Abstract

Background

This research was done to evaluate the bond strength using two repair methods with lithium disilicate ceramic.

Methods

Cojet and clearfil repair methods were used to repair lithium disilicate ceramic. The ceramic was sliced into slices before sintering (30 samples). Vita Ambria (Vita, Zahnfabrik, Germany) ceramic was used, surface-treated with the 2 repair systems and then bonded to composite. Samples are stored, thermocycling was done, and then, shear loading was done until fracture. Bond strength values were collected and statistically analysed.

Results

The results showed that the cojet surface treatment showed significantly more bond strength (14.43 ± 1.46 Mpa) than the clearfil surface treatment showing (4.16 ± 1.33) as indicated by paired t-test p ≤ 0.05.

Conclusions

Bond strength between composite and the ceramic Vita Ambria is better using cojet surface treatment than using the clearfil system.

Similar content being viewed by others

Background

Ceramics are used nowadays on a very large scale worldwide as it has superior aesthetic quality, but this should be accompanied by proper longevity and serving time. Lithium disilicate ceramics are considered relatively with low fracture toughness and that is why it is subjected to fracture due to crack propagation, especially the veneering layer (Garbelotto et al. 2019). There are many causes for the chipping of the veneering part or piece of it, as improper design of the infrastructure, problem in the matching of coefficient of thermal expansion, improper preparation, improper laboratory steps, presence of porosities, improper occlusion, excessive force by trauma or habits as bruxism (Maawadh et al. 2020). The chipping need to be well assessed and to reach a decision whether do we have to replace it or it can be repaired (Zarone et al. 2019).

Heintze and Rousson in 2010 described three chipping degrees with different clinical response: grade 1 (small, to be just polished), grade 2 (moderate, to be repaired with composite) and grade 3 (severe, the prosthesis must be replaced) (Heintze and Rousson 2010). From the most common sites that are considered an indication for repair, the incisal edges are prone to chipping due to improper occlusion sometimes (Nogueira et al. 2023). In most cases, repair should be done to prevent aesthetic and functional complaining of the patient (Stefanie et al. 2023).

The ceramic repair is considered an easy, cheap approach with saved chairside time and patient’s time. Before taking the decision to repair, the restoration should have good margins and aesthetics (Reston et al. 2008). In addition, how large is the chipping and its site is an important factor to determine the success of the repair and the ability to be done clinically (Soares 2023). Repair could be done directly intraorally or indirectly in the laboratory.

To have a successful repair for a reasonable time, there should be proper bonding between the ceramic and the composite (Özcan 2014). Many methods are introduced to repair the ceramic with good bond with the composite. The ceramic surface should be treated using sandblasting with alumina particles (accompanied by silica coating or not), and surfaces of glass ceramics as lithium disilicates should be etched with 10% hydrofluoric acid for 1 min (Özcan and Volpato 2015). Then adhesion promoters as silane and composite resin should be applied.

This study was done to assess the bond strength between the composite and lithium disilicate ceramic after surface treatment with two methods, the cojet and the clearfil systems. The null hypothesis is that the cojet system will aid in more bond strength with the composite resin used for repair.

Methods

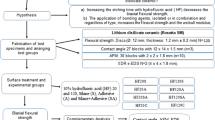

Thirty lithium disilicate samples were used. Vita Ambria was divided into 2 groups, 1 and 2, according to the surface treatment systems.

Group 1: Vita Ambria repair using cojet repair system (3 M ESPE, Seenfeld, Germany) n = 15.

Group 2: Vita Ambria repair using clearfil repair system (Kuraray Medical INC 1621 Sakazu, Kurashiki, Japan) n = 15.

Blocks of Vita Ambria were sliced into slices of 2 mm thickness. They were cut by 0.5 mm disc (Buehler USA) attached to Isomet 4000 low-speed precision sectioning saw at velocity 2500 rpm under continuous water irrigation, and finishing was done using silicon carbide papers 300 grits, which were cleaned for 3 min in ultrasonic cleaner with distilled water.

The Vita Ambria slices were fired in compatible ceramic furnace (VITA Vacumat) according to manufacturer’s instructions. Holding time of crystallization was 10 min at temperature 830 °C. Slices were removed from the furnace and grouped into two groups according to the repair system.

Slices were put in acrylic blocks leaving one surface uncovered, for proper handling during shear bond strength assessment.

Surface treatment was done with each repair kit according to the manufacturer’s instructions. A special mould was manufactured to standardize the dimensions of the composite samples that will be bonded to the ceramic slices. The mould has inner hole with diameter 5 mm and height of 2 mm with outer stabilizing ring.

The air pressure of the microetcher was set to 30–45 psi, so the energy of impact is enough for proper coating. Cojet sand was used with the etcher (30 μ aluminium oxide particles covered with silicone oxide). Blasting was done from distance 7–10 mm perpendicular to the slices. Even coating was done for 15 s. After coating, ESPE silane was painted using clean brush and left to dry for 5 min. Visio bond was applied to the silanized surface of the slices with a brush and light-cured for 20 s. Z 100 light-cured composite resin was applied to the ceramic using the tailored Teflon mould and cured with light 500 mW/cm2 intensity and 5 mm away from the slices.

For the other group, particle abrasion was done for 20 s by 50 μ alumina with 2.5 bars pressure from a distance of 10 mm. Slices were rinsed and then dried with oil-free air using a compressor. Etching with phosphoric acid was done to the surface, left for 20 s, then washed and dried. Clearfil SE bond primer containing phosphate monomer and clearfil porcelain bond activator (silane) was applied to the surface and left for 5 s. The volatile constituents were evaporated using air stream. Proper dryness of the surface was done. Clearfil SE bond containing phosphate monomer was applied. Methacrylate monomer, hydroxyethyl methacrylate and inorganic fillers were applied to the surface with a brush, uniformed with light air stream and light-cured for 10 s. Clearfil AP-X light-cured composite was used; it contains silanated barium glass, colloidal silica, silica, BISGMA, TEGDMA and dicamphorquinone. Composite was put using the mould and light-cured for 40 s, 500mW/cm2 from 5 mm distance. The slices were stored for 7 days in distilled water and then thermocycled between 5 and 55 °C for 7500 cycles with a 30 s dwell time.

Shear test was done to assess the bond strength, using computer-controlled material testing machine with load cell of 5 KN, and then, data were recorded. Shear test was done by compressive mode of load applied at the ceramic composite bond using mono bevelled chisel shaped metallic rod at crosshead speed of 0.5 mm/minute. Load needed for breaking the bond was recorded in Newton. Load was divided by the bonded area to show bond strength Ʈ = p/πr.2, Ʈ = shear bond strength, Mpa), p = load at failure (N), π = 3.14, and r = radius of disc (mm).

Results

GraphPad InStat (GraphPad, Inc.) software is used. Significance value was p ≤ 0.05. Variance was checked if it is homogenous. Errors as well as normal distribution were also checked.

Descriptive analysis for shear bond strength (Mpa) was carried out to find the mean, standard deviation (SD), minimum, maximum and 95% confidence interval of the 2 surface treatments tested (Table 1 and Fig. 1).

Surface treatment with cojet method showed significantly higher bond strength with composite 14.43 Mpa than when using clearfil 4.16 Mpa as indicated by paired t test (p = 0.0001).

Discussion

Repair of lithium disilicate ceramics is a very important point to study. This type of ceramics is still considered weak and liable to chipping although it gives the best aesthetic results. Therefore, repair method is an important point of concern to dentists. In vitro studies mainly give a clue to the clinical performance. Lithium disilicate (Amber Mill) shows after etching loose structure of many small thin lithium disilicate crystals 0.2 μm in length, with patches of glassy matrix. The unsintered material shows cracks that are gone with crystallization giving strength of 450 Mpa.

Bonding to lithium disilicate ceramics depends on mechanical and chemical methods as it has a glassy content (Phark et al. 2016). Bonding is done with the surface after application of bonding resin. Hydrofluoric acid is used to remove the amorphous glass in glass ceramics only, so the irregular crystals are exposed, and then, the resin composite can penetrate and be locked after polymerization. Etching can precipitate silica fluoride salts on the surface that can impair bonding, so ultrasonic cleaning is beneficial (Shimada et al. 2002). Silane bifunctional organic molecules are used after etching; it can bond with the resin of the composite and on the other side with the silica of the glass ceramics only (Phark and Duarte 2022).

Other surface treatments are used air abrasion with alumina particles with or without silica layer for promoting repair of fractured part of ceramic with composite (Garbelotto et al. 2019). Increasing the surface area increases the bonded surface area and the bond strength (Sato et al. 2016). This is one of the explanations approving the results of our study where the abrasion using the cojet method showed more bonding to the repair composite than the clearfil method. Opposing our results, other studies as done by Ataoll and Ergun in 2018 showed that the etching as with clearfil gives more uniform bonding than with blasting as done with the cojet and with more preferable bond (Seda et al. xxxx). (Figs. 2 and 3)

The cojet system has fine particle size for abrasion 30 μ, so the speed should be slow. During the process, heat is generated and particles are embedded deep 15 μ in the surface. Studies augmenting our findings as Barutcigil et al. in 2019 explained the better results with the cojet system in bonding the ceramic with the resin by the fact that the silica coated on the surface after abrasion with silica-coated alumina particles will react chemically with the silane applied after linking it with the resin of the repair composite (Barutcigil et al. 2019). Another study by Khan et al. in 2017 reviewed the researches adding to the prove that chemical coating with silica increased bond strength between the ceramic and composite chemically. Other studies showed equal results of bonding after using cojet and clearfil as that by Galal et al. in 2022, but this was with zirconia oxide-based ceramics (Galal et al. 2022). But opposing our results, Wang et al. in 2022 found that among many methods of repair, one of them is the cojet; the hydrofluoric acid etching followed by the universal adhesive showed the best bond strength results (Wang et al. 2022).

Also confirming our results, some studies as that by Schwenter et al. in 2016 who found that the hydrofluoric acid etching and silane application might be a cause to decrease bond strength due to some surface changes (Schwenter et al. 2016). In addition, Silva et al. in 2018 found that mechanical grinding and then application of bonding resin give better bond than with the use of hydrofluoric acid etching (Silva et al. 2018). But as a fact, how durable is the repair depends on the surface created and how the dentist stick to the proper instructions of the repair procedure as found by Mesquita et al. in 2021 (Mesquita et al. 2021). Also this was concluded in a review by Alqarawi et al. in 2022 that it was all about the proper following of the dentist to the manufacturer’s instructions in using the repair system chosen (Alqarawi and Alhumaidan 2022).

In our study, storage in water and thermocycling were used to simulate the intraoral environment somehow. In addition, it gives an effect from the early stages of ageing (Byeon et al. 2017). According to our study, the use of cojet system is preferred over the clearfil system for bonding of this type of lithium disilicate ceramic. From the limitations of this study, other types of ceramics with modifications in the filler content need to be studied. In addition, shear bond strength was the only tested forces here, which is not the situation intraorally. In addition, more clinical research needs to be done to approve our results.

Conclusions

Bond strength between composite and the ceramic Vita Ambria is better with cojet surface treatment than with the clearfil system. Clinical implication: Cojet system is recommended for repair process of restorations made from this new ceramic.

Availability of data and materials

Data are available under reasoning demand.

References

Alqarawi FK, Alhumaidan AA, Aldakhili A, Alfayez A, Abushowmi T, Alramadan A, Alzoubi F (2022) Intraoral repair of fractured ceramics: a literature review. F1000Rearch 8(11):1275

Ataol AS, Ergun G (2018) Repair bond strength of resin composite to bilayer dental ceramics. J Adv Prosthodont 10(2):101–112

Barutcigil K, Barutcigil Ç, Kul E, Özarslan MM, Buyukkaplan US (2019) Effect of different surface treatments on bond strength of resin cement to a CAD/ CAM restorative material. J Prosthodont 28:71–78

Byeon SM, Lee MH, Bae TS (2017) Shear bond strength of Al2O3 sandblasted Y-TZP ceramic to the orthodontic metal bracket. Materials 10(2):148

Galal RM, Hamza GE, ElHotieby MM (2022) Evaluation of repair bond strength with different methods for zirconia restorations. Bull Nat Res Centre 46:209. https://doi.org/10.1186/s42269-022-00900-2

Garbelotto LG, Fukushima KA, Özcan M, Cesar PF, Volpato CA (2019) Chipping of veneering ceramic on a lithium disilicate anterior single crown: description of repair method and a fractographic failure analysis. J Esthet Restor Dentistry 31(4):299–303

Garbelotto LG, Fukushima KA, Özcan M, Cesar PF, Volpato CA (2019) Chipping of veneering ceramic on a lithium disilicate anterior single crown: description of repair method and a fractographic failure analysis. J Esthet Restor Dentistry. 31(4):299–303

Heintze SD, Rousson V (2010) Survival of zirconia—and metal—supported fixed dental prostheses: a systematic review. Int J Prosthodont 23:493–502

Khan AA, Al Kheraif AAA, Jamaluddin S, Elsharawy M, Divakar DD (2017) Recent trends in surface treatment methods for bonding composite cement to zirconia: a review. J Adhes Dent 19:7–19

Maawadh AM, Almohareb T, Al-Hamdan RS, Al Deeb M, Naseem M, Alhenaki AM, Vohra F, Abduljabbar T (2020) Repair strength and surface topography of lithium disilicate and hybrid resin ceramics with LLLT and photodynamic therapy in comparison to hydrofluoric acid. J Appl Biomater Funct Mater 18:2280800020966938

Mesquita AMM, Al-Haj Husain N, Molinero-Mourelle P et al (2021) An intraoral repair method for chipping fracture of a multi-unit fixed zirconia reconstruction: a direct dental technique. Eur J Dent 15(1):174–178

Nogueira IO, Pereira CNB, Abreu LG, Diniz IMA, Magalhães CS, Silveira RRD (2023) Do different protocols affect the success rate or bond strength of glass-ceramics repaired with composite resin? A systematic review and metaanalysis. J Prosthet Dent. https://doi.org/10.1016/j.prosdent.2023.06.020

Özcan M (2014) How to repair ceramic chipping or fracture in metal-ceramic fixed dental prostheses intraorally: step-by-step procedures. J Adhes Dent 16:491–492

Özcan M, Volpato CAM (2015) Surface conditioning protocol for the adhesion of resin-based materials to glassy matrix ceramics: how to condition and why? J Adhes Dent 17:292–293

Phark J-H, Duarte S Jr (2022) Microstructural considerations for novel lithium disilicate glass ceramics: a review. J Esthet Restor Dent 34(1):92–103. https://doi.org/10.1111/jerd.12864

Phark J-H, Sartori N, Duarte S (2016) Bonding to silica-based glass-ceramics: a review of current techniques and novel self-etching ceramic primers. Quintessence Dent Technol 2016:27–36

Reston EG, Filho SC, Arossi G, Cogo RB, Rocha CS, Closs LQ (2008) Repairing ceramic restorations: final solution or alternative procedure? Oper Dent 33:461–466

Sato TP, Anami LC, Melo RM, Valandro LF, Bottino MA (2016) Effects of surface treatments on the bond strength between resin cement and a new zirconia-reinforced lithium silicate ceramic. Oper Dent 41:284–292

Schwenter J, Schmidli F, Weiger R, Fischer J (2016) Adhesive bonding to polymer infiltrated ceramic. Dent Mater J 35(5):796–802. https://doi.org/10.4012/dmj.2015-271

Shimada Y, Yamaguchi S, Tagami J (2002) Micro-shear bond strength of dual-cured resin cement to glass ceramics. Dent Mater 18(5):380–388

Silva PN, Martinelli-Lobo CM, Bottino MA, Melo RM, Valandro LF (2018) Bond strength between a polymer-infiltrated ceramic network and a composite for repair: effect of several ceramic surface treatments. Braz Oral Res 32:e28

Soares PM, da Rosa LS, Pereira GK, Valandro LF, Rippe MP, Dal Piva AM, Feilzer AJ, Kleverlaan CJ, Tribst JP (2023) Mechanical behavior of repaired monolithic crowns: a 3D finite element analysis. Dentistry J 11(11):254

Stefanie L, Iris F, Reinhard H,· Alexander C, Andreas K, Retrospective clinical study on the performance and aesthetic outcome of pressed lithium disilicate restorations in posterior teeth up to 8.3 years. Clinical Oral Investigations. Published online 23 Oct 2023.

Wang Y, Hui R, Gao Li, Ma Y, Xiangnan Wu, Meng Y, Hao Z (2022) Effect of surface treatments on bond durability of zirconia reinforced lithium silicate ceramics: an in vitro study. J Prosthet Dent 128(6):1350.e1-1350.e10

Zarone F, Mauro MID, Ausiello P, Ruggiero G, Sorrentino R (2019) Current status on lithium disilicate and zirconia: a narrative review. BMC Oral Health 19:134

Acknowledgements

The authors refer deep acknowledgment to all colleagues and professors in National Research Centre.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

RM carried out the practical work, collected the data and was a major contributor in writing the manuscript. GE performed the statistical analysis, made final revision and wrote the manuscript. MM carried out final writing and editing, plagiarism step and submission. YE carried out the laboratory work and performed grammar correction. All authors have read and approved the final manuscript before submission.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

No competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Galal, R.M., Hamza, G.E., Elhotieby, M.M. et al. Assessment of two repairing techniques for a novel lithium disilicate-based ceramic. Bull Natl Res Cent 48, 21 (2024). https://doi.org/10.1186/s42269-024-01168-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42269-024-01168-4