Abstract

Wine yeast (Saccharomyces cerevisiae D8) and non-Saccharomyces wine yeasts (Hanseniaspora uvarum S6 and Issatchenkia orientalis KMBL5774) were studied using air-blast drying instead of the conventional drying methods (such as freeze and spray drying). Skim milk—a widely used protective agent—was used and in all strains, the highest viabilities following air-blast drying were obtained using 10% skim milk. Four excipients (wheat flour, nuruk, artichoke powder, and lactomil) were evaluated as protective agents for yeast strains during air-blast drying. Our results showed that 7 g lactomil was the best excipient in terms of drying time, powder form, and the survival rate of the yeast in the final product. Finally, 7 types of sugars were investigated to improve the survival rate of air-blast dried yeast cells: 10% trehalose, 10% sucrose, and 10% glucose had the highest survival rate of 97.54, 92.59, and 79.49% for S. cerevisiae D8, H. uvarum S6, and I. orientalis KMBL5774, respectively. After 3 months of storage, S. cerevisiae D8 and H. uvarum S6 demonstrated good survival rates (making them suitable for use as starters), whereas the survival rate of I. orientalis KMBL5774 decreased considerably compared to the other strains. Air-blast dried S. cerevisiae D8 and H. uvarum S6 showed metabolic activities similar to those of non-dried yeast cells, regardless of the storage period. Air-blast dried I. orientalis KMBL5774 showed a noticeable decrease in its ability to decompose malic acid after 3 months of storage at 4 °C.

Similar content being viewed by others

Introduction

Wine is one of the oldest fermented foods in history and is produced as a result of complicated interplay between the metabolic reactions of various microorganisms such as yeast and lactic acid bacteria (Zagorc et al. 2001). Wine yeast, Saccharomyces cerevisiae, has been used to make wine with high stability because of its high ethanol tolerance and ability to inhibit bacteria and other undesirable microorganisms during the fermentation process (Casey and Ingledew 1986; Philliskirk and Young 1975). On the other hand, non-Saccharomyces yeasts, which grow during the initial stages of fermentation, affect the taste and aroma of wine, suggesting that suitable co-fermentation using Saccharomyces yeasts mixed with non-Saccharomyces yeast is an important factor in making wine of high quality (Ciani and Maccarelli 1998; Rojas et al. 2001; Jolly et al. 2006; Esteve-Zarzoso et al. 1998).

Several Korean wine-makers have widely utilized S. cerevisiae Fermivin from Netherlands, S. cerevisiae W-3 from Japan, and S. cerevisiae EC1118 from Canada because these strains can be handled conveniently and offer reliable starter quality. Although most Korean wine has been made using these imported yeast starters, several studies have reported that indigenous yeasts can also contribute to making distinctive wines based on the grape cultivar and the geographical region (Heard and Fleet 1985; Mercado et al. 2007; Querol et al. 1992; Schütz and Gafner 1993; Hong and Park 2013).

The Campbell Early grape, which is the most dominant cultivar in Korea, has a high malic acid content due to early harvesting for enhancing grape color. High malic acid content lowers the quality of Korean wine due to high acidity, which has resulted in the poor competitive value of indigenously manufactured wine against imported wine (Kim et al. 1999; Lee et al. 2016). For this reason, isolating and utilizing indigenous yeasts instead of imported yeast starters are necessary to make Korean wine competitive. Developing optimal industrial starter cultures for winemaking is essential for increasing the prevalence of indigenous Korean yeast starter products. Previously, S. cerevisiae D8, Hanseniaspora uvarum S6, and Issatchenkia orientalis KMBL5774 were isolated from Korean Campbell Early grape cultivar and their biological and physiological characteristics were studied. Kim et al. (2013b) reported that wine fermented by S. cerevisiae D8 had higher color and taste scores compared to the wine fermented by S. cerevisiae W-3. Hong and Park (2013) described that wine fermented by H. uvarum S6 (previously SS6) showed slower fermentation rate but had higher organic acid content and sensory evaluation scores compared to wine fermented by S. cerevisiae W-3. Seo et al. (2007) and Kim et al. (2008) reported that I. orientalis KMBL5774 could degrade malic acid during alcohol fermentation, and co-fermentation with I. orientalis KMBL5774 and S. cerevisiae W-3 resulted in better color, flavor, and taste compared to the fermentation using only S. cerevisiae W-3.

The most important factors for developing microbial starters include maintenance of cell viability, capacity for long-term storage and the drying method used. Several studies have utilized freeze-drying (Lodato et al. 1999; Ale et al. 2015; Abadias et al. 2001a), fluidized bed drying (Bayrock and Ingledew 1997), and spray drying (Luna-Solano et al. 2005; Isono et al. 1995) to make starter products. Freeze-drying is disadvantageous owing to the high expenses incurred, and fluidized bed drying and spray drying are not suitable due to low viability in the starter cultures induced by the high temperature during drying. In contrast, air-blast drying can lower the cost fivefold, result in comparatively less cell damage, as well as provide easier control of moisture in the starter compared with other drying methods (Santivarangkna et al. 2007). Even though air-blast drying has many advantages for making yeast starters, only a few studies related to the air-blast dried yeast have been attempted. Similar to freeze-drying, the selection of protective agents is very important in air-blast drying because intracellular accumulation of the appropriate solutes is related to strain survival following air-blast drying (Kets et al. 1996; Champagne et al. 2012). Suitable agents can protect the proteins and membranes of the microorganisms (Leslie et al. 1995; Champagne and Gardner 2001).

In this study, we aimed to optimize the development of Saccharomyces and non-Saccharomyces yeast starters at the industrial level using air-blast drying, instead of the conventionally used freeze-drying method, as well as using various types of excipients and sugars at different concentrations to enhance the survival rate of air dried-yeast cells. Furthermore, the long-term storage properties of each dried-yeast strain and the metabolic activity of air-blast dried yeast cells during storage at 4 °C were also investigated.

Materials and methods

Strains, media, and culture conditions

Saccharomyces cerevisiae D8 (KACC 93245P), H. uvarum S6 (KACC 93248P) and I. orientalis KMBL5774 (KACC 93124P) isolated from the Korean grape cultivar were used in this study (Hong and Park 2013; Kim et al. 2013a; Seo et al. 2007). Each strain was cultured at 30 °C with shaking (150 rpm) in sterilized YPD media composed of 1% yeast extract, 2% bacto-peptone, and 2% glucose and the cells were harvested for making the starters. All strains were stored at −70 °C in 20% glycerol until they were used for the experiments.

Protective agent conditions

Skim milk (5 and 10%) and 7 sugars (5 and 10% of glucose, fructose, lactose, maltose, raffinose, sucrose, and trehalose) were used to evaluate the survival rate of air-blast dried yeast cells. All protective solutions, including skim milk and sugars were sterilized at 121 °C for 15 min before experiments. Four kinds of excipients—wheat flour (CJ Cheiljedang Corp., Seoul, Korea), nuruk (Songhak Agri. Corp., Gwangju, Korea), artichoke powder and lactomil (composed of lactose 89% and maltodextrin 11%; Seo Kang Dairy & Food Co., LTD, Sacheon, Korea)—were used to process the yeast starters into an appropriate powdered form. Artichoke was obtained from Gimcheon, Korea, and it was processed by lyophilization and grinding to be converted into powdered form. All excipients were added at quantities of 2 g (lactomil amounts ranged from 2 to 8 g) to compare their protective ability and availability as a starter product in powdered form for each strain of the dried yeast. All excipients were used with the yeast pellet directly.

Air-blast drying process

Each yeast strain was cultured in 100 mL YPD broth and incubated at 30 °C for 16 h. After culturing, yeast cells were harvested by centrifugation (3578×g for 10 min) and rinsed twice in a 0.85% NaCl solution. The pellet was mixed with 2 g of various excipients such as wheat flour, nuruk, and artichoke powder, and lactomil (2–8 g) as well as 1 mL protective agent solutions consisting of the skim milk and sugars. The mixed yeast cell pellets were dried using Clear Air Oven (HB-509C, HanBaek, Bucheon, Korea) at 37 °C until the moisture content of dried yeast starter was <10%. After air-blast drying, the samples were immediately analyzed to determine their moisture content and survival rate, then stored at 4 °C for 3 months, after which their survival rate was determined.

Measurement of cell viability and moisture content

After air-blast drying, each sample was reconstituted to its original volume with distilled water for rehydration. Then, the serially diluted samples were spread on YPD agar plates and incubated at 30 °C for 24 h. The white colonies that formed on YPD agar were counted. The survival rate of each sample was calculated as (%) survival = (N/N0) × 100, where N represents the number of viable cell count after air-blast drying (cfu mL−1) and N0 represents the number of viable cell count before air-blast drying (cfu mL−1). Moisture content of dried yeast starters was measured by determining the weight loss after 10 h at 105 °C (AOAC 1990).

Morphology of air-blast dried yeast cells

The morphologies of air-blast dried Saccharomyces and non-Saccharomyces yeast cells were observed by scanning electron microscopy (SEM), as described by Hongpattarakere et al. (2013). The air-blast dried sample was affixed to “stubs” using double-sided metallic adhesive tape and then coated with gold using sputter coater (WI-RES-Coater-001). The morphology of the sample was observed under a SU8220 scanning electron microscope (Hitachi, Tokyo, Japan) that was operated at an accelerating voltage of 10 kV. Images were obtained under 2000× magnification.

Metabolic activities of air-blast dried yeast cells

Metabolic activities of yeast cells stored for 0–3 months after air-blast drying were analyzed and non-dried yeast cells were used as the control. Air-blast dried S. cerevisiae D8 and H. uvarum S6 were incubated in 100 mL YPD broth containing 20% glucose (yeast extract 10 g L−1, peptone 20 g L−1, and glucose 200 g L−1) at 30 °C with shaking (150 rpm) to measure the glucose fermentation rate. A water trap apparatus containing conc. H2SO4 was attached to the top of each flask to trap water evaporated from the flask during the fermentation. The amount of CO2 produced was directly measured as the decrease in the weight of the whole flask. The fermentation ratio was expressed as the percentage of the amount of CO2 produced per the theoretical CO2 production from the glucose due to the ethanol fermentation (Jung and Park 2005). Air-blast dried I. orientalis KMBL5774 was incubated in 10 mL YPD broth containing 2% malic acid at 30 °C with shaking (150 rpm) to measure the malic acid decomposition rate. Malic acid content was determined using the l-Malic Acid Assay Kit (K-LMALR; Megazyme, Wicklow, Ireland) (Lee et al. 2016).

Statistical analysis

All experiments were carried out in at least triplicates and the results were analyzed using the Statistical Package for the Social Sciences (SPSS, version 12.0 for Windows, Chicago, IL, USA) in order to obtain average and standard deviations. Significance was determined to be p < 0.05 using one-way analysis of variance (ANOVA), followed by Duncan’s multiple range test.

Results

Effect of skim milk on the survival rate of air-blast dried yeast cells

Skim milk is typically used as a protective agent to protect cell membrane while drying microbial strains. It has been suggested that milk proteins may cover the cells to prevent damage (Abadias et al. 2001b). In this study, the protective effect of skim milk on air-blast dried cells was investigated. For this, 5–10% skim milk solutions were mixed with centrifuged yeast cells and the mixed cells were air-blast dried at 37 °C for 2 h until dried cells were obtained in the appropriate powdered form. The survival rates of all air-blast dried yeast cell strains mixed with skim milk increased in a dose-dependent manner compared to that of the control (Fig. 1). When 10% skim milk was mixed with the dried yeast cells, the viable count of S. cerevisiae D8, H. uvarum S6, and I. orientalis KMBL5774 increased to approximately 0.89, 0.71, and 1.03 log cfu mL−1, respectively. Thus, 10% skim milk was utilized in subsequent experiments.

Effect of various excipients on the survival rate and moisture content of air-blast dried yeast cells

The selection of the excipient is very important in generating a stable powdered form and shape for improving the stability and quality of the final product (Georgetti et al. 2008). In this study, four excipients (wheat flour, nuruk, artichoke powder, and lactomil) were utilized to prevent cell membrane damage caused by the drying environment and the survival rates and moisture contents were determined. All samples were air-blast dried until the moisture content reached <10%. The air-blast dried yeast samples mixed with wheat flour showed the longest drying time of 7 h and the lowest survival rate of 0.27–1.39%, whereas the samples mixed with lactomil showed the shortest drying time of 2.5 h and the highest survival rate of 1.01–3.40% (Table 1). On analysis of the shape of the powdered form obtained by adding various excipients, we found that the samples mixed with wheat flour and nuruk showed a lump form after air-blast drying, and the samples mixed with artichoke powder and lactomil could be easily collected due to their impalpable powdered form (Fig. 2). Based on the survival rate, drying time, and the properties of the powdered form of air-blast dried yeast products, 2 g lactomil was considered as the most suitable excipient for making yeast starters by air-blast drying. Based on the results of the yeast samples added to various excipients, the survival rates of air-blast dried yeast cells in relation to the amount of lactomil added were investigated (Table 2). As the amount of lactomil added was increased, drying time for each sample with <10% moisture content was reduced and the survival rate of air-blast dried yeast cells increased in a dose-dependent manner until the addition of 7 g lactomil. In case of S. cerevisiae D8, the survival rate of the sample added to 7 g lactomil was measured as 59.12%, which was higher than the survival rate of the sample added to 8 g lactomil. In case of H. uvarum S6 and I. orientalis KMBL5774, the survival rates measured for 7–8 g of lactomil were not significantly different. Although the drying time of the samples added to 8 g lactomil was 0.3 h shorter than that of the samples added to 7 g lactomil, after considering the excipient cost and the similar protective effect of 7–8 g of lactomil, 7 g was considered as the optimal amount of lactomil required for maintaining the viability of air-blast dried yeast cells. Therefore, subsequent experiments were carried out by adding 10% skim milk and 7 g lactomil to the yeast cells, followed by air-blast drying for 1.5 h.

Effect of sugar additives as a protective agent on the survival rate of air-blast dried yeast cells

To determine the protective effect of sugar on air-blast dried yeast cells, the survival rate of air-blast dried yeast cells (depending on the type and concentration of sugars as protective agents with 10% skim milk) were investigated (Table 3). In case of S. cerevisiae D8, the addition of 10% sugars (except for fructose) resulted in a survival rate of >90%, and addition of 10% trehalose resulted in the highest survival rate of 97.54%. In case of H. uvarum S6, the high survival rates of all samples added to sugars resulted in considerably higher viability than that of samples with no sugar addition. All samples added to 10% sugars had higher survival rate than those added to 5% sugars; in particular, 10% sucrose resulted in the highest survival rate of 92.59%. In case of I. orientalis KMBL5774, most sugar additions did not show a significant increase of the survival Malic acid content was determined rate compared to no sugar addition, but addition of 10% glucose and 10% fructose noticeably increased its survival rate to 79.49 and 65.17%, respectively. The morphology of air-blast dried yeast cells was observed using SEM (Fig. 3). The SEM images showed that each yeast cell was coated with skim milk, sugar, and lactomil and the cells were densely accumulated, which suggest that protective agents and excipients protect yeast cells from the adverse drying environment.

Images of air-blast dried yeast cells observed by a scanning electron microscope (SEM) at ×2000 magnification. 10% skim milk and 7 g lactomil were used in all samples. Ten percent trehalose, 10% sucrose, and 10% glucose were used as protective agents for S. cerevisiae D8 (a), H. uvarum S6 (b), and I. orientalis KMBL5774 (c), respectively

Long-term storability of air-blast dried yeast starter products

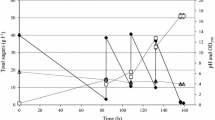

Changes in the survival rate and viable count of air-blast dried yeast cells were investigated in products that had been stored at 4 °C for 3 months (Fig. 4). All samples were prepared based on the optimal conditions determined in the present study. Air-blast dried S. cerevisiae D8 and H. uvarum S6 continued to show a high survival rate of 42.24 and 49.74% after 2 months, whereas the survival rate of air-blast dried I. orientalis KMBL5774 rapidly decreased compared to the other yeast strains and showed a survival rate of only 3.08% after 2 months of storage. After 3 months, the viable count of S. cerevisiae D8 and H. uvarum S6 decreased to 1.18 and 0.51 log cfu mL−1 compared to the viable counts measured immediately after air-blast drying. Therefore, air-blast dried yeast cells of both strains, S. cerevisiae D8 and H. uvarum S6, have excellent potential as a starter product. On the other hand, although I. orientalis KMBL5774 also showed high survival rate immediately after air-blast drying, further study on the long-term storage of I. orientalis KMBL5774 is necessary because it showed very low viable count after 3 months of storage (2.38 log reduction).

Changes in the survival rate (left panel) and viable count (right panel) of air-blast dried yeast cells stored at 4 °C for 3 months. Empty circles, filled squares, and filled diamonds in the left panel represent the survival rates of S. cerevisiae D8, H. uvarum S6, and I. orientalis KMBL5774, respectively. Bars in the histogram (right panel) represent viable counts of yeast cells before (black) and after (gray) air-blast drying and yeasts stored for 1 (white), 2 (diagonally patterned), and 3 (dotted) months. 10% skim milk and 7 g lactomil were used in all samples. 10% trehalose, 10% sucrose, and 10% glucose were used as protective agents for S. cerevisiae D8, H. uvarum S6, and I. orientalis KMBL5774, respectively. All data are expressed as the mean ± SD (n = 3)

Changes in metabolic activities of air-blast dried yeast cells

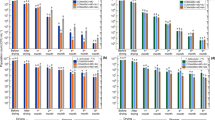

The metabolic activities of each air-blast dried yeast cell were investigated depending on the storage period (Fig. 5). Glucose fermentation ability of air-blast dried S. cerevisiae D8 and H. uvarum S6, and malic acid decomposition ability of I. orientalis KMBL5774 were examined. All samples were prepared by the optimal manufacturing process based on results obtained in the present study and non-dried yeast cultures were used as control to compare the metabolic activity. Non-dried S. cerevisiae D8 decomposed glucose slightly faster compared to both air-blast dried S. cerevisiae D8 immediately after drying and after 3 months of storage. However, all samples showed similar fermentability on the second day and completed the fermentation process on third day. Similarly, both air-blast dried H. uvarum S6 just after drying and after 3 months of storage showed similar fermentation rates compared to non-dried H. uvarum S6. Non-dried I. orientalis KMBL5774 initiated and completed malic acid decomposition first, but the duration of malic acid decomposition was not significantly different from that observed for air-blast dried I. orientalis KMBL5774 immediately after drying. In case of air-blast dried I. orientalis KMBL5774 after 3 months of storage at 4 °C, malic acid degradation was delayed by 12 h compared to that of the control. The results of the metabolic activities of air-blast dried yeast cells after 3 months of storage suggest that S. cerevisiae D8 and H. uvarum S6 retained their capacities and efficiencies as yeast starters, whereas reduction of the survival rate after long-term storage possibly induced the decrease in the malic acid degradation rate in I. orientalis KMBL5774.

Fermentation rate of air-blast dried S. cerevisiae D8 (diamonds) and H. uvarum S6 (circles) (a) and malic acid content fermented by air-blast dried I. orientalis KMBL5774 (squares) (b). Empty figures represent non-dried yeast cells, filled figures represent air-blast dried yeast cells just after air-blast drying, and gray figures represent air-blast dried yeast cells after 3 months of storage. All data are expressed as the mean ± SD (n = 3)

Discussion

In this study, air-blast drying was established as a suitable substitute to conventional drying methods, such as freeze-drying or spray-drying for manufacturing yeast starters for wine. Skim milk, generally used as a protective agent in freeze-drying, was added at 5 and 10% to air-blast dried yeast cells and the addition resulted in the increase in the survival rate of air-blast dried yeast cells in a dose-dependent manner (Fig. 1). Ananta et al. (2005) reported that when 20% reconstituted skim milk added to Lactobacillus rhamnosus GG was spray dried at an outlet temperature of 80 °C, its survival rate was measured to be >60%. Abadias et al. (2001a) reported that freeze-dried Candida sake showed the highest survival rate of 40% when 10% skim milk and 10% lactose were added as protective agents. Similarly, our study also showed that skim milk had a protective effect on air-blast dried yeast cells.

Four excipients (wheat flour, nuruk, artichoke powder, and lactomil) were evaluated to make an appropriate powdered form of the final product of the air-dried yeast starter (Table 1). According to a study by Beker and Rapoport (1987), 12–13% moisture content is not suitable for storage of yeast, whereas at 8–10% moisture content, yeast retain a remarkable degree of cell viability during storage. Therefore, all samples were air-blast dried until moisture content of each sample was <10%. Drying times for samples with the excipients wheat flour and artichoke were relatively longer than those observed for the other excipients. This result could be attributed to the water or moisture in these excipients, which could lead to increased viscosity due to starch gelatinization and binding to the gluten network in wheat flour (Fessas and Schiraldi 2001), and to the high dietary fiber content in the artichoke (insoluble 18.11% and soluble 26.74%), which could interact with the water held in the capillary structure of the artichoke (Lintas and Capeloni 1988; López et al. 1996). Nuruk, a Korean traditional starter prepared by the natural proliferation of fungi and other microorganisms (Yoo et al. 2011), was also investigated as excipient for yeast starter. Although drying time for nuruk was shorter than wheat flour and artichoke, the physical properties of nuruk as well as that of wheat flour were not suitable for preparing the final starter product because they led to the formation of lumps after air-blast drying (Fig. 2). On the contrary, lactomil (consisting of lactose and maltodextrin) was considered as the most suitable excipient for yeast starter because it yielded a rapid drying time of 2.5 h and the highest yeast cell survival rate and formed a fine powder. Furthermore, the survival rates of air-blast dried yeast cells, based on the amount of lactomil added, were investigated and all samples mixed with 7 g lactomil statistically showed the highest and optimal survival rate (Table 2).

Sugars have been widely used as protective agents due to their low price, chemically innocuous nature, and general utilization in the food industry (Peighambardoust et al. 2011). The protective effects of various sugars on the survival rate of microbial starters such as yeast and bacteria have been determined in the last few decades (Jofré et al. 2014; Lodato et al. 1999; Niu et al. 2016). Our study showed that each strain showed its highest capacity for survival with different optimal protective agents (Table 3). S. cerevisiae D8 added to 10% trehalose showed the highest survival rate of 97.54% and most sugar-based protectants (except for fructose) demonstrated excellent protective effects with >90% survival rate. H. uvarum S6 showed the highest survival rate (92.59%) when 10% sucrose was added as a protectant and other sugars were also shown to demonstrate notable protective effects compared to no sugar addition. Contrary to S. cerevisiae D8 and H. uvarum S6, only 10% glucose and 10% fructose remarkably increased the survival rate of I. orientalis KMBL5774, whereas other sugars demonstrated protective effects that only slightly increased the survival rate of I. orientalis KMBL5774. The morphology of air-blast dried yeast starters was also observed by SEM to confirm the accumulation of yeast cells (Fig. 3). Pereira et al. (2003) reported that 10% trehalose was able to reduce oxidative damage caused by dehydration in S. cerevisiae and Garay-Arroyo et al. (2004) reported that S. cerevisiae could be easily adapted to various environmental stresses, including oxidative stress, heat shock, freezing shock, osmotic, and ionic stress. A study by Lemetais et al. (2012) on S. cerevisiae showed that the plasma membrane is an essential structure for the survival of cells during dehydration by air-drying. In a study on the survival rate of H. uvarum lyophilized without cryoprotectant and stored at −80 °C for 0–12 months, the viable counts showed a reduction of 2.47–2.82 log cfu mL−1 from the values recorded before freeze-drying (Pietrowski et al. 2015). A study by Kim et al. (2016) reported that S. cerevisiae D8, H. uvarum S6, and I. orientalis KMBL5774 entrapped in 2% Ca-alginate beads by air-blast drying showed 90.67, 90.81, and 87.04% survival rate when 10% skim milk and 10% sugars (sucrose, trehalose, and glucose for S. cerevisiae D8, H. uvarum S6 and I. orientalis KMBL5774, respectively) were used as protectants. Miyamoto-Shinohara et al. (2010) reported that I. orientalis had an 8.6 and 28.2% survival rate on freeze-drying and liquid drying, respectively, without any protective agent.

Long-term storage is the most important factor in developing microbial starters for industrial use. In our study, long-term storage effect of air-blast drying on each yeast strain stored at 4 °C for 3 months was investigated (Fig. 4). Air-blast dried S. cerevisiae D8 and H. uvarum S6 showed 1.18 and 0.51 log reductions, which means that these strains retained a good viable count after 3 months of storage. However, since I. orientalis KMBL5774 showed a 2.38 log reduction after 3 months of storage, further study would be needed to improve its storability. Several studies have reported storability based on various drying method and protectants. A study by Miyamoto-Shinohara et al. (2006) reported that freeze-dried S. cerevisiae showed 0.010 log reduction per year for 20 years. Zayed and Roos (2004) demonstrated that 4% sucrose, 4% trehalose, and 18% skim milk, used as protective solutions for freeze-dried Lactobacillus salivarius maintained the survival rate at 83–85% for 7 weeks of storage. In a study by Gardiner et al. (2000), the survival rate of spray-dried Lactobacillus paracasei NFBC 338 grown in 20% reconstituted skim milk was maintained at constant at ~1 × 109 cfu g−1 during 2 months of storage at 4 °C, while storage of L. salivarius UCC 118 under the same conditions showed 1 log reduction (from 7.2 × 107 to 9.5 × 106 cfu g−1).

Fermentation rates of air-blast dried S. cerevisiae D8 and H. uvarum S6 and the malic acid decomposition ability of air-blast dried I. orientalis KMBL5774 after 3 months of storage were analyzed to evaluate their metabolic capacities (Fig. 5). Fermentation rates of S. cerevisiae D8 and H. uvarum S6 showed no significant difference in all samples. On the other hand, malic acid degradation by air-blast dried I. orientalis KMBL5774 after 3 months of storage was delayed by 12 h compared to that of non-dried yeast cells; this result could be attributed to the low survival rate of air-blast dried I. orientalis KMBL5774 after 3 months of storage. In a study by Bekatorou et al. (2001), freeze-dried S. cerevisiae cells immobilized on gluten pellets showed higher glycolytic activity concerning the fermentation time than free freeze-dried S. cerevisiae cells because immobilization increased the viable count of freeze-dried cells. A study by Pietrowski et al. (2015) demonstrated that the maximum fermentation rate of lyophilized H. uvarum took longer to achieve than the cryopreserved H. uvarum because of reduction in the initial cell population (104 cfu mL−1).

In summary, air-blast drying method is a suitable alternative to conventional drying methods for making yeast starter. Yeast cells retained excellent viability after air-blast drying when 10% skim milk and 10% sugars were used as protective agents and 7 g lactomil was used an excipient. The viability and availability of these yeast starter products (except for I. orientalis KMBL5774) was supported by the results of long-term storability and metabolic activity. Therefore, our study suggests that the air-blast drying method can contribute to optimal manufacturing processes for microbial starters of industrial value.

References

Abadias M, Benabarre A, Teixidó N, Usall J, Viñas I (2001a) Effect of freeze drying and protectants on viability of the biocontrol yeast Candida sake. Int J Food Microbiol 65:173–182

Abadias M, Teixidó N, Usall J, Benabarre A, Viňas I (2001b) Viability, efficacy, and storage stability of freeze-dried biocontrol agent Candida sake using different protective and rehydration media. J Food Prot 64:856–861

Ale CE, Otero MC, Pasteris SE (2015) Freeze-drying of wine yeasts and Oenococcus oeni and selection of the inoculation conditions after storage. J Bioprocess Biotech 5:248

Ananta E, Volkert M, Knorr D (2005) Cellular injuries and storage stability of spray-dried Lactobacillus rhamnosus GG. Int Dairy J 15:399–409

AOAC (1990) Official methods of analysis, 15th edn. Association of official analytical chemists, Arlington

Bayrock D, Ingledew WM (1997) Mechanism of viability loss during fluidized bed drying of baker’s yeast. Food Res Int 30:417–425

Bekatorou A, Koutinas AA, Kaliafas A, Kanellaki M (2001) Freeze-dried Saccharomyces cerevisiae cells immobilized on gluten pellets for glucose fermentation. Process Biochem 36:549–557

Beker MJ, Rapoport AI (1987) Conservation of yeasts by dehydration. Adv Biochem Eng Biotechnol 35:127–171

Casey GP, Ingledew WM (1986) Ethanol tolerance in yeasts. Crit Rev Microbiol 13:219–280

Champagne CP, Gardner NJ (2001) The effect of protective ingredients on the survival of immobilized cells of Streptococcus thermophilus to air and freeze-drying. Electron J Biotechnol 4:146–152

Champagne CP, Raymond Y, Simon JP (2012) Effect of water activity and protective solutes on growth and subsequent survival to air-drying of Lactobacillus and Bifidobacterium cultures. Appl Microbiol Biotechnol 95:745–756

Ciani M, Maccarelli F (1998) Oenological properties of non-Saccharomyces yeasts associated with wine-making. World J Microbiol Biotechnol 14:199–203

Esteve-Zarzoso B, Manzanares P, Ramón D, Querol A (1998) The role of non-Saccharomyces yeasts in industrial winemaking. Int Microbiol 1:143–148

Fessas D, Schiraldi A (2001) Water properties in wheat flour dough I: classical thermogravimetry approach. Food Chem 72:237–244

Garay-Arroyo A, Covarrubias A, Clark I, Niňo I, Gosset G, Martinez A (2004) Response to different environmental stress conditions of industrial and laboratory Saccharomyces cerevisiae strains. Appl Microbiol Biotechnol 63:734–741

Gardiner GE, O’Sullivan E, Kelly J, Auty MAE, Fitzgerald GF, Collins JK, Ross RP, Stanton C (2000) Comparative survival rates of human-derived probiotic Lactobacillus paracasei and L. salivarius strains during heat treatment and spray drying. Appl Environ Microbiol 66:2605–2612

Georgetti SR, Casagrande R, Souza CRF, Oliveira WP, Fonseca MJV (2008) Spray drying of the soybean extract: effects on chemical properties and antioxidant activity. LWT-Food Sci Technol 41:1521–1527

Heard GM, Fleet GH (1985) Growth of natural yeast flora during the fermentation of inoculated wines. Appl Environ Microbiol 50:727–728

Hong YA, Park HD (2013) Role of non-Saccharomyces yeasts in Korean wines produced from Campbell Early grapes: potential use of Hanseniaspora uvarum as a starter culture. Food Microbiol 34:207–214

Hongpattarakere T, Rattanaubon P, Buntin N (2013) Improvement of freeze-dried Lactobacillus plantarum survival using water extracts and crude fibers from food crops. Food Bioprocess Tech 6:1885–1896

Isono Y, Araya G, Hoshino A (1995) Immoblization of Saccharomyces cerevisiae for ethanol fermentation on γ-alumina particles using a spray-dryer. Process Biochem 30:743–746

Jofré A, Aymerich T, Garriga M (2014) Impact of different cryoprotectants on the survival rate of freeze-dried Lactobacillus rhamnosus and Lactobacillus casei/paracasei during long-term storage. Benef Microbes 6:381–386

Jolly NP, Augustyn OPH, Pretorius IS (2006) The role and use of non-Saccharomyces yeasts in wine production. S Afr J Enol Vitic 27:15–39

Jung YJ, Park HD (2005) Antisense-mediated inhibition of acid trehalose (ATH1) gene expression promotes ethanol fermentation and tolerance in Saccharomyces cerevisiae. Biotechnol Lett 27:1855–1859

Kets EPW, Teunissen PJM, de Bont JAM (1996) Effect of compatible solutes on survival of lactic acid bacteria subjected to drying. Appl Environ Microbiol 62:259–261

Kim JS, Kim SH, Han JS, Yoon BT, Yook C (1999) Effects of sugar and yeast addition on red wine fermentation using Campbell Early. Korean J Food Sci Technol 31:516–521

Kim DH, Hong YA, Park HD (2008) Co-fermentation of grape must by Issatchenkia orientalis and Saccharomyces cerevisiae reduces the malic acid content in wine. Biotechnol Lett 30:1633–1638

Kim MS, Hong YA, Yeo SH, Baek SY, Yun HJ, Rhee CH, Kim KP, Park HD (2013a) Environmental resistance of indigenous Saccharomyces cerevisiae with tolerance to potassium metabisulfite at the microbial succession stage of fermenting Campbell Early grape. Korean J Food Preserv 20:886–893

Kim MS, Yeo SH, Park HD (2013b) Fermentation characteristics of Campbell Early wine by indigenous Saccharomyces cerevisiae yeasts with resistance to potassium metabisulfite and a high sugar concentration. Korean J Food Preserv 20:744–750

Kim DH, Lee SB, Park HD (2016) Effect of air-blast drying and the presence of protectants on the viability of yeast entrapped in calcium alginate beads with an aim to improve the survival rate. Appl Microbiol Biotechnol. doi:10.1007/s00253-016-7744-9

Lee SB, Kim DH, Park HD (2016) Effects of protectant and rehydration conditions on the survival rate and malolactic fermentation efficiency of freeze-dried Lactobacillus plantarum JH287. Appl Microbiol Biotechnol 100:7853–7863

Lemetais G, Dupont S, Beney L, Gervais P (2012) Air-drying kinetics affect yeast membrane organization and survival. Appl Microbiol Biotechnol 96:471–480

Leslie SB, Israeli E, Lighthart B, Crowe JH, Crowe LM (1995) Trehalose and sucrose protect both membranes and proteins in intact bacteria during drying. Appl Environ Microbiol 61:3592–3597

Lintas C, Capeloni M (1988) Content and composition of dietary fiber in raw and cooked vegetables. Food Sci Nutr 42:117–124

Lodato P, Segovia de Huergo M, Buera MP (1999) Viability and thermal stability of a strain of Saccharomyces cerevisiae freeze-dried in different sugar and polymer matrices. Appl Microbiol Biotechnol 52:215–220

López G, Ros G, Rincón F, Periago MG, Martínez MC, Ortuňo J (1996) Relationship between physical and hydration properties of soluble and insoluble fiber of artichoke. J Agric Food Chem 44:2773–2778

Luna-Solano G, Salgado-Cervantes MA, Rodríguez-Jimenes GC, García-Alvarado MA (2005) Optimization of brewer’s yeast spray drying process. J Food Eng 68:9–18

Mercado L, Dalcero A, Masuelli R, Combina M (2007) Diversity of Saccharomyces strains on grapes and winery surfaces: analysis of their contribution to fermentative flora of Malbec wine from Mendoza (Argentina) during two consecutive years. Food Microbiol 24:403–412

Miyamoto-Shinohara Y, Sukenobe J, Imaizumi T, Nakahara T (2006) Survival curves for microbial species stored by freeze-drying. Cryobiology 52:27–32

Miyamoto-Shinohara Y, Nozawa F, Sukenobe J, Imaizumi T (2010) Survival rate of yeasts stored after freeze-drying or liquid drying. J Gen Appl Microbiol 56:107–119

Niu X, Deng L, Zhou Y, Wang W, Yao S, Zeng K (2016) Optimization of a protective medium for freeze-dried Pichia membranifaciens and application of this biocontrol agent on citrus fruit. J Appl Microbiol 121:234–243

Peighambardoust SH, Tafti AG, Hesari J (2011) Application of spray drying for preservation of lactic acid starter cultures: a review. Trends Food Sci Technol 22:215–224

Pereira E, Panek AD, Eleutherio ECA (2003) Protection against oxidation during dehydration of yeast. Cell Stress Chaperones 8:120–124

Philliskirk C, Young TW (1975) The occurrence of killer character in yeasts of various genera. Antonie Van Leeuwenhoek 41:147–151

Pietrowski GAM, Grochoski M, Sarton GF, Gomes TA, Wosiacki G, Nogueira A (2015) Viability of Hanseniaspora uvaum yeast preserved by lyophilization and cryopreservation. Yeast 32:559–565

Querol A, Barrio E, Huerta T, Ramon D (1992) Molecular monitoring of wine fermentations conducted by active dry yeast strains. Appl Environ Microbiol 58:2948–2953

Rojas V, Gil JV, Piñaga F, Manzanares P (2001) Studies on acetate ester production by non-Saccharomyces wine yeasts. Int J Food Microbiol 70:283–289

Santivarangkna C, Kulozik U, Foerst P (2007) Alternative drying processes for the industrial preservation of lactic acid starter cultures. Biotechnol Prog 23:302–315

Schütz M, Gafner J (1993) Analysis of yeast diversity during spontaneous and induced alcoholic fermentations. J Appl Bacteriol 75:551–558

Seo SH, Rhee CH, Park HD (2007) Degradation of malic acid by Issatchenkia orientalis KMBL 5774, an acidophilic yeast strain isolated from Korean grape wine pomace. J Microbiol 45:521–527

Yoo JG, Kim DH, Park EH, Lee JS, Kim SY, Kim MD (2011) Nuruk, a traditional Korean fermentation starter, contains the bioactive compound 2,6-dimethoxy-1,4-benzoquinone (2,6-DMBQ). J Korean Soc Appl Biol Chem 54:795–798

Zagorc T, Maráz A, Cadez N, Povhe Jemec K, Péter G, Resnik M, Nemanič J, Raspor P (2001) Indigenous wine killer yeasts and their application as a starter culture in wine fermentation. Food Microbiol 18:441–451

Zayed G, Roos YH (2004) Influence of trehalose and moisture content on survival of Lactobacillus salivarius subjected to freeze-drying and storage. Process Biochem 39:1081–1086

Authors’ contributions

SBL, SHY and HDP conceived the idea and designed the experiments. SBL, WSC and HJJ performed the experiments. SBL and HDP analyzed the data and wrote the manuscript. All authors read and approved the final manuscript.

Acknowledgements

This study was supported by the Rural Development Administration, Republic of Korea (Research Grant PJ012425022016).

Competing interests

The authors declare that they have no competing interests.

Ethics approval

This article does not contain any studies concerned with experiment on human or animals.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Lee, SB., Choi, WS., Jo, HJ. et al. Optimization of air-blast drying process for manufacturing Saccharomyces cerevisiae and non-Saccharomyces yeast as industrial wine starters. AMB Expr 6, 105 (2016). https://doi.org/10.1186/s13568-016-0278-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13568-016-0278-9