Abstract

Background

Silage is achieved by anaerobic fermentation of lactic acid bacteria. However, harvest stage and Lactiplantibacillus plantarum (L. plantarum) content affect the changes of microbial community in silage, which play an important role in silage quality and mycotoxin levels. The current study evaluated the effects exerted by the application of L. plantarum on fermentation, mycotoxins and bacterial community of whole-crop corn silage at different harvest stages. The fresh whole plant corn from the same area was harvested during the milk stage and the dough stage, following which from each harvest stage was subjected to four L. plantarum treatments: 0 cfu/g; 1 × 106 cfu/g; 1 × 107 cfu/g; and 1 × 108 cfu/g in a 2 × 4 factorial experimental design. Samples were collected on days 0, 3, 7, 21 and 42. Subsequently, nutrition parameters, fermentation parameters, mycotoxin levels and bacterial community were determined.

Results

Prolonging the harvest stage resulted in an increase in the levels of starch and dry matter as well as deoxynivalenol in corn silage. Addition of 1 × 107 cfu/g and 1 × 108 cfu/g of L. plantarum applied after 42 d of ensilage reduced dry matter loss, which significantly lowered deoxynivalenol concentration in corn silage at the dough stage (P < 0.01). The pH of corn silage decreased, whereas the lactic acid concentration increased after ensiling. The effects exerted by the interaction (harvest stage × dose of L. plantarum) on pH on day 21 as well as on fermentation and lactic acid on days 21 and 42 were significant (P < 0.05). Addition of 1 × 107 cfu/g of L. plantarum at the dough stage significantly increased the relative abundance of Firmicutes while decreasing that of Bacteroidetes, compared to when L. plantarum was not added (P < 0.05).

Conclusions

Adding L. plantarum improved the fermentation quality and bacterial community of silage, which reduced part of mycotoxin content and relative abundance of harmful bacteria. In addition, adding L. plantarum in dough stage resulted in greater improvements to mycotoxin content and bacterial community.

Similar content being viewed by others

Background

Corn used for whole-crop silage is planted worldwide [1] and is characterized by relatively stable yields [2], high energy content [3] and good palatability [4]] under various environments and planting conditions. Feed intake is elevated in dairy animals fed whole-crop corn silage, resulting in an increase in the yield as well as in the protein content of milk [5, 6]. Therefore, it has come to be considered as a key ingredient in the diet of dairy animals all around the world [7]. Planting of corn used for whole-crop corn silage has significantly increased during the past few decades, the amount planted being second only to forage grass. The nutritional value of whole-crop corn silage largely depends on its dry matter (DM) and starch content, as well as its starch degradation rates. Although the starch content of corn silage increases with corn maturity, the digestibility of starch and neutral detergent fiber (NDF) [8] in the rumen decreases. Thus, harvest stage exerts a significant impact on quality [9], feed intake [10] and milk yield of whole-crop corn silage [11]. Mycotoxins, which are mostly produced by mold in the field [12], may also be produced during aerobic deterioration [13, 14]. During ensiling, insufficient compaction density and oxygen availability lead to the reproduction of yeasts, molds and harmful bacteria, causing a further loss in DM and other nutrients in silage [15, 16]. Mycotoxins, which are harmful to the health of dairy cows, may even enter their milk via blood, thereby threatening human health. Addition of homofermentative lactic acid bacteria, such as L. plantarum, to silage causes rapid fermentation of silage, producing lactic acid and reducing the pH, both of which inhibit plant enzymes and the reproduction of harmful bacteria, thus preserving silage associated nutrients [17, 18]. Karolina et al. showed that application of L. plantarum decreased the amount of deoxynivalenol (DON) in wheat by 56.6%, compared to untreated control wheat samples [19]. Other studies have shown that aflatoxin production was reduced in silage inoculated with lactobacillus buchneri [20, 21]. Recently, Ma et al. [22] reported that aflatoxin B1 (AFB1) concentration in whole-crop corn silage could be reduced within 3 days of ensiling regardless of the type of lactobacillus inoculated. whole-crop corn silage quality and mycotoxins may affect the health and production of dairy cows, thereby reducing the economic benefits of pasture. In the current era of precision feeding, nutritionists strive to increase the nutritional value of feed by increasing its consistency, to optimize dietary formulation and feed bunk management [23]. Therefore, a deeper understanding of the effects exerted by additives at different harvest stages on silage quality may enable their application to be harmonized with harvest stages. Therefore, we hypothesized that adding L. plantarum to whole-crop corn silage from different harvest periods may result in silage quality with different degrees of enhancement, and reduce the content of mycotoxin in whole-crop corn silage as well.

Therefore, the current study aimed to determine the effects of the harvest period, L. plantarum dose and their interaction on nutrition parameters, fermentation parameters, mycotoxin levels and bacterial community.

Methods

Silage harvesting and treatment

Whole-crop corn was reaped with a forage harvester on the 14th (milk stage) and 27th (dough stage) of September, 2019, at a field in Baicheng, China (45°N, 122°E). While reaping, the forage harvester cut the whole-crop corn into 2 cm pieces, which were brought back to the ruminant nutrition laboratory of Jilin Agricultural University (Changchun, China), for prompt silage production. A 2 × 4 factorial experimental design was used: the fresh whole corn plant was harvested during the milk and dough stages, and subjected to 4 concentrations of L. plantarum (China Center of Industrial Culture Collection: CICC 22703; 0 cfu/g, 1 × 106 cfu/g, 1 × 107 cfu/g, and 1 × 108 cfu/g). The different treatments are shown in Fig. 1. Samples were collected on days 0, 3, 7, 21, and 42. Three replicates were examined for each group. L. plantarum was revitalized with de Man, Rogosa, and Sharpe (MRS) agar medium, then inoculated into liquid MRS broth for 24 h. The colony counts of L. plantarum in the final liquid MRS broth were 9.6 (± 1.14) × 107 cfu/g. L. plantarum was diluted to required concentrations using distilled water. Then, the diluted L. plantarum solution was sprayed onto whole-crop corn and mixed well. The glass silos were cleaned with a brush and detergent, then washed with clean water and rinsed with deionized water three times and dried. Treated whole-crop corn (1.75 kg) was filled and compacted into glass silos with a capacity of 2.5 L (diameter: 10 cm; height: 19 cm; silage density: 700 kg/m3). The lid with the sealing rubber ring was covered on the silos and sealed with 3 turns of adhesive tape. After 0, 3, 7, 21 and 42 d of ensiling, whole-crop corn silage in each silo were taken out and mixed well. Mixed whole-crop corn silage were put in zip lock bags, and kept frozen in a − 20℃ refrigerator until needed for further analyses.

Measurement of nutrition parameters and mycotoxins

The 0-, 3-, 7-, 21-, and 42-d silages frozen were thawed at room temperature and then mixed. Half of the thawed samples were dried at 65 ℃ for 48 h to determine dry matter (DM) concentration (0 d silage was fresh whole-crop corn). Dried samples were milled through a 1-mm sieve for the estimation of fermentation parameters (Hainai ship Hi-100C, Hainai Yinjiang Litongtrade company Lit., Zhejiang, China). Crude protein (CP) and starch were determined as proposed by AOAC (1990) [24]. An Ankom 200 fiber analyser (Ankom Technology Corp., Fairport, NY, USA) was used to measure neutral detergent fiber (NDF) and acid detergent fiber (ADF) concentrations according to the method described by Van Soest et al. [25]. All nutrition parameters were expressed in terms of DM.

Enzyme-linked immunosorbent assay kits (R-Biopharm Co., Ltd, Germany) were used to measure the contents of the following mycotoxins: zearalenone (ZEN), deoxynivalenol (DON) and aflatoxin B1 (AFB1).

Measurement of fermentation parameters

Twenty grams of the other half of the sample after thawing were soaked in 180 mL of distilled water, following which the mixed liquid was shaken for 2 h at room temperature. The mixed liquid were filtered to obtain the extract via the four layers of gauze. The extract was centrifuged in a 1.5-mL centrifuge tube for 10 min at 10,000 r/min for volatile fatty acid (VFA) analysis, and 3 mL of the extract was centrifuged in a 5-mL centrifuge tube for 10 min at 4000 r/min for ammoniacal nitrogen (NH3–N) analysis. A Sanxin MP523-04 pH meter (Shanghai Sanxin Instrumentation, Inc., Shanghai, China) was inserted into the remaining extract to measure pH. VFA concentrations were analyzed using an Agilent 7890B gas chromatograph (Agilent Technology, Inc., Santa Clara, CA, USA). Measurement conditions were established according to Isac et al. [26]. Lactic acid concentrations were determined using high performance liquid chromatograph (SHIMADZU-10A, Kyoto, Japan), via the measurement method described by Wang et al. [27]. The concentration of NH3–N was determined according to the phenol–sodium hypochlorite colorimetric method [28].

Microbial community and data analysis

The samples of the ZM (0 cfu/g + milk stage), MM (1 × 107 cfu/g + milk stage), ZD (0 cfu/g + dough stage), and MD (1 × 107 cfu/g + dough stage) groups ensiled for 42 d were selected for microbial community analysis according to the results of fermentation parameters, nutrition parameters and mycotoxins. Five grams of each silage corn sample was ground with liquid nitrogen and placed in cryogenic vials. These treated samples were sent to Shanghai Parsons Biotech Co., Ltd (Shanghai China) for bacterial community analysis. The experimental process mainly involved the extraction of total DNA via genomic–DNA extraction Kits (TIANGEN Biotech Co. Ltd., Beijing, China), PCR amplification of V3—V4 regions (forward primer: ACTCCTACGGGAGGCAGCA; reverse primer: TCGGACTACHVGGGTWTCTA-AT), fluorescence quantification of amplified products [fluorescent reagent: quant-iT PicoGreen dsDNA assay kit; quantitative instrument: microplate reader (BioTek, FLx800, Vermont, USA)], and preparation of sequencing library and high-throughput sequencing performed on an Illumina HiSeq platform (Illumina, Shanghai, China). Dada2 [29] was used for primer removal, quality filtering, denoising, splicing and chimera removal to generate feature sequence. Microbial community data were analyzed at phylum and genus levels using the Silva database (Release132, http://www.arb-silva.de). The online Personalbio Genescloud Platform (www.genescloud.cn) was used to analyze high-throughput sequencing. A rarefaction curve was drawn using QIIME2 (2019.4) to explore the variation of sample alpha diversity with leveling depth. Chao1 [30] and Simpson [31] indices were estimated to assess the alpha diversity of microbial communities.

Statistical analysis

The General Linear Models procedure in SPSS (IBM, Armonk, NY, USA) was used to analyze the 2 × 4 full factorial experimental design. The model was as follows: Yijk = μ + Fi + Vj + Fi × Vj + eijk, where μ is the overall mean, Fi is the effect of harvest stage (i = 1–2), Vj is the effect of the dose of L. plantarum (j = 1–4), Fi × Vj is the harvest stage × dose of L. plantarum, and eijk is the residual effect. Then, eight treatment groups were analyzed by one-way ANOVA. The results are presented as the mean and standard error of the mean (SEM), and the differences among means were tested for significance by Duncan’s multiple range test. For all analyses, statistical significance was set at P < 0.05.

Results

Nutrient parameters, fermentation parameters and mycotoxin contents of fresh whole-crop corn at milk and dough stages are shown in Table 1. The contents of dry matter (DM), starch, lactic acid and deoxynivalenol (DON) at the milk stage were significantly higher than those at the dough stage (P < 0.01). However, the contents of crude protein (CP), neutral detergent fiber (NDF), acid detergent fiber (ADF), pH, acetic acid and Aflatoxin B1 (AFB1) at the milk stage were lower than those at the dough stage, although the difference was not significant.

Effects of Lactiplantibacillus plantarum on nutrition parameters

The effects of the harvest stage and the dose of L. plantarum added, as well as their interaction, on nutrition parameters in whole-crop corn silage are shown in Tables 2 and 3. Overall, all nutrition parameters (DM, starch, NDF, ADF, and CP) decreased with ensiling. DM, starch and NDF concentrations at the milk stage were significantly lower than those at the dough stage for the whole ensiling period. Starch concentration in the MM group was significantly higher than that in the ZM group only on day 42 of silage fermentation (P > 0.05). At the dough stage, addition of 1 × 107 cfu/g L. plantarum reduced DM loss compared with DM loss without the addition of L. plantarum. Harvest stage and the addition of L. plantarum, as well as their interaction, did not significantly affect CP concentrations of whole-crop corn silage for the whole fermentation period (P > 0.05). On day 7 of fermentation, the NDF concentration in the 1 × 108 cfu/kg L. plantarum group was significantly high than that in no addition and 1 × 106 cfu/g L. plantarum groups (P > 0.05). Harvest stage and the dose of L. plantarum added, as well as their interaction, significantly affected ADF in the whole-crop corn silage on day 42 (P < 0.05).

Effects of Lactiplantibacillus plantarum on fermentation parameters

The important effects of L. plantarum on fermentation parameters after 3–42 days of ensiling are presented in Tables 4 and 5. The interaction effects of harvest stage × the dose of L. plantarum added on pH on day 21 of fermentation and on lactic acid on days 21 to 42 of fermentation were significant (P < 0.05). Whole-crop corn silage at the dough stage had a significantly higher pH compared with that at the milk stage on days 7–42 (P < 0.01). The dose of L. plantarum added exerted a significant effect on pH on silage fermentation days 21–42 (P < 0.01). Harvest stages (days 3 and 42) as well as the dose of L. plantarum added exerted a significant effect on lactic acid concentration on days 3 and 21 to 42 of fermentation (P < 0.05). The pH in the MM and HM groups at the milk stage were significantly lower than that in the ZM and LM groups on day 21, while pH in the MM group was significantly lower than that in the other three groups on day 42 (P < 0.01). Lactic acid concentration in the silage of MM groups on day 21 was significantly higher compared to that in the other three groups, while pH values in the MM and HM groups on day 42 were significantly higher than those in the ZM and LM groups on day 42 (P < 0.01). Harvest stage × dose of L. plantarum exerted a significant interaction effect on NH3–N concentration on day 3 of fermentation (P < 0.05). The dose of L. plantarum exerted a significant effect on the concentrations of both NH3–N and acetic acid in silage on days 3–7 (P < 0.01). At the milk stage, the NH3–N concentration in the MD group as well as in the HD group was significantly lower than that in the ZD group on days 3–7 (P < 0.01). However, acetic acid concentration in MD as well as in HD was significantly higher than that in ZD on days 3–7 (P < 0.01). At the dough stage, the NH3–N concentration in LD as well as in MD was significantly lower than that in ZD on day 3 (P < 0.01).

Effects of Lactiplantibacillus plantarum on mycotoxins

The harvest stage and the dose of L. plantarum and their interaction effects on the mycotoxin content of the whole-crop corn silage are presented in Table 6. During the whole ensiling process, the DON content at the milk stage was always significantly lower than that at the dough stage. On day 3 of ensiling, harvest stage × dose of L. plantarum exerted a significant interaction effect on DON content (P < 0.01). Furthermore, the DON content in the 1 × 107 cfu/g group was significantly lower than that in the 1 × 106 cfu/g and 1 × 108 cfu/g groups (P < 0.01). At the dough stage, the DON content in MD as well as in HD was significantly lower than that in ZD on day 42 of ensiling (P < 0.01). As far as AFB1 content was concerned, the AFB1 content in milk stage was significantly higher than that in the dough stage on days 7–42 of ensiling (P < 0.01). At the dough stage, the AFB1 content in MD as well as in HD was significantly lower than that in ZD as well as in LD on day 3 of ensiling (P < 0.01). The zearalenone (ZEN) content in each group was lower than the minimum limit of the kit, so it was not described.

Effects of Lactiplantibacillus plantarum on bacterial community

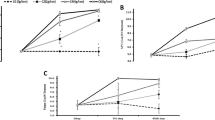

A total of 3,996,296 valid sequences and 2,430,268 high-quality sequences (nonchimeric) were detected. A sequencing depth of 20,000 sequences (97%) was reached, indicating that the sequencing was sufficient to reflect the diversity in the samples (Fig. 2). Diversity and richness were represented by the Chao1 index and the Simpson index, respectively, in Fig. 3. The Chao1 index among groups did not indicate a difference in either the harvest stage or the L. plantarum treatment. The Simpson index of the ZD group was significantly higher than that of the ZM group (P < 0.01), indicating that bacterial diversity at the dough stage was higher than that at the milk stage. Addition of L. plantarum to silage reduced the Simpson index indicating that the bacterial diversity was reduced; however, the difference was not significant. These results showed that microbial community diversity was greater during the dough harvest, and that addition of 1 × 107 cfu/g L. plantarum reduced diversity in the microbial community.

Abundance of the top 5 bacteria at the phylum level and the top 18 bacteria at the genus level of corn silage for 42 days of fermentation are presented in Fig. 4. Firmicutes was the dominant phylum, its relative abundance accounting for more than 77% in each group (Table 7). The relative abundances of both Firmicutes and Proteobacteria were influenced by harvest stage and the dose of L. plantarum. Addition of L. plantarum significantly increased the abundance of Firmicutes, but decreased the abundance of Proteobacteria. Lactobacillus was the dominant genus in all silage, its relative abundance reaching more than 74% in each group. The relative abundances of Lactobacillus, Weissella, Enterobacter, Gluconobacter, Lactococcus, Sphingomonas, Pantoea, Asaia, Serratia, Stenotrophomonas, Cedecea and Methylobacterium were significantly affected by harvest stage in Table 8 (P < 0.01). Addition of 1 × 107 cfu/g L. plantarum to the silage significantly reduced the relative abundances of Weissella, Klebsiella, Leuconostoc, Enterobacter, Gluconobacter, Pantoea and Asaia compared with no addition of L. plantarum (P < 0.01). The relative abundances of Weissella, Klebsiella, Gluconobacter, Asaia and Pediococcus in the silage were significantly affected (P < 0.01) by the interaction between harvest stage and the dose of L. plantarum.

Comparison of bacterial alpha diversity indices among each group. a Chao1 index among each group. b Simpson index among each group. 0 cfu/g of L. plantarum + milk stage (ZM); 1 × 107 cfu/g of L. plantarum + milk stage (MM); 0 cfu/g of L. plantarum + dough stage (ZD); 1 × 10.7 cfu/g of L. plantarum + dough stage (MD)

a Silage on day 42 bacterial community at the phylum level. b Silage on day 42 bacterial community at the genus level. 0 cfu/g of L. plantarum + milk stage (ZM); 1 × 107 cfu/g of L. plantarum + milk stage (MM); 0 cfu/g of L. plantarum + dough stage (ZD); 1 × 107 cfu/g of L. plantarum + dough stage (MD).

Discussion

Effects of harvest period and Lactiplantibacillus plantarum on the quality of silage

Harvest stage plays a major role in the nutrient parameters of corn silage. With the extension of the harvesting period, the grain filling stage of maize increases, and more soluble sugar is transformed into starch, thereby increasing the starch content and decreasing neutral detergent fiber (NDF) and acid detergent fiber (ADF) contents in whole-crop corn silage [32, 33]. In the current experiment, the contents of dry matter (DM) and starch in whole-crop corn silage at the dough stage were significantly increased compared with those at the milk stage, whereas the NDF and ADF content of whole-crop corn silage at the milk stage was higher than those at the dough stage. Even the addition of L. plantarum did not change this trend. Some studies have suggested that NDF was transformed into starch during the maturation process [2, 34].

High lactic acid content is considered as a positive indicator of silage quality, whereas high acetic and butyric acid contents are considered to be negative indicators [35]. In this study, the concentrations of propionic acid and butyric acid were almost undetectable (< 0.3%), while the concentration of acetic acid was within the normal range. This indicated that the corn silage was successfully fermented. Lactic acid content increased gradually with the extension of fermentation time, whereas the pH was gradually reduced. L. plantarum utilizes soluble carbohydrates to produce lactic acid, resulting in a large accumulation of lactic acid [36]. The decrease in pH during corn silage fermentation is mainly caused by an excessive production of lactic acid. It is more difficult to accumulate lactic acid during the dough stage compared with the milk stage, as the utilization of soluble carbohydrates by L. plantarum decreases with the extension of harvest time [23].

Ammoniacal nitrogen (NH3–N) production is the main route by which nitrogen is lost during whole-crop corn silage fermentation. Wang et al. reported [37] that during the fermentation of whole-crop corn silage, crude protein (CP) degradation in plants caused by plant enzymes and proteolytic bacteria was accompanied by the production of NH3–N. Wang et al. [38] found that compared with the control group, inoculation with two strains of L. plantarum could rapidly reduce pH values, leading to lower NH3–N/TN. As L. plantarum doses increased, DM and CP contents linearly increased, while NH3–N content linearly decreased [39]. Our results also indicated that adding 1 × 106 and 1 × 107 cfu/g of L. plantarum significantly reduced the NH3–N content compared with that in the control group, leading to the retention of CP content. This may be due to the low pH environment caused by the rapid fermentation of L. plantarum, which inhibited the activities of plant enzymes and proteolytic bacteria [40, 41]. Therefore, adding the proper concentration of L. plantarum to whole-crop corn silage at different harvest stages may reduce nitrogen loss.

Effects of harvest period and Lactiplantibacillus plantarum on the mycotoxins of silage

Mycotoxin content acts as an important parameter in evaluating corn silage hygiene. Mycotoxins mainly include aflatoxin B1 (AFB1), deoxynivalenol (DON) and zearalenone (ZEN). AFB1 is produced by Aspergillus flavus, an aerobic fungus. Cavallarin et al. [21] reported that the addition of Lactobacillus brucei to corn silage limited the reproduction of aerobic spoilage bacteria, and may have limited the ability of Aspergillus flavus to produce AFB1. DON is a mycotoxin produced by Fusarium spp. Pigs fed DON contaminated feed display food refusal, diarrhea, and reproductive issues [42], while ruminants that show a certain degree of resistance to DON, are able to transform it into less toxic secondary metabolites using rumen microbes [43, 44]. A study has shown that L. plantarum remains active and accumulates in grain samples contaminated with DON [2]. In our study, the DON content of whole-crop corn silage at the dough stage was significantly higher than that of whole-crop corn silage at the milk stage. This may be attributed to the fact that prolonging the harvest period may have extended the exposure of crops to temperature and humidity conditions suitable for mold growth and mycotoxin production [45]. We found that adding L. plantarum to whole-crop corn silage at the milk stage did not reduce the DON content in whole-crop corn silage during fermentation, whereas adding L. plantarum to whole-crop corn silage at the dough stage significantly reduced the DON content after ensiling, compared to the that in the control group. Niderkorn et al. [46] reported that L. plantarum may adsorb DON, while Franco et al. [47] found that L. plantarum degraded DON. The results of this study also indicated that adding L. plantarum to whole-crop corn silage while extending fermentation time may decrease AFB1 concentration compared with that of the control group. In summary, we surmise that adding more than 1 × 107 cfu/g L. plantarum to silage made from whole-crop corn at the dough harvest stage, may inhibit DON production or even degrade it.

Effects of harvest period and Lactiplantibacillus plantarum on bacterial community of silage

We found that Firmicutes was the dominant phylum in the bacterial community of each group, followed by Proteobacteria, which is consistent with the report of Ni et al. [48]. At the genus level, the dominant genera in this experiment included Lactobacillus, Weissella and Klebsiella, the sum of the relative abundances of which was greater than 75%. However, this result was different from that of Lv et al. [49]. Although the most dominant bacteria in both was Lactobacillus, the second and third dominant bacteria reported by Lv et al. differed from those found in our results, which may be attributed to silage made from different varieties, as well as to nutrients, growth environments, and regions [50]. Lactic acid bacteria and propionic acid bacteria were considered desirable during ensiling, but bacteria of the Enterobacteriaceae family, acetic acid bacteria, spore-forming bacteria (Bacillus and Clostridium), Listeria, as well several species of molds and yeasts, were considered undesirable [51]. In addition, the distribution of bacterial genus levels in silage may also be related to the types of additives. A study demonstrated that addition of Lactiplantibacillus plantarum and cellulase decreased the abundance of Weissella and Leuconostoc [52]. Another study indicated that adding both 1 × 105 and 1 × 107 cfu/g of L. plantarum could reduce the relative abundance of Weissella in silage[53], and the optimum addition amount of Lactiplantibacillus plantarum is 1 × 107 cfu/g FW, which was consistent with our results. In this study, the addition of L. plantarum also significantly decreased the relative abundance of Weissella compared with that of the control group. In addition, the abundances of Enterobacter and Klebsiella were decreased, which were considered desirable, because Enterobacter and Klebsiella are pathogenic bacteria [54]. The storage period and kernel maturity were the most important factors responsible for changes in the bacterial community of silages. Yang et al. [55] also found that the activity of Enterobacter was inhibited in a low pH environment. which may be due to the rapid reduction of pH in silage caused by the addition of L. plantarum. Some bacteria are inhibited due to their inability to adapt to acidic environments [56], leading to a reduction in bacterial diversity. This theory was confirmed by Ma et al. [57]. They found that inoculating L. plantarum into the whole corn plant could significantly reduce the bacterial diversity in corn silage, which was consistent with our results. In terms of maturity, Carvalho et al. [58] believed that the storage period and maturity were the most important factors responsible for changes in the bacterial community of silages. Because corn plants collected at the dough stage stayed longer in the field than those collected at the milk stage, they probably suffered more stress, which may make them more likely to be contaminated by harmful bacteria. However, because of the addition of L. plantarum in this study, the relative abundance of harmful bacteria in corn silage in the dough stage was reduced, thereby improving its quality.

Conclusions

Adding L. plantarum to whole-crop corn silage from different harvest stages could improve the quality of silage and reduce the relative abundance of harmful bacteria, but the effect was different. The study indicated that more than 1 × 107 cfu/g of L. plantarum should be added to the whole-crop corn silage at the dough stage of harvest. Although the addition of L. plantarum could reduce parts of mycotoxins content in the whole-crop corn silage, the accumulation of a large number of mycotoxins caused by the harvest period could not be completely eliminated. So the harvest period could not be blindly prolonged to pursue high DM and starch content in corn silage, and mycotoxin contents should also be considered important indicators.

Availability of data and materials

All data generated or analyzed during this study are included in this published article.

Abbreviations

- L. plantarum :

-

Lactiplantibacillus plantarum

- DM:

-

Dry matter

- DON:

-

Deoxynivalenol

- AFB1:

-

Aflatoxin B1

- CP:

-

Crude protein

- NDF:

-

Neutral detergent fiber

- ADF:

-

Acid detergent fiber

- VFA:

-

Volatile fatty acid

- NH3–N:

-

Ammoniacal nitrogen

- ZEN:

-

Zearalenone

- ASV:

-

Amplicon sequence variant

References

Erenstein O, Jaleta M, Sonder K, Mottaleb K, Prasanna BM. Global maize production, consumption and trade: trends and R&D implications. Food Sec. 2022. https://doi.org/10.1007/s12571-022-01288-7.

Amler R. Maize Harvest to Measure. Gesunde Pflanz. 2014;66:41–51.

Serbester U, Akkaya MR, Yucel C, Gorgulu M. Comparison of yield, nutritive value, and in vitro digestibility of monocrop and intercropped corn-soybean silages cut at two maturity stages. Ital J Anim Sci. 2016;14:66–70.

Keady TWJ, Kilpatrick DJ, Mayne CS, Gordon FJ. Effects of replacing grass silage with maize silages, differing in maturity, on performance and potential concentrate sparing effect of dairy cows offered two feed value grass silages. Livest Sci. 2008;119:1–11.

Kliem KE, Morgan R, Humphries DJ, Shingfield KJ, Givens DI. Effect of replacing grass silage with maize silage in the diet on bovine milk fatty acid composition. Animal. 2008;2:1850–8.

Khan NA, Tewoldebrhan TA, Cone JW, Hendriks WH. Effect of corn silage harvest maturity and concentrate type on milk fatty acid composition of dairy cows. J Dairy Sci. 2012;95:1472–83.

Khan NA, Cone JW, Fievez V, Hendriks WH. Causes of variation in fatty acid content and composition in grass and maize silages. Anim Feed Sci Technol. 2012;174:36–45.

Bueno JL, Bolson DC, Jacovaci FA, Gomes ALM, Daniel JLP. Storage length interacts with maturity to affect nutrient availability in unprocessed flint corn silage. R Bras Zootec. 2020;49: e20190247.

Rabelo CHS, De Rezende AV, Rabelo FHS, Basso FC, Harter CJ, Reis RA. Effects of hybrid, kernel maturity, and storage period on the bacterial community in high-moisture and rehydrated corn grain silages. Rev Caatinga. 2015;28:107–16.

Zaralis K, Norgaard P, Helander C, Murphy M, Weisbjerg MR, Nadeau E. Effects of maize maturity at harvest and dietary proportion of maize silage on intake and performance of growing/finishing bulls. Livest Sci. 2014;168:89–93.

Warner D, Dijkstra J, Hendriks WH, Pellikaan WF. Passage kinetics of 13C-labeled corn silage components through the gastro intestinal tract of dairy cows. J Dairy Sci. 2013;96:5844–58.

Garon DE, Richard L, Sage V, Bouchart D, Pottier LP. Microflora and multimycotoxin detection in corn silage: Experimental study. J Agric Food Chem. 2006;54:3479–84.

Gonzalez-Pereyra ML, Alonso VA, Sager R, Morlaco MB. Fungi and selected mycotoxins from pre- and post-fermented corn silage. J Appl Microbiol. 2008;104:1034–41.

Cavallarin L, Tabacco E, Antoniazzi S, Borreani G. Afla-toxin accumulation in whole crop maize silage as a result of aerobic exposure. J Sci Food Agric. 2011;91:2419–25.

Anesio AHC, Santos MV, Silva LD, Silveira RR, Braz TGS, Pereira RC. Effects of ensiling density on chemical and microbiological characteristics of sorghum silage. J Anim Feed Sci. 2017;26:65–9.

Sucu E, Kalkan H, Canbolat O, Filya I. Effects of ensiling density on nutritive value of maize and sorghum silages. J Anim Sci. 2016;45:596–660.

Schmidt RJ, Kung L. The effects of Lactobacillus buchneri with or without a homolactic bacterium on the fermentation and aerobic stability of corn silage made at different locations. J Dairy Sci. 2010;93:1616–24.

Tabacco E, Righi F, Quarantelli A, Borreani G. Dry matter and nutritional losses during aerobic deterioration of corn and sorghum silages as influenced by different lactic acid bacteria inocula. J Dairy Sci. 2011;94:1409–19.

Trakselyte-Rupsiene K, Juodeikiene G, Hajnal EJ, Bartkevics V, Bartkiene E. Challenges of lactobacillus fermentation in combination with acoustic screening for deoxynivalenol and deoxynivalenol conjugates reduction in contaminated wheat—based products. Food Control. 2021;134:108699.

Iglesias C, Bach A, Devant M, Adelantado C, Calvo MA. The effect of Lactobacillus buchneri inoculation on corn silages conservation. Proceedings XI Jornadas sobre Pro-ducción Animal, Spain. 2005, p. 611–613.

Cavallarin L, Tabacco E, Antoniazzi S, Borreani G. Aflatoxin accumulation in whole crop maize silage as a result of aerobic exposure. J Sci Food Agric. 2011;91:2419–25.

Ma ZX, Amaro FX, Romero JJ, Pereira OG, Jeong KC, Adesogan AT. The capacity of silage inoculant bacteria to bind aflatoxin B1 in vitro and in contaminated corn silage. J Dairy Sci. 2017;100:7198–210.

Yuan X, Yang X, Wang W, Li J, Dong Z, Zhao J, Shao T. The effects of natamycin and hexanoic acid on the bacterial community, mycotoxins concentrations, fermentation profiles, and aerobic stability of high moisture whole-crop corn silage. Anim Feed Sci Technol. 2022;286: 115250.

Association of Official Agricultural Chemists. Association of analytical communities, Official Methods of Analysis. Washington: Association of Official Agricultural Chemists (US); 1990.

Van Soest PJ, Robertson JB, Lewis BA. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci. 1991;74:3583–97.

Isac MD, García MA, Aguilera JF, Alcaide EM. A comparative study of nutrient digestibility, kinetics of digestion and passage and rumen fermentation pattern in goats and sheep offered medium quality forages at the maintenance level of feeding. Arch Tierernahr. 1994;46:37–50.

Wang M, Franco M, Cai Y, Yu Z. Dynamics of fermentation profile and bacterial community of silage prepared with alfalfa, whole-plant corn and their mixture. Anim Feed Sci Tech. 2020;270: 114702.

Broderick GA, Kang JH. Automated simultaneous determination of ammonia and total amino acids in ruminal fluid and in vitro media. J Dairy Sci. 1980;63:64–75.

Callahan BJ, Mcmurdie PJ, Rosen MJ, Han AW, Johnson AJ, Holmes SP. Dada2: high-resolution sample inference from illumina amplicon data. Nat Methods. 2016;13:581–3.

Chao A. Nonparametric estimation of the number of classes in a population. Scan J Stat. 1984;11:265–70.

Simpson EH. Measurement of diversity. Nature. 1949;163:688.

Hatew B, Podesta SC, van Laar H, Pellikaan WF, Ellis JL, Dijkstra J, Bannink A. Effects of dietary starch content and rate of fermentation on methane production in lactating dairy cows. J Dairy Sci. 2015;98:486–99.

Ferraretto LF, Shaver RD, Luck BD. Silage review: Recent advances and future technologies for whole-plant and fractionated corn silage harvesting. J Dairy Sci. 2018;101:3937–51.

Bal MA, Shaver RD, Jirovec AG, Shinners KJ, Coors JG. Crop processing and chop length of corn silage: Effects on intake, digestion, and milk production by dairy cows. J Dairy Sci. 2000;83:1264–73.

Kung L, Shaver RD, Grant RJ, Schmidt RJ. Silage review: Interpretation of chemical, microbial, and organoleptic components of silages. J Dairy Sci. 2018;101:4020–33.

Adesogan AT, Salawu MB. The effect of different additives on the fermentation quality, aerobic stability and in vitro digestibility of pea/wheat bi-crop silages containing contrasting pea to wheat ratios. Grass Forage Sci. 2002;57:25–32.

Wang Q, Wang Z, Awasthi MK, Jiang Y, Li R, Ren X, Zhao J, Shen F, Wang M, Zhang Z. Evaluation of medical stone amendment for the reduction of nitrogen loss and bioavailability of heavy metals during pig manure composting. Bioresour Technol. 2016;220:297–304.

Wang NW, Xiong Y, Wang XK, Guo LN, Lin YL, Ni KK, Yang FY. Effects of Lactobacillus plantarum on Fermentation Quality and Anti-Nutritional Factors of Paper Mulberry Silage. Fermentation. 2022. https://doi.org/10.3390/fermentation8040144.

da Silva NC, Nascimento CF, Nascimento FA, de Resende FD, Daniel JLP, Siqueira GR. Fermentation and aerobic stability of rehydrated corn grain silage treated with different doses of Lactobacillus buchneri or a combination of Lactobacillus plantarum and Pediococcus acidilactici. J Dairy Sci. 2018;101:4158–67.

Ni KK, Wang FF, Zhu BG, Yang JX, Zhou GA, Pan Y, Tao Y, Zhong J. Effects of lactic acid bacteria and molasses additives on the microbial community and fermentation quality of soybean silage. Bioresour Technol. 2017;238:706–15.

Zhao J, Dong ZH, Lia JF, Chen L, Bai YF, Jia YS, Sha T. Evaluation of Lactobacillus plantarum MTD1 and waste molasses as fermentation modifier to increase silage quality and reduce ruminal greenhouse gas emissions of rice straw. Sci Total Environ. 2019;688:143–52.

Canady RA, Coker RD, Rgan SK, Krska R, Kuiper-Good-man T, Olsen M, Pestka JJ, Resnik S, Schlatter J. Safety Evaluation of Certain Mycotoxins in Food. Fifty-Sixth Report of the Joint FAO/WHO Expert Committee on Food Additives. International Programme on Chemical Safety, World Health Organization, Geneva, Switzerland.2001, p. 420–555.

Jamie MH, Dominique PB. Deoxynivalenol: mechanisms of action and its effects on various terrestrial and aquatic species. Food Chem Toxicol. 2021;157: 112616.

Marczuk J, Obremski K, Lutnicki K, Gajeck MA, Gajecki M. Zearalenone and deoxynivalenol mycotoxicosis in dairy cattle herds. Pol J Vet Sci. 2012;15:365–72.

Munkvold GP. Crop management practices to minimize the risk of mycotoxins contamination in temperate-zone maize. In: Leslie JF, Logrieco AF, editors. Mycotoxin reduction in grain chains. America: Academic; 2014. p. 59–75.

Niderkorn V, Boudra H, Morgavi DP. Binding of Fusarium mycotoxins by fermentative bacteria in vitro. J Appl Microbiol. 2006;101:849–56.

Franco TS, Garcia S, Hirooka EY, Ono YS, Santos JSD. Lactic acid bacteria in the inhibition of Fusarium graminearum and deoxynivalenol detoxification. J Appl Microbiol. 2011;111:739–48.

Ni K, Zhao J, Zhu B, Su R, Pan Y, Ma J, Zhou G, Tao Y, Liu X, Zhong J. Assessing the fermentation quality and microbial community of the mixed silage of forage soybean with crop corn or sorghum. Bioresour Technol. 2018;265:563–7.

Lv H, Pian R, Xing Y, Zhou W, Yang F, Chen X, Zhang Q. Effects of citric acid on fermentation characteristics and bacterial diversity of Amomum villosum silage. Bioresour Technol. 2020;307: 123290.

Wu Z, Luo YN, Bao JZ, Luo Y, Yu Z. Additives affect the distribution of metabolic profile, microbial communities and antibiotic resistance genes in high-moisture sweet corn kernel silage. Bioresour Technol. 2020;315: 123821.

Vila CLS, Carvalho BF. Silage fermentation - updates focusing on the performance of micro - organisms. J Appl Microbiol. 2019;128:966–84.

Wang QD, Wang RX, Wang CY, Dong WZ, Zhang ZX, Zhao LP, Zhang XY. Efects of cellulase and Lactobacillus plantarum on fermentation quality, chemical composition, and microbial community of mixed silage of whole-plant corn and peanut vines. Appl Biochem and Biotech. 2022;194:2465–80.

Zhu YC, Xiong HM, Wen ZY, Tian HC, Chen YY, Wu LG, Guo YQ, Sun BL. Effects of different concentrations of Lactobacillus plantarum and Bacillus licheniformis on silage quality, in vitro fermentation and microbial community of hybrid Pennisetum. Animals. 2022. https://doi.org/10.3390/ani12141752.

Feasey NA, Dougan G, Kingsley RA, Heyderman RS, Gordon MA. Invasive non-typhoidal salmonella disease: an emerging and neglected tropical disease in Africa. Lancet. 2012;379:2489–99.

Yang L, Yuan X, Li J, Dong Z, Shao T. Dynamics of microbial community and fermentation quality during ensiling of sterile and nonsterile alfalfa with or without Lactobacillus plantarum inoculant. Bioresour Technol. 2019;275:280–7.

Zhang L, Zhou X, Gu Q, Liang M, Mu S, Zhou B, Huang F, Lin B, Zou C. Analysis of the correlation between bacteria and fungi in sugarcane tops silage priorto and after aerobic exposure. Bioresour Technol. 2019;291:121835.

Ma ZY, Ungerfeld E, Ouyang Z, Zhou XL, Han XF, Zeng YQ, Tan ZL. Effect of Lactobacillus plantarum inoculation on chemical composition, fermentation, and bacterial community composition of ensiled sweet corn whole plant or stover. Fermentation. 2022. https://doi.org/10.3390/fermentation8010024.

Carvalho-Estrada PD, Fernandes J, da Silva EB, Tizioto P, Paziani SD, Duarte AP, Coutinho LL, Verdi MCQ, Nussio LG. Effects of hybrid, kernel maturity, and storage period on the bayst. Appl Microbiol. 2020. https://doi.org/10.1016/j.syapm.2020.126131.

Acknowledgements

Not applicable.

Funding

This study was supported by the Jilin Province Feed Engineering and Technology Research Center (20170623075TC).

Author information

Authors and Affiliations

Contributions

J-ND and S-ZL: wrote the original manuscript; J-ND, S-ZL, and XC: completed the experimental operation; J-ND, S-ZL, and X-FZ: collected and analyzed data; G-XQ and Y-GZ: contributed to conception and design of the study; TW, ZS, YS, ND, and X-FZ: contributed to review and editing; all authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Dong, J., Li, S., Chen, X. et al. Effects of Lactiplantibacillus plantarum inoculation on the quality and bacterial community of whole-crop corn silage at different harvest stages. Chem. Biol. Technol. Agric. 9, 57 (2022). https://doi.org/10.1186/s40538-022-00326-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40538-022-00326-y