Abstract

This study analyzed two glass eye beads discovered in an ancient tomb complex at Dongxin Furniture Square in Datong, Shanxi Province in China. The tomb complex was dated to the Northern Wei Dynasty (398–494 AD), when Datong was known as Pingcheng. We used scanning electron microscopy (SEM) and energy dispersive spectrometry (EDS) as well as a 3D microscope system with ultra-depth of field to conduct non-destructive tests on the beads. We examined the beads’ manufacturing techniques, including matrices, eye patterns, and bead holes. The composition analysis revealed that both beads belonged to the mix of v-Na-Ca and m-Na-Al glass system, which is a key indicator of local production in Java. The bases were colored using Co2+, whereas the white, red, and yellow colors of the eye patterns were achieved using SnO2, Cu2O, or Cu0, and PbSnO3, respectively. These findings indicated that both objects were Jatim beads originating in the Kingdom of Java in Southeast Asia. This study provides valuable insights into ancient trade routes between different regions and offers reliable scientific evidence of the glass trade and technical exchanges in ancient times.

Similar content being viewed by others

Introduction

The Northern Wei Dynasty (386–534 AD) was the first of the Northern Dynasties, and was established by Tuoba Gui from the Xianbei tribe in the north of ancient China. Datong was known as Pingcheng during the Northern Wei Dynasty. It served as the Dynasty’s capital for nearly a century from 398 AD, the first year of the Tianxing Era under the reign of Emperor Daowu, to 494 AD, the 18th year of the Taihe Era under the reign of Emperor Xiaowen. Earlier in the Western Han Dynasty (202 BC–8 AD), before the Xianbei people established a capital in Pingcheng, they engaged in activities along the Silk Road. Shortly after the Tuoba Clan of the Xianbei Tribe founded the Northern Wei Empire, they started to expand their territory. During the reign of Emperor Taiwu, whose name was Tuoba Tao, the Northern Wei Empire conquered several neighboring kingdoms, including Rouran, Xia, Northern Yan, and Northern Liang, and unified the Yellow River Basin. These victories reopened the Silk Road, which had been congested since the chaotic Sixteen Kingdoms period. Pingcheng grew into an international metropolis with a population of nearly one million people. The Empire’s envoys and Buddhist monks engaged in frequent exchanges with kingdoms across the Xiyu and Haidong regions [1]. An array of cultural relics from this period, including gold and silverware, glassware, tomb figures of the Hu people, and rock-cut cave temples, attest to the diverse and prosperous cultural landscape at the time.

Glass is one of the oldest manufactured materials in human civilizations. It was invented in Mesopotamia between the twenty-fifth and twenty-third centuries BC as a raw material for beaded accessories. Single-color beads were invented in the West between the sixteenth and thirteenth centuries BC, multi-colored beads were created in the fifteenth century BC, and inlaid beads (commonly known as dragonfly eye beads in China) were popular ornaments between the tenth and sixth centuries BC [2]. The shift from single-colored to multi-colored and then to eye beads was gradual. Eye beads are created based on a single-colored bead (known as the matrix) by inlaying one or several glass pieces of different colors on the bead, which form concentric or non-concentric circular patterns on the surface of the matrix. Due to their resemblance to animal eyeballs, these types of beads are known as “compound eye beads” in the West and “dragonfly eye beads” in China. The Eye of Horus was the inspiration for the circular patterns on the beads. People in the West wore eye beads primarily to ward off evil spirits, as they believed that the multiple eyes on the beads were protective [3]. The oldest eye bead discovered dates to the 18th Dynasty of Egypt (1550–1307 BC). The first eye beads excavated in China were found in Luntai and Baicheng of the Xinjiang region, and dated to the late Western Zhou Dynasty (1046–771 BC) [4]. Eye beads present significant physical records of ancient China’s cultural exchanges with foreign countries, trade routes, and the development of glass in ancient times. As only a small number of eye beads from the Northern Wei Dynasty have been excavated to date, this study was the first to conduct a composition analysis of such beads. The findings of this study could guide future investigations into the development of ancient glass manufacturing techniques.

Background information about the samples

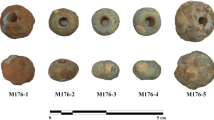

Datong, located in the north of Shanxi Province, is a major center in the search for the archaeology of the Pingcheng period of the Northern Wei Dynasty in China. The two eye beads examined in this study were unearthed from the Northern Wei tomb complex excavated at Phase Two of Dongxin Furniture Square by the Datong Institute of Archaeology in 2013. Grave goods found in the complex included gold and silverware, ironware, bronzeware, and ceramicware. Both beads are slightly weathered but fairly well-preserved. These spherical beads are harmonious and well-proportioned in form. They both have smooth surfaces, each with a round hole in the middle.

Excavation M292-6: labeled as No. DX-1, weighing 10.3 g with a diameter of 1.6 cm (Fig. 1a). The upper and lower openings of its hole vary in size, with diameters of 0.35 and 0.41 cm, respectively. One of the openings seamlessly merges with the matrix, whereas the other slightly protrudes from its surface. The matrix is dark blue with double-layered rings of “eye sockets” of different shapes randomly distributed over its surface. Each eye socket consists of two irregularly shaped white concentric rings. Some eye sockets are distorted due to compression, whereas others remain partially open. The “eyeballs” are the same dark blue as the matrix.

Excavation M302-3: labeled as DX-2, weighing 10.8 g (Fig. 1b). The diameters of the bead and its hole are 1.8 cm and 0.33 cm, respectively. One opening of the hole seamlessly merges with the matrix, whereas the other slightly protrudes from its surface. The matrix is dark blue with red and white rings surrounding the eye sockets. Some eyeballs are the same dark blue as the matrix, whereas others are yellow. This design creates a visually impactful effect with intense contrast and high saturation.

Analytical methods and test conditions

3D microscope with ultra-depth of field

VHX-5000 (Keyence, Japan), a three-dimensional (3D) microscope with ultra-depth of field, was adopted to microscopically examine the morphology of the beads. This instrument possesses features such as depth composition, high resolution, and low distortion. It uses 3D synthesis to provide excellent observation results for various uneven cultural artifacts. It can detect craft structures that are not recognizable or clearly distinguishable to the naked eye.

Scanning electron microscopy (SEM) and energy dispersive spectrometry (EDS)

Scanning electron microscopy and energy dispersive spectrometry (SEM–EDS) was conducted for microscopic observations of the morphology of bead matrices and eyes as well as for component micro-area analysis. The brand and model of the SEM was Tescan Vega 3, and the EDS was Oxford instruments. Due to the significant value of these samples, we did not apply a carbon or metal coating. The following test conditions were applied: high voltage of 15 kV, BSE detector, working distance of 15 mm, low-vacuum environment, beam intensity of 10, and collection time of 60 s. Before testing, three glass samples synthesized at the Corning Glass Works and collected by the School of Archaeology and Museology, Peking University were used to calibrate the instrument to optimal conditions. Table 1 presents the major and minor compositions of the Corning glasses [5].

Results and discussions4.1. 3D microscope analysis

As shown in Fig. 2, the eyes on DX-1 are densely distributed, each outlined by two layers of white rings and filled with blue. However, a closer examination reveals various distinctions between the eyes, including the shape of the rings in the eye socket, ring size, and relative position of inner and outer rings. In most cases, both eye socket rings are fully closed; however, partially open outer rings, partially open inner and outer rings, half inner and outer rings, and inner layers rendered into dots instead of circles due to excessively thick lines can also be observed. The majority of eye sockets are round, some are squeezed into ovals, and a few exhibit distinct, pointy angles. The eye sockets adjacent to the bead hole have more unique shapes. Three severely distorted eyes are seen next to one of the hole’s openings. We may infer that their shapes were altered without significant consideration due to a lack of space. Conversely, several droplet-shaped eyes are arranged around the other opening in a radial pattern. This eye type can be seen only around the bead hole and appears to be a deliberate design.

DX-2 has an elegant and sophisticated design with clear patterns. Except for a few incomplete eye sockets, most are closed patterns. However, they vary in color and size. As shown in Fig. 3, the eyes on DX-2 can be divided into: (1) eyes outlined in white and red and filled with the same blue color as the matrix and (2) eyes outlined in red and filled with yellow. The first type can be subdivided into three-ring eyes with white, red, and red-white outlines progressing from the outer to inner layer, and two-ring eyes with white and red outlines in the same outer-to-inner layer sequence. In areas of dense eye distribution, eyes overlap and press against one another, whereas in other areas, they are positioned loosely. Multiple eyes with similar droplet shapes are arranged radially around the bead hole, where the opening slightly protrudes from the surface. Furthermore, the red and white outlines of these eyes are smooth. These eye shapes and positions strongly resemble those around the bead hole of DX-1. However, inside the bead hole of DX-2, the remaining parts of the red and white outlines of an eye and its yellow eyeball can be clearly seen. This means that one part of this eye is on the surface of the bead body, close to the bead hole, whereas the other part is pressed into the hole. Rather than being on the same surface, its two parts meet at right angles. Although the eyes near the other opening of the hole are distributed more loosely, a similar pattern emerges, with part of the red eye socket pressed into the hole.

Chemical composition system and source of raw materials

The chemical composition analysis of ancient glass is significant, as differences in raw materials and manufacturing techniques often result in distinct features based on period and region. Ancient glass was mainly made from quartz sand, fluxing agents, and a stabilizer. Some colored glass included colorants, opacifiers, and clarifying agents [6]. As shown in Table 2, the blue matrix of DX-1 has a Na2O content of 10.5–17.0 wt% and a CaO content of 3.5–6.7 wt%. The blue matrix of DX-2 has a Na2O content of 9.3–15.4 wt% and a CaO content of 5.7–6.8 wt%. Both blue matrices of the beads belong to the Na-Ca glass system. Soda-lime glass can be further divided into plant-ash and natron glass based on the fluxing agents used. Plant-ash glass uses plant ashes as fluxing agents, containing K2O and MgO with mass fractions higher than 1.5%. It was commonly found in Egypt and Mesopotamia during the Later Sasanian and Islamic Empires [7]. Natron glass uses natural soda developed from pure Na2CO3 crystals as fluxing agents. The content of its impurities, namely K2O and MgO, is lower than 1.5%. The blue maritrices of the beads have a K2O content of 1.1–3.4 wt% and MgO content of 1.1–2.5 wt%. Thus, the blue matrices are considered to be v-Na-Ca glass. However, for the white part of DX-1 and the white, red and yellow regions of DX-2, the content of Al2O3 is significantly higher than that of CaO. The different colors of glass appear to indicate varying practices. The blue and white glass might suggest a mixing of different glass recipes, whereas the red glass seems more typical of m-Na-Al glass. On the whole, the composition of DX-1 and DX-2 should be attributed to the mixed glass system of v-Na-Ca and m-Na-Al.

In addition to SiO2, Na2O, and CaO, the matrices have a fairly high Al2O3 content, which primarily originates from the m-Na-Al glass, whether in the mixed (blue and white) or unmixed (red) cases. In the m-Na-Al glass. The alumina comes from the poorly refined sand, while the sand is the sources of silica [8].

Colorants and opacifiers of the eye beads

Ancient glass craftsmen used colorants and opacifiers to make colorful glass artifacts. Major colorants for glass included Cu and Co. Co2+ is an effective blue colorant, and if its content is above 0.01%, the glass exhibits a bright blue color [9]. Our tests revealed that the CoO content in the matrices of the two beads was 0.1 and 0.2 wt%, indicating that these elements were added by the craftsmen. A failure to detect CoO in certain sections might be influenced by the sensitivity of the instrument. CoO was adopted as a glass colorant in ancient China starting from approximately the Eastern Han Dynasty (25–220 AD), whereas cobalt blue was first applied in Mesopotamia and ancient Egypt in approximately 1000 BC [10]. The cobalt material used in both beads exhibited high iron and low manganese content, which differed from the chemical composition of the cobalt materials made in China. The blue matrix of the two glass beads tested contained very low levels of MnO2, between 0.1–0.4wt%, which is more compatible with the eastern Mediterranean origin, as cobalt blue coloring from South Asia or China is associated with MnO2 in excess of 1.0wt%. [11, 33].

Both DX-1 and DX-2 have white eye socket patterns. As shown in Figs. 4 and 5, many bright white points on the white eye sockets are distributed randomly. An EDS test identified these bright spots as SnO2, with a content of 16.1–69.5 wt%, as depends on the thickness and size of the spots analyzed, including the influence of the glassy matrices. This indicates that tin white (SnO2) was used as an opacifier. The use of tin white dates to the 18th Dynasty of Egypt. It was applied in glass manufacturing in the Roman and Byzantine periods after the fourth century AD. Because of the fact that the opaque glasses were used mainly for mosaic tesserae, while marble or limestone provided a cheaper and easier source of white tesserae, the tin oxide-colored white glass was not prevalent during this period [12, 13].

The red eye sockets of DX-2 have a substantial Cu2O presence of 1.9–5.2 wt%. Their vibrant red hue indicates the presence of copper as the coloring element. Copper present in glass as Cu2O and Cu0 displays a red color [14]. Determining the exact form of copper requires additional phase analysis. Chinese craftsmen did not start making copper red glazes until approximately the seventh–tenth centuries AD [15], which was significantly later than production in the West.Copper red glass occured widely in Europe, the Middle East, South Asia, and Southeast Asia in this period [16,17,18], Copper red glass was among the colored glass excavated from Mesopotamia and dates to 250 BC [19]; thus, we inferred that the copper red coloring material was not native to China.

The yellow eyeballs of DX-2 contain characteristic elements, such as Pb and Sn. The oxides of these two elements, namely PbO and SnO2, have contents of 24.8–37.9 wt% and 10.7–20.7 wt%, respectively. This indicates that lead–tin yellow (PbSnO3 or PbSn1−xSixO3) was adopted as an opacifier. Both lead–tin yellow and tin white are tin-based opacifiers; however, lead–tin yellow was invented later than tin white. It was applied in glass manufacturing in the Roman Empire between the second and first centuries BC. After the fourth century AD, it was widely used in glass manufacturing in the Roman and Byzantine periods. In Europe and West Asia, tin-based compounds were extensively used in manufacturing Islamic glass, mural paints, enamelware, and ceramic glazes [13, 20, 21]. Antimony-based opacifiers, including white calcium and yellow lead antimonates, appeared earlier than tin-based opacifiers. An antimony mine in the Caucasus, located between the Caspian and Black Seas, was exploited as early as the seventeenth century BC [22]. Archaeological records indicate that ancient glass craftsmen in the 18th Dynasty of Egypt (approximately 1575–1308 BC) mastered the methods of using antimony [12]. In the long history of the development of glass manufacturing techniques, tin-based opacifiers gradually replaced the previously dominant antimony-based opacifiers. Tite argues that this change could result from insufficient antimony supply or the development of tin-based opacifier manufacturing techniques [13]. Likewise, Cheng states that tin was more easily accessible than antimony and could achieve the same artistic effects as antimony with lower costs for mass production [23]. Sb2O3 was detected in several spots of the yellow eyeballs of DX-2 with a content of 2.5 wt%. Sb is a mineral that could be associated with tin. The Sb2O3 contents are unusually high, exceeding typical levels in Roman glass and surpassing mere impurities. Considering that this is only surface analysis, future in-depth analysis may help elucidate this issue. Lead–tin yellow is an ancient pigment manufactured according to the following process. A compound of PbO and SnO2 is heated to create the orthorhombic Pb2SnO4 at a temperature of 300–700 °C. PbO and SiO2 are added and heated to a temperature of 850 °C. The orthorhombic Pb2SnO4 transforms into cubic PbSnO3, which contributes to creating the yellow opaque color of the glass. If the temperature exceeds 950 °C, PbSnO3 decomposes [24]. According to Li, during the manufacturing process of soda-lime glass, the temperature is maintained between 1000 and 1100 °C; thus, PbSnO3 should be synthesized in advance and added to the glass matrix. This process is known as a transposing opacifying technique [25]. Freestone divided opacifiers into Types A and B. Type A refers to white or colorless opacifiers, such as tin white and calcium antimonate, which do not change the glass color after being added to the glass melt. Type B includes color opacifiers, such as lead antimonate and lead–tin yellow, which both opacify and color the glass melt [26]. Therefore, the yellow eyeballs on DX-2 use PbSnO3, which is a Type B opacifier. Transposing opacification was adopted in the manufacturing process of the yellow eyeballs.

Ancient glass colorants can be divided into three types: transition metal ions, such as Fe2+, Fe3+, Co2+, and Cu2+; chemical compounds, such as SnO2 and lead–tin yellow; and metallic nanoparticles, such as Cu, Ag, and Au. Metallic nanoparticles are used for coloration by recovering the metal ions in glass through a robust process of restoration. The size of these nanoparticles plays a pivotal role in determining the resulting glass color. Thus, identifying the types of opacifiers and examining their invention, development, and application helps reveal the origins of glass raw materials and dissemination of manufacturing techniques.

Manufacturing process and origin of glass beads

Ancient eye beads were made by winding melted glass strips around a metal stick covered in clay and sand. As the stick continued to rotate, the bead matrix was shaped. Before the matrix cooled down and hardened, eye slices prepared in advance were pressed into the matrix, and the entire bead was rolled on a stone or metal board. After the glass hardened, the bead was removed from the metal stick, completing the process, which was somewhat random [27]. We utilized a microscope with ultra-depth of field and SEM to conduct morphological observation and obtain microscopic images of the bead matrices, eye patterns, holes, and bubble shapes. The matrices of DX-1 and DX-2 have spherical forms with partially irregular shapes. Both bead holes have even and slightly protruding openings. The eyes around the protruding opening on both beads are distorted, assuming a shape distinct from other eyes on the matrix surface. Around the even openings, the eye patterns are pressed into irregular long and narrow shapes. Both bead holes have a regular circular shape. The bead hole interior of DX-1 is the same color as the matrix. Conversely, the bead hole interior of DX-2 is the same color as the matrix on one side, and has red eye sockets and yellow eyeballs on the other side, as these patterns are pressed into the hole. In addition, a green spot that differs in color from the blue base is present on the matrix of DX-2. A crack can be clearly seen where the blue and green portions meet. These features vary from those produced by the winding technique. Based on the manufacturing style, techniques, and existing literature, we conclude that DX-1 and DX-2 are typical Jatim beads.

Jatim beads originated in the Java region in the sixth century AD [28]. At least ten Jatim beads were unearthed in Gyeongju, Korea, from tombs belonging to members of the upper social class, and were dated between the late fourth and mid-sixth centuries AD. They were considered to be closely related to the eastern Java region, where the majority of Jatim beads have been discovered [29]. DX-1 and DX-2 share multiple features with a Jatim bead excavated from the Sikrichong tomb in Gyeongu, including bead forms, matrix colors, eye-shaped patterns, and the distorted patterns around the protruding bead hole opening. The production time is also roughly the same because the late fourth century to the middle of the sixth century in the Gyeongju region of Korea is basically consistent with the Pingcheng period of the Northern Wei Dynasty in China (AD 398-AD 494). As shown in Fig. 6, Korean Jatim beads have the white eye patterns of DX-1 and the red and yellow eye patterns and white dots of DX-2. These beads are considered to be associated with maritime trade and the introduction of Buddhism to Korea. Jatim beads are crafted through a process involving the application of thin mosaic sheets onto glass tubes. The adorned glass tubes are reheated and subsequently cut into individual beads using specialized tools. This technique is referred to as hot pinch or hot pressing. One end of the bead is formed through either hot pressing or cold cutting, followed by a rolling process that culminates in a circular shape [30, 31]. The application of the hot pinch technique during the manufacture of Jatim beads results in the elongation of the eye patterns toward the bead hole, contributing to a main feature that distinguishes Jatim beads from West Asian eye beads. The mosaic technique utilized in crafting Jatim beads mirrors the predominant glass craftsmanship and decoration styles of ancient Rome and the Mediterranean. The tradition was later adopted by Byzantine and Islamic craftsmen and introduced to Java via maritime trade [32]. Local glass artisans in Java assimilated foreign glassmaking techniques, creatively combining them to produce the renowned Jatim beads. Thus the production and decoration of Jatim beads formed a unique technology, wherein the most significant feature of these beads’ chemical composition was the use of mixed glass components, such as m-Na-Al and v-Na-Ca mix glass. Through extensive research, James W. Lankton found that the components of mixed glass are very rare in South Asia and Southeast Asia, and there is no extensive trade. Jatim beads contain a large number of glass beads with mixed components (from the recycling and remelting of glass), which can be basically determined that these glasses are mixed at the Jatim bead making site, rather than imported pre-mixed glass material, It can be said that Jatim bead manufacturers are very fond of the use of mixed glass ingredients [33].

Ancient Java was prosperous and independent, and was known as Yediao in the Hang Dynasty, Yepoti in the Jin Dynasty, Shepo in the Southern Dynasties, and Heling in the Tang Dynasty [34]. According to Shundi Benji (Records of Emperor Shun) in Hou Han Shu (Book of the Later Han, 131), “the Yediao kingdom beyond the border at Rinan County sent an envoy to pay tribute in the sixth year of the Yongjian reign.” This indicates that Java and China engaged in friendly exchanges during the Han Dynasty. During the Jin and Northern and Southern Dynasties, countries in South and Southeast Asia sent envoys to China to pay tribute to the emperors [35]. In Fo Guo Ji (Records of the Buddhist Kingdom, 411), Faxian (334–420), a Buddhist monk in the Jin Dynasty, describes taking a ship from the Lion Kingdom and staying in Yepoti for 5 months after arriving in Southeast Asia. In 412 AD, he returned to Changguang County in Qingzhou of the Jin Dynasty [36]. After the decline of the Roman empire, merchants from South Asia turned to Southeast Asia and established a close connection with the East [37]. Lankton argues that Jatim beads were integrated into international trade dynamics before the sixth century AD [38]. Due to scarce archaeological records on Jatim beads in China, we can only infer that the eye beads discovered in the Northern Wei tomb complex originated in Java. Their import routes must have included the Maritime Silk Road; however, further archaeological investigation is required to determine the specific routes that led them to Pingcheng.

Conclusions

In this study, two glass eye beads unearthed from the Northern Wei tomb complex in Dongxin were comprehensively analyzed by various means. The physical examination of the beads included observation of microscopic morphology, and description and measurement of shape, color, size, aperture, etc. Chemical tests focused on composition analysis and coloration mechanisms, and comparative analysis was conducted in combination with a review of the archaeological and documentary data. The results show that the two eye beads belong to the v-Na-Ca and m-Na-Al mix glass system, the most prominent feature of Jatim beads in terms of chemical composition is the use of mixed glass components. Their bases were colored using Co2+, and the white, red, and yellow eye patterns used SnO2, Cu2O, or Cu0, and PbSnO3 as colorants or opacifiers, respectively. Based on the manufacturing process of the artificial pigment PbSnO3, we assume that the transposing opacification technique was applied in the manufacturing of the yellow eyeballs. The styles, decorative features, and manufacturing techniques of DX-1 and DX-2 indicate that they are Jatim beads formed by segmenting glass tubes. The hot pinching technique used in the manufacturing process of the Jatim beads resulted in some eye patterns being stretched toward the bead hole. This feature distinguishes these beads from West Asian eye beads. Some other eye beads from the Pingcheng period of the Northern Wei Dynasty have been unearthed, but only two glass beads similar to this shape can be attributed to Jatim beads. Jatim beads’ origin in the Kingdom of Java provides indirect evidence of exchange between Pingcheng of the Northern Wei Dynasty and the Kingdom of Java in Southeast Asia. Determining the specific route from Java to Pingcheng, and whether it is related to the maritime Silk Road, requires more archaeological data support. These two Jatim beads not only represent the diversity of material and cultural exchanges in the Pingcheng era of the Northern Wei Dynasty more than 1500 years ago, but also provide a scientific basis for the trade and exchange of ancient glass. The reasons these two Jatim beads were imported into Pingcheng and the mediators of their dissemination are worth considering in subsequent research. Figure 6 Jatim bead unearthed from the Sikrichong Tomb in Gyeongju, Korea [26]

Data availability

The data are available from the authors upon reasonable request.

Abbreviations

- SEM:

-

Scanning electron microscopy

- EDS:

-

Energy dispersive spectrometry

References

Wang Y. Silk Road and Pingcheng in Northern Wei Dynasty. Jinan J. 2014;36(1):139–50.

Gan F, Li Q, Gu D, Zhang P, Cheng H, Zhang B, Ma B. Study on early glass beads unearthed from Baicheng and Tacheng of Xinjiang. J Chin Ceramic Soc. 2003;31(7):663–8.

An J. Archaeological research on three finds of glass articles. Cult Relics. 2000;1:89–98.

Zhao D. Studies on compound eye beads unearthed in China. Acta Archaeologica Sinica. 2012;2:177–216.

Vicenzi EP, Eggins S, Logan A, Wysoczanski R. Microbeam characterization of Corning archeological reference glasses: new additions to the smithsonian microbeam standard collection. J Res Natl Inst Stand Technol. 2002;107(6):719–27.

Wen R, Cao S, Liu R, Zhu Y. Manufacturing technologies and composition analysis of glass fragments from the Yemule site in Xinjian. Sci Conserv Archaeol. 2019;31(4):47–54.

Freestone IC, Leslie KA, Thirlwall M, Gorin-Rosen Y. Strontium isotopes in the investigation of early glass production: Byzantine and early Islamic glass from the Near East. Archaeometry. 2003;45(1):19–32.

Henderson J. The raw materials of early glass production. Oxf J Archaeol. 1985;4(3):267–91.

Cui J, Yang Y, Zhu Z, Wang H. Analysis and investigation of Han glass beads unearthed at a tomb in Xueguanbao in Luliang County, Yunnan. Archaeol. 2016;2:111–20.

Gan F, Cheng H, Hu Y, Ma B, Gu D. A study on the dragonfly eye beads first unearthed in China at Xujialing Xichuan Henan. Sci Sin. 2009;39(4):787–92.

Yang J, Zhao H, Yu P. Analysis of composite glass beads (eye-beads) unearthed from the Shahe Tomb in the Changping District of Beijing. Sci Conserv Archaeol. 2012;24(2):74–83.

Brill RH. Chemical analyses of early glasses. Corning: Corning Museum of Glass; 1999.

Tite M, Pradell T, Shortland A. Discovery, production and use of tin-based opacifiers in glasses, enamels and glazes from the late iron age onwards: a reassessment. Archaeometry. 2008;50(1):67–84.

Arletti R, Dalconi MC, Quartieri S, Triscari M, Vezzalini G. Roman coloured and opaque glass: a chemical and spectroscopic study. Appl Phys A. 2006;83:239–45.

Fu Q, Kuang G, Lv L, Mo H, Li Q, Gan F. Nondestructive analysis of the glass artifacts of the Han dynasties excavated from Guangzhou. J Chin Ceramic Soc. 2013;41(7):994–1003.

Dussubieux L, Kusimba CM, Gogte V, Kusimba SB, Gratuze B, Oka R. The trading of ancient glass beads: new analytical data from South Asian and East African soda–alumina glass beads. Archaeometry. 2008;50(5):797–821.

Marilee W. Glass beads from pre-European contact sub-Saharan Africa: Peter Francis’s work revisited and updated. Archaeol Res Asia. 2016;16:65–80.

Dussubieux L, Gratuze B, Blet-Lemarquand M. Mineral soda alumina glass: occurence and meaning. J Archaeol Sci. 2010;37(7):1646–55.

Gan F. The history of glass manufacturing technologies in ancient China. Shanghai: Shanghai Scientific & Technical Publishers; 2016.

Heck M, Rehren Th, Hoffmann P. The production of lead-tin yellow at merovingian schleitheim (Switzerland). Archaeometry. 2003;45(1):33–44.

Borgia I, Brunetti BG, Miliani C, Ricci C, Seccaroni C, Sgamellotti A. The combined use of lead-tin yellow type I and II on a canvas painting by Pietro Perugino. J Cult Herit. 2007;8(1):65–8.

Chernykh E N. Ancient metallurgy in the USSR: the early metal age. Translated by Sarah Wright. Cambridge: Cambridge University Press. 1992.

Cheng Q, Guo J. The application of antimony and tin in ancient glass manufacturing in the West. In: Cheng Q, Guo J, editors. New discussions on the preservation and research of cultural relics: a symposium of the 10th National Seminar on Archaeology and Cultural Relic Preservation. Beijing: Cultural Relics Press; 2008.

Cavallo G, Riccardi MP. Glass-based pigments in painting: smalt blue and lead-tin yellow type II. Archaeol Anthropol Sci. 2021;13:199.

Li Q, Liu S, Su B, Zhao H, Fu Q, Dong J. Characterization of some tin-contained ancient glass beads found in China by means of SEM–EDS and raman spectroscopy. Microsc Res Tech. 2013;2:133–40.

Freestone I. Looking into glass. In: Bowman S, editor. Science and the past. New York: Wiley; 1991. p. 37–56.

An J. The introduction and development of inlaid glass beads: land routes of the Silk Roads and the cultural exchanges between the East and West before the 10th century. Beijing: New World Press; 1996.

Lee I-S, Tian Y, Cui C. Silk road treasures from Sila—gold and glass. West Region Archaeol. 2008;0:275–84.

Lankton JW, Bernbaum M. An archaeological approach to understanding the meaning of beads using the example of Korean national treasure 634, a bead from a 5th/6th-century Royal Silla Tomb. BEADS. 2007;19:32–41.

Lankton JW, Lee I-S, Allen JD. Javanese (Jatim) beads in late fifth to early sixth century Korean (Silla) tombs. In: Lankton JW, editor. Annales du 16e Congrès de l’Association Internationale pour l’Histoire du Verre. Nottingham: AIHV; 2003.

Allen JD. The manufacture of intricate glass canes, and a new perspective on the relationship between chevron-star beads and mosaic-millefiori beads. In: Hayes CF, editor. Proceedings of the 1982 Glass Trade Bead Conference. Rochester: Research Division Rochester Museum and Science Center; 1983.

Zhu X. Ancient beads dictionary. Guangxi, China: Guangxi Arts Publishing House; 2021.

Lankton JW, Dussubieux L, Rehren T. A study of mid-first millennium CE Southeast Asian specialized glass beadmaking traditions. In: Bacus E, Glover I, Sharrock P, editors. Interpreting Southeast Asia’s past. Singapore; 2008.

Xu Y. Maritime routes between China and Java during the Ming and Qing dynasties. J Maritime Hist Stud. 1990;2:54–61.

Li Y. On Sino-foreign tributary system from Han to Tang Dynasty. East Forum. 2002;6:79–86.

Sang X. Faxian: the pioneering monk promoting Buddhism along maritime routes. Grand Garden Sci. 2009;23:70–1.

Yan H, Zhu W, Nie Z, Zhao Z. Maritime interchange in the ancient world: the maritime Silk Road in a global perspective. China Cult Herit Sci Res. 2016;2:17–22.

Lankton JW. A bead timeline. Prehistory to 1200 CE. Washington DC: The Bead Society of Greater Washington; 2003.

Acknowledgements

We thank Mr. Qinghui Li from Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, and Mr. Muzhe Han from Jiangsu University for their valuable discussions and the relevant literature used to prepare the manuscript. We would like to express our gratitude for your selfless help in making this article possible.

Funding

We are grateful for the financial support of the project "Scientific and Technological Archaeology Research on Pingcheng and the Northern Wei Silk Road and Ethnic Integration" (project No. 21–4-15–1400-107) approved by the Shanxi Provincial Cultural Heritage Bureau.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Yanqin Jia, Jianfeng Cui, and Chenming Cao. The first draft of the manuscript was written by Yanqin Jia, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Jia, Y., Cui, J. & Cao, C. Analysis of two glass eye (Jatim) beads unearthed from the Northern Wei tomb complex in Dongxin, Datong. Herit Sci 12, 204 (2024). https://doi.org/10.1186/s40494-024-01319-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-024-01319-w