Abstract

This paper analyzed five dragonfly eye beads excavated from M176 of the Hejia Cemetery in the Late Warring States period (around 3rd c. BC) by using a super depth of field 3D microscope system (OM), scanning electron microscope-energy dispersive spectrum (SEM–EDS) and Raman spectroscopy. The analytical results confirmed that all the beads were glazed pottery and the glaze material belongs to the lead-barium-silicate (PbO-BaO-SiO2) system. The color component of the glaze is Chinese Blue (BaCuSi4O10). Three beads, M176-2, M176-3, and M176-4, were formed with an inner core support and were made in the same batch. Additionally, two weathering products, CuPb4(SO4)2(OH)6 and PbCO3, were detected on the glaze layer surface. The results of scientific and technological analysis show that these beads have differences in the composition of the body and glaze, and the color composition in the glaze layer is relatively rare in previous studies. The discovery of lead-barium glazed pottery beads from the Late Warring States period in northern China provides new evidence for further exploration into the origins and evolution of early glazed pottery. The identification of weathering products formed on the beads’ surface within an alkaline burial environment holds valuable implications for the study of weathering and deterioration in silicate artifacts.

Similar content being viewed by others

Introduction

Dragonfly eye beads are a type of bead imitating the structure of a dragonfly’s compound eye by inlaying different colored-glass onto the base [1, 2]. It first appeared in ancient Egypt during the 18th dynasty (1550–1307 BC) [3], then became widely popular on the Mediterranean coast and the Iranian plateau [4, 5], and came into China through trade at a later time. However, the exact route of transmission has not been found clearly. Many different shapes of dragonfly eye beads have been excavated from various sites in China. Currently, the earliest dragonfly eye glass bead found in China can date back to the mid-Western Zhou to the mid-Spring and Autumn period (around the 9th to sixth century BC), excavated at the IM27 of Luntai Qunbak Cemetery in Xinjiang [6]. According to the different raw materials, dragonfly eye beads can be categorized into different types such as glass, faience [7], frit [8], glazed pottery [9], pottery and so on. Among them, dragonfly eye glass beads made of different silicate systems have been found in Shaanxi, Hebei, Hubei, and Sichuan and other provinces. Based on the research contents and methods, the studies related to Chinese dragonfly eye beads can be concluded into three main categories. The first category focus on classifying dragonfly eye beads from the similarities and differences in the production process and their characteristics across different periods. The second category involves identifying the origin and transmission routes by combining their spatial and temporal distribution in both China and the Western regions. The third category involves employing various modern scientific and technological methods to conduct archaeological research on dragonfly eye beads.

The excavation of dragonfly eye glass beads in China has facilitated and broadened existing research. With the help of scientific and technological analysis, the findings are diverse and comprehensive. Therefore, archaeologists have attained a clearer comprehension of the types and applications of dragonfly eye glass beads across different periods in ancient China. They also achieved further investigations in the study of the production process and origin. However, due to the small number and less representative of dragonfly eye beads in other materials, there is a gap between the native derivatives and original dragonfly eye beads in China.

Research aim

The Hejia Cemetery, located at the former site of Hejia village in Xianyang, Shaanxi Province, contains a large number of tombs. Most of the tombs can date back to the Warring States (475 BC-221 BC) and Qin Dynasty (221 BC-206 BC), with a small number belonging to other dynasties. A certain number of purple octagonal prismatic wares and a few dragonfly eye beads were excavated. To further investigate the origin and evolution of dragonfly eye beads as well as their chemical composition system, color components, and chemical changes within the burial environment, this study employed non-invasive testing and analysis on dragonfly eye beads excavated from the Hejia Cemetery dating back to the Late Warring States period (around 3rd c. BC) in northern China. The results will provide references for subsequent research.

Materials and methods

Dragonfly eye beads

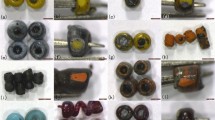

The study samples consisted of 5 beads excavated from M176 of the Hejia Cemetery (Fig. 1). These beads were found on the east side of the humerus of the tomb owner and used as ornaments. Beads M176-1 and M176-5 were poorly preserved, the glaze layer of M176-1 had almost completely flaked off, revealing its red pottery body, while the surface of M176-5 was weathered seriously and contaminated in some areas. Beads M176-2, M176-3, and M176-4 were better preserved, with no obvious weathering traces on the surface, partially broken.

The detailed information of the samples is shown in Table 1.

OM analysis

The microscopic morphology of beads was observed using a super depth of field 3D microscope (HIROX KH-7700 model from Japan). The observation aimed to study the preservation condition, color, and detailed information of these beads. The sample surface was observed at magnifications of 50 × , 100 × , and 200 × , and the most suitable representative area was later selected for subsequent analysis.

SEM–EDS analysis

The microstructure and chemical composition of each bead were analyzed using scanning electron microscopy with energy-dispersive spectroscopy (SEM–EDS). It was carried out with a TESCAN VEGA 3XM scanning electron microscope equipped with an Oxford X-ACT type X-ray energy spectrometer detector and AZtec software for data analysis at the Ministry of Education Key Laboratory of Cultural Heritage Study and Conservation, Northwest University in Xi’an, China. To ensure non-invasive analysis, the samples were placed directly in the sample compartment using conductive adhesive tape. The test conditions were: acceleration voltage of 20 kV, magnification of 800 ~ 1000 × , and working distance (WD) of 14.1 mm.

Raman analysis

The physical phase structure of samples was studied using Raman Spectroscopy. It was carried out with a Thermo Fisher DXR 2 Raman Spectroscopy equipped with a 532 nm ion laser at the laboratory of the College of Chemistry and Materials Science, Northwest University in Xi’an, China. The test was performed by placing the samples on slides and observing them with a microscope at low magnification, followed by switching to high magnification to determine the measurement points. The spectra obtained from the experiments were processed with OMNIC software. The test conditions were: magnification of 500 × , a grating slit of 50 μm, and laser output power of 2.5 mW.

Results

Archaeological typology classification

Based on the appearance of the samples, the five beads analyzed belong to the same type—“concentric circular pattern eye beads” (M176-1 surface weathering is too serious to be distinguished from the shape, ignored). These beads have a convex surface decoration slightly protruding from the surface, two layers. The bottom layer is white oval, while the surface layer is light blue round. Beads M176-2, M176-3, and M176-4 have 4 groups of concentric circular patterns on the surface, with one at the top and one at the bottom in a regular arrangement. Bead M176-5 has 8 groups of concentric circular patterns on the surface, with no obvious order of arrangement.

According to the size information of the beads, the inside diameter, outside diameter, and height of beads M176-2, M176-3, and M176-4 are nearly the same, with a similar shape, which is highly likely that they were produced in the same batch.

Micromorphology

Figure 2 shows some of the sample micrographs. All samples are glazed pottery material, with a red pottery body and blue glaze layer. The glaze layer consists of blue, white, yellow, and brown granular materials of different shades, among which blue particles are the main color-revealing material. Figure 2c shows a micrograph of the perforation of M176-3, with smooth internal hole walls and traces of spiral drilling. The shape, size, and dimension of the perforations of beads M176-2, M176-3, and M176-4 are very similar, combined with the appearance and morphology, they should have been produced in the same batch and made by sintering after using a hard inner core to form a uniform size.

Elemental composition

The results of the elemental analysis of the glaze layer of the samples are shown in Table 2. The glaze layer was Pb-Ba silicate system and all samples had more concentrated Ba content values, ranging from 6.17 to 9.89%, with an average value of 7.53%; while the Pb content values varied widely, ranging from 7.47 to 29.83%, with an average value of 18.23%. Among the results, the Pb/Ba value of M176-1 and M176-3 were lower than the other three groups, and the Pb content was significantly lower. According to the research from Wood N [10], the elemental loss is often present in lead-barium silicate products and bronze artifacts, and Pb is more easily lost compared to Ba. Therefore, the Pb/Ba value in the results of the elemental analysis can be used as an indicator to identify the weathering degree of the samples to evaluate the preservation condition.

The results of the elemental analysis of the samples’ body are shown in Table 3, expressed in oxide contents. Compared to the glaze layer, the type and content of elements in the body were relatively different, containing elements such as Al, Ca, K, and higher Fe, which are commonly found in clay, without Cu and Ba.

Physical phase structure

The common colorants in ancient silicate products are Co+, Cu2+, and Fe3+/Fe2+ [11,12,13,14,15]. All samples analyzed in this study contained Cu in the blue glaze layer, with elemental content ranging from 1.32 to 3.36% and an average value of 2.52%, which may be typical of Cu2+ chromogenic. However, bead M176-2 (Fig. 2d) had mostly purple surface circular areas with a few blue particles at the edges, and microscopic observation also revealed a very small amount of purple particle masses in the blue glaze layer. Therefore, further analysis was performed to investigate the chromogenic composition of the samples.

Beads M176-2 and M176-4, which were in relatively good condition, were selected for Raman Spectroscopy analysis, and some of the results obtained are shown in Fig. 3. In both M176-2 and M176-4, the physical phase structures of Chinese Blue (BaCuSi4O10) and Chinese Purple (BaCuSi2O6) were detected, and the Raman signals of the samples were strong. Through the microscope window of the Raman spectrometer, the copper barium silicate crystals were full-colored, with white crystal particles interspersed around. In addition to copper barium silicate crystals, other physical phase structures, CuPb4(SO4)2(OH)6, PbCO3, SiO2, and TiO2, were detected in the glaze layer of the samples (Fig. 4). Among them, CuPb4(SO4)2(OH)6 and PbCO3 are considered as the weathering products in this paper, while SiO2 and TiO2 are common raw material components.

Discussion

Lead-barium glazed pottery

Lead-barium glaze is a kind of low-temperature glaze [16, 17], fired under a relatively low-temperature condition. Its origin has been a controversial point in academia. Early views presumed that the technology of lead-barium glaze originated from lead-barium glass. While another view gradually emerged with the emergence of more archaeological evidence, suggesting that lead-barium glaze and lead-barium glass did not inherit from each other but coexist [18, 19].

The painted glazed pottery excavated from Jiangsu Hongshan Cemetery shows that artisans had mastered the production technology of lead-barium glazed pottery as early as the early Warring States period [19]. However, the early lead-barium glazed pottery archaeological excavations are few, partly collected in foreign countries, and the related scientific analysis and research are relatively less. Available data from scientific and technical analysis studies are primarily concentrated in Hubei and Jiangsu Provinces in China [9, 20].

Dong Junqing found that the content of PbO in the glaze layer of glazed pottery beads excavated from Hongshan Yue Cemetery in Jiangsu Province dating back to the early Warring States period ranged from 0.14 to 16.63% [9]. The content of BaO in the glaze layer ranged from 11.21 to 26.60%, with copper and iron ions as coloring elements. In the meantime, they also found the content of PbO in the glaze layer of glazed pottery pieces and beads excavated from the Jiangling Chu Cemetery in Hubei Province dating back to the Warring States period ranged from 0.33 to 12.25%, while the content of BaO in glaze layer ranged from 0.00 to 13.48%. The Pb and Ba content of these glazed pottery objects was lower than that of the early lead-barium glass in China (Warring States period and Han Dynasty).

Dong Junqing analyzed some glazed pottery tubes and beads excavated from the Jiangling Chu Cemetery in Hubei Province dating back to the Warring States and found that the content of PbO in the glaze layer ranged from 7.77 to 38.66%, while the content of BaO in glaze layer ranged from 4.72 to 17.29% [20]. Compared with Pb and Ba element contents of early glazed pottery (Fig. 5), the distribution range of Pb and Ba content of glazed pottery beads excavated from the Hejia Cemetery is more similar to that of Hubei Province, with the content of Pb spanning a wide range and generally higher than the content of Ba, though the content of Pb and Ba is more concentrated in the former. In contrast, the content of Pb and Ba in glazed pottery excavated from Jiangsu Province is close to each other, with the content of Pb slightly lower than Ba. In addition, the content of Cu in glazed pottery beads excavated from the Hejia Cemetery is slightly higher than that of the Hubei and Jiangsu Provinces.

Lead-barium silicate artifacts

Except for lead-barium glazed pottery, there are also other lead-barium silicate artifacts such as lead-barium faience, lead-barium glass, and copper barium silicate.

Faience artifacts are often recognized as the former of glass and consists of a large amount of quartz sand interspersed with a small amount of glass phase. From the Western Zhou (1046BC-771BC) to Spring and Autumn period (770BC-476BC) in China, faience artifacts unearthed from archaeological excavations contained rich potassium fluxes, which were mostly blue or green glaze (Cu2+) [9, 21,22,23]. During the Warring States period, there was still a relatively high Cu content. But lead fluxes replaced potassium fluxes and the original composition of the glaze has been changed due to the addition of Ba, which facilitated the formation of faience with copper barium silicate as a colorant [21].

Lead-barium glass was a unique glass system in ancient China that only existed from the Warring States to the Eastern Han period (206BC-220AD). There were plenty of lead-barium glass products during this time and the earliest lead-barium glass was excavated from Chaijiagou Cemetery in Bozhou, Anhui Province, dating back to Late Spring and Autumn and early Warring States [24]. According to the available archaeological excavations, early lead-barium glass was mainly concentrated in the Chu region centered on Hubei and Hunan Provinces, and later spread to other regions. Compared to lead-barium glazed pottery, there are higher content of Pb and Ba in lead-barium glass and more types of colorants (Co+, Cu2+, Fe3+/Fe2+), with Co+ coloration being more common [24, 26, 27].

As the earliest artificial synthetic pigment in China, the earliest trace of copper barium silicate was found on a spindle-shaped bead excavated from the Dabuzishan site in Li County, Gansu Province, dating back to the early Spring and Autumn period. It was recognized as a product of unintentional generation. Early traces of the use of copper barium silicate were found in silicate products such as beads, faience, and octagonal pillars from the Spring and Autumn to the Warring States period. A larger number of objects were excavated from the Warring States in particular, while the emergence of Chinese purple as a pigment was not seen until the Qin Dynasty.

Lead-barium glass, lead-barium glazed pottery, and copper barium silicate flourished from the end of the Spring and Autumn period to the Han Dynasty. Among these artifacts, lead-barium glass and lead-barium glazed pottery constantly changed the type and ratio of raw material and derived more kinds based on the development of the prototype. While copper barium silicate was only produced and used during the historical period from the Spring and Autumn period to the Eastern Han Dynasty and then disappeared. Early lead-barium glazed pottery excavations were not very common and concentrated in Hubei and Jiangsu Provinces. There is a large overlap with the territory of lead-barium glass excavation, which suggests a deeper connection between the two. Copper barium silicate products were mostly found in the Yellow River basin of Gansu, Shaanxi, and Henan Provinces in the early days and later expanded to Jiangsu and Shandong, and other provinces.

The excavation of many copper barium silicate products in the early days indicates that artisans at that time had already skilled in processing and production by controlling kiln temperature, raw material ratios, fluxes, and other conditions. However, the appearance of copper barium silicate on the surface of these samples was intentional or unintentional? Combined with the results of elemental analysis and previous research, the appearance of copper barium silicate on these beads is considered to be accidental in this paper. From the viewpoint of material synthesis conditions, the glazed pottery contains elements like Ba, Cu, Si, and Pb in the glaze layer. It is available to synthesize copper barium silicate under the condition of raw materials and synthesis temperature [28, 29]. There are a series of simulation synthesis studies carried out by several scholars in China and abroad [30, 31]. From the results of the physical phase structure analysis, except for Chinese Blue, a very small amount of Chinese Purple was also detected. The mixture of multiple products implies that the appearance of Chinese Blue was not the main production purpose. In addition, purple copper barium silicate octagonal prisms, which are relatively rare in archaeological excavations, were found in large quantities in the Hejia Cemetery. This suggests that ancestors had mastered the production of copper barium silicate octagonal prisms and formed a certain scale in the Late Warring States period. Therefore, the appearance of copper barium silicate on the surface of glazed pottery beads may have been influenced by their processing technology.

Weathering products

The occurrence of the two weathering products and the results of elemental analysis are mutually verified. CuPb4(SO4)2(OH)6 is a type of lead-copper secondary ore (Chenite), discovered in Scotland in 1986 [32]. In a Raman analysis of corrosion products of bronze, Bouchard M detected three rarely seen alkaline copper sulfate minerals on the surface: CuPb4(SO4)2(OH)6, CuPb4(SO4)(OH)8, and Cu2Pb5(SO4)3(OH)6, in addition to some common rusts such as alkaline copper carbonate and blue copper ore [33]. Bronze is usually a Cu-Sn-Pb ternary alloy that can easily generate various corrosion products in contact with H2O, CO2, SO2, and other compounds. To lower the melting point in the process of firing copper barium silicate, ancient artisans would add lead compounds as fluxes. The appearance of lead compounds is an important fingerprint for the identification of the artificial synthetic copper barium silicate. In this study, CuPb4(SO4)2(OH)6 crystals appeared on the surface of the sample intermingled with copper barium silicate crystals, which can be seen in Figs. 3, 4. Since these beads were excavated in northern China with an alkaline soil environment [34], it is tentatively assumed that CuPb4(SO4)2(OH)6 is a weathering product generated by the reaction of Cu and Pb in the glaze layer with sulfur oxides in an alkaline environment. This has not been detected in the previous similar artifacts, providing new evidence for the study of weathering of silicate artifacts.

PbCO3 is a common weathering product of silicate artifacts such as lead-containing glass [35, 36]. In addition, it is also detected in Pb-containing bronzes [37]. In burial environment, the deterioration of Pb will generate new weathering products deposited on the surface of the object, completely changing the original composition and structure. Glazed pottery beads with high content of Pb in the glaze layer are prone to generate PbCO3 in an alkaline burial environment.

Conclusions

In the present paper, five dragonfly eye beads excavated from the Hejia Cemetery in Shannxi Province were analyzed using technological methods from multiple perspectives. All five dragonfly eye beads were made of glazed pottery material and had a significant difference between body and glaze. The body was made of red pottery and the glaze layer was lead-barium glaze with Chinese Blue (BaCuSi4O10) as the main colorant. Based on the previous studies, the occurrence of Chinese Blue in the glaze layer is considered to be fortuitous. Combing the microscopic observation results with the morphological characteristics of the sample appearance, it is presumed that the three glazed pottery beads, M176-2, M176-3, and M176-4, were produced in the same batch and were made by sintering after using a hard inner core to form a uniform size. The detection of alkaline Pb compounds, CuPb4(SO4)2(OH)6 and PbCO3, indicates that the loss of Pb in the glaze layer combined with other substances to generate new compounds under an alkaline burial environment, which provides a reference for the study of weathering of silicate artifacts.

The occurrence of dragonfly eye glazed pottery beads in the Yellow River basin of northern China and their origin is another focus of our attention. In comparison with other studies, although the glazed pottery beads excavated from the Hejia Cemetery have some similarities with early glazed pottery objects from Hubei Province in terms of Pb and Ba elemental content, there is no clear correlation in the principal component analysis. Therefore, it still needs further studies with more archaeological background and scientific analysis, whether these glazed pottery beads are commodities of inter-regional technology exchange and dissemination, trade exchange, or local products imitating dragonfly eye glass beads.

Availability of data and materials

All data generated or analyzed during this study are included in this published article.

References

Zhao DY. Studies on compound eye beads unearthed in China. Acta Archaeologica Sinica. 2012;02:177–216.

Keer R, Wood N, Mei-Fen T, Zhang FK. Science and civilisation in China volume 5: chemistry and chemical technology, part 12, ceramic technology. Cambridge: Cambridge University Press; 2004.

Beck H. Classification and nomenclature of beads and pendants. Archaeologia. 1928;77:1–76. https://doi.org/10.1017/S0261340900013345.

Woolley L. Alalakh: an account of the excavations at tell Atchana in the Hatay, 1937–1949. London: Society of Antiquaries; 1955.

Eisen G. The characteristics of eye beads from the earliest times to the present. Am J Archaeol. 1916;20(1):1–27. https://doi.org/10.2307/497200.

Cong DX, Chen G. Briefing on the second and third excavations of Qunbak burial mounds in Luntai County, Xinjiang. Acta Archaeologica Sinica. 1991;8:684-703+736+769-771.

Griffin PS. Reconstructing the materials and technology of Egyptian Faience and Frit. MRS Proc. 2001. https://doi.org/10.1557/PROC-712-II4.2.

Yang YM, Wang LH, Wei SY, Song GD, Kenoyer JM, Xiao TQ, Zhu J, Wang CS. Nondestructive analysis of dragonfly eye beads from the warring states period, excavated from a Chu tomb at the Shenmingpu site, Henan Province, China. Microsc Microanal. 2013;19(2):335–43. https://doi.org/10.1017/S1431927612014201.

Gan FX. Development history of ancient Chinese glass. Shanghai: Shanghai Scientific and Technological Press; 2016. p. 262–70.

Wood N. Chinese glazes: their origins, chemistry, and recreation. Philadelphia: University of Pennsylvania Press; 1999.

Klysubun W, Thongkam Y, Pongkrapan S, Won-in K, T-Thienprasert J, Dararutana P. XAS study on copper red in ancient glass beads from Thailand. Anal Bioanal Chem. 2010;399(9):3033–40. https://doi.org/10.1007/s00216-010-4219-1.

Abe Y, Harimoto R, Kikugawa T, Yazawa K, Nishisaka A, Kawai N, Yoshimura S, Nakai I. Transition in the use of cobalt-blue colorant in the New Kingdom of Egypt. J Archaeol Sci. 2012;39(6):1793–808. https://doi.org/10.1016/j.jas.2012.01.021.

Basso E, Invernizzi C, Malagodi M, La Russa MF, Bersani D, Lottici PP. Characterization of colorants and opacifiers in roman glass mosaic tesserae through spectroscopic and spectrometric techniques. J Raman Spectrosc. 2014;45(3):238–45. https://doi.org/10.1002/jrs.4449.

Koleini F, Colomban P, Antonites A, Pikirayi I. Raman and XRF classification of Asian and European glass beads recovered at Mutamba, a southern African Middle Iron Age site. J Archaeol Sci Rep. 2017;13:333–40. https://doi.org/10.1016/j.jasrep.2017.04.004.

Henderson J, Adlington LW, Ritter M, Schibille N. Production and provenance of architectural glass from the Umayyad period. PloS ONE. 2020;15(9). https://doi.org/10.1371/journal.pone.0239732.

Rong B, Zhou T. Current science conservation and research of ancient pottery. Sci Conserv Archaeol. 2011;23(02):75–86. https://doi.org/10.1633/j.cnki.cn31-1652/k.2011.02.019.

Živković J, Power T, Georgakopoulou M, López J. Defining new technological traditions of Late Islamic Arabia: a view on Bahlā Ware from al-Ain (UAE) and the lead-barium glaze production. Archaeol Anthrop Sci. 2019;11(9):4697–709. https://doi.org/10.1007/s12520-019-00807-6.

Lang JF, Cui JF. A study of the style and producing area of the glazed pottery Lei liquid vessels unearthed from a Qi State tomb of the Warring State period in Linzi City: also on the problem of the origination of Chinese lead-glazed pottery. Huaxia Archaeol. 2017;02:95–101. https://doi.org/10.1614/j.cnki.1001-9928.2017.02.009.

Nanjing Museum, Jiangsu Provincial Institute of Archaeology, Cultural Relics Management Committee of Xishan District, Wuxi. Excavation report on the burials of the Yue State at Hongshan. Cultural relics Press; 2007. p. 170

Dong JQ, Li QH, Liu S. Scientific analysis of some glazed pottery unearthed from Warring States Chu tombs in Jiangling, Hubei province: indication for the origin of the low-fired glazed pottery in China. Xray Spectrom. 2020;49(5):538–53. https://doi.org/10.1002/xrs.3145.

Wang Y, Ma H, Chen K, Huang X, Cui J, Sun Z, Ma Q. Identification of PbO (BaO) faience from an early and middle Warring States period cemetery at Zhaitouhe, northern Shaanxi, China. Archaeometry. 2019;61(1):43–54. https://doi.org/10.1111/arcm.12401.

Gu Z, Zhu J, Xie YT, Xiao TQ, Yang YM, Wang CS. Nondestructive analysis of faience beads from the Western Zhou dynasty, excavated from Peng State cemetery, Shanxi Province, China. J Anal At Spectrom. 2014;29(8):1438–43. https://doi.org/10.1039/C4JA00031E.

Liu N, Yang YM, Wang YQ, Hu WL, Jiang XC, Ren M, Yang M, Wang CS. Nondestructive characterization of ancient faience beads unearthed from Ya’er cemetery in Xinjiang, early iron age China. Ceram Int. 2017;43(13):10460–7. https://doi.org/10.1016/j.ceramint.2017.05.086.

Gan FX, Cheng HS, Li QH. Origin of Chinese ancient glasses—study on the earliest Chinese ancient glasses. Sci China Ser E Technol Sci. 2006;49(6):701–13. https://doi.org/10.1007/s11431-006-2036-8.

Zhao HX, Li QH. Combined spectroscopic analysis of stratified glass eye beads from China dated to the Warring States Period. J Raman Spectrosc. 2017;48(8):1103–10. https://doi.org/10.1002/jrs.5177.

Colomban P. Lapis lazuli as unexpected blue pigment in Iranian Lâjvardina ceramics. J Raman Spectrosc. 2003;34(6):420–3. https://doi.org/10.1002/jrs.1014.

Tanevska V, Colomban P, Minčeva-Šukarova B, Grupče O. Characterization of pottery from the republic of macedonia I: raman analyses of byzantine glazed pottery excavated from prilep and skopje (12th-14th century). J Raman Spectrosc. 2009;40(9):1240–8. https://doi.org/10.1002/jrs.2273.

Johnson-McDaniel D, Salguero TT. Exfoliation of Egyptian blue and Han blue, two alkali earth copper silicate-based pigments. J Vis Exp. 2014;86:57686. https://doi.org/10.3791/51686.

Qin Y, Wang Y, Chen X, Li H, Li X. A discussion on the emergence and development of ancient Chinese artificial barium copper silicate pigments from simulation experiments. Archaeometry. 2016;58(5):796–806. https://doi.org/10.1111/arcm.12205.

Berke H, Wiedemann HG. The chemistry and fabrication of the anthropogenic pigments Chinese blue and purple in Ancient China. East Asian Sci Technol Med. 2000;17(1):94–119. https://doi.org/10.1163/26669323-01701006.

Zhang ZG, Ma QL, Berke H. Man-made blue and purple barium copper silicate pigments and the pabstite (BaSnSi3O9) mystery of ancient Chinese wall paintings from Luoyang. Herit Sci. 2019;7(1):97. https://doi.org/10.1186/s40494-019-0340-4.

Paar WH, Mereiter K, Braithwaite RSW, Keller P, Dunn PJ. Chenite, Pb4Cu(SO4)2(OH)6, a new mineral, from Leadhills, Scotland. Mineral Mag. 1986;50(355):129–35. https://doi.org/10.1017/minmag.1986.050.355.17.

Bouchard M. Evaluation des Capacités de la Microscopie Raman dans la Caractérisation Minéralogique et physicochimique de Matériaux Archéologiques : Métaux, Vitraux & Pigments (Evaluation of the capacity of Raman Microscopy in the mineralogical and physico-chemical characterization of archaeological material : corroded metals, stained-glass and pigments)(French). Matériaux. Museum national d'histoire naturelle - MNHN PARIS, 2001. Français. https://theses.hal.science/tel-00131055

Institute of soil science, academia sinica. The soil atlas of China. Beijing: Cartographic publishing house; 1986.

Zhang KX, Wang J, Yu WD, Zhao J, Yue XZ, Luo HJ. Corrosion mechanisms for lead-barium glass from the Warring States period. Herit Sci. 2023;11(1):79. https://doi.org/10.1186/s40494-023-00930-7.

Duan HY, Zhang XQ, Kang BQ, Wang GY, Qu L, Lei Y. Non-destructive analysis and deterioration study of a decorated famille rose porcelain bowl of Qianlong Reign from the Forbidden City. Stud Conserv. 2019;64(6):311–22. https://doi.org/10.1080/00393630.2019.1617589.

Ingo GM, Riccucci C, Guida G, Pascucci M, Giuliani C, Messina E, Fierro G, Carlo GD. Micro-chemical investigation of corrosion products naturally grown on archaeological Cu-based artefacts retrieved from the Mediterranean sea. Appl Surf Sci. 2019;470:695–706. https://doi.org/10.1016/j.apsusc.2018;11.144.

Acknowledgements

Authors would like to express their gratitude to the Shaanxi Academy of Archaeology for all the efforts they have provided in this research. They also would like to thank Ms. Zhihui Ren from the College of Chemistry and Materials Science, Northwest University, for her guidance and assistance.

Funding

This research was supported by the National Natural Science Foundation of China (Grant No. 22101226), 111 project (D18004).

Author information

Authors and Affiliations

Contributions

All authors contributed to the conception and design of the study. Material preparation, data collection, and analysis were performed by HY, FS, and YZ. YZ provided the samples. The first draft of the manuscript was written by HY, and all authors read and revised the previous versions of the manuscript. All authors reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Yan, H., Sun, F. & Zhang, Y. Scientific and technical analysis of lead-barium glaze dragonfly eye beads from the Late Warring States period in China. Herit Sci 11, 186 (2023). https://doi.org/10.1186/s40494-023-01032-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40494-023-01032-0