Abstract

Traditional complementary foods in Africa are cereal-based, low in nutrient-density; hence, causing severe-acute-malnutrition. This study was aimed to formulate and evaluate nutritional quality of complementary foods (CF) using locally available food materials. Yellow maize (raw, germinated & fermented), defatted groundnut (DGF) and ginger flour (GGF) were blended to obtain RDG (76.7% raw yellow maize, 20.8% DGF and 2.5% GGF), GDG (74.4% germinated yellow maize, 23.1% DGF, 2.5% GGF), and FDG (72.6% fermented yellow maize, 24.9% DGF, 2.5% GGF). Food samples were evaluated for nutritional qualities and sensory attributes using standard methods. Protein (g/100 g), energy value (kCal/100 g), total amino acids and essential amino acids (g/100 g protein) of formulated CF ranged from 19.38 to 28.58, 373.49 to 394.53, 87.33 to 91.89 and 36.17 to 37.63, respectively, and were comparable to control (17.07, 401.22, 94.47 & 35.35). Minerals were present in appreciable amount in the foods, while phytate/mineral (Ca, Fe, Zn) and oxalate/calcium molar ratios were lower than critical levels. Bulk density (1.4 - 1.6 g/mL), least gelation (4 - 6%), water absorption capacity (10.5 - 15.8%) and swelling capacity (0.5 - 1.2%) were significantly (p < 0.05) lower in formulated CF than in control, except for bulk density. Biological value (78.44%) of FDG was significantly (P < 0.05) higher than GDG (78.4%) and RDG (75.87%), respectively, but lower than control (93.48%). Pack cell volume (22.50%), haemoglobin concentration (7.5 g/dL), red blood cell (3 × 103 mm− 3), albumin (3.72 g/dL), total blood protein (5.62 g/dL) and globulin (1.9 g/dL) of rats fed on FDG were significantly (p < 0.05) higher than other diets, but comparable to that of control. Kidney (urea, 10.16 mg/dL; creatinine, 4.8 mg/dL) and liver function index (AST/ALT ratio, 0.38) of rats fed on FDG were lower than in those rats fed on RDG, GDG and control. For sensorial attributes, RDG was ranked best next by FDG in appearance, aroma, texture, taste and overall acceptability, but were significantly (p < 0.05) rated lower than control. Finally, the study established that FDG (72.6% fermented yellow maize, 24.9% defatted groundnut and 2.5% ginger) was the best in nutritional quality and growth performance in rats; hence, this CF may be suitable to mitigate expensive commercial infant formula in alleviating severe-acute-malnutrition in children.

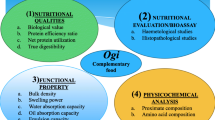

Graphical abstract

Similar content being viewed by others

Introduction

Adequate nutrition is essential for healthy growth and brain development of children, particularly within the first 5 years of life for them to attain full potential (Motuma et al. 2016). Ironically, in developing countries including Nigeria, many under privileged nursing mothers or caregivers as result of poverty and lack of nutrition knowledge to utilize locally available food materials to formulate infant foods (Samuel et al. 2021) are unable to provide adequate nutrient to their children. Hence, there is high prevalence of moderate and severe-acute-malnutrition with consequences of high morbidity, mortality and hospital admission among the young children (Michaelsen et al. 2009).

Recently, epidemiological studies have implicated traditional complementary foods in the developing countries as one of the main causes of growth faltering and poor brain development among children (Adesanmi et al. 2020; Mengistu et al. 2016). Traditional complementary foods are cereal-based, and characterized with low protein, energy density and bulky (Shiriki et al. 2015), and often fail to meet the nutritional need of infant due to poor nutritive values (Mengistu et al. 2016). Complementary food is usually introduced to infants between the ages of 6 months to 2 years when breast milk alone is no longer adequate to meet nutritional needs of the infant (Taha et al. 2020). In developing countries, the cost of fortified, nutritious and proprietary complementary foods is always unaffordable to less privileged families. Therefore, such families often depend on un-supplemented cereal-based complementary foods made from maize, sorghum and millet, which are deficient in vital nutrients (Nnam 2000). However, it is evident that adequate complementation of traditional complementary food from cereals with locally available legumes may be more nutritious than most of the commercial formulas (Noah 2017; Okoye & Ene 2018).

Maize (Zea mays), a cereal crop, is grown widely in Nigeria and other part of the world. Chemically, the grains are rich in carbohydrate, essential micronutrients (minerals & vitamins), dietary fibre and good source of energy (Linda 2013). However, studies have also established that cereals are deficient in some essential amino acid like lysine and tryptophan, which are required for infants (Nuss & Tanumihardjo 2011). It is well established that children at high risk of stunting may have limitations of essential amino acids in their diet such as tryptophan and lysine (Nuss & Tanumihardjo 2011). Evidence has shown that lysine and tryptophan deficiencies in cereals can be complemented with legumes that are rich in lysine and tryptophan to compensate for the deficiency of these essential amino acids in cereal (Onwurafor et al. 2020). In Nigeria, maize is extensively consumed in form breakfast meals or used as complementary foods for infants. The unsupplemented maize-based complementary foods have been implicated as the main causes of protein-energy malnutrition among the children in developing countries (Tufa et al. 2016).

Groundnut (Arachis hypogaea L.) also known as peanut is a legume, and widely cultivated in Nigeria. Nutritionally, groundnut kernel contains appreciable amount of essential oil, protein, essential amino acids, fatty acids and micronutrients (Adlak et al. 2021; Asibuo et al. 2008). Groundnut kernel is usually consumed as snacks or used in food preparation to increase protein content, and flavour enhancer (Asibuo et al. 2008; Rossi-Márquez et al. 2021).

Ginger is a monocotyledonous herbaceous plant, widely used as a spice in food. Ginger contains bioactive phytochemicals like gingerols, especially the 6-gingerol (Singh et al. 2008) with anti-inflammatory and antioxidant properties (Mashhadi et al. 2013). Studies have utilized ginger powder to enhance sensorial attributes of the food productions like biscuits, breads, etc. (Akinwande et al. 2008; Balestra et al. 2011), and it prolongs the shelf life of food products (Oluwamodupe et al. 2012). Ginger exhibits some peculiar health benefits like alleviating nausea or vomiting (Basirat et al. 2009) and antioxidative properties (Stoilova et al. 2007).

Materials and methods

Sources of materials

Yellow maize (Zea mays), Groundnut (Arachis hypogea L.) and ginger (Zinger officinale Roscoe) were purchased from Erekesan Market, Akure, Ondo State, Nigeria. The male and female weanling Wistar rats were obtained from Central Animal House, University of Ibadan, Ibadan, Nigeria.

Flour sample preparations

Raw yellow maize kernels flour processing

Raw yellow maize kernels were processed into flour using modified method of Mankambou et al. (2021). The kernels were sorted to remove unwanted materials like stones, pebbles and other foreign seeds, washed with double distilled water and drained. The kernels were oven dried at 60 °C for 20 h using a hot-air oven (Plus11 Sanyo Gallenkamp PLC, Loughborough, Leicestershire, UK), milled with a laboratory blender (Model KM 901D; Kenwood Electronic, Hertfordshire, UK) and passed through a 60 mm mesh sieve (British Standard) to obtain raw yellow maize flour. The flour was packed in a plastic container, sealed and stored at temperature ~ 4 °C until analysis.

Germinated yellow maize flour processing

Raw yellow maize kernels were processed into germinated flour using modified method of Mankambou et al. (2021). The kernels were sorted to remove unwanted materials like stones, pebbles and other foreign seeds, soaked in distilled water for 6 h and drained. The kernels were spread on moisten muslin bag and cover with another muslin bag, watered and left to germinate in a dark cupboard at room temperature (30 ± 1 °C) for 3 - 4 days. After germination, the kernels re-washed, oven dried at 60 °C for 20 h using a hot-air oven (Plus11 Sanyo Gallenkamp PLC, Loughborough, Leicestershire, UK), milled with a laboratory blender (Model KM 901D; Kenwood Electronic, Hertfordshire, UK) and passed through a 60 mm mesh sieve (British Standard) to obtain germinated yellow maize flour. The flour was packed in a plastic container, sealed and stored at temperature ~ 4 °C until analysis.

Fermented yellow maize flour processing

The yellow maize flour was prepared as described by Ijarotimi et al. (2012) with slight modification. The grains were sorted to remove foreign materials, washed with distilled water and soaked in distilled water at room temperature for 3 days. Thereafter, the grains were thoroughly washed, drained, wet milled, sieved with muslin cloth, decanted, and the slurry was oven dried with a hot-air oven (Plus11 Sanyo Gallenkamp PLC, Loughborough, Leicestershire, UK) at 60 °C for 20 h., The oven dried sorghum flour was re-milled (Laboratory blender (Model KM 901D; Kenwood Electronic, Hertfordshire, UK) and sieved with a 60 mm wire mesh sieve (British Standard). The flour was packed in a plastic container, sealed and stored at temperature ~ 4 °C until used.

Defatted groundnut flour processing

The groundnut kernels (1.0 kg) were manually sorted to remove foreign substances; and the kernels were thoroughly washed with distilled water, drained, oven dried in hot-air oven (plus11 Sanyo Gallen Kamp plc) at 60 °C for 20 h. After oven dried, the kernels were milled using Philip laboratory blender (model HR2811). The groundnut flour (500 g) was defatted using n-hexane as solvent in a Soxhlet apparatus for 12 h. The defatted flour was oven dried using a hot-air oven (Plus11 Sanyo Gallenkamp PLC, Loughborough, Leicestershire, UK) at 40 °C for 2 h to allow the solvent to escape. The defatted flour was sieved with a 60 mm wire mesh sieve (British Standard), and stored at room temperature (~ 27 °C) in a plastic zip lock bag and stored at temperature ~ 4 °C until used.

Ginger flour processing

Ginger rhizomes were processed into flour using modified method of Adakole et al. (2020). The rhizomes were sorted to remove unwanted materials like stones, pebbles and other foreign seeds, washed with distilled water and drained. The rhizomes were manually sliced into small pieces, oven dried at 60 °C for 20 h using a hot-air oven (Plus11 Sanyo Gallenkamp PLC, Loughborough, Leicestershire, UK), milled with a laboratory blender (Model KM 901D; Kenwood Electronic, Hertfordshire, UK) and passed through a 60 mm mesh sieve (British Standard) to obtain ginger flour. The flour was packed in a plastic container, sealed and stored at temperature ~ 4 °C until analysis.

Formulation of complementary foods

The flour of yellow maize (raw, germinate & fermented), defatted groundnut and ginger were blended to obtain the following formulated samples, i.e., RDG (76.7% raw yellow maize, 20.8% defatted groundnut and 2.5% ginger), GDG (74.4% germinated yellow maize, 23.1% defatted groundnut and 2.5% ginger), and FDG (72.6% fermented yellow maize, 24.9% defatted groundnut and 2.5% ginger). The proportion of each flour samples in the formulations was determined using material balance equations (Smith 2003) to give 18-25 g protein/100 g food as recommended by the protein advisory group (PAG, 1971) for infant diets, as described by Solomon (2005). The blends were mixed thoroughly using a Phillips blender (model HR-1702). The basal diet was prepared from cornstarch (80 g/100 g), corn oil (10 g/100 g), salt (4 g/100 g), sugar (1 g/100 g), vitamin premix (1 g/100 g) and non-nutritive fibre (rice-bran) (4 g/100 g). The food samples were packaged in dark-coloured polyethylene bags and stored in airtight containers at room temperature prior to analysis. Nutribom (NBM, a maize-based complementary food) was used as a control sample.

Chemical analyses of formulated complementary foods

Proximate composition determination

The proximate composition (i.e., ash, crude fiber, crude fat & crude protein) of formulated complementary foods was determined using methods Association of Official Analytical Chemists (AOAC 2012) methods, while carbohydrate content was calculated by difference as follows:

Energy value determination

The calorific value (kCal/ 100 g) of the complementary food samples were calculated using Atwate’s conversion factors (4 x proteins, 9 x fats and 4 x carbohydrates) (Atwater conversion Factor 2019).

Mineral composition determination

The mineral elements (i.e. Ca, Mg, Fe, Cu and Zn) in the formulated complementary foods were determined using Atomic Absorption Spectrophotometer (AAS Model SP9). Sodium and potassium were determined using flame emission photometer (Sherwood Flame Photometer 410, Sherwood Scientific Ltd. Cambridge, UK) with NaCl and KCl as the standards (AOAC 2012). Phosphorus was determined using Vanodo-molybdate method (AOAC 2012). The mineral molar ratios (Na/K & Ca/P) and phytate/mineral molar ratios (Phytate/Zn, Ca/Phytate and [Ca][Phytate]/[Zn]) were calculated as described by Ferguson et al. (1988).

Amino acid profile determination

The amino acid profile (except tryptophan) of formulated complementary foods was determined using Pico-Tag methods as described by Bidlingmeyer et al. (1984). Cysteine and methionine (sulphur-containing amino acids) were determined after perfomic acid oxidation as described by Gehrke et al. (1985), while tryptophan was determined after alkaline hydrolysis as described by AOAC (2010). Briefly, the hydrolysed sample (10 μL) and Norleucine (a standard) (10 μL) were dispensed into the cartridge of the analyser, and then loaded into Technicon Sequential Multi-Sample Amino Acid Analyser (TSM-1) (Technicon Instruments Corporation, New York, USA). The values of both samples and standard were recorded and printed out as chromatogram peaks by the chart recorder, respectively.

Calculation from the peaks

The net height of each peak produced on the chromatogram (each representing amino acid) was measured. The half-height of each peak was located and the width of the peak at half-height was accurately measured. Approximate area of each peak was then obtained by multiplying the height with the width of the half height.

Fatty acids determination

The lipid in complementary food samples was extracted with chloroform:methanol (2:1 v/v) and solid non-liquid material was removed by filtration. The extracted lipid was recovered after solvent removal in a stream of nitrogen, re-dissolved in anhydrous chloroform/methanol (19:1 v/v), and clarified by centrifugation at 10,000 -x g for 10 min. The tranmethylation was performed using 14% (w/v) boron triflouride (BF3) in methanol (Solomon & Owolawashe 2007). Fifty nanograms of heptadecanoic acid (internal standard) and 1 mL aliquot of each sample were transferred to a 15 mL Teflon-lined screw-cap tube. After removal of solvent by nitrogen gassing, the samples were mixed with 0.5 ml of BF3 reagent (14% w/v), placed in warm bath at 100 °C for 30 min and cooled. After the addition of saline solution, the transmethylated fatty acids were extracted into hexane. A calibration mixture of fatty acid standards was processed in parallel. Aliquots of the hexane phase were analyzed by gas chromatography. Fatty acids were separated and quantified using a Hewlett-Packard gas chromatograph (5890 Series II) equipped with a flame-ionization detector. Two microliter aliquot of the hexane phase were injected in split-mode onto a fused silica capillary column (Omegawax: 30 m × 0.32 mm ID, Supleco, Bellefonte, PA). The injector temperature was set at 200 °C, detector at 230 °C, oven at 120 °C initially, then 120-205 °C for 18 min. The carrier gas was helium and the flow rate was approximately 50 cm/sec. Electronic pressure control in the constant flow mode was used. The internal standard (heptadecanoic acid, C17:0) and calibration standards (NuCheck, Elysian, MN) were used for quantitation of fatty acids in the lipid extracts. The fatty acids reported represent the average of three determinations.

Determination of antinutrient/phytochemical composition

Phytic acid determination

The phytic acid in the formulated sample was determined as described by Darambazar (2018). This method depends on an iron to phosphorus ratio of 4: 6. Five grams of the experimental sample was extracted with 3% trichloro acetic acid. The phytate was precipitated as ferric phytate and converted to ferric hydroxide and soluble sodium phytate by adding sodium hydroxide. The precipitate was dissolved in hot 3.2 M HNO and the colour was read immediately at 480 nm3. The standard solution was prepared from Fe [NO3]3 and the iron content was extrapolated from a Fe (NO3)3 standard curve. The phytate concentration was calculated from the iron results assuming a 4: 6 iron:phosphorus molecular ratio. The phytic acid was estimated by multiplying the amount of phytate-phosphorus by the factor 3.55 based on the empirical formula C6P6O24H18.

Tannin content determination

Tannin content was determined by the modified vanillin-HCl methods (Jaffe 2003). The sample (5 g) was extracted with 50 mL 99.9% methanol for 20 min at room temperature with constant agitation. After centrifugation for 10 min at 653 x g, 5 mL of vanillin-HCl [2% vanilli and 1% HCl] reagent was added to 1 mL aliquots and the colour developed after 20 min at room temperature was read at 500 nm. Correction for interference light natural pigments in the sample was achieved by subjecting the extract to the conditions of the reaction, but without vanillin reagent. A standard curve was prepared using catechin [Sigma Chemical, St. Louis, MO] after correcting for blank and tannin concentration was expressed in g/100 g. Tannin content was calculated as: Tannin (g/100 g) = concentration of standard ×Absorbance of sample.

Oxalate content determination

Oxalate was determined by AOAC (2005) method. 1 g of the sample was weighed into 100 ml conical flask. 75 ml of 3 M H2SO4 was added and the solution was carefully stirred intermittently with a magnetic stirrer for about 1 h and then filtered using whatman No.1 filter paper. The sample filtrate [extract] (25 mL) was collected and titrated against hot [80 - 90 °C] 0.1 N KMnO4 solution to the point when a faint pink colour appeared that persisted for at least 30 s. The concentration of oxalate in each sample was obtained from the calculation: 1 ml 0.1 permanganate = 0.006303 g oxalate.

Trypsin inhibition activity (TIA) determination

The trypsin inhibition activity was assayed in terms of the extent to which an extract of the sample inhibited the action of bovine trypsin [EC 3.4.21.4] on the substrate benzoyl-DL-arginine-p-nitrianilide [BAPNA] hydrochloric (Spelbrink et al. 2011). The sample (1 g) was extracted with 50 mL of 10 mM NaOH, and continuously shaking using a mechanical shaker [GallenKamp orbital shaker Surrey, UK] at pH 9.4 (1 M NaOH) and ambient temperature for 3 h. After extraction, the suspension was shaken and diluted with distilled water such that 1 cm3 of the extract produced trypsin inhibition of 40 - 60% at 37 °C. The respective dilutions were noted. Consequently, TIA was calculated in terms of mg pure trypsin [Sigma type lll, lot 20H0868]

Where D is the dilution factor, A is the change in absorbance at 410 mm due to trypsin inhibition per cm3 diluted sample extract and S is the weight of the sample.

Determination of molar ratio of Phytate:mineral and oxalate:mineral

The mole of oxalate, phytate, zinc, calcium and iron was calculated by dividing the weight of oxalate, phytate and minerals (zinc, calcium and iron) with its molecular weight (88.019 g/mol for oxalate, 660 g/mol for phytate, 65 g/mol for zinc, 40 g/mol for calcium and 56 g/mol for iron) (Mahfuz et al. 2016; Norhaizan & Nor Faizadatul Ain 2009). The molar ratio was obtained by dividing the mole of oxalate and phytate with the mole of zinc, calcium and iron. Phytate: minerals and Oxalate: minerals ratios were used to estimate the bioavailability of minerals. The recommended limits of phytate:iron, phytate:calcium and phytate:zinc in millimolar were ≥ 1000, ≥200,000 and ≥ 15,000, respectively (Mahfuz et al. 2016).

Determination of functional properties of formulated complementary foods

Water absorption capacity (WAC)

Water absorption capacity was determined according to the modified method of Wani et al. (2015). The sample (2 g) was weighed into a conical graduated centrifuge tube. Using a whirl mixer (Sri Murugan Foundry Equipment) samples were mixed thoroughly with 10 mL distilled water for 30 seconds. The sample was allowed to stand for 30 minutes at room temperature (23 - 25 °C) and then centrifuged at 3000 x g for 20 min (5810R, Eppendorf, Hamburg, Germany). The volume of free water (the supernatant) was read directly from the graduated centrifuge tube. The water absorption capacity was expressed as grams of water absorbed (or retained) per gram of sample.

Bulk density

Bulk density was measured in grams per millilitre as weight of flour per unit volume according to the method of Wani et al. (2013). A 50 g flour sample was put into a 100 mL measuring cylinder and tapped continuously on the bench top from a height of 5 cm until a constant volume was obtained. The bulk density (g/mL) was calculated using the equation below.

Swelling capacity (%)

This was determined with the method described by Alawode et al. (2017) with modification for small samples. One gram (1.0 g) of the flour sample was mixed with 10 mL distilled water in a centrifuge tube and heated at 80 °C for 30 min. This was continuously shaken during the heating period. After the heating, the suspension was centrifuged at 10,000 x g for 15 min. The supernatant was decanted and the weight of the paste taken. The swelling power was calculated as follows:

Gelation capacity

The least gelation concentration was determined using the modified method of Sathe et al. (1982). The flour dispersions of 2, 4, 6, 8, 10, 12, 14, 16, 18 and 20% (w/v) were prepared in 5 mL distilled water in test tubes, which were heated at 90 °C for 1 hour in water bath (Gallenkamp). The heated dispersions were cooled rapidly under running tap water and then at 4 °C for 2 h. The least gelation concentration was determined as that concentration when the sample from the inverted tube did not slip or fall.

Nutritional quality evaluation

Preparation of Iso-nitrogenous diets for the experimental Wistar rats

The Iso-nitrogenous of the formulated complementary foods and control samples (Nutribom) were calculated with reference to 10% of protein content. The iso-nitrogenous diets were obtained by diluting protein content (%) in the formulated complementary foods to 10% protein level with basal diet (Olapade & Aworh 2012).

Equations

Where:

X = weight of sample required for the new feed mixture.

Y = proposed total weight of the basal diet to be added to the feed (e.g., 100%).

Experimental design

Weaning-aged male (14) and female (11) Wistar rats were purchased from Central Animal House, Department of Biochemistry, Federal University of Technology, Akure, Nigeria. On arrival, the rats were acclimatized for 7 days and fed with commercial feed and water ad libitum. The rats were divided into five groups, and each of the groups contained five rats. The rats were individually housed in metabolic cages, and fed on weighed experimental diets and water ad libitum for 28 days. The anthropometric measurements, i.e., length (cm) and weight (g) of the rats were measured at 3 days interval during the experimental periods (Odebode et al. 2017). The following anthropometrical indices were used to determine the growth pattern of the rats, i.e., length-for-age (stunting) and weight-for-age (underweight). The faeces and urine were of the rats were collected and pooled for each group, and analysed for nitrogen using AOAC (2005) method.

After 28 days, each of the rats was anaesthetized with chloroform inside a dessicator and sacrificed, blood was collected via cardiac puncture and poured into bijour bottle containing a speck of dried ethylene diamine tetrachloroacetic acid (EDTA) powder as anti-coagulant, and analysed for various haematological parameters. The organ of the rats, that is, liver, kidney and heart were excised, freed of fat, blotted with clean tissue paper and then weighed. Faeces and urine voided within the last 14 days of the experimental periods were collected, and faeces were oven dried at 60 °C, while urine was preserved in 10 mL of 10% H2SO4 to eliminate microbial activities and prevent nitrogen losses by evaporation of ammonia and then stored in a deep freezer (− 4 °C) prior to nitrogen determination. The weight gained, feacal and urinary nitrogen were used to evaluate protein qualities of the formulated foods using the following mathematical equations as described by AOAC (2012) and Agbede and Aletor (2003).

Where: Ni (Nitrogen intake), Nf (fecal nitrogen), Nef (endogenous fecal nitrogen), Nu (Urinary nitrogen), Neu (endogenous urinary nitrogen)

Blood collection and hematological indices determinations

At the end of 28 days of experimental period, Wistar rats were fasted overnight with access to water ad libitum and sacrificed under chloroform anaesthesia. The blood samples were collected through cardiac puncture with syringe and poured into heparinised and non-heparinised tubes. The non-heparinised tubes were allowed to clot and were centrifuged at 3000 xg for 25 min to obtain the sera, and the blood samples were stored in a deep freezer prior to haematological and biochemical analyses at the Medical Laboratory Unit of University Health Centre, Federal University of Technology, Akure (Biadgo et al. 2016). The haematological indices, that is, pack cell volume (PCV), red blood cells (RBC), pack cell volume (PCV), haemoglobin concentration (Hbc), white blood cells (WBC), neutrophil (NEU) and lymphocytes (LYM) were determined using methods described by Dacie and Lewis (1984) and slight modification by Adeyemo (2005). Mean corpuscular haemoglobin (MCH), mean corpuscular haemoglobin concentrated (MCHC) and means corpuscular volume (MCV) were calculated (Adeyemo 2005; Dacie & Lewis 1984).

Sensory attributes evaluation

The sensory attributes of formulated diets and control sample were evaluated as reported by Olapade and Aworh (2012). Both experimental and control food samples were prepared into porridges by mixing 50 g of the samples with 150 mL of boiled water (100 °C for 15 min) to make slurry. The reconstituted slurry were coded and served warm to twenty (20) semi-trained panelists recruited from the Nursing mothers/caregivers attending Postnatal Clinic section of the Comprehensive Health Centre, Akure, Ondo State, Nigeria. To each of the panelists, clean water was provided to rinse their month in-between testing of the food samples to avoid residual effect. The Panelists were asked to assess and score each of the samples based on the appearance, aroma, taste, consistency and overall acceptability using 9-point Hedonic scale from dislike extremely (1) to like extremely (9), respectively.

Statistical analysis

The results were presented as mean ± standard deviations (SD) and the test for statistical difference was performed using one-way analysis of variance (ANOVA). The statistical package used to determine significant differences was Statistical Package for Social Sciences (SPSS, Version 20). Significant means were separated using Duncan’s New Multiple Range Test (DNMRT). Differences were considered significant at p < 0.05.

Results and discussion

Energy, proximate and mineral composition of formulated complementary foods

The energy value (kCal.), proximate (g/100 g) and mineral composition (mg/kg) of formulated complementary foods from maize, defatted groundnut and ginger flour blends are presented in Table 1. The moisture content of FDG (4.13) was significantly (p < 0.05) higher than in RDG (3.96) and GDG (3.80), respectively. The moisture content of complementary foods in this present study is comparatively lower than in maize-based complementary foods supplemented with black bean and crayfish flours reported by Okoye and Ene (2018), and that of recommended value (< 10%) reported by NIS (2004). The variation between moisture content of the present study complementary foods and that of similar studies may be due to differences in raw materials and processing techniques. It is well established from the previous studies that low moisture content of flour products may inhibit growth and biochemical activities of microorganisms; and thereby, prolonging shelf life and nutritional quality of the formulated food products (Adesanmi et al. 2020; Okoye & Ene 2018). Hence, low moisture content obtained in this present study may prolong shelf life of the formulated food products. The protein content in GDG (28.58 g/100 g) was significantly (p < 0.05) higher than in FDG (24.91) and RDG (19.38), respectively. The protein content in GDG was appreciably high compared to other food samples, and this observation could be attributed to the germinated maize. This finding agrees with similar studies, which reported that germination usually increased protein and other essential nutrients of germinated seed based foods (Adesanmi et al. 2020).

Energy value of FDG (394.53 kCal/100 g) was the highest followed by RDG (375.18 kCal/100 g) and GDG (371.49 kCal/100 g), respectively, and were comparable to the control sample (401.22 kCal/100 g). Quality protein and high energy-density complementary foods are desirable for infants after six-month when breast milk is no longer adequate to provide necessary nutrients for normal growth in infants. Interestingly, the present formulated complementary foods are high in protein and energy values, hence, these formulations are suitable to provide above 100% of protein and 50% of daily energy requirements for infant per 100 g of the food samples. It is well known that nutrient-dense complementary foods formulated from variety of food materials are desirable for weaning children with a small stomach that can only accommodate small amounts of food at a time (Rajeshwari et al. 2010).

For the mineral compositions (mg/kg), Potassium (6.04 - 7.07) had the highest concentration followed by sodium (2.73 - 3.12), while manganese (0.01) had the lowest concentration. The essential minerals such as Zinc (0.1 - 0.15), iron (0.02 - 0.03) and calcium (1.28 - 1.66) were appreciably present in the formulated complementary foods. Interestingly, previous studies reported that iron and zinc are required for blood formation and brain development, respectively, while calcium is required for teeth and bone formation (Al-Mamun & Ghani 2017; Makori et al. 2017). The sodium/potassium (Na/K) and calcium/phosphorous (Ca/P) molar ratios varied from 0.64 to 0.85 and 12.36 to 18.42, respectively. These molar ratios agree with the recommended values of < 1.0 and > 0.5, respectively, and in addition, further indicate nutritional quality and suitability of formulated complementary foods to the infants. Studies have established that Ca/P molar ratio above > 0.5 may facilitate bone and teeth formation, while Na/K molar ratio of less than one (< 1.0) may not cause any damage to the immature heart of the children (Ciosek et al. 2021; Ijarotimi et al. 2022).

Amino acids profile of formulated complementary foods

The amino acid profiles of complementary foods are presented in Table 2. The result indicated that glutamic acid had the highest concentration of all the amino acids that were determined, and these values varied from 12.44 to 13.67 g/100 g protein, and were comparatively lower than in control sample. This finding is in line with the previous studies that glutamic acid is usually present in abundant in plant-based foods (Kumar et al. 2017). Nutritionally, studies have established that adequate intakes of essential amino acids are required in infants to prevent stunted growth and cognitive retardation; and that children with stunted growth had lower serum concentrations of all nine essential amino acids (tryptophan, isoleucine, leucine, valine, methionine, threonine, histidine, phenylalanine, and lysine) compared with non-stunted children (Semba et al. 2016). The essential amino acids (35.35 - 37.63 g/100 g protein) found in these complementary foods were comparatively higher than in the control sample (35.35 g/100 g protein), and that of recommended values (33.9 g/day) (United States Department of Agriculture 2018). This finding indicates that these complementary foods may be adequate in providing essential amino acids that are required for normal growth and cognitive development in young children. Besides, non-essential amino acids (arginine, glutamine, glycine, proline, and tyrosine) were adequately present in the formulated complementary foods with concentration ranged from 6.01 to 6.46, 12.44 to 13.67, 4.37 to 4.48, 4.44 to 5.04, and 5.15 to 5.68 g/100 g protein, respectively. It is worth to note that some of these amino acids are conditionally essential in infant, because they cannot be produced in sufficient amount endogenously (Abumrad & Barbul 2004; Flynn et al. 2002; Sidney 2006). Nutritional studies have shown that adequate amount of amino acids in infant diets is required for normal growth and maintenance of good health, and that excessive intake may have negative effect on immature kidneys and liver. It is well established that increased kidney size in formula-fed infants is an adaptive response to high renal solute load, because of higher protein intake compared with non-formula-fed infants (Kim & Frank 2014). Hence, the protein in the present study formulations is found to be moderate, and thereby may not affect the kidney.

Phytochemical composition of formulated complementary foods

Phytochemical composition (mg/100 g), oxalate/calcium and phytate/minerals (Ca, Zn & Fe) milimolar ratios of formulated complementary foods are presented in Table 3. From the results, trypsin, saponin, and tannin varied from 14.91 to 22.45, 67.0 to 79.09 and 2.4 to 3.74, respectively, while oxalate and phytate ranged from 1.67 to 3.65 and 9.48 to 31.31, respectively. However, the antinutrients in the formulated complementary foods were comparable to that of control sample, but lower than what reported by Gemede (2020) for complementary food formulated from the flour blends of maize, pea, and anchote. It is worthy to note that the concentration of tannin and trypsin in the present study complementary foods was comparatively lower than the critical levels; hence, this may enhances digestibility and bioavailability of vital nutrients like protein and minerals. Scientific study has established that tannin and trypsin have the ability to interfere with the digestion of nutrients (protein or minerals) either by hindering the enzyme activities or by chelating with food components like proteins or minerals to form indigestible complex compounds (Alagbaoso et al. 2015).

Bioactive phytochemicals like saponin is also present in tolerable levels in these formulated complementary diets. Evidence has shown that saponin exhibits antioxidant properties; besides, it has ability to prevent certain diseases in human (Lesinski et al. 2015; Zhang et al. 2015). For instance, studies have advocated for low intakes of bioactive phytochemicals like saponin and polyphenols to prevent and manage overweight/obesity and other associated diseases (Singh et al. 2015; Zhang et al. 2014). The prevalence of childhood overweight/obesity and associated diseases is increasing in many parts of developing countries, including Nigeria, due to poor complementary food formulations and feeding practices (Adebimpe 2019). Obesity is one of the major risk factors, which predispose children to the development of non-communicable diseases such as heart disease, diabetes, cancer, etc., and as a result, leading to increase in morbidity and premature death (Danquah et al. 2020; Ezzati et al. 2004). Prevention and treatment of this childhood obesity via qualitative complementary foods is extremely important, hence, this present study formulations with low saponin concentration would be of health benefits in preventing obesity and associated diseases in children.

The phytate, oxalate and minerals (Phytate/Ca, Phytate/Fe, Phytate/Zn and Oxalate/Ca) milimolar ratios are the indices of bioavailability of minerals like Ca, Fe and Zn. In the present study, the calculated phytate/oxalate and minerals molar ratios are lower than critical values (Ma et al. 2007). This indicates that interaction between phytate/oxalate and minerals like Ca, Fe and Zn would be minimized; hence, these essential minerals may be readily available for utilization in children. Evidences have shown that Ca, Fe and Zn are particularly essential for the formation of bone, blood and brain development in children, and that their deficiencies in diets may lead to anaemia, rickets and poor cognitive development (Awuchi et al. 2020).

Functional properties of formulated complementary foods

The functional properties of complementary foods from maize, defatted groundnut and ginger flour blends are shown in Table 4. Bulk density, least gelation and water absorption capacity of the formulated complementary foods varied from 1.4 to 1.6 g/mL, 4.0 to 6.0% and 10.5 to 15.8%, respectively, while swelling capacity ranged from 0.5 to 1.2%. The functional properties of formulated complementary foods were significantly (p < 0.05) lower than commercial food (NBM), except for bulk density. It is worth to note that these values agree with the finding of Zakari et al. (2018), who reported low functional properties for complementary foods formulated from millet, soybean and African locust bean fruit pulp flour blends. It is well established that low BD is desirable for infant diets, because high bulk density complementary food limits the caloric and nutrient intake per meal of infant, and that young children are sometimes unable to consume enough to meet their energy and nutrient requirements (Zakari et al. 2018). Besides, low bulk-density enhances energy-nutrient density of a complementary food and economical food packaging (Zakari et al. 2018). Among the formulated complementary foods, GDG (germinated maize and defatted groundnut blend) had the highest value for least gelation compared with other samples. This implies that GDG requires higher concentration to form gel, with reduced viscosity, plasticity and elasticity properties; hence, this diet would be less bulky, and highly desirable for infant with less gastric capacity to metabolize thick or viscous foods. The water absorption capacity (WAC) of the formulated complementary foods was generally low for all the samples. This is also desirable in that the microbial activities of the food products would be reduced, and thereby prolonging the shelf life of the formulated complementary foods. Besides, it is evident from the previous study that low water absorption capacity is desirable for making thinner gruels with high caloric density per unit volume (James et al. 2018). From this study, it was observed that GDG had the lowest WAC compared to other food samples, and this finding agrees with the report of Akinsola et al. (2018).

Nutritional quality of formulated complementary foods

Protein quality of formulated complementary foods from maize, defatted groundnut and ginger flour blends in Wistar rats is presented in Table 5. The Wistar rats consumed more of FDG (596.74 g/28d) followed by RDG (581.45 g/28d) and GDG (552.76 g/28d), respectively, and were significantly (p < 0.05) lower than in NBM (a control) (684.76 g/28 days). The variation between the amount consumed in the experimental food samples and that of control could be attributed to the flavour and taste, which is more pronounced in the control sample, hence, this mighty have been responsible for its higher intake. For the biological values (BV), true digestibility, net protein utilization and protein efficiency ratio, NBM had the highest values compared to experimental complementary food samples. However, among the formulated food samples, FDG (78.44%) had the highest BV followed by GDG (78.4%) and RDG (75.87%), respectively. This finding may be attributed to fermentation process, which mighty have improved nutritional quality and bioavailability of essential nutrients of the food products. It is worth to note that the BV of the present study is comparatively higher than the report of Adesanmi et al. (2020) for complementary food formulated from defatted almond seed, yellow maize and quality-protein-maize flours (9.83 - 36.73%), and also, above 70% recommended value for ideal food products with biologically quality protein (Ijarotimi & Keshinro 2013). For the growth performance of the rats (Fig. 1), the finding established that FDG (fermented maize, defatted groundnut & ginger flour) exhibited highest growth performance in rats, while RDG had the least potential. This observation was in line with the result of biological value of FDG that showed highest value when compared with other formulated complementary foods.

Weight-for-age (WFA, underweight) and Length-for-age (LFA, stunting) of Wistar rats fed on complementary diets. RDG- Raw maize, defatted groundnut and ginger in ratio 76.7:20.8:2.5. GDG- Germinated maize, defatted groundnut and ginger in ratio 74.4:23.1:2.5. FDG- Fermented maize, defatted groundnut and ginger in ratio 72.6:24.9:2.5. NBM- Nutribom (a commercial maize-based complementary food)

Haematological and biochemical indices of rats fed on formulated complementary foods

The haematological indices of Wistar rats fed on formulated complementary foods from the maize, defatted groundnut and ginger flour blends in Wistar rats are presented in Table 6. The rats fed on FDG exhibited highest pack cell volume (PCV) (22.5%), haemoglobin concentration (Hb) (7.5 g/dL), red blood cell concentrations (RBC) (3.0 × 103 mm− 3), MCHC (34.2 g/dL), MCH (38.4 pg), MCV (98 fL), neutrophils (40.4%), lymphocytes (68.6), and monocytes (3.2%). While rats fed on RDG had the least values in PCV (20%), Hb (6.7 g/dL) and RBC (2.2 × 103 mm− 3), and GDG was lower in MCHC (33.3 g/dL), MCH 29.8 pg), MCV (89.3 fL), neutrophils (29%) and lymphocytes (59%), respectively. The haematological variation between rats fed on FDG and other experimental foods (RDG & GDG) could be attributed to fermentation process, which might have increased the bioavailability of essential nutrients such as protein and iron that are required for blood formations. Interestingly, the haemoglobin concentration (7.5 g/dL) and red blood cell concentration (3.0 × 103 mm− 3) of fermented complementary food (FDG) in this study are comparable to the reference values for infants (6 -12 months) (11.3 - 14.1 g/dL; 3.74 - 4.62 × 103 mm− 3, respectively) (Nathan & Oski 1987; Nicholson & Pesce 2011). This finding is in line with the report of Adesanmi et al. (2020), who reported that fermentation process improved the blood formation of rats fed on complementary foods from fermented yellow maize and quality-protein-maize flour enriched with defatted almond seed. Hence, the present formulations, particularly FDG, have the potential to promote blood formation, and thereby prevent anaemia in children.

The biochemical property of formulated complementary foods in Wistar rats indicated that albumin (3.72 g/dL), total protein (5.62 g/dL) and globulin (1.9 g/dL) concentration of rats fed on FDG were significantly (p < 0.05) higher than in rats fed on GDG (3.52, 3.57 & 0.05) and RDG (3.07, 3.4 & 0.33), respectively. Comparatively, the albumin, total protein and globulin concentration in rats fed on FDG were insignificantly (p > 0.05) lower than in rats fed on control sample (NBM), but were within the range of recommended values (3.4 - 5.8 and 5.6 - 7.6 g/dL, respectively) (Diana 2007; Giannini et al. 1999). The effect of formulated diets on kidney function indicate that in rats fed on FDG had low blood urea (10.16 mg/dL) and creatinine (4.8 mg/dL) concentration, and were significantly lower than in rats fed on GDG (11.56 & 5.63 mg/dL) and RDG (14.75 & 6.15 mg/dL), respectively. However, these concentrations (urea and creatinine) were significantly (P < 0.05) lower than in control (NBM) (7.77 & 2.07 mg/dL), but within the recommended values (7 - 20 & 2 - 8 mg/dL, respectively) (Diana 2007; Giannini et al. 1999). Similarly, for the liver function, the blood concentration of aspartate aminotransferase (AST), alanine aminotransferase (ALT), and alkaline phosphatase (ALP) ranged from 19.30 to 20.86 U/L, 41.41 to 61.33 U/L and 40.71 to 50.46 U/L, respectively. While AST/ALT ratios ranged from 0.38 in FDG to 051 in RDG, and were lower than recommended value (< 1.0) (Diana 2007; Giannini et al. 1999). The low concentration of urea, creatinine and cytosol enzymes (AST, ALT & ALP) in rats fed on these experimental diets indicates that the diets are non-toxic, and safe as complementary food. Scientific studies have established that renal and liver dysfunction can be evaluated through the elevation of blood urea or serum creatinine (Oh & Hustead 2011), and serum enzymes (AST, ALT & ALP) (Ekpenyong et al. 2012; Jaroslaw et al. 2009). Liver and kidney are complex organs, and once the hepatic or renal cell membrane is damaged, the cytosol enzymes (AST, ALT & ALP), blood urea and creatinine concentration are increased (Nicholson & Wilson 1991).

Sensory attributes of formulated complementary foods

The sensory attributes of formulated complementary foods from maize, defatted groundnut and ginger flour blends are shown in Table 7. The appearance, aroma, texture and taste of complementary foods ranged from 5.97 to 7.17, 5.53 to 6.67, 4.93 to 6.03 and 4.07 to 6.40, respectively, while overall acceptability varied from 4.80 to 6.80; and were significantly (p < 0.05) rated lower than in control samples (NBM). The variation between formulated complementary foods rating and that of control sample could be attributed to the familiarity of the panellists to the control sample or variation in food compositions. However, among the formulated complementary foods, RDG was the most preferred followed by FDG and GDG, respectively, and this could also be ascribed to differences in processing techniques, i.e., fermentation and germination, which might have influenced sensorial attributes of the food samples. This finding is in contrary to the report of Syeunda et al. (2019) and Fikiru et al. (2017), who reported that malting influenced sensory attributes of malted complementary food positively. However, it is well established that germination and fermentation are usually used to enhance the nutritional quality and organoleptic properties of food products (Ebisa et al. 2021).

Selection criteria for determining optimal formulated food sample

The best formulated complementary food was determined using a ranking system with reference to some nutritional criteria, that is, protein content, energy value, total essential amino acids, selected minerals (Fe & Zn), mineral molar ratios (Ca/P & Na/K), biological values, overall acceptability and growth performance as described by Oluwajuyitan et al. (2020) with slight modification. Based on the relative importance and interrelationship of these criteria, ranking was reported on an equal score basis. The scoring scale of these criteria was to produce identical conclusive results. The experimental food samples were ranked from 1 (worst) to 3 (best) to objectively determine the choice of the blends. The blend scored with the highest percentage was considered to possess the best nutritional qualities (Table 8). Using these criteria, FDG sample had the highest percentage score (83.3%) compared to GDG (66.6%) and RDG (53.3%).

Conclusion

The study established that FDG (Fermented maize, Defatted groundnut and Ginger) was ranked best over GDG (Germinated maize, Defatted groundnut and Ginger) and RDG (Raw maize, Defatted groundnut and Ginger) in terms of nutritional composition, ability to support growth in rats and overall acceptability. Hence, FDG food sample may be suitable to mitigate expensive commercial infant complementary foods in alleviating anaemia and protein-energy malnutrition in children. However, clinical trial is required to substantiate nutritional potential and acceptability of this formulated complementary food particularly in children.

Availability of data and materials

Data are available upon request by contacting the authors.

Abbreviations

- EDTA:

-

Ethylene diamine tetrachloroacetic acid

- TSM:

-

Technicon Sequential Multi-Sample

- TAA:

-

Total amino acids

- NEAAS:

-

Non-essential amino acids

- EAAs:

-

Essential amino acids

- Ni:

-

Nitrogen intake

- Nf:

-

Fecal nitrogen;

- Nef:

-

Endogenous fecal nitrogen

- Nu:

-

Urinary nitrogen

- Neu:

-

Endogenous urinary nitrogen

- TPD:

-

True protein digestibility

- FER:

-

Protein efficiency ratio

- NR:

-

Nitrogen retention

- FER:

-

Food efficiency

- BV:

-

Biological value

- IN:

-

Iso-Nitrogenous

- AST:

-

Aminotransferase

- ALT:

-

Alanine aminotransferase

- ALP:

-

Alkaline phosphatase

- PCV:

-

Pack cell volume

- RBC:

-

Red blood cells

- Hbc:

-

Haemoglobin concentration

- WBC:

-

White blood cells

- NEU:

-

Neutrophil

- LYM:

-

Lymphocytes

- MCH:

-

Mean corpuscular haemoglobin

- MCHC:

-

Mean corpuscular haemoglobin concentrated

- MCV:

-

Means corpuscular volume

- BCAAs:

-

Branched amino acids

- ArAA:

-

Aromatic amino acids

- SAA:

-

Sulphur amino acids

- Nutribom:

-

NBM, a maize-based complementary food

References

Abumrad, N. N., & Barbul, A. (2004). The use of arginine in clinical practice. In: Cynober LA, editor. Metabolic & Therapeutic Aspects of Amino Acids in Clinical Nutrition, Boca Raton, FL: CRC Press; 2014, 595–611.

Adakole, M. I., Ikya, J. K., Girgih, A. T., Ogori, A. F., & Upev, V. (2020). Effect of ginger flour supplementation on fermented millet flour ‘ibyer’ anti-diabetic and biochemical properties. Archive of Food and Nutritional Science, 4, 029–035.

Adebimpe, W. O. (2019). Prevalence and knowledge of risk factors of childhood obesity among school-going children in Osogbo, South-Western Nigeria. Malawi Medical Journal, 31(1), 19–24.

Adesanmi, A. R., Malomo, S. A., & Fagbemi, T. N. (2020). Nutritional quality of formulated complementary diet from defatted almond seed, yellow maize and quality protein maize flours. Food Production, Processing and Nutrition, 2(1), 1–12.

Adeyemo, O. K. (2005). Haematological and histopathological effects of cassava mill effluent in Clarias gariepinus. African Journal of Biomedical Research, 8, 179–183.

Adlak, T., Tiwari, S., Gupta, N., Tripathi, M. K., Sikarwar, R. S., Sastya, R., & Gupta, V. (2021). Assessment for yield and nutritional profiling of groundnut with the help of allele specific markers for desirable fatty acids. International Journal of Current Microbiology & Applied Science, 10(02), 1625–1637.

Agbede, J. O., & Aletor, V. A. (2003). Evaluation of fishmeal replaced with leaf protein concentrate in diets of broiler chicks. Effects on performance, muscle growth, haematology and serum metabolism. International Journal of Poultry Science, 2, 14–19.

Akinsola, A. O., Idowu, M. A., Babajide, J. M., Oguntona, C. R. B., & Shittu, T. A. (2018). Production and functional property of maize-millet based complementary food blended with soybean. African Journal of Food Science, 12(12), 360–366. https://doi.org/10.5897/AJFS2015.1387.

Akinwande, B. A., Ade-Omowaye, B. I. O., Olaniyan, S. A., & Akintaro, O. O. (2008). Quality evaluation of ginger-flavoured soy-cassava biscuit. Nutrition & Food Science, 38(5), 473–481. https://doi.org/10.1108/00346650810906994.

Alagbaoso, S. O., Nwosu, J. N., Njoku, N. E., Umelo, M. C., Eluchie, C., & Agunwa, I. M. (2015). Effect of processing on the nutritional and anti nutritional properties of Canavalia plagiosperma piper seeds. European Journal of Food Science and Technology, 3(3), 45–69.

Alawode, E., Idowu, M., Adeola, A., Oke, E., & Omoniyi, S. (2017). Some quality attributes of complementary food produced from flour blends of orange flesh sweet potato, sorghum, and soybean. Croatia Journal of Food Science and Technology, 122–129. https://doi.org/10.17508/CJFST.2017.9.2.06.

Al-Mamun, M. A., & Ghani, R. B. A. (2017). The role of iron and zinc in cognitive development of children. Asian Journal of Medical and Biological Research, 3(2), 145–151. https://doi.org/10.3329/ajmbr.v3i2.33561.

AOAC (2005). Official methods of analysis 18th edn, association of official analytical chemists. Washington, DC: Official methods of analysis 18th ed, association of official analytical chemists.

AOAC (2010). Official methods of analysis. Washington D.C: Association of official analytical chemists, 18th ed.

AOAC (2012). Official methods of analysis, (pp. 806–842). Arlington: 18th ed, Association of Official Analytical Chemists.

Asibuo, J. Y., Akromah, R., Safo-Kantanka, O., Adu-Dapaah, H. K., Ohemeng-Dapaah, S., & Agyeman, A. (2008). Chemical composition of groundnut, Arachis hypogaea (L) landraces. African Journal of Biotechnology, 7(13), 2203–2208.

Atwater conversion Factor (2019). The “4-4-9” Method for calculating calorie ratios, Retrieved from: http://dietsoftware.com/atwater.html.

Awuchi, C. G., Igwe, V. S., & Amagwula, I. O. (2020). Nutritional diseases and nutrient toxicities: A systematic review of the diets and nutrition for prevention and treatment. International Journal of Advanced Academic Research, 6(1), 1–46.

Balestra, F., Cocci, E., Pinnavaia, G., & Romani, S. (2011). Evaluation of antioxidant, rheological and sensorial properties of wheat flour dough and bread containing ginger powder. LWT-Food Science and Technology, 44(3), 700–705. https://doi.org/10.1016/j.lwt.2010.10.017.

Basirat, Z., Moghadamnia, A., Kashifard, M., & Sarifi-Razavi, A. (2009). The effect of ginger biscuit on nausea and vomiting in early pregnancy. Acta Medica Iranica, 51–56.

Biadgo, B., Melku, M., Abebe, S. M., & Abebe, M. (2016). Hematological indices and their correlation with fasting blood glucose level and anthropometric measurements in type 2 diabetes mellitus patients in Gondar, Northwest Ethiopia. Diabetes Metabolism Syndromes and Obesity, 9, 91–99. https://doi.org/10.2147/DMSO.S97563.

Bidlingmeyer, B., Cohen, S., & Tarvin, T. (1984). The rapid analysis of amino acids using pre-column derivatization. Journal of Chromatography, 33, 93–104.

Canadian Council on Animal Care (1993). Guide to the care and use of experimental animals, (vol. 1, 2nd ed., p. 212). Ottawa: CCAC.

Ciosek, Z., Kot, K., Kosik-Bogacka, D., Łanocha-Arendarczyk, N., & Rotter, I. (2021). The effects of calcium, magnesium, phosphorus, fluoride, and Lead on bone tissue. Biomolecules, 11, 506. https://doi.org/10.3390/biom11040506.

Dacie, J. V., & Lewis, S. N. (1984). Practical Haematology, (6th ed., ). Edinburg: Churchill Livingstone.

Danquah, F. I., Ansu-Mensah, M., Bawontuo, V., Yeboah, M., & Kuupiel, D. (2020). Prevalence, incidence, and trends of childhood overweight/obesity in sub-Saharan Africa: A systematic scoping review. Arch Public Health, 78, 109. https://doi.org/10.1186/s13690-020-00491-2.

Darambazar, E. (2018). Method of phytic acid determination in food, feed, and plant materials. Assay protocol, (p. 4). Canada: University of Saskatchewan. https://doi.org/10.13140/RG.2.2.14852.27520.

Diana N. C. (2007). Appendix: therapeutic drug monitoring and laboratory reference ranges. In: Stephen JM, Maxine AP (eds) Current medical diagnosis and treatment, 46th edn. McGraw Hill, New York, pp 1767–1775.

Ebisa O. K., Yetenayet B. T., Geremew B. S., Sirawdink F. F. (2021). Optimization of nutritional and sensory qualities of complementary foods prepared from sorghum, soybean, karkade and premix in Benishangul - Gumuz region, Ethiopia, Heliyon, 7:(9):e07955, doi: https://doi.org/10.1016/j.heliyon.2021.e07955.

Ekpenyong, C. E., Akpan, E. E., & Udoh, N. S. (2012). Phytochemistry and toxicity studies of Telfairia occidentalis aqueous leaves extract on liver biochemical indices in wistar rats. American Journal of Medicine and Medical Sciences, 2(5), 103–110. https://doi.org/10.5923/j.ajmms.20120205.03.

Ezzati, M., Alan, D., Lopez, A. R., & Murray, C. J. L. (2004). Overweight and obesity (body mass index). Comparative quantification of health risks., 1(1), 497–496.

Ferguson, E. L., Gibson, R. S., Thompson, L. U., & Ounpuu, S. (1988). Phytate, zinc, and calcium contents of 30 east African foods and their calculated phytate: Zn, ca: Phytate, and [ca][phytate]/[Zn] molar ratios. Journal of Food Composition and Analysis, 1(4), 316–325.

Fikiru, O., Bultosa, G., Fikreyesus Forsido, S., & Temesgen, M. (2017). Nutritional quality and sensory acceptability of complementary food blended from maize (Zea mays), roasted pea (Pisum sativum), and malted barley (Hordium vulgare). Food Science & Nutrition, 5(2), 173–181.

Flynn, N. E., Meininger, C. J., Haynes, T. E., & Wu, G. (2002). The metabolic basis of arginine nutrition and pharmacotherapy. Biomedicine & Pharmacotherapy, 56(9), 427–438.

Gehrke, C. W., Wall, L. L., Sr., Absheer, J. S., Kaiser, F. E., & Zumwalt, R. W. (1985). Sample preparation for chromatography of amino acids: acid hydrolysis of proteins. Journal of Association of Official Analytical Chemists, 68, 811–821.

Gemede, H. F. (2020). Nutritional and antinutritional evaluation of complementary foods formulated from maize, pea, and anchote flours. Food Science and Nutrition, 00, 1–9. https://doi.org/10.1002/fsn3.1516.

Giannini, E., Botta, F., Fasoli, A., Ceppa, P., Risso, D., Lantieri, P. B., … Testa, R. (1999). Progressive liver functional impairment is associated with an increase in AST/ALT ratio. Digestive Diseases and Sciences, 44(6), 1249–1253.

Ijarotimi, O. S., Fatiregun, M. R., & Oluwajuyitan, T. D. (2022). Nutritional, antioxidant and organoleptic properties of therapeutic-complementary-food formulated from locally available food materials for severe acute malnutrition management. Bulletin of the National Research Centre, 46, 39 (2022). https://doi.org/10.1186/s42269-022-00725-z.

Ijarotimi, O. S., & Keshinro, O. O. (2013). Determination of nutrient composition and protein quality of potential complementary foods formulated from the combination of fermented popcorn, African locust and Bambara groundnut seed flour. Polish Journal of Food and Nutrition Science, 155–166. https://doi.org/10.2478/v10222-012-0079-z.

Ijarotimi, O. S., Oluwalana, I. B., & Ogunedojutimi, M. O. (2012). Nutrient composition, functional, sensory and microbial status of popcorn-based (Zea mays everta) complementary foods enriched with cashew nut (Anacardium occidentale L.) flour. African Journal of Food, & Agriculture, Nutrition & Development, 12, 6425–6446.

Jaffe, C. S. (2003). Analytical chemistry of food. Blackie Academic and Professional, New York, 1, 200.

James, S., Akosu, N. I., Maina, Y. C., Baba, A. I., Nwokocha, L., Amuga, S. J., Audu, Y., & Omeiza, M. (2018). Effect of addition of processed bambara nut on the functional and sensory acceptability of millet-based infant formula. Food science & nutrition, 6(4), 783–790. https://doi.org/10.1002/fsn3.618.

Jaroslaw, S., Armand, M., Gizowska, M., Marcinek, M., Sasim, E., & Szafran, E. (2009). Ceramic-in-polymer versus polymer-in-ceramic polymeric electrolytes: A novel approach. Journal of Power Sources, 194, 66–72. https://doi.org/10.1016/j.jpowsour.2009.01.070.

Kim, F. M., & Frank, R. G. (2014). Protein needs early in life and long-term health. The American Journal of Clinical Nutrition, 99(3), 718S–722S. https://doi.org/10.3945/ajcn.113.072603.

Kumar, V., Sharma, A., Kaur, R., Thukral, A. K., Bhardwaj, R., & Ahmad, P. (2017). Differential distribution of amino acids in plants. Amino Acids, 49(5), 821–869. https://doi.org/10.1007/s00726-017-2401-x.

Lesinski, G. B., Reville, P. K., Mace, T. A., Young, G. S., Ahn-Jarvis, J., Thomas-Ahner, J., … Clinton, S. K. (2015). Consumption of soy isoflavone enriched bread in men with prostate cancer is associated with reduced proinflammatory cytokines and immunosuppressive cells. Cancer Prevention Research, 8, 1036–1044. https://doi.org/10.1158/1940-6207.capr-14-0464.

Linda, C. F. (2013). Corn. In A. F. Smith (Ed.), The Oxford encyclopedia of food and drink in America, (vol. 2013, 2nd ed., pp. 551–558). Oxford: Oxford University Press.

Ma, G., Li, Y., Jin, Y., Zhai, F., Kok, F. J., & Yang, X. (2007). Phytate intake and molar ratios of phytate to zinc, iron and calcium in the diets of people in China. European Journal of Clinical Nutrition, 61(3), 368–374. https://doi.org/10.1038/sj.ejcn.1602513.

Mahfuz, S., Hasan, A., Hassan, M., Saha, S., Islam, M., Billah, M., & Islam, S. (2016). Dietary phytate intake inhibits the bioavailability of iron and calcium in the diets of pregnant women in rural Bangladesh : A cross-sectional study. BMC Nutrition, 1–10. https://doi.org/10.1186/s40795-016-0064-8.

Makori, N., Kassim, N., Kinabo, J., & Matemu, A. O. (2017). Nutrient composition of cereals based complementary F lour and its nutritional adequacy in infants nutrition. Journal of Food Research, 6(6), 45–55.

Mankambou, J. G., Fagbohoun, J. B., Ya, K. C., Blei, S. K., & Kouame, L. P. (2021). Assessment of minerals, vitamins and functional properties of flours from germinated yellow maize (Zea mays L.) seeds from Daloa (Côte D’Ivoire). International Journal of Food Science and Nutrition Engineering, 11(2), 35–42. https://doi.org/10.5923/j.food.20211102.01.

Mashhadi, N. S., Ghiasvand, R., Askari, G., Hariri, M., Darvishi, L., & Mofid, M. R. (2013). Anti-oxidative and anti-inflammatory effects of ginger in health and physical activity: Review of current evidence. International Journal of Preventive Medicine, 4(1), S36.

Mengistu, A. T., Kelbessa, U., Geremew, T. W., & Betre, G. M. (2016). Development and nutritional assessment of complementary foods from fermented cereals and soybean. Journal of Food Science & Nutrition, 2, 14–20.

Michaelsen, K. F., Hoppe, C., Roos, N., Kaestel, P., Stougaard, M., Lauritzen, L., … Friis, H. (2009). Choice of foods and ingredients for moderately malnourished children 6 months to 5 years of age. Food and Nutrition Bulletin, 30(3), S343–S404.

Motuma, A., Azeb, L., & Bekeso, G. (2016). Complementary feeding: Review of recommendations, feeding practices, and adequacy of homemade complementary food preparations in developing countries – Lessons from Ethiopia. Frontiers in Nutrition, 3–41. https://doi.org/10.3389/fnut.2016.00041.

Nathan, D. G., & Oski, F. A. (1987). “Hematology of infancy and childhood”, third addition.

Nicholson, J. F., & Pesce, M. A. (2011). Laboratory testing in infants and children. In R. E. Behrman (Ed.), Nelson textbook of pediatrics, (19th ed., ). Philadelphia: Saunders.

Nicholson, J. K., & Wilson, I. D. (1991). Strategic applications of proton nuclear magnetic resonance spectroscopy in clinical biochemistry and analytical toxicology. In Analytical Proceedings, 28(6), 183–184.

Nnam, N. M. (2000). Chemical evaluation of multimixes formulated from some local staples for use as complementary foods in Nigeria. Plant Foods for Human Nutrition, 55(3), 255–263.

Noah, A. A. (2017). Nutrient composition and sensory evaluation of complementary food made from maize, plantain soybean blends. International Journal of Current Microbiology and Applied Sciences, 6(12), 5421–5428. https://doi.org/10.20546/ijcmas.2017.612.507.

Norhaizan, M. E., & Nor Faizadatul Ain, A. W. (2009). Determination of phytate, iron, zinc, calcium contents and their molar ratios in commonly consumed raw and prepared food in Malaysia. Malaysian Journal of Nutrition, 15(2), 213–222.

Nuss, E. T., & Tanumihardjo, S. A. (2011). Quality protein maize for Africa: Closing the protein inadequacy gap in vulnerable populations. Advance Nutrition., 2, 217–224.

Odebode, F. D., Ekeleme, O. T., Ijarotimi, O. S., Malomo, S. A., Idowu, A. O., Badejo, A. A., & Fagbemi, T. N. (2017). Nutritional composition, antidiabetic and antilipidemic potentials of flour blends made from unripe plantain, soybean cake and rice bran. Journal of Food Biochemistry, e12447, 1–9. https://doi.org/10.1111/jfbc.12447.

Oh, R. C., & Hustead, T. R. (2011). Causes and evaluation of mildly elevated liver transaminase levels. American Family Physician, 84(9), 1003–1008.

Okoye, J. I., & Ene, G. I. (2018). Evaluation of nutritional and organoleptic properties of maize-based complementary foods supplemented with black bean and crayfish flours. Global Advanced Research Journal of Food Science and Technology, 6(1), 001–009.

Olapade, A. A., & Aworh, O. C. (2012). Chemical and nutritional evaluation of extruded complementary foods from blends of Fonio (Digitaria exilis Stapf) and cowpea (Vigna unguiculata L. Walp) flours. International journal of food and nutrition. Science, 1(3), 1–8.

Oluwajuyitan, T. D., Ijarotimi, O. S., & Fagbemi, T. N. (2020). Nutritional, biochemical and organoleptic properties of high protein-fibre functional foods developed from plantain, defatted soybean, rice-bran and oat-bran flour. Nutrition and Food Science, 50(6), 1–32. https://doi.org/10.1108/NFS-06-2020-0225.

Oluwamodupe, G., Francisca, O., Omolara, O. A., et al. (2012). Effect of ginger spices (Zingiber officinale) on the shelflife of cookies (biscuit) produced from blends of melonflour ‘egusi’ (Critrullus coloynthis l) and wheat flour (Triticum spp)[J]. Prime Journal of Microbiology and Research., 5(2), 131–136.

Onwurafor, E., Ani, J., Nneka, U., & Ziegle, G. (2020). Quality evaluation of fermented maize-based complementary foods as affected by amylase-rich mungbean malt. Journal of Food Stability, 3(1), 26–37.

Rajeshwari, K., Bang, A., Chaturvedi, P., Kumar, V., Yadav, B., Bharadva, K., … Agarwal, R. (2010). Infant and young child feeding guidelines: 2010. Indian Pediatrics, 47, 995–1004.

Rossi-Márquez, G., Helguera, M., Briones, M., Dávalos-Saucedo, C. A., & Di Pierro, P. (2021). Edible coating from enzymatically reticulated whey protein-pectin to improve shelf life on roasted peanuts. Coatings, 11(3), 329.

Samuel, F. O., Akintayo, B., & Eyinla, T. E. (2021). Complementary feeding knowledge and practices of caregivers in orphanages improved after nutrition education intervention in Ibadan, Nigeria. Open Journal of Nursing, 11(7).

Sathe, S. K., Deshpande, S. S., & Salunkhe, D. K. (1982). Functional properties of winged bean proteins. Journal of Food Science, 47, 503–508.

Semba, R. D., Shardell, M., Ashour, F. A. S., Moaddel, R., Trehan, I., Maleta, K. M., … Manary, M. J. (2016). Child stunting is associated with low circulating essential amino acids. EBioMedicine, 6, 246–252.

Shiriki, D., Igyor, M. A., & Gernah, D. I. (2015). Nutritional evaluation of complementary food formulations from maize, soybean and peanut fortified with Moringa oleifera leaf powder. Food and Nutrition Sciences, 6(05), 494–500.

Sidney, M. M. J. (2006). Arginine: Beyond protein. The American Journal of Clinical Nutrition, 83(2), 508S–512S. https://doi.org/10.1093/ajcn/83.2.508S.

Smith, P. G. (2003). Introduction to Food Process Engineering. New York: Kluwer Academic/Plenum Publishers. https://doi.org/10.1007/978-1-4615-0201-2.

Singh, G., Kapoor, I. P. S., Singh, P., de Heluani, C. S., de Lampasona, M. P., & Catalan, C. A. (2008). Chemistry, antioxidant and antimicrobial investigations on essential oil and oleoresins of Zingiber officinale. Food and Chemical Toxicology, 46(10), 3295–3302. https://doi.org/10.1016/j.fct.2008.07.017.

Singh, G., Suresh, S., Bayineni, V. K., & Kadeppagari, R. K. (2015). Lipase inhibitors from plants and their medical applications. International Journal of Pharmacy and Pharmaceutical Sciences., 7, 1–5.

Solomon, M. (2005). Nutritive value of three potential complementary foods based on cereals and legumes. The African journal of food, agriculture, Nutrition and Development (AJFAND), 5, 1–14.

Solomon, M., & Owolawashe, H. (2007). The analyses of amino acid, fatty acid and mineral in legume-cereal based complementary food blend used in Jos, Nigeria. The Internet Journal of Nutrition and Wellness, 4, 3–7.

Spelbrink, R. E. J., Gerrits, P. J., Mooij, C., & Giuseppin, M. L. F. (2011). Quantitative determination of trypsin inhibitory activity in complex matrices. The Open Food Science Journal, 2011(5), 42–46.

Stoilova, I., Krastanov, A., Stoyanova, A., Denev, P., & Gargova, S. (2007). Antioxidant activity of a ginger extract (Zingiber officinale). Food Chemistry, 102(3), 764–770. https://doi.org/10.1016/j.foodchem.2006.06.023.

Syeunda, C. O., Anyango, J. O., & Faraj, A. K. (2019). Effect of compositing precooked cowpea with improved malted finger millet on anti-nutrients content and sensory attributes of complementary porridge. Food and Nutrition Sciences, 10(9), 1157–1178.

Taha, Z., Garemo, M., & Nanda, J. (2020). Complementary feeding practices among infants and young children in Abu Dhabi, United Arab Emirates. BMC Public Health, 20, 1308. https://doi.org/10.1186/s12889-020-09393-y.

Tufa, M., Urga, K., Weledesemayat, G., & Mitiku, B. (2016). Development and nutritional assessment of complementary foods from fermented cereals and soybean. Journal of Food Science and Nutrition, 2, 1–8.

United States Department of Agriculture (2018). USDA National Nutrient Database for standard reference https://www.ars.usda.gov/northeast-area/beltsville-mdbhnrc/beltsville-human-nutrition-research-center/nutrient-datalaboratory/docs/usdanational-nutrient-database-for-standard-reference/

Wani, I. A., Sogi, D. S., Wani, A. A., & Gill, B. S. (2013). Physico-chemical and functional properties of flours from Indian kidney bean (Phaseolus vulgaris L.) cultivars. LWT-Food Science and Technology, 53(1), 278–284.

Wani, I. A., Wani, A. A., Gani, A., Muzzaffar, S., Gul, K. M., Masoodi, F. A., & Wani, T. A. (2015). Effect of gamma-irradiation on physico-chemical and functional properties of arrowhead (Sagittaria sagittifolia L.) tuber flour. Food Bioscience, 11, 23–32.

Zakari, U. M., Hassan, A., & Kida, F. (2018). Chemical composition, functional and organoleptic properties of complementary foods formulated from millet, soybean and African locust bean fruit pulp flour blends. African Journal of Food Science, 12(6), 126–130. https://doi.org/10.5897/AJFS2018.1692.

Zhang, G., Xu, Z., Gao, Y., Huang, X., & Yang, T. (2015). Effects of germination on the nutritional properties, phenolic profiles, and antioxidant activities of buckwheat. Journal of Food Science, 80, H1111–H1119. https://doi.org/10.1111/1750-3841.12830.

Zhang, W. L., Zhu, L., & Jiang, J. G. (2014). Active ingredients from natural botanicals in the treatment of obesity. Obesity Reviews., 2014(15), 957–967.

Acknowledgements

The author would like to acknowledge the laboratory staff of the Department of Food Science and Technology as well as Department of Biochemistry of the Federal University of Technology, Akure, Nigeria.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Ijarotimi O. S. designed the experiment, collected and analysed data with the assistance of Oguntuase S. O. a laboratory Technologist in the Department of Food Science and Technology, Akure, Nigeria; and as well as prepared the manuscript and serving as corresponding author. The author(s) read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The Ethical Committee for human and Laboratory Animals of School of Agriculture and Agricultural Technology, Akure, Nigeria (FUTA/ SAAT/2021/027) approved the study protocol. The experimental design was conducted in accordance with the force laws and regulations as regards both human and animal use and care as contained in the Canadian Council on Animal Care Guidelines and Protocol Review (Canadian Council on Animal Care, 1993).

Consent for publication

Not applicable.

Competing interests

The author declares that there is no competing interest on this research work that would bias the collection, analysis, reporting or publishing of this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ijarotimi, O.S. Nutritional quality, functional property and acceptability of maize (Zea mays) based complementary foods enriched with defatted groundnut (Arachis hypogea L.) and ginger (Zinger officinale Roscoe) powder in Wistar rats. Food Prod Process and Nutr 4, 13 (2022). https://doi.org/10.1186/s43014-022-00091-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s43014-022-00091-3