based on the Miura-Ori pattern. Montreal: 2020 IEEE International Symposium on Antennas and Propagation and North American Radio Science Meeting. 2020, pp. 91–2. https://doi.org/10.1109/IEEECONF35879.2020.9329994.

Xu L, Shyu TC, Kotov NA. Origami and kirigami nanocomposites. ACS Nano. 2017;11(8):7587–99.

Zhai Z, Wu L, Jiang H. Mechanical metamaterials based on origami and kirigami. Appl Phys Rev. 2021;8(4):041319.

Wang C, Lv Z, Mohan MP, Cui Z, Liu Z, Jiang Y, et al. Pangolin-inspired stretchable, microwave‐invisible metascale. Adv Mater. 2021;33(41):2102131.

Tanoto H, Ding L, Teng J. Tunable terahertz metamaterials. Intern J Terahertz Sci Tech. 2013;6:1–25.

Han Z, Kohno K, Fujita H, Hirakawa K, Toshiyoshi H. Tunable terahertz filter and modulator based on electrostatic MEMS reconfigurable SRR array. IEEE J Sel Top Quantum Electron. 2014;21(4):114–22.

Manjappa M, Pitchappa P, Singh N, Wang N, Zheludev NI, Lee C, Singh R. Reconfigurable MEMS Fano metasurfaces with multiple-input-output states for logic operations at terahertz frequencies. Nat Commun. 2018;9(1):4056.

Kim DH, Lu N, Ma R, Kim YS, Kim RH, Wang S, et al. Epidermal electronics. Science. 2011;333(6044):838–43.

Huang L, Chen HT. A brief review on terahertz metamaterial perfect absorbers. Terahertz Sci Technol. 2013;6(1):26–39.

Costa F, Monorchio A, Manara G. Theory, design and perspectives of electromagnetic wave absorbers. IEEE Electromagn Compat Magazine. 2016;5(2):67–74.

Zahra S, Ma L, Wang W, Li J, Chen D, Liu Y, et al. Electromagnetic metasurfaces and reconfigurable metasurfaces: a review. Front Phys. 2021;8: 593411.

Wang L, Zhang Y, Guo X, Chen T, Liang H, Hao X, et al. A review of THz modulators with dynamic tunable metasurfaces. Nanomaterials. 2019;9(7): 965.

Sun S, He Q, Hao J, Xiao S, Zhou L. Electromagnetic metasurfaces: physics and applications. Adv Opt Photonics. 2019;11(2):380–479.

Qiu C-W, Zhang T, Hu G, Kivshar Y. Quo vadis, metasurfaces? Nano Letters. 2021;21(13):5461–74.

Xiao S, Wang T, Liu T, Zhou C, Jiang X, Zhang J. Active metamaterials and metadevices: a review. J Phys D. 2020;53(50):503002.

Jiang S, Liu X, Liu J, Ye D, Duan Y, Li K, et al. Flexible metamaterial electronics. Adv Mater. 2022;34:2200070.

Hsu WL, Chen YC, Yeh SP, Zeng QC, Huang YW, Wang CM. Review of metasurfaces and metadevices: advantages of different materials and fabrications. Nanomaterials. 2022;12(12):1973.

He Q, Sun S, Zhou L. Tunable/reconfigurable metasurfaces: physics and applications. Research. 2019;2019:1849272. https://doi.org/10.34133/2019/1849272.

Hu J, Bandyopadhyay S, Liu YH, Shao LY. A review on metasurface: from principle to smart metadevices. Front Phys. 2021;8:586087.

Hsiao HH, Chu CH, Tsai DP. Fundamentals and applications of metasurfaces. Small Methods. 2017;1(4):1600064.

Guanxing Z, Liu Z, Deng W, Zhu W. Reconfigurable metasurfaces with mechanical actuations: towards flexible and tunable photonic devices. J Opt. 2020;23(1):013001.

Xu C, Ren Z, Wei J, Lee C. Reconfigurable terahertz metamaterials: from fundamental principles to advanced 6G applications. Iscience. 2022:;25: 103799.

Nemati A, Wang Q, Hong M, Teng J. Tunable and reconfigurable metasurfaces and metadevices. Opto-Electronic Adv. 2018;1(5):180009.

Hashemi MR, Cakmakyapan S, Jarrahi M. Reconfigurable metamaterials for terahertz wave manipulation. Rep Prog Phys. 2017;80(9):094501.

Walia S, Shah CM, Gutruf P, Nili H, Chowdhury DR, Withayachumnankul W, et al. Flexible metasurfaces and metamaterials: a review of materials and fabrication processes at micro-and nano-scales. Appl Phys Rev. 2015;2(1):011303.

Monacelli B, Pryor JB, Munk BA, Kotter D, Boreman GD. Infrared frequency selective surface based on circuit-analog square loop design. IEEE Trans Antennas Propag. 2005;53(2):745–52.

Pitilakis A, Tsilipakos O, Liu F, Kossifos KM, Tasolamprou AC, Kwon DH, et al. A multi-functional reconfigurable metasurface: electromagnetic design accounting for fabrication aspects. IEEE Trans Antennas Propag. 2020;69(3):1440–54.

Zhou Y, Cao X, Gao J, Yang H, Li S. Reconfigurable metasurface for multiple functions: magnitude, polarization and phase modulation. Opt Express. 2018;26(22):29451–9.

Tao H, Strikwerda AC, Fan K, Padilla WJ, Zhang X, Averitt RD. MEMS based structurally tunable metamaterials at terahertz frequencies. J Infrared Millim Terahertz Waves. 2011;32(5):580–95.

Arbabi E, Arbabi A, Kamali SM, Horie Y, Faraji-Dana M, Faraon A. MEMS-tunable dielectric metasurface lens. Nat Commun. 2018;9(1):1–9.

Xu R-J, Lin Y-S. Actively MEMS-based tunable metamaterials for advanced and emerging applications. Electronics. 2022;11(2): 243.

Khorasaninejad M, Chen W, Zhu A, Oh J, Devlin R, Rousso D, Capasso F. Multispectral chiral imaging with a metalens. Nano Lett. 2016;16(7):4595–600.

Wang B, Zhou J, Koschny T, Kafesaki M, Soukoulis CM. Chiral metamaterials: simulations and experiments. J Opt A: Pure Appl Opt. 2009;11(11): 114003.

Zhang S, Park Y-S, Li J, Lu X, Zhang W, Zhang X. Negative refractive index in chiral metamaterials. Phys Rev Lett. 2009;102(2): 023901.

Wu Z, Zeng B, Zhong S. A double-layer chiral metamaterial with negative index. J Electromagn Waves Appl. 2010;24(7):983–92.

Nishijima Y, Balčytis A, Naganuma S, Seniutinas G, Juodkazis S. Kirchhoff’s metasurfaces towards efficient photo-thermal energy conversion. Sci Rep. 2019;9(1):1–9.

Liu J, Zeng H, Cheng M, Wang Z, Wang J, Cen M, et al. Photoelastic plasmonic metasurfaces with ultra-large near infrared spectral tuning. Mater Horiz. 2022;9(3):942–51.

Niu D, Jiang W, Li D, Ye G, Luo F, Liu H. Reconfigurable shape-morphing flexible surfaces realized by individually addressable photoactuator arrays. Smart Mater Struct. 2021;30(12):125032.

Liberal I, Li Y, Engheta N. Reconfigurable epsilon-near-zero metasurfaces via photonic doping. Nanophotonics. 2018;7(6):1117–27.

Ma F, Lin YS, Zhang X, Lee C. Tunable multiband terahertz metamaterials using a reconfigurable electric split-ring resonator array. Light Sci Appl. 2014;3(5):e171-e.

Valente J, Ou J-Y, Plum E, Youngs IJ, Zheludev NI. Reconfiguring photonic metamaterials with currents and magnetic fields. Appl Phys Lett. 2015;106(11):111905.

Qin J, Deng L, Kang T, Nie L, Feng H, Wang H, et al. Switching the optical chirality in magnetoplasmonic metasurfaces using applied magnetic fields. ACS Nano. 2020;14(3):2808–16.

Chen L, Ruan Y, Luo SS, Ye FJ, Cui HY. Optically transparent Metasurface Absorber based on reconfigurable and flexible Indium Tin Oxide Film. Micromachines. 2020;11(12): 1032.

Fan X, Li Y, Chen S, Xing Y, Pan T. Mechanical terahertz modulation by skin-like ultrathin stretchable metasurface. Small. 2020;16(37):2002484.

Jang K-I, Chung HU, Xu S, Lee CH, Luan H, Jeong J, et al. Soft network composite materials with deterministic and bio-inspired designs. Nat Commun. 2015;6(1):6566.

Zeng S, Sreekanth KV, Shang J, Yu T, Chen CK, Yin F, et al. Graphene–gold metasurface architectures for ultrasensitive plasmonic biosensing. Adv Mater. 2015;27(40):6163–9.

Gollub J, Yurduseven O, Trofatter KP, Arnitz D, Imani F, Sleasman M. Large metasurface aperture for millimeter wave computational imaging at the human-scale. Sci Rep. 2017;7(1):1–9.

Zhen Z, Qian C, Jia Y, Fan Z, Hao R, Cai T, et al. Realizing transmitted metasurface cloak by a tandem neural network. Photon Res. 2021;9(5):B229–35.

Jiang S, Liu J, Xiong W, Yang Z, Yin L, Li K, Huang Y. A snakeskin-inspired, soft‐hinge kirigami metamaterial for self‐adaptive conformal electronic armor. Adv Mater. 2022;34(31):2204091.

Wang Z, Jing L, Yao K, Yang Y, Zheng B, Soukoulis CM, et al. Origami-based reconfigurable metamaterials for tunable chirality. Adv Mater. 2017;29(27): 1700412.

Jing L, Wang Z, Zheng B, Wang H, Yang Y, Shen L, et al. Kirigami metamaterials for reconfigurable toroidal circular dichroism. NPG Asia Mater. 2018;10(9):888–98.

Xu Z, Lin YS. A stretchable terahertz parabolic-shaped metamaterial. Adv Opt Mater. 2019;7(19):1900379.

Güell-Grau P, Pi F, Villa R, Nogues J, Alvarez M, Sepulveda B. Ultrabroadband light absorbing Fe/polymer flexible metamaterial for soft opto-mechanical devices. Appl Mater Today. 2021;23: 101052.

Choi C, Mun SE, Sung J, Choi K, Lee SY, Lee B. Hybrid state engineering of phase-change metasurface for all‐optical cryptography. Adv Funct Mater. 2021;31(4): 2007210.

Guo J, Wang T, Zhao H, Wang X, Feng S, Han P, et al. Reconfigurable terahertz metasurface pure phase holograms. Adv Opt Mater. 2019;7(10): 1801696.

Kim I, Kim W-S, Kim K, Ansari MA, Mehmood MQ, Badloe T, et al. Holographic metasurface gas sensors for instantaneous visual alarms. Sci Adv. 2021;7(15):eabe9943.

Zhu Y, Birla M, Oldham KR, Filipov ET. Elastically and plastically foldable electrothermal micro-origami for controllable and rapid shape morphing. Adv Funct Mater. 2020;30(40):2003741.

Ho CP, Pitchappa P, Lin Y-S, Huang C-Y, Kropelnicki P, Lee C. Electrothermally actuated microelectromechanical systems based omega-ring terahertz metamaterial with polarization dependent characteristics. Appl Phys Lett. 2014;104(16):161104.

Bosch M, Shcherbakov MR, Won K, Lee H-S, Kim Y, Shvets G. Electrically actuated varifocal lens based on liquid-crystal-embedded dielectric metasurfaces. Nano Lett. 2021;21(9):3849–56.

Li J, Yu P, Zhang S, Liu N. Electrically-controlled digital metasurface device for light projection displays. Nat Commun. 2020;11(1):1–7.

Kwon H, Faraon A. NEMS-tunable dielectric chiral metasurfaces. ACS Photonics. 2021;8(10):2980–6.

Montgomery SM, Wu S, Kuang X, Armstrong CD, Zemelka C, Ze Q, et al. Magneto-mechanical metamaterials with widely tunable mechanical properties and acoustic bandgaps. Adv Funct Mater. 2021;31(3):2005319.

Chen Y, Liang Q, Ji C-Y, Liu X, Wang R, Li J. A magnetic actuation scheme for nano-kirigami metasurfaces with reconfigurable circular dichroism. J Appl Phys. 2022;131(23):233102.

Jackson JA, Messner MC, Dudukovic NA, Smith WL, Bekker L, Moran B, et al. Field responsive mechanical metamaterials. Sci Adv. 2018;4(12): eaau6419.

Musorin A, Barsukova M, Shorokhov A, Luk’yanchuk B, Fedyanin A. Manipulating the light intensity by magnetophotonic metasurfaces. J Magn Magn Mater. 2018;459:165–70.

Park J-S, Zhang S, She A, Chen WT, Lin P, Yousef KM, et al. All-glass, large metalens at visible wavelength using deep-ultraviolet projection lithography. Nano Lett. 2019;19(12):8673–82.

Verre R, Odebo Länk N, Andrén D, Šípová H, Käll M. Large-scale fabrication of shaped high index dielectric nanoparticles on a substrate and in solution. Adv Opt Mater. 2018;6(7): 1701253.

Choi J, Cho W, Jung YS, Kang HS, Kim H-T. Direct fabrication of micro/nano-patterned surfaces by vertical-directional photofluidization of azobenzene materials. ACS Nano. 2017;11(2):1320–7.

Cardoso G, Hamouda F, Dagens B. Improved PDMS mold fabrication by direct etch with nanosphere self-assembly mask for soft UV-NIL subwavelength metasurfaces fabrication. Microelectron Eng. 2022;258: 111755.

Huo F, Zheng Z, Zheng G, Giam LR, Zhang H, Mirkin CA. Polymer pen lithography. Science. 2008;321(5896):1658–60.

Piner RD, Zhu J, Xu F, Hong S, Mirkin CA. Dip-pen nanolithography. Science. 1999;283(5402):661–3.

Carlotti M, Mattoli V. Functional materials for two-photon polymerization in microfabrication. Small. 2019;15(40): 1902687.

Bunea A-I, del Castillo Iniesta N, Droumpali A, Wetzel AE, Engay E, Taboryski R, editors. Micro 3D printing by two-photon polymerization: configurations and parameters for the nanoscribe system. Micro: MDPI; 2021.

Wu K, Zhao X, Bifano TG, Anderson SW, Zhang X. Auxetics-inspired tunable metamaterials for magnetic resonance imaging. Adv Mater. 2022;34(6): 2109032.

Iwanaga M. High-sensitivity high-throughput detection of nucleic acid targets on metasurface fluorescence biosensors. Biosensors. 2021;11(2): 33.

Wang Y, Ali MA, Chow EK, Dong L, Lu M. An optofluidic Metasurface for lateral flow-through detection of breast cancer biomarker. Biosens Bioelectron. 2018;107:224–9.

Patel SK, Surve J, Parmar J. Detection of cancer with graphene metasurface-based highly efficient sensors. Diam Relat Mater. 2022:;129: 109367.

Krishnan SR, Ray TR, Ayer AB, Ma Y, Gutruf P, Lee K, et al. Epidermal electronics for noninvasive, wireless, quantitative assessment of ventricular shunt function in patients with hydrocephalus. Sci Transl Med. 2018;10(465): eaat8437.

Krishnan SR, Su CJ, Xie Z, Patel M, Madhvapathy SR, Xu Y, et al. Wireless, battery-free epidermal electronics for continuous, quantitative, multimodal thermal characterization of skin. Small. 2018;14(47): 1803192.