Abstract

The simultaneous determination of trace pesticides in complex matrices containing high concentrations of natural pigments remains challenging. In this study, quick, easy, cheap, effective, rugged, and safe (QuEChERS) sample preparation together with high-performance liquid chromatography with ultraviolet detection (HPLC–UV) was applied for the multi-residue analysis of seven sulfonylurea herbicides (SUHs) in tomatoes. SUH residue was extracted using the QuEChERS procedure, followed by solid-phase extraction (SPE) and dispersive SPE (d-SPE). To reduce the amount of carotenoids in tomato extracts, several d-SPE clean-up procedures were compared, and octadecylsilane (C18) provided the best color removal rate (%) of tomato extracts and recoveries (%) for all the tested SUHs. The validation results indicate good linearity (R2 > 0.9970), accuracy, and precision. Recoveries of 70–120% and relative standard deviations < 20% were achieved for all analytes at three spiked concentrations. The limits of detection and quantification for the 7 SUHs were 0.003 mg kg−1 and 0.008–0.009 mg kg−1, respectively. The developed method was subsequently used to quantify multi-residue SUHs during real sample analysis. None of the tested samples had SUH residue levels higher than the maximum residue limits established by the Korean Ministry of Food and Drug Safety. The results suggest that QuEChERS sample preparation employing a combination of C18 is a high-throughput and rapid clean-up procedure for the multi-residue analysis of SUHs in tomatoes.

Similar content being viewed by others

Introduction

Herbicide classes represent approximately 50% of the demand for agricultural protection chemicals [1]. Sulfonylurea herbicides (SUHs) are an important group of herbicides belonging to the acetolactate synthase-inhibiting herbicide family [2]. SUHs are widely used to control most broadleaf weeds and annual grasses in tomato cultivation owing to their high selectivity and low mammalian toxicity [3]. Although SUHs are used at lower application rates than other herbicides, SUH residues can be present in tomatoes because of their prolonged use and wide application as pre- and post-emergence herbicides [4]. Exposure to pesticide residues causes serious direct and indirect adverse effects on the human immune, central nervous, and reproductive systems [5, 6]. Therefore, monitoring SUH residues in foodstuffs is essential for ensuring consumer safety. As a result, Korea and the European Union (EU) have set the maximum residue limits (MRLs) for most SUH residues in tomatoes at 0.01 mg kg−1 [7, 8].

Tomatoes (Solanum lycopersicum L.) are one of the most widely cultivated vegetable crops worldwide. Determining pesticide residues in tomatoes is particularly challenging compared to other types of vegetables because of their high pigment content. The red pigments of tomatoes are water-insoluble compounds, mainly β-carotene and lycopene [9]. High concentrations of carotenoids co-extracted with other analytes of interest can interfere with the accuracy and sensitivity of chromatographic analysis [9, 10]. Reducing interference in samples is an essential step in pesticide residue analysis because trace amounts of pesticide residues are present in tomatoes. To remove interference in tomatoes, several sample preparation techniques, including solid–liquid extraction with low-temperature purification [11], supercritical fluid extraction [12], matrix solid-phase dispersion [13], magnetic graphene solid-phase extraction [14], and solid-phase extraction (SPE) [15] have been studied and validated.

Quick, easy, cheap, effective, rugged, and safe (QuEChERS) methods have been widely applied for decades to determine pesticide residues in various food matrices. The procedure consists of a salting-out partitioning step with acetonitrile and water, followed by a dispersive-SPE (d-SPE) clean-up step [16]. Graphitized carbon black (GCB), a sorbent used in d-SPE, effectively removes water-insoluble pigments. However, the use of GCB should be avoided in the analysis of planar pesticides in samples because of its pesticide adsorption capacity along with pigments [17]. A large amount of the GCB sorbent can be employed in highly pigmented samples when pesticides do not include planar structures [18]. The QuEChERS method using GCB provides relatively poor recovery values (< 70%) for some SUHs [19]. The use of alternative sorbents for complex matrices has been proposed to improve the performance of QuEChERS. Zirconium-based sorbents, including Z-Sep and Z-Sep+, have been introduced as alternatives to GCB for the removal of water-insoluble pigments and lipids [20, 21]. The QuEChERS method using Z-Sep+ has been satisfactorily validated and showed good recovery for SUH analysis in edible seeds [4]. However, increasing the amount of Z-Sep+ resulted in significantly lower recoveries for some SUHs in soymilk samples [22]. The use of 100 mg of Z-Sep+ for sample clean-up was reported to have resulted in poor recovery of some SUHs [4]. The presence of interferences, such as water-insoluble pigments, may obstruct the accurate measurement of trace SUHs in food samples [9]. In our preliminary study, 100 mg of Z-Sep+ was insufficient for carotenoid removal from tomato extracts. Therefore, an optimized QuEChERS method that efficiently recovers SUH residues and sufficiently removes interference from tomato extracts must be developed.

The purpose of this study was to evaluate the clean-up efficiency and recovery of SUH residues using d-SPE sorbents for carotenoid removal from tomato extracts. To the best of our knowledge, the QuEChERS method for SUH residue analysis in tomatoes has not been widely reported. We developed and validated a multiresidue method for the determination of seven SUH residues in tomatoes using HPLC–UV. The developed method was applied to determine the concentrations of SUH residues in real tomato samples.

Materials and methods

Reagents and chemicals

The end-capped octadecylsilane (C18) sorbent was purchased from Agilent Technologies (Santa Clara, CA, USA). GCB sorbent was obtained from Waters (Milford, MA, USA). Z-Sep+, sodium acetate, magnesium sulfate, and formic acid were obtained from Sigma-Aldrich (St. Louis, MO, USA). Standard herbicide solutions (nicosulfuron, thifensulfuron-methyl, flucetosulfuron, imazosulfuron, propyrisulfuron, metazosulfuron, and halosulfuron-methyl) were obtained from AccuStandard (New Haven, CT, USA). Standard stock solutions (each 100 μg mL−1) were prepared in acetonitrile. All the solvents were of analytical or HPLC grade.

Sample preparation

Tomato samples were collected from local markets and stored at 4 °C. To extract pesticide residues, the AOAC 2007.01 official method was followed [23]. Samples were homogenized, and 10 g of each sample was placed in a 50 mL centrifuge tube. A 10 mL solution of 1% acetic acid in acetonitrile was added as the extraction solvent, and the mixture was shaken vigorously for 1 min. The centrifuge tube was immediately cooled in an ice bath to prevent pesticide degradation after 1.5 g of sodium acetate and 6 g of magnesium sulfate were added. The centrifuge tube was shaken again for 10 min and centrifuged at 4000 × g for 7 min at 4 °C. An 8-mL aliquot of the upper layer (acetonitrile layer) was transferred to a 15-mL tube.

Sample preparation for purifying the extract solution incorporated a two-step clean-up, including SPE and QuEChERS dispersive-SPE. The SPE cartridge containing 1 g of C18 was activated with acetonitrile (10 mL). The previously collected sample solution (8 mL) was loaded onto an activated SPE cartridge. Acetonitrile (2 mL) was subsequently employed for elution, and the eluted extract was evaporated by a nitrogen stream in the 37 ℃ heating block. The dried extracts were reconstituted with 10 mL of acetonitrile and transferred into a 15-ml d-SPE tube containing different amounts of sorbents (clean-up 1: 1–10 mg of GCB; clean-up 2: 10–300 mg of C18; clean-up 3: 10–300 mg of Z-Sep+; clean-up 4: 3.5 g of GCB and 200 mg of C18; clean-up 5: 100 mg of Z-Sep+ and 100 mg of C18). The tube was tightly closed and vortexed for 1 min, and then centrifuged at 4000 × g for 7 min at 4 °C. A concentration procedure was performed to increase instrumental sensitivity for pesticide residues. A 7-mL aliquot was transferred to a glass tube, and acetonitrile was evaporated by nitrogen purging. After reconstitution with 0.28 mL of acetonitrile, the extract was transferred to an autosampler vial for HPLC.

HPLC chromatographic conditions

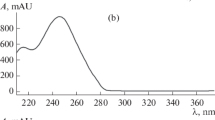

A Nexera XR HPLC system (Shimadzu, Kyoto, Japan) equipped with a photodiode array detector was used for analysis. Chromatographic separation was achieved using an Agilent Eclipse XDB-C18 reserved-phase column (250 mm × 4.6 mm i.d., 5 μm). The mobile phase consisted of 0.1% (v/v) formic acid in water (A) and 0.1% (v/v) formic acid in acetonitrile (B). The mobile phase solvent gradient was used as follows: 80% A at 0 min, 65% A at 8 min, 60% A at 18 min, 50% A at 25 min, 50% A at 28 min, 45% A at 30 min, 40% A at 33 min, 35% A at 36 min, 30% A at 37 min, 80% A at 38 min, and 80% A at 40 min. The flow rate, column oven temperature, and injection volume were 1.0 mL min−1, 40 °C, and 10 μL, respectively. Pesticide residues in the samples were detected at a wavelength of 250 nm. The analytes were identified by comparing their retention times and UV–visible spectra with those of the authentic substances. The concentration of each pesticide was determined by using a matrix-matched calibration curve.

Method validation and matrix effect

This method was validated according to the European Commission SANTE/11312/2021 [24] and International Conference on Harmonisation (ICH) [25] protocols. Linearity was determined by analyzing the matrix-matched standards at seven concentrations ranging from 0.156 to 10.0 mg L−1. Recoveries were determined by spiking experiments (0.01, 0.05, and 0.1 mg kg−1) using pesticide-free samples. Each spiked sample was analyzed in triplicate. The recovery (%) was expressed as recovery (%) = (measured concentration/spiked concentration) × 100. The precision, in terms of intra-day repeatability and inter-day reproducibility, was evaluated by performing recovery studies. The precision was expressed as the relative standard deviation (RSD). The repeatability and within-laboratory reproducibility of the method were evaluated using six replicate analyses on the same as well as on different days. The limit of detection (LOD) and limit of quantification (LOQ) were determined from seven independently spiked concentrations of pesticides (0.008–0.5 mg kg−1 of tomatoes). LOD and LOQ were calculated using the formula: LOD = 3.3 × the standard deviation of the y-intercept/the average value of the slope, and LOQ = 10 × the standard deviation of the y-intercept/the average value of the slope.

The calibration curves of the pesticide standards in acetonitrile and the slope of the matrix-matched calibration curves fortified with pesticides in the blank extracts were used to calculate the matrix effect. The matrix effect (%) was expressed as matrix effect (%) = (the slope of the calibration curve of the extract/the slope of the calibration curve of solvent—1) × 100.

Results and discussion

Optimization of HPLC conditions

The Eclipse XDB-C18 reserved-phase column provided satisfactory chromatographic separation for all the tested SUHs. The analyte peaks were eluted separately and exhibited satisfactory resolution at a spiked level of 5 µg mL−1 in the blank sample (Fig. 1). The gradient elution method used in this study allowed for a satisfactory separation of the analytes in a single chromatographic run. The mobile phase (water and acetonitrile) containing 0.1% of formic acid as an organic acid modifier contributed to the symmetric and sharp peaks without peak tailing. A previous study [26] reported that 0.1% of formic acid in the mobile phase resulted in good peak shape and separation of analytes. This is consistent with the composition of the mobile phase used in previous studies on the chromatographic separation of pesticides. To improve the detection efficiency, the flow rate and injection volume were set at 1.0 mL min−1 and 10 μL, respectively.

HPLC chromatograms of sulfonylurea herbicides in tomato extracts after QuEChERS extraction without spiking (A) and with spiking (B). Each spiked concentration of sulfonylurea herbicides was 5 µg mL−1. 1, nicosulfuron; 2, thifensulfuron-methyl; 3, flucetosulfuron; 4, imazosulfuron; 5, propyrisulfuron; 6, metazosulfuron; 7, halosulfuron-methyl

Effects of sorbents on pigment removal and pesticide recovery

The QuEChERS approach was applied to develop a fast, easy, and reliable method for the residue analysis of selected SUHs. QuEChERS has been modified and optimized according to the analyte and sample matrices by many researchers [27,28,29]. Acetonitrile containing 1% of acetic acid is commonly used as a QuEChERS extraction solvent owing to its potential for the extraction of pesticides with a wide polarity range [28]. As described in the Materials and methods section, 10 mL of acetonitrile was added to the tomato sample, and 1.5 g of sodium acetate and 6 g of magnesium sulfate were used for the salting-out liquid–liquid partitioning step of the QuEChERS extraction. All the selected SUHs achieved satisfactory recoveries in the partitioning step. Wu and Ding [30] reported that QuEChERS extraction using an acetate-buffered version showed good recovery of SUHs from the herbal matrix.

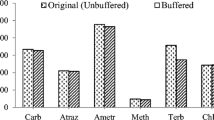

Co-extracted impurities, including pigments in the extraction solution, can contaminate detection equipment and produce matrix effects, thereby affecting the accuracy of analysis [27, 28]. The pigments in tomatoes exhibit visible interference. In the QuEChERS extraction step, visible co-extractives were observed in acetonitrile solution. The SPE process with a C18 sorbent was applied to remove nonpolar pigments such as carotenoids. However, significant amounts of nonpolar pigments from 10 g of the tomato samples were still present in the acetonitrile solution. HPLC–UV detection has some drawbacks, such as limited selectivity and sensitivity for the analysis of analytes at very low concentrations in a complex matrix [31]. Thus, the remaining carotenoids in the extracts were removed using d-SPE. Further clean-up was performed using different amounts of C18, Z-Sep+, or GCB as d-SPE sorbents. Table 1 shows the removal rate (%) of carotenoids from tomato extracts using the d-SPE sorbents. Carotenoid removal was determined by measuring differences in absorbance at 450 nm [32]. When GCB clean-up was used, the color of the extract became light, and 20 mg of GCB almost removed (98.1% of the removal rate) the carotenoids in extracts (Table 1). As reported previously [33], even small amounts of GCB provided satisfactory results for the removal of visible pigments. Despite the efficiency of GCB in the clean-up step, the recoveries of SUH residues decreased with increasing amounts of added GCB (Fig. 2). Increasing the amount of GCB reduced the recovery of SUHs. When 20 mg of GCB was used as d-SPE sorbent, six out of seven SUHs showed low recoveries of less than 70% (Fig. 2). This result was confirmed by Song et al. [34] during the extraction of SUHs from strawberries. GCB simultaneously retained the carotenoid and SUH residues in the tomato extracts. Therefore, a clean-up procedure using alternative d-SPE sorbents is necessary to achieve superior recovery and effectively remove pigments.

The use of alternative sorbents to remove hydrophobic interference has improved the performance of d-SPE clean-up procedures. Zirconium dioxide-based sorbents, including Z-Sep and Z-Sep+, belong to a hydrophobic class that enables Lewis acid–base interactions [35]. Z-Sep+ is recommended for the clean-up of matrices containing more than 15% fat. Z-Sep+ provides a satisfactory balance between SUH recovery and fat removal from edible oils [4]. The color of the tomato extracts gradually decreased from 10 mg of Z-Sep+ (Table 1). A 73.0% color removal rate was observed for 300 mg of Z-Sep+ (Table 1). The clean-up Z-Sep+ efficiency was less than that of GCB; thus, more than 300 mg of Z-Sep+ is needed to achieve a similar color removal effect. However, nicosulfuron was strongly retained in 100 mg of the Z-Sep+ phase, which led to a poor recovery rate of less than 70% (Fig. 2). In particular, some SUHs showed less than 70% recovery when 100 mg of Z-Sep+ was used for sample clean-up [4].

Clean-up using C18 as the d-SPE sorbent resulted in satisfactory color removal and analyte recovery. All the tested SUHs afforded acceptable recovery ranges between 70 and 120% (Fig. 2). Recoveries (%) of all the tested SUHs using 100–300 mg of C18 sorbent were greater than 80%. Moreover, an 88.1% color removal rate was observed with 300 mg of C18 (Table 1). The color removal rate of 300 mg of C18 was comparable to that of 10 mg of GCB (Table 1). The octanol–water partition coefficient (log P, at a pH of 7 and temperature of 23 ℃) values for the SUHs tested in this study range from − 1.58 for nicosulfuron to − 0.02 for halosulfuron-methyl. C18 is the most hydrophobic material, based on its reversed phase, and retains non-polar compounds such as carotenoids [2]. However, C18 did not retain hydrophilic SUHs in acetonitrile, and its clean-up efficiency was satisfactory.

Previous studies on the determination of pesticide residues in food matrices used a combination of sorbents for a more effective clean-up procedure [26, 28]. Two combinations of sorbents, 100 mg of C18 and 100 mg of Z-Sep+, were used to determine color removal efficiency. A 78.5% color removal rate was observed for 100 mg C18 and 100 mg Z-Sep+ (Table 1). The clean-up efficiency was lower than when using C18 alone. A combination of sorbents with 200 mg of C18 and 3.5 mg of GCB was used as the d-SPE sorbent, resulting in satisfactory color removal efficiency. This result showed a color removal rate similar to that of 300 mg of C18 (Table 1). However, some SUHs, including nicosulfuron and metazosulfuron, showed low recoveries in the 69–73% range with the clean-up using up 3.5 g of GCB in our preliminary study. According to Kaczyński et al. [36] the combination of Z-Sep+ and C18 strongly retained herbicides, leading to low recoveries, whereas C18 alone showed satisfactory recoveries during the clean-up. Based on the color removal rate and analyte recovery, 300 mg of C18 was selected for the d-SPE clean-up.

Matrix effect

Co-eluting interferents can cause analyte response modifications (suppression or enhancement) and affect the accuracy of the analytical results. Minimizing matrix interference by sample clean-up improves chromatographic selectivity [37]. For unavoidable signal modification, a matrix-matched calibration curve was used to compensate for the matrix effect. Signal suppression caused by the matrix was observed for all tested SUHs (Fig. 3). The results showed that nicosulfuron and flucetosulfuron had large matrix effects (< − 20%) and the other five had mild matrix effects (between − 20 and 20%). Therefore, a quantitative analysis using a matrix-matched calibration curve was used to improve the accuracy of the results.

Method validation

The validation data for the seven SUHs in tomato extracts are listed in Table 2. Linearities, recoveries, precisions, LODs, and LOQs, following the European Commission SANTE/11312/2021 [24] and ICH [25] protocols, were used to evaluate the extraction and d-SPE clean-up procedures based on the use of C18. Calibration curves for the seven SUHs showed good linearity, with coefficients of determination exceeding 0.9970 in the 0.156–10.0 mg L−1 range of analyte concentrations.

The LODs and LOQs for the 7 SUHs were 0.003 mg kg−1 and 0.008–0.009 mg kg−1, respectively (Table 2). In cases where MRL was not established, a general default MRL of 0.01 mg kg−1 was applied. Overall, the LOQs obtained in this study were lower than those recommended by the EU and the Korean Ministry of Food and Drug Safety [7, 8]. The LODs and LOQs obtained in this study were comparable to those reported in other studies [38, 39]. Thifensulfuron-methyl, flucetosulfuron, imazoosulfuron, and metazosulfuron had LOQs similar to their MRLs. This suggests that considerable attention should be paid to quantitative analysis.

Validated method performance should comply with the SANTE/11312/2021 guidelines, with a recovery range of 70–120% and a %RSD of less than 20% [24]. To evaluate the accuracy and precision of the developed method, the recoveries were determined with blank samples spiked at three fortification levels of 0.01, 0.05, and 0.1 mg kg−1 (Table 2). The recoveries observed for all the SUHs show 81.5–98.5% accuracy at the spiked concentrations of 0.01, 0.05, and 0.1 mg kg−1. Precision, in terms of intra-day repeatability and inter-day reproducibility, was expressed as %RSD. For all SUHs, the repeatability RSD (%) was less than 11.6% and the reproducibility RSD was less than 13.3%. All seven analytes exhibited acceptable recoveries and good precision.

Applying the developed method to real-life sample analysis

Ten tomato samples were obtained from a local market and were used to determine the suitability of the developed method. The quantitative results revealed that none of the samples contained any of the seven SUHs in quantities exceeding the LOD values (Table 3). No Korean or EU MRLs were exceeded in any of the tomato samples (Table 3). These results demonstrate that a two-step clean-up, including SPE and QuEChERS d-SPE using C18, can be applied to determine the quantities of the seven SUHs in real tomato samples.

Availability of data and materials

All data generated or analysed during this study are included in this published article.

Abbreviations

- C18 :

-

Octadecylsilane

- D-SPE:

-

Dispersive solid-phase extraction

- EU:

-

European Union

- GCB:

-

Graphitized carbon black

- HPLC:

-

High performance liquid chromatography

- ICH:

-

International Conference on Harmonisation

- LOD:

-

Limit of detection

- LOQ:

-

Limit of quantification

- MRLs:

-

Maximum residue limits

- QuEChERS:

-

Quick, easy, cheap, effective, rugged and safe

- RSD:

-

Relative standard deviation

- SPE:

-

Solid-phase extraction

- SUHs:

-

Sulfonylurea herbicides

References

Jeschke P (2016) Progress of modern agricultural chemistry and future prospects. Pest Manag Sci 72(3):433–455. https://doi.org/10.1002/ps.4190

Rejczak T, Tuzimski T (2017) Method development for sulfonylurea herbicides analysis in rapeseed oil samples by HPLC–DAD: comparison of zirconium-based sorbents and EMR-lipid for clean-up of QuEChERS extract. Food Anal Methods 10:3666–3679. https://doi.org/10.1007/s12161-017-0939-6

Tiwari R, Bashyal M, Kanissery R (2022) Weed management strategies for tomato plasticulture production in Florida. Plants 11(23):3292. https://doi.org/10.3390/plants11233292

Hernández-Mesa M, García-Campaña AM (2020) Determination of sulfonylurea pesticide residues in edible seeds used as nutraceuticals by QuEChERS in combination with ultra-high-performance liquid chromatography-tandem mass spectrometry. J Chromatogra A 1617:460831. https://doi.org/10.1016/j.chroma.2019.460831

Rani L, Thapa K, Kanojia N, Sharma N, Singh S, Grewal AS, Srivastav AL, Kaushal J (2021) An extensive review on the consequences of chemical pesticides on human health and environment. J Clean Prod 283:124657. https://doi.org/10.1016/j.jclepro.2020.124657

Yuan X, Lee J, Park E, Lee HK, Kim JH (2021) Toxicometabolomics of lindane in adult zebrafish (Danio rerio) using GC-MS/MS and LC-Orbitrap-MS/MS. Appl Biol Chem 64:52. https://doi.org/10.1186/s13765-021-00623-4

European Commission (2023) EU Pesticide Database. https://ec.europa.eu/food/plant/pesticides/eu-pesticides-database/start/screen/mrls Accessed 17 May 2023

Ministry of Food and Drug Safety (2023) Pesticides and Veterinary Drugs Information. http://www.foodsafetykorea.go.kr/residue/prd/mrls/list.do?menuKey=1&subMenuKey=161. Accessed 17 May 2023

Rivoira L, Del Bubba M, Cecconi G, Castiglioni M, Testa V, Isola M, Bruzzoniti MC (2023) Experimental design and multiple response optimization for the extraction and quantitation of thirty-four priority organic micropollutants in tomatoes through the QuEChERS approach. Separations 10(3):174. https://doi.org/10.3390/separations10030174

Emami S, Taha AY (2023) Effects of carotenoid pigmentation in salmon on antibiotic extraction recovery, matrix effects and accuracy of quantification by ultrahigh performance liquid chromatography coupled to tandem mass spectrometry. J Chromatogra B 1216:123585. https://doi.org/10.1016/j.jchromb.2022.123585

de Pinho GP, Neves AA, de Queiroz MELR, Silvério FO (2010) Pesticide determination in tomatoes by solid–liquid extraction with purification at low temperature and gas chromatography. Food Chem 121(1):251–256. https://doi.org/10.1016/j.foodchem.2009.11.080

Cortés JM, Vázquez A, Santa-María G, Blanch GP, Villén J (2009) Pesticide residue analysis by RPLC–GC in lycopene and other carotenoids obtained from tomatoes by supercritical fluid extraction. Food Chem 113(1):280–284. https://doi.org/10.1016/j.foodchem.2008.07.010

dos Santos EO, Gonzales JO, Ores JC, Marube LC, Caldas SS, Furlong EB, Primel EG (2019) Sand as a solid support in ultrasound-assisted MSPD: a simple, green and low-cost method for multiresidue pesticide determination in fruits and vegetables. Food Chem 297:124926. https://doi.org/10.1016/j.foodchem.2019.05.200

Li N, Chen J, Shi YP (2015) Magnetic graphene solid-phase extraction for the determination of carbamate pesticides in tomatoes coupled with high performance liquid chromatography. Talanta 141:212–219. https://doi.org/10.1016/j.talanta.2015.04.018

Bayat M, Hassanzadeh-Khayyat M, Mohajeri SA (2015) Determination of diazinon pesticide residue in tomato fruit and tomato paste by molecularly imprinted solid-phase extraction coupled with liquid chromatography analysis. Food Anal Methods 8:1034–1041. https://doi.org/10.1007/s12161-014-9984-6

Anastassiades M, Lehotay SJ, Stajnbaher D, Schenck FJ (2003) Fast and easy multiresidue method employing acetonitrile extraction/partitioning and ‘‘dispersive solid-phase extraction” for the determination of pesticide residues in produce. J AOAC Int 86(2):412–431. https://doi.org/10.1093/jaoac/86.2.412

Rejczak T, Tuzimski T (2015) Recent trends in sample preparation and liquid chromatography/mass spectrometry for pesticide residue analysis in food and related matrixes. J AOAC Int 98(5):1143–1162. https://doi.org/10.5740/jaoacint.SGE1_Rejczak

Islam AKMM, Lee HS, Ro JH, Kim D, Kwon H (2019) Application of high-surface-area graphitized carbon black with primary secondary amine as an alternative quick, easy, cheap, effective, rugged, and safe cleanup material for pesticide multi-residue analysis in spinach. J Sep Sci 42(14):2379–2389. https://doi.org/10.1002/jssc.201900066

Zhang P, Bui A, Rose G, Allinson G (2014) Mixed-mode solid-phase extraction coupled with liquid chromatography tandem mass spectrometry to determine phenoxy acid, sulfonylurea, triazine and other selected herbicides at nanogram per litre levels in environmental waters. J Chromatogr A 1325:56–64. https://doi.org/10.1016/j.chroma.2013.12.021

Han L, Matarrita J, Sapozhnikova Y, Lehotay SJ (2016) Evaluation of a recent product to remove lipids and other matrix co-extractives in the analysis of pesticide residues and environmental contaminants in foods. J Chromatogr A 1449:17–29. https://doi.org/10.1016/j.chroma.2016.04.052

Rutkowska E, Łozowicka B, Kaczyński P (2018) Modification of multiresidue QuEChERS protocol to minimize matrix effect and improve recoveries for determination of pesticide residues in dried herbs followed by GC-MS/MS. Food Anal Methods 11:709–724. https://doi.org/10.1007/s12161-017-1047-3

Rejczak T, Tuzimski T (2016) Simple, cost-effective and sensitive liquid chromatography diode array detector method for simultaneous determination of eight sulfonylurea herbicides in soya milk samples. J Chromatogr A 1473:56–65. https://doi.org/10.1016/j.chroma.2016.10.023

Lehotay SJ (2007) Determination of pesticide residues in foods by acetonitrile extraction and partitioning with magnesium sulfate: collaborative study. J AOAC Int 90:485–520. https://doi.org/10.1093/jaoac/90.2.485

European Commission (2021) Guidance document on analytical quality control and method validation for pesticide residues analysis in food and feed SANTE 11312/2021. https://food.ec.europa.eu/system/files/2022-02/pesticides_mrl_guidelines_wrkdoc_2021-11312.pdf. Accessed 17 May 2023

ICH (2005) International Conference on Harmonisation of technical requirements for registration of pharmaceuticals for human use. Paper presented at the ICH harmonised tripartite guideline, validation of analytical procedures: text and methodology Q2 (R1). ICH, Geneva

Liu L, Rao L, Li W, Zhou W, Li B, Tang L (2020) Detection of Glyamifop residues in rice and its environment by the QuEChERS method combined with HPLC–MS. Microchem J 158:105157. https://doi.org/10.1016/j.microc.2020.105157

Lamas M, Rodrigues F, Amaral MH, Delerue-Matos C, Fernandes VC (2023) Contaminant cocktails of high concern in honey: challenges QuEChERS extraction and levels. Separations 10(2):142. https://doi.org/10.3390/separations10020142

Song NE, Kim DB, Lim TG, Lee YY, Yoo M, Nam TG (2019) Determining pesticide residues in wheat flour by ultrahigh-performance liquid chromatography/quadrupole time-of-flight mass spectrometry with QuEChERS extraction. Food Addit Contam Part A 36(9):1337–1347. https://doi.org/10.1080/19440049.2019.1628356

Yuan X, Lee J, Han H, Ju B, Park E, Shin Y, Lee J, Kim JH (2021) Translocation of residual ethoprophos and tricyclazole from soil to spinach. Appl Biol Chem 64:47. https://doi.org/10.1186/s13765-021-00619-0

Wu X, Ding Z (2023) Evaluation of matrix effects for pesticide residue analysis by QuEChERS coupled with UHPLC-MS/MS in complex herbal matrix. Food Chem 405:134755. https://doi.org/10.1016/j.foodchem.2022.134755

Khesina ZB, Iartsev SD, Revelsky AI, Buryak AK (2021) Microextraction by packed sorbent optimized by statistical design of experiment as an approach to increase the sensitivity and selectivity of HPLC-UV determination of parabens in cosmetics. J Pharm Biomed Anal 195:113843. https://doi.org/10.1016/j.jpba.2020.113843

Song S, Zhang Z, Zou N, Chen R, Han L, Pan C, Sapozhnikova Y (2017) Determination of six paraben residues in fresh-cut vegetables using QuEChERS with multi-walled carbon nanotubes and high-performance liquid chromatography–tandem mass spectrometry. Food Anal Methods 10:3972–3979. https://doi.org/10.1007/s12161-017-0970-7

Faraji M, Noorbakhsh R, Shafieyan H, Ramezani M (2018) Determination of acetamiprid, imidacloprid, and spirotetramat and their relevant metabolites in pistachio using modified QuEChERS combined with liquid chromatography-tandem mass spectrometry. Food Chem 240:634–641. https://doi.org/10.1016/j.foodchem.2017.08.012

Song NE, Yoo M, Nam TG (2019) Multi-residue analysis of 203 pesticides in strawberries by liquid chromatography tandem mass spectrometry in combination with the QuEChERS method. CyTA J Food 17(1):976–987. https://doi.org/10.1080/19476337.2019.1680579

Lozano A, Rajski Ł, Uclés S, Belmonte-Valles N, Mezcua M, Fernández-Alba AR (2014) Evaluation of zirconium dioxide-based sorbents to decrease the matrix effect in avocado and almond multiresidue pesticide analysis followed by gas chromatography tandem mass spectrometry. Talanta 118:68–83. https://doi.org/10.1016/j.talanta.2013.09.053

Kaczyński P, Łozowicka B, Jankowska M, Hrynko I (2016) Rapid determination of acid herbicides in soil by liquid chromatography with tandem mass spectrometric detection based on dispersive solid phase extraction. Talanta 152:127–136. https://doi.org/10.1016/j.talanta.2016.02.001

Marittimo N, Grasselli G, Arigò A, Famiglini G, Palma P, Saeed M, Perry S, Navarro P, Clarke P, Brittin M, Cappiello A (2023) Sustainable and rapid determination of two halogenated pesticides in a commercial formulation by solid phase microextraction and liquid phase chemical ionization mass spectrometry. Separations 10:325. https://doi.org/10.3390/separations10060325

Ma J, Jiang L, Wu G, Xia Y, Lu W, Li J, Hen L (2016) Determination of six sulfonylurea herbicides in environmental water samples by magnetic solid-phase extraction using multi-walled carbon nanotubes as adsorbents coupled with high-performance liquid chromatography. J Chromatogr A 1466:2–20. https://doi.org/10.1016/j.chroma.2016.08.065

Pang J, Song X, Huang X, Yuan D (2020) Porous monolith-based magnetism-reinforced in-tube solid phase microextraction of sulfonylurea herbicides in water and soil samples. J Chromatogr A 1613:460672. https://doi.org/10.1016/j.chroma.2019.460672

Acknowledgements

This work was supported by Kyonggi University Research Grant 2021.

Funding

This work was supported by Kyonggi University Research Grant 2021.

Author information

Authors and Affiliations

Contributions

SGH: experiments, investigation, data curation, and writing-original draft preparation. TGN: supervision, experimental design, and writing.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Han, S.G., Nam, T.G. Simultaneous determination of sulfonylurea herbicides in tomatoes using the QuEChERS method coupled with HPLC. Appl Biol Chem 67, 12 (2024). https://doi.org/10.1186/s13765-024-00866-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13765-024-00866-x