Abstract

Edible insects constitute a potential source of alternative proteins as a food supplement. The present study aimed to investigate the chemical composition, energy and nutritional values, the digestibility and functional properties of Carbula marginella (Thunberg) and Cirina butyrospermi (Vuillet) defatted flour, protein concentrates, and isolates. Carbula marginella has shown the highest content of protein (41.44%), lipid (51.92%), calcium (33.92 mg/100 g) and sodium (185.84 mg/100 g) while the highest contents of carbohydrate (34.54%), ash (4.77%), iron (31.27 mg/100 g), magnesium (150.09 mg/100 g), and potassium (1277 mg/100 g) have been observed for C. butyrospermi. Linoleic (30.23%), palmitic (27.54%), oleic (26.41%) and stearic (8.90%) acids were the most dominant fatty acids found in C. marginella. Cirina butyrospermi was characterized by high levels of oleic (27.01%), stearic (21.02%), linolenic (20.42%), palmitic (13.06%), and linoleic (8.01%) acids. Protein and essential amino acid contents of the protein isolates in both insect species were 1.7–2 times higher than that of their defatted flours. The protein isolate of C. marginella exhibited the highest protein digestibility (87.63%), while the highest fat absorption capacity (8.84 g/g) and foaming capacity (48.40%) have been obtained from the protein isolate of C. butyrospermi. These findings indicate that the protein concentrates and isolates of C. marginella and C. butyrospermi have great potential for industrial applications.

Similar content being viewed by others

Introduction

Proteins are major nutritional components providing both essential and non-essential amino acids to the human body [1]. The current world demand for dietary proteins, estimated at 202 billion tons, is projected to reach around 404 billion tons in 2050 [2]. In addition to their nutritional properties, proteins have several functional properties (water absorption capacity, fat absorption capacity, emulsifying capacity, foaming capacity) in a few food products [3]. The isolation of protein-rich fractions from both animal and plant sources has grown in importance in recent years. The main sources for protein extractions are cereals, pulses, tubers, oilseeds, milk, meat, and fish [2, 4, 5].

Edible insects have been described as sources of protein with an average content ranging from 35.34 to 61.32% [6]. Species from the order of Orthoptera displayed high protein content ranging from 58.90 to 77.13% [6]. Edible insects of Diptera order can cover the adults’ requirements for methionine and methionine + cysteine which are limited amino acids of cereal and pulse seeds [6]. However, edible insect protein has a lower digestibility compared to casein [7]. But, insect protein digestibility can be improved by removing the chitin exoskeleton which lowers its level of digestibility [8]. Insect protein functional properties can be improved by their extraction, thus making them suitable food supplements [9, 10]. Carbula marginella and Cirina butyrospermi are both the most preferred edible insects in Burkina Faso[11]. Cirina butyrospermi is a pest from the shea butter tree, belonging to the Lepidoptera order. In the southern Sudan area, it is mainly consumed fried or as ingredients in various sauces by the Bobo, Guin, Sambla, Senoufo, and Turka ethnic groups [11]. It is exclusively found in the south Sudanian zone under specific rainfall (900 to 1000 mm) and humidity conditions (70–85%) [12]. Cirina butyrospermi is also consumed in some countries such as Botswana, Cote d’Ivoire, Democratic Republic of Congo, Ghana, Mali, Mozambique, Namibia, Nigeria, South Africa, Togo, and Zambia [11, 13,14,15]. Cirina butyrospermi, being specifically rich in protein (55.41–62.74%) and fat (14.51–28.71%), is highly nutritious [16, 17]. It contains all essential amino acids and also has a high content of linolenic acid [16, 17].

Carbula marginella belongs to the Hemiptera (true bugs) order, consumed in the northern Sudanian zone by the Mossi and Fulani ethnic groups. It is found in cave holes in this area during the dry season (October to January) and it is consumed roasted [11]. However, to the best of our knowledge, there are no published data on the chemical composition, nutritional value, digestibility, and functional properties of defatted flour, protein concentrates, and isolates of both C. marginella and C. butyrospermi. The aim of the present study was to compare the chemical composition, energy and nutritional values, digestibility, and functional properties of defatted flour, protein concentrates, and isolates of C. marginella and C. butyrospermi, two common species of insects used as food in Burkina Faso.

Materials and methods

Materials

Carbula marginella adults (Fig. 1) were collected in the village of Boudtenga (12° 29′ 11′′ N; 1° 15′ 57′′ W) in the North Sudanian zone in December 2016. C. butyrospermi (Fig. 2), at the fourth stage of its development (larval stage), was collected in the South Sudanian zone from July to August 2015 and 2017 in the village of Koumi (N 11° 07′ 54.7′′, W 004° 25′ 41.5′′). The insects were immediately placed in cooler boxes containing ice and brought to the laboratory. Specimen were identified at the Department of Environment and Forests using the Scholtz classification [18]. Samples were cleaned and the inedible parts were removed. Then, they were washed with distilled water and dried for 24 h in an oven at 40–50 °C.

Alpha-chymotrypsin (MP Biomedicals, USA), nitric acid (Carlo Erba, France, 96%), boric acid (Sigma-Aldrich, USA, 98%), ethanol (Chromasolv, absolute, for HPLC, Sigma-Aldrich, Germany), n-hexane (Chromasolv, Germany), hydrochloric acid (Carlo Erba, France, 37%), Kjeldahl catalyst (Carlo Erba, Germany), phenylisothiocyanate (Thermo Scientific, USA), methanol (HPLC Gradient Grade for free amino acids analysis, Prolabo Chemicals, France), Pico Tag diluent (Waters, USA), sodium hydroxide (Carlo Erbo, France), triethylamine (Sigma-Aldrich, Belgium, 99%) and trypsin from bovine pancreas (Sigma Aldrich, USA) were used.

Preparation of protein isolate

The protein isolate was extracted according to the Wolf method with minor modifications [19]. Briefly, the defatted flour was stirred for 2 h at room temperature (about 25 °C) with de-ionized water, pH adjusted to 11.0 with 1 N NaOH [water: flour ratio, 1:20 (w/v)]. The slurry was centrifuged at 10,000g for 30 min at 4 °C. The pellet was re-dissolved with adjusted pH de-ionized water, as described above, and cold-centrifuged again. The supernatants were mixed together, the pH was adjusted to 4.5 with 1 N HCl. The mixture was then kept for 2 h at room temperature and subsequently centrifuged at 10,000g for 30 min at 4 °C. The precipitate was washed with de-ionized water and re-dissolved in de-ionized water. The pH was neutralized to 7.0 with 1 N NaOH at room temperature, and then freeze-dried.

Preparation of protein concentrate

The protein concentrate was prepared according to the process described by Wolf with minor modifications [19]. The defatted flour was stirred for 1 h at room temperature (about 25 °C). The suspension was filtered and the residues were air-dried in a fume hood. Residues were dispersed in de-ionized water (1:20, w/v) at room temperature. The pH was adjusted to 4.5 by the addition of 1 N HCl. The slurry was stirred for 2 h and centrifuged (10,000g, 30 min, 4 °C). The precipitate was washed with de-ionized water, re-dissolved in de-ionized water, and the pH was neutralized to 7.0 with 1 N NaOH at room temperature, and then freeze-dried.

Proximate analysis and energy value

Moisture, fat, protein, and ash contents were determined according to AOAC official methods 950.46, 960.39, 979.09, and 920.153, respectively [20]. Moisture percentage was calculated by drying the sample in an oven at 105 °C for 3 h. Fat percentage was calculated by drying fats after extraction in a Soxhlet using petroleum ether. Crude protein was determined by the Kjeldahl method and the total protein content was calculated as the amount of total determined N multiplied by the nitrogen to a protein conversion factor of 6.25. Ash percentage was calculated by combusting the samples at 550 °C for 4 h in a porcelain crucible placed in a muffle furnace. The Atwater conversion factors were used to calculate the energy value [21]. All the analyses were performed in triplicate and expressed as mean ± standard deviation.

Mineral compositions

To determine the mineral content of insect flour, 5.0 g of powdered samples were incinerated in a furnace at 550 °C and the residues were dissolved in 50 mL of 0.5 M HNO3 solution. The concentrations of calcium (Ca), iron (Fe), magnesium (Mg), potassium (K), sodium (Na), and zinc (Zn) were determined according to AOAC official method 999.11 [20]. The analyses were performed in triplicate and expressed as mean ± standard deviation.

Fatty acid methyl ester preparation and gas chromatography (GC) analysis

The fatty acid (FA) compositions of the oils were determined following the International Union of Pure and Applied Chemistry (IUPAC) method [22]. Fatty acid methyl esters (FAME) were prepared following the method described by Khan [23]. About 50 mg of the oil samples were weighed into a test tube and dissolved with 1 mL hexane by vortexing for 30 s. Then, 2 mL of 4 M methanolic KOH was added into the test tube which was vortexed again for 30 s. The mixture was placed in the React-Therm module for 30 min at 50 °C and cooled at room temperature. 1 mL of de-ionized water was then added. An aliquot of the organic layer was transferred into a vial for injection. FA compositions were determined using a Gas Chromatograph-FID (Agilent Technologies 6890 N, Palo Alto, CA, US) with a DB23 capillary column (60 m ID: 0.25 mm, film: 0.25 μm, J&W Scientific Co., CA, USA). The working conditions of Gas Chromatography (GC) were as follows: 1 µL injection volume, 1:50 injector split ratio, 1 mL/min flow rate, Nitrogen as a carrier gas, hydrogen (40 mL/min), and dry air (450 mL/min) as detector gases, 200 °C inlet temperature, and 250 °C detector temperature. The oven temperature was in gradient mode programs from 130 to 240 °C. The oven was programmed to operate at 130 °C for 5 min, increased to 170 °C at 5 °C/min, to 215 °C at 1.5 °C/min, to 240 °C at 40 °C/min, and kept constant for an additional 5 min. FA was identified by using a FAME standard mixture (30-components, Supelco, Bellefonte, PA, USA). All determinations were performed in three replicates.

Protein content and amino acid composition

The profile and amount of amino acids were determined by reverse-phase of High-Performance Liquid Chromatography (HPLC) using the Pico Tag method described by Bidlingmeyer et al. [24]. The samples were defatted with n-hexane and hydrolyzed with 6 N hydrochloric acid. About 0.4 g of the defatted sample was transferred in a bottle with 15 mL of hydrochloric acid and incubated in an oven at 110 °C for 24 h. The sample was then left to cool to room temperature, poured into a 50 mL volumetric flask, completed with Milli-Q water, and mixed. Approximately 1 mL of the diluted and homogenized solution was filtered through a Polytetrafluoroethylene (PTFE) filter of 0.45 μm. An aliquot of 10 µL of the solution was dried under vacuum for 15 min using Pico Tag Workstation. The sample was then re-dissolved in 10 µL of ethanol/water/triethylamine (2:2:1 volume) and replaced again at the Pico Tag Workstation under vacuum dehydration for 15 min. The dehydrated sample was mixed again with 20 µL of derivatization solution incorporated of ethanol/triethylamine/water/phenylisothiocyanate (7:1:1:1 volume). This was kept for 20 min at room temperature and the excess reagent was removed with a vacuum for 45 min [25]. The amino acid derivatives were then separated by HPLC and detected by UV detector at 254 nm after elution through a Pico Tag precolumn [Nova-Pak C18 Guard Column, 60Å, 4 μm, 3.9 mm × 20 mm) and column (C18 PICO’TAG Column Waters (3.9 × 150mm)] according to the conditions described by Bidlingmeyer et al. [24]. The analysis (identification and quantification) of amino acids was then carried out using Empower 2 software (Waters, USA).

Protein digestibility

The three-enzyme method of Hsu et al. [26] and Satterlee et al. [27] was used. Ten millilitre of an aqueous protein suspension (1 mg per mL distilled water) was equilibrated at 37 °C to pH 8.0. One millilitre of three-enzyme solution (1.61 mg trypsin, 3.96 mg chymotrypsin, and 2.36 mg peptidase per mL) was added to the protein suspension, and after exactly 10 min of incubation, the pH was recorded. The calculation of in-vitro digestibility coefficients has been obtained from:

X is the Volume of NaOH (mL poured at T = 10 min to maintain the pH at 8.0.

Functional properties

Water absorption capacity (WAC)

Water absorption capacity (WAC) was determined by the method outlined by Diniz and Martin [28] with slight modifications. 0.5 g of defatted flour, protein concentrate, or protein isolate was dispersed in 20 mL of distilled water and stirred with a shaker at 540 rpm for 30 min. Afterward, the dispersion was centrifuged at 8000g for 15 min and the precipitate was weighed. Then, WAC was calculated as follows:

where W is the weight of the dry sample (in g), W1 is the weight of the tube plus the dry sample (in g) and W2 is the weight of the tube plus the sediment (in g).

Fat absorption capacity

Fat absorption capacity (FAC) was determined using the procedure of Haque and Mozaffar with slight modifications [29]. 0.5 g of defatted flour, protein concentrate, or protein isolate was added to 10 mL of vegetable oil and vortexed for 30 s to mix. Afterward, the dispersion was centrifuged at 8000g for 15 min and the precipitate was weighed. Then, FAC was calculated as follows:

where F0 is the weight of the dry sample (in g), F1 is the weight of the tube plus the dry sample (in g) and F2 is the weight of the tube plus the sediment (in g).

Foaming capacity

Foaming capacity (FC) was determined according to the method described by Guo et al. [30]. Twenty milliliters of 1% sample were homogenized in a high shear homogenizer mixer at a speed of 16,000 rpm for 2 min. The whipped sample was immediately transferred into a cylinder. FC was calculated according to the formula:

where V is the volume before whipping (mL), V0 is the volume after whipping (mL).

Statistical analysis

The analytical measures were performed at least in triplicate and the results of the different parameters were presented by the means ± standard deviation. Statistical analysis was performed using the XLSTAT software for Windows (XLSTAT 2016.02.27444). A comparison of the means was performed by One-way analysis of variance (ANOVA) followed by Tukey test.

Result

The fresh matters of both C. marginella and C. butyrospermi were characterized by high moisture contents of 64.9 ± 1.49 and 73.84 ± 2.86 g/100 g, respectively (Table 1). Significant differences were observed in their proximate composition and energy value (p < 0.05). Carbula marginella had the highest content of protein (41.44 ± 0.05%), lipid (51.92 ± 0.40%) and energy value (650.23 ± 2.11 Kcal/100 g of dry matter) whereas C. butyrospermi exhibited the highest ash (4.77 ± 0.02%) and carbohydrate (34.54 ± 0.29%) contents (Table 1).

Fe, Mg, and K contents of Cirina butyrospermi were two to threefolds higher than those of C. marginella. Carbula marginella had 14 times higher Na content than that of C. butyrospermi while for Zn and Ca contents, no significant difference was found between the two edible insects (Table 2).

The fatty acid compositions of C. marginella and C. butyrospermi are given in Table 3. Carbula marginella and C. butyrospermi contained 38.04 and 42.07% saturated fatty acid (SFA), 30.79%, and 29.23% mono-unsaturated fatty acid (MUFA), and 31.13 and 29.01% poly-unsaturated fatty acid (PUFA), respectively. Quantitatively, the most abundant fatty acids in the oil of C. marginella were linoleic acid (30.23 ± 0.08%), palmitic acid (27.54 ± 0.14%), and oleic acid (26.41 ± 0.05%). The oil of C. butyrospermi was characterized by high contents of oleic acid (27.01 ± 0.68%), stearic acid (21.02 ± 0.26%), linolenic acid (20.42 ± 0.45%), and palmitic acid (13.06 ± 1.32%).

Significant differences were found in protein contents and amino acid compositions of isolate, concentrate, and defatted flour of C. marginella and C. butyrospermi (Tables 4 and 5) (p < 0.05). The highest protein content was found in the isolate fractions for both C. butyrospermi (87.41 ± 0.24%) and C. marginella (85.78 ± 0.58%) whereas defatted flours exhibited about half of the isolate content of 40.81 ± 0.20 and 41.49 ± 0.05% for C. butyrospermi and C. marginella, respectively.

The content of total essential amino acids of C. marginella increased from 20.43 g/100 g dry matter for defatted flour to 27.91 and 41.44 g/100 g dry matter for the protein concentrate and isolate, respectively. Similar increases were observed for C. butyrospermi with the values of 21.29, 28.26 and 37.23 g/100 g dry matter for the defatted flour, concentrate and isolate, respectively.

The compositions of essential amino acids of the flour, concentrate, and isolate of C. marginella were significantly different (p < 0.05). Methionine + cysteine was the abundant essential amino acid in the defatted flour while histidine and threonine were in the highest concentration in the concentrate. Valine, isoleucine, leucine, lysine, and phenylalanine + tyrosine were found in the highest concentration in the isolate. Threonine, methionine + cysteine, isoleucine, leucine and lysine contents of isolate fractions of C. butyrospermi were significantly higher than those in the protein concentrate and defatted flour while valine and phenylalanine + tyrosine were in the highest content in the protein concentrate and defatted flour, respectively.

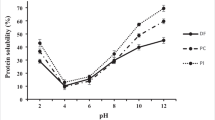

The isolate fractions of both C. marginella (86.57 ± 0.75%) and C. butyrospermi (87.63 ± 0.75%) exhibited the highest protein digestibility (Fig. 3). The lowest digestibility was recorded for the defatted flour and protein concentrates for both C. marginella and C. butyrospermi which were not significantly different too.

The water absorption capacity was comprised between 2.03 and 4.81 g/g for the protein isolates of C. butyrospermi and the protein concentrates of C. butyrospermi, respectively (Fig. 4). No significant difference was observed between the defatted flours and the protein concentrates of both C. marginella and C. butyrospermi, and the protein isolates of C. marginella while the protein isolates of C. butyrospermi was different from the others.

The highest (8.84 ± 0.29 g/g) and the lowest (2.17 ± 0.21 g/g) fat absorption capacities were obtained with the protein isolates and the defatted flour of C. butyrospermi, respectively (Fig. 5). The fat absorption capacities of the defatted flour, the protein concentrates, and isolates of C. marginella were not significantly different (p < 0.05).

The protein isolate of C. butyrospermi had the highest foaming capacity (48.40 ± 0.56%) while the lowest was obtained for the defatted flour of C. marginella (9.00 ± 1.47%) (Fig. 6). Foaming capacities of the defatted flour, the protein concentrates, and isolates of both C. marginella and C. butyrospermi were significantly different (p < 0.05).

Discussion

Moisture contents

The moisture contents on the fresh basis of both C. marginella and C. butyrospermi (Table 1) were in the range of those reported for Oecophylla smaragdina, Odontotermes sp., Hermetia illucens L., Apis mellifera ligustica, and Musca domestica L. [31,32,33]. These high moisture contents make them sensitive to rapid degradation. This could explain why they are immediately processing by boiling and drying after collection.

Ash and mineral contents

Minerals are essential for the metabolic processes of the human body. The ash contents of C. marginella and C. butyrospermi (Table 1) were lower and higher than the mean value of 5.03 and 4.51% reported for Hemiptera and Lepidoptera members, respectively [6]. The ash content of C. marginella was similar to that of Neortholomus sp [34]. Cirina butyrospermi had an ash content similar to that reported by Yapo et al. [17] in Côte d’Ivoire but lower than the 5.10% value already recorded in Burkina Faso [16] with the same species.

Carbula marginella had lower calcium, iron, magnesium, potassium, sodium, and zinc contents (Table 2) than that reported for Agonoscelis pubescens, Aspongubus viduatus, and Euschistus sp., members of Hemiptera order [34, 35]. Iron, potassium, and sodium contents of C. butyrospermi were higher than those previously reported in Burkina Faso and in Côte d’Ivoire while its calcium and magnesium contents were higher and lower than that found in Côte d’Ivoire and in Burkina Faso, respectively [16, 17]. The zinc content was lower and higher than the values previously reported by the same authors in Côte d’Ivoire and in Burkina Faso, respectively [16, 17]. Variations in these values could be due to analytical methods, insect feed, and geographical location. Fe and Zn contents obtained with C. marginella and C. butyrospermi covered the recommended dietary intake of Fe for adults [36]. Both C. marginella and C. butyrospermi can be used as an alternative source of Fe and Zn in the food supplementation program [37].

Fat and fatty acid compositions

The fat contents of both C. marginella and C. butyrospermi (Table 1) were higher and lower than those reported for the members of Hemiptera and Lepidoptera orders, respectively [6]. The fat content of C. butyrospermi was lower and higher than that of 28.71 and 14.51% previously reported by Yapo et al. [17] and Anvo et al. [16], respectively.

The content of palmitic, oleic, and linoleic acids of C. marginella (Table 3) were, respectively, in the range of 2.47 to 31.80 ; 0.92 to 45.53 and 4.90 to 35.21 reported for A. pubescens, A. viduatus, Lethocerus indicus, and Meimuna opalifera, members of Hemiptera order [34, 35, 38, 39]. Compared to these members, C. marginella oil had a relatively balanced fatty acid composition which included 38.04% of saturated fatty acids, 30.79% of monounsaturated fatty acids, and 31.13% of polyunsaturated fatty acids.

The crude oil of C. butyrospermi was characterized by oleic, stearic, linolenic, and palmitic acids as abundant fatty acids (Table 3). This composition was different from those previously reported by Yapo et al. [17] and Anvo et al. [16] which described stearic (39.53–35.40%, respectively) and linolenic (23.89–35.82%, respectively) acids as the dominant ones. The crude oil of C. butyrospermi can be considered a good source of linolenic acid, which is an essential fatty acid.

Protein contents and amino acid compositions

The crude protein content of the defatted flour of C. marginella was described in the range of 27–72% for the members of Hemiptera order [6]. The protein content of the flour of C. butyrospermi was lower than those of 55.41 and 62.74% previously reported by Anvo et al. [16] and Yapo et al. [17], respectively. However, this protein content remained in the range of other Lepidoptera larvae, including Galleria mellonella (41.25%), Heliothis zea (42.00%), and Aegiale hesperiaris (40.24%) [34, 40, 41].

The higher protein content of isolate for both C. marginella and C. butyrospermi compared to concentrate could be due to diverging extraction methods. The alkaline extraction-isoelectric precipitation method improves the protein content [42]. Thus, Mishyna et al. [10] also reported that alkaline and sonication-assisted extractions enhanced protein content in Schistocerca gregaria powder by 14.8 and 19.4% respectively compared to raw powder. A similar increase was recorded for A. mellifera, where protein contents reached 39.6 and 55.2% for alkaline and sonication-assisted extractions. Wu et al. [43] also observed an increase in the protein content of the peanut protein isolate from 55.88% for peanut powder to 96.65% for the isolate. As legume protein isolates and concentrates that of C. marginella and C. butyrospermi can find applications in pasta and desserts industries [44,45,46].

With the exception of phenylalanine + tyrosine, all the essential amino acids in the Hemiptera order were lower than those of the flour of C. marginella [6]. The total essential amino acid content of the flour of C. marginella was higher than those reported by Mariod et al. [35] for A. pubescens and A. viduatus.

Except for valine, all the essential amino acids in the Lepidoptera order were lower than those of the flour of C. butyrospermi. The total essential amino acid content of the defatted flour of C. butyrospermi (Table 5) was lower than the value of 29.88 g/100 g dry matter previously reported by Anvo et al. [16]. Histidine, threonine, leucine, lysine, and phenylalanine + tyrosine contents of C. butyrospermi were lower than those reported by Anvo et al. [16] and Yapo et al. [17] for the same species. Variations in these values could be due to insect feeding, geographical location, and the different treatments undergone by the insects after collection. The protein concentrates and isolates of C. marginella and C. butyrospermi had lysine contents higher than those recommended by the FAO for the daily requirement of adults [44]. Cereals and pulses are characterized by low contents of Lysine and Methionine + cysteine, respectively [45, 46]. The high values of lysine and methionine + cysteine in concentrates and isolates of both species suggest that they can be used as dietary supplements in cereal and legume-based foods.

Carbohydrates and energy values

The carbohydrate content of the defatted flour of both C. marginella and C. butyrospermi was described in the range of 0.01–26% and 1–66.10% for the member of Hemiptera and Lepidoptera orders, respectively [6]. The carbohydrate content of the flour of C. butyrospermi was higher than that reported by Yapo et al. [17] in Côte d’Ivoire and Anvo et al. [16] in Burkina Faso.

The energy value of C. marginella (650.23 ± 2.11 Kcal/100 g) was higher than the range of 328.99–622 Kcal/100 g described for the members of Hemiptera order [6]. It was also higher than that found by Durst et al. [41] with Neortholomus sp. (542.08 Kcal/100 g) and Edessa petersii (530 Kcal/100 g). The energy value of C. butyrospermi (480.20 ± 0.49 Kcal/100 g) was in the range of 293–776.85 Kcal/100 g described for the members of Lepidoptera order [6]. It was higher than that reported by Anvo et al. (432 Kcal/100 g) [16] but lower than that obtained by Yapo et al. [17] (492.31 Kcal/100 g) with the same species.

Protein digestibility

Protein quality in food is determined by amino acid profile and the ability of digestive enzymes to liberate the amino acids [47]. The protein digestibility of the defatted flour of C. marginella and C. butyrospermi (Fig. 3) was similar to that reported for Ruspolia differens (82.34%), Cirina forda (81.71%), Gryllus assimilis (80.82%) and lower than the values of 84.98%, 85.67%, 83.41–90.49%, 90.66% reported for Macrotermes nigeriensis, Ruspolia differens, Macrotermes subhyalinus, and Melanoplus foedus, respectively [7]. The insect exoskeleton contains chitin which could lower its digestibility [48]. The high digestibility of isolate and concentrate fractions could be explained by the elimination of the chitin.

Functional properties

Water absorption capacity (WAC) is the amount of water that can be bound or retained by proteins [49]. The water absorption capacity of defatted flour and concentrate of both C. marginella and C. butyrospermi (Fig. 4) was higher than those of the defatted flour of C. forda [50], the defatted flour of Imbrasia oyenmensis [51], and the concentrate of Gryllodes sigillatus [9]. The water absorption capacity of C. butyrospermi isolate was lower than that of the soy isolate [52] but higher than that of the isolate of peanut [43]. The highest values of water absorption capacity of the defatted flour and the concentrate of both C. marginella and C. butyrospermi could be due to the high content of hydrophilic amino acids [9]. The fat absorption capacity (FAC) is defined as the amount of fat retained by the proteins. It is also the sum of lipids bound by hydrophobic interactions between the protein and the fat itself, and the physically trapped fat in the protein matrix [49]. The defatted flour and the concentrate of C. butyrospermi showed lower FAC values than the defatted flour of Acheta domesticus and G. sigillatus [9, 53]. The FAC values of the isolate of C. butyrospermi were twofold higher than the highest value of 3.58 g/g reported in the literature [54]. The FAC is related to protein content, types of proteins, and the amino acid composition of proteins, especially to hydrophobic residues that interact with hydrocarbon chains in fat molecules [55]. The high FAC value of the isolate of C. butyrospermi could be due to the high content of non-polar amino acids which play an important role in the mechanism of oil absorption [9]. This is important since oil acts as a flavor retainer and increases the palatability of foods [56]. Foams are gas dispersions in a continuous phase that is usually a liquid [57]. Their formation requires the solubilization of the proteins in the aqueous phase and their rapid unfolding to form a cohesive layer of proteins around the gas/air droplets [58]. The foaming capacity of the defatted flour and the concentrate C. butyrospermi (Fig. 6) were in the range of that reported for the flour and the protein concentrate of Tenebrio molitor [9] while that of its isolate was similar to that of the protein concentrate of A. mellifera [10]. The lower foaming capacity of the defatted flour, the protein concentrates, and isolates of C. marginella compared to that of Ci. butyrospermi may be due to the physicochemical properties of their proteins [9]. Functional properties of protein products are physicochemical indicators that determine the behavior of proteins in the production of food products. These properties are mainly related to the structure and amino acid composition of native proteins. [54]. Foods with high water absorption capacities are used in the preparation of viscous foods, such as soups, sauces, pasta, and baked foods [59]. The protein concentrates and isolates of C. marginella could be used in the preparation of these types of foods. Knowledge of fat absorption capacity is important in food technology as it imparts certain characteristics to the product, such as flavor retention, palatability enhancement and increase in shelf life by reducing humidity and fat loss [60]. This property is mainly used in many food applications such as the meat and bakery industries [9]. Therefore, Protein concentrates and isolates of C. marginella and C. butyrospermi could be used in these industries due to their high oil absorption capacity.

Conclusion

The study showed that both C. marginella and C. butyrospermi are potential sources of protein, fat, and ash. Both insects were also excellent sources of iron, zinc, calcium, potassium, and essential fatty acids. Moreover, the protein concentrates and isolates of both species showed good technological properties. Both C. marginella and C. butyrospermi can therefore be used in the strategies to fight against protein-energy malnutrition and micronutrient deficiencies.

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- AOAC:

-

Association of Official Analytical Chemists

- Ca:

-

Calcium

- FA:

-

Fatty acid

- FAC:

-

Fat absorption capacity

- FAME:

-

Fatty acid methyl esters

- FC:

-

Foaming capacity

- Fe:

-

Iron

- GC:

-

Gas chromatography

- HPLC:

-

High-performance liquid chromatography

- IUPAC:

-

International Union of Pure and Applied Chemistry

- K:

-

Potassium

- Mg:

-

Magnesium

- MUFA:

-

Monounsaturated fatty acids

- Na:

-

Sodium

- PTFE:

-

PolyTetraFluoroEthylene

- PUFA:

-

Polyunsaturated fatty acids

- SFA:

-

Saturated fatty acids

- WAC:

-

Water absorption capacity

- Zn:

-

Zinc

References

Millward DJ, Layman DK, Tomé D, et al. Protein quality assessment: impact of expanding understanding of protein and amino acid needs for optimal health. Am J Clin Nutr. 2008;87(5):1576S–1581S. https://doi.org/10.1093/ajcn/87.5.1576S.

Henchion M, Hayes M, Mullen A, et al. Future protein supply and demand: strategies and factors influencing a sustainable equilibrium. Foods. 2017;6(7):53. https://doi.org/10.3390/foods6070053.

Ogunwolu SO, Henshaw FO, Mock H-P, et al. Functional properties of protein concentrates and isolates produced from cashew (Anacardium occidentale L.) nut. Food Chem. 2009;115(3):852–8. https://doi.org/10.1016/j.foodchem.2009.01.011.

Sari YW, Mulder WJ, Sanders JP, et al. Towards plant protein refinery: review on protein extraction using alkali and potential enzymatic assistance. Biotechnol J. 2015;10(8):1138–57. https://doi.org/10.1002/biot.201400569.

Wouters AG, Rombouts I, Fierens E, et al. Relevance of the functional properties of enzymatic plant protein hydrolysates in food systems. Compr Rev Food Sci Food Saf. 2016;15(4):786–800. https://doi.org/10.1111/1541-4337.12209.

Rumpold BA, Schlüter OK. Nutritional composition and safety aspects of edible insects. Mol Nutr Food Res. 2013;57(5):802–23. https://doi.org/10.1002/mnfr.201200735.

Oibiokpa FI, Akanya HO, Jigam AA, et al. Protein quality of four indigenous edible insect species in Nigeria. Food Sci Hum Wellness. 2018;7(2):175–83. https://doi.org/10.1016/j.fshw.2018.05.003.

Ozimek L, Sauer WC, Kozikowski V, et al. Nutritive value of protein extracted from honey bees. J Food Sci. 1985;50(5):1327–9. https://doi.org/10.1111/j.1365-2621.1985.tb10469.x.

Zielińska E, Karaś M, Baraniak B. Comparison of functional properties of edible insects and protein preparations thereof. LWT Food Sci Technol. 2018;91:168–74. https://doi.org/10.1016/j.lwt.2018.01.058.

Mishyna M, Martinez J-JI, Chen J, et al. Extraction, characterization and functional properties of soluble proteins from edible grasshopper (Schistocerca gregaria) and honey bee (Apis mellifera). Food Res Int. 2019;116:697–706. https://doi.org/10.1016/j.foodres.2018.08.098.

Séré A, Bougma A, Ouilly JT, et al. Traditional knowledge regarding edible insects in Burkina Faso. J Ethnobiol Ethnomed. 2018;14(1):59. https://doi.org/10.1186/s13002-018-0258-z.

Zampaligré N, Dossa LH, Schlecht E. Climate change and variability: perception and adaptation strategies of pastoralists and agro-pastoralists across different zones of Burkina Faso. Reg Environ Chang. 2014;14(2):769–83. doi https://doi.org/10.1007/s10113-013-0532-5.

Van Huis A. Insects as food in sub-Saharan Africa. Int J Trop Insect Sci. 2003;23(3):163–85. https://doi.org/10.1017/S1742758400023572.

Kelemu S, Niassy S, Torto B, et al. African edible insects for food and feed: inventory, diversity, commonalities, and contribution to food security. J Insects Food Feed. 2015;1(2):103–19. https://doi.org/10.3920/JIFF2014.0016.

Ehounou G, Ouali-N’Goran S, Niassy S. Assessment of entomophagy in Abidjan (Cote Divoire, West Africa). Afr J Food Sci. 2018;12(1):6–14. Accessed 03 August 2019.

Anvo MPM, Toguyéni A, Otchoumou AK, et al. Nutritional qualities of edible caterpillars Cirina butyrospermi in southwestern Burkina Faso. IJIAS. 2016;18(2):639.

Yapo FL, Amara RF, Tuo Y. Nutritional value of shea caterpillar (Cirina butyspermii Vuillet) sold at the market of Korhogo (Côte d’Ivoire). Int J Agron Agri R. 2017;10(5):35–44.

Scholtz CH. The higher classification of Southern African insects. Afr Entomol. 2016;24(2):545–55. https://doi.org/10.4001/003.024.0545.

Wolf WJ. Soybean proteins. Their functional, chemical, and physical properties. J Agric Food Chem. 1970;18(6):969–76. https://doi.org/10.1021/jf60172a025.

AOAC. Official methods of analysis. 14th ed. Washington DC: Association of Official Analytical Chemists; 1999.

Merrill AL, Watt BK. Energy value of foods: basis and derivation. Human Nutrition Research Branch, Agricultural Research Service, US; 1955.

International Union of Pure and Applied Chemistry (IUPAC). Standards methods for analysis of oils, fats and derivatives. 6th ed. Oxford: Pergamon Press; 1979.

Khan AI (2013) A GC-FID method for the comparison of acid-and base-catalyzed derivatization of fatty acids to FAMEs in three edible oils. Thermo Scientific Application Note 20733

Bidlingmeyer BA, Cohen SA, Tarvin TL. Rapid analysis of amino acids using pre-column derivatization. J Chromatogr. 1984;336(1):93–104. https://doi.org/10.1016/S0378-4347(00)85133-6.

Cohen SA, Strydom DJ. Amino acid analysis utilizing phenylisothiocyanate derivatives. Anal Biochem. 1988;174(1):1–16. https://doi.org/10.1016/0003-2697(88)90512-x.

Hsu H, Vavak D, Satterlee L, et al. A multienzyme technique for estimating protein digestibility. J Food Sci. 1977;42(5):1269–73. https://doi.org/10.1111/j.1365-2621.1977.tb14476.x.

Satterlee L, Marshall H, Tennyson J. Measuring protein quality. J Am Oil Chem Soc. 1979;56(3Part1):103. https://doi.org/10.1007/BF02671431.

Diniz F, Martin A. Effects of the extent of enzymatic hydrolysis on functional properties of shark protein hydrolysate. LWT Food Sci Technol. 1997;30(3):266–72. https://doi.org/10.1006/fstl.1996.0184.

Haque ZU, Mozaffar Z. Casein hydrolysate. II. Functional properties of peptides. Food Hydrocoll. 1992;5(6):559–71. https://doi.org/10.1016/S0268-005X(09)80125-2.

Guo F, Xiong YL, Qin F, et al. Surface properties of heat-induced soluble soy protein aggregates of different molecular masses. J Food Sci. 2015;80(2):C279–87. doi https://doi.org/10.1111/1750-3841.12761.

Chakravorty J, Ghosh S, Megu K, et al. Nutritional and anti-nutritional composition of Oecophylla smaragdina (Hymenoptera: Formicidae) and Odontotermes sp. (Isoptera: Termitidae): two preferred edible insects of Arunachal Pradesh, India. J Asia-Pac Entomol. 2016;19(3):711–20. https://doi.org/10.1016/j.aspen.2016.07.001.

Finke MD. Complete nutrient content of four species of feeder insects. Zoo Biol. 2013;32(1):27–36. https://doi.org/10.1002/zoo.10031.

Ghosh S, Jung C, Meyer-Rochow VB. Nutritional value and chemical composition of larvae, pupae, and adults of worker honey bee, Apis mellifera ligustica as a sustainable food source. J Asia-Pacif Entomol. 2016;19(2):487–95. https://doi.org/10.1016/j.aspen.2016.03.008.

Ramos-Elorduy J, Neto E, Pino J, et al. Knowledge about useful entomofauna in the county of La Purisima Palmar de Bravo, Puebla State, Mexico. Biotemas. 2007;20:121–34.

Mariod AA, Abdel-Wahab SI, Ain NM. Proximate amino acid, fatty acid and mineral composition of two Sudanese edible pentatomid insects. Int J Trop Insect Sci. 2011;31(3):145–53. https://doi.org/10.1017/S1742758411000282.

Bukkens S. Insects in the human diet: nutritional aspects. In: Paoletti WMG, editor. Ecological implications of minilivestock role of rodents, frogs, snails, and insects for sustainable development. Enfield: Wyd Science Publiscers Inc; 2005. p. 545–77.

Michaelsen KF, Hoppe C, Roos N, et al. Choice of foods and ingredients for moderately malnourished children 6 months to 5 years of age. Food Nutr Bull. 2009;30(3_suppl3):343–404.

Yang LF, Siriamornpun S, Li D. Polyunsaturated fatty acid content of edible insects in Thailand. J Food Lipids. 2006;13(3):277–85. https://doi.org/10.1111/j.1745-4522.2006.00051.x.

Raksakantong P, Meeso N, Kubola J, et al. Fatty acids and proximate composition of eight Thai edible terricolous insects. Food Res Int. 2010;43(1):350–5. https://doi.org/10.1016/j.foodres.2009.10.014.

Finke MD. Complete nutrient composition of commercially raised invertebrates used as food for insectivores. Zoo Biol. 2002;21(3):269–85.

Durst PB, Johnson DV, Leslie RN, et al. Forest insects as food: humans bite back. Bangkok: FAO; 2010. pp. 189–200.

Mao X, Hua Y. Composition, structure and functional properties of protein concentrates and isolates produced from walnut (Juglans regia L.). Int J Mol Sci. 2012;13(2):1561–81. https://doi.org/10.3390/ijms13021561.

Wu H, Wang Q, Ma T, et al. Comparative studies on the functional properties of various protein concentrate preparations of peanut protein. Food Res Int. 2009;42(3):343–8. https://doi.org/10.1016/j.foodres.2008.12.006.

FAO/WHO/UNU. Protein and amino acid requirements in human nutrition. Geneva: World Health Organization; 2007. p. 935.

Shewry PR. Improving the protein content and composition of cereal grain. J Cereal Sci. 2007;46(3):239–50.

Tiwari BK, Singh N. Pulse chemistry and technology. Cambridge: Royal Society of Chemistry; 2012.

Gauthier SF, Vachon C, Jones JD, et al. Assessment of protein digestibility by in vitro enzymatic hydrolysis with simultaneous dialysis. J Nutr. 1982;112(9):1718–25. https://doi.org/10.1093/jn/112.9.1718.

Schlüter O, Rumpold B, Holzhauser T, et al. Safety aspects of the production of foods and food ingredients from insects. Mol Nutr Food Res. 2017;61(6):1600520. https://doi.org/10.1002/mnfr.201600520.

Zayas JF. Solubility of proteins. In: Functionality of proteins in food. Berlin: Springer; 1997. p. 6–75.

Omotoso O. Nutritional quality, functional properties and anti-nutrient compositions of the larva of Cirina forda (Westwood) (Lepidoptera: Saturniidae). J Zhejiang Univ Sci B. 2006;7(1):51–5. https://doi.org/10.1631/jzus.2006.B0051.

Akpossan RA, Dué EA, Kouadio JPE, et al. Nutritional value and physico-chemical characterization of the fat of the caterpillar (Imbrasia oyemensis) dried and sold at the Adjamé market in Abidjan, Côte d’Ivoire. J Anim Plant Sci JAPS. 2009;3(3):243–50.

Zhao X, Zhang X, Liu H, et al. Functional, nutritional and flavor characteristic of soybean proteins obtained through reverse micelles. Food Hydrocoll. 2018;74:358–66. https://doi.org/10.1016/j.foodhyd.2017.08.024.

Ndiritu AK, Kinyuru JN, Gichuhi PN, et al. Effects of NaCl and pH on the functional properties of edible crickets (Acheta domesticus) protein concentrate. J Food Meas Charact. 2019;13(3):1788–96. https://doi.org/10.1007/s11694-019-00097-5.

Gravel A, Doyen A. The use of edible insect proteins in food: challenges and issues related to their functional properties. Innov Food Sci Emerg Technol. 2019. https://doi.org/10.1016/j.ifset.2019.102272.

Sathe S, Deshpande S, Salunkhe D. Functional properties of winged bean [Psophocarpus tetragonolobus (L.) DC] proteins. J Food Sci. 1982;47(2):503–9. https://doi.org/10.1111/j.1365-2621.1982.tb10112.x.

Kinsella JE. Functional properties of soy proteins. J Am Oil Chem Soc. 1979;56(3Part1):242–58. https://doi.org/10.1007/BF02671468.

Foegeding EA, Davis JP. Food protein functionality: a comprehensive approach. Food Hydrocoll. 2011;25(8):1853–64.

Tang S, Hettiarachchy N, Horax R, et al. Physicochemical properties and functionality of rice bran protein hydrolyzate prepared from heat-stabilized defatted rice bran with the aid of enzymes. J Food Sci. 2003;68(1):152–7. https://doi.org/10.1111/j.1365-2621.2003.tb14132.x.

Ndiritu AK, Kinyuru JN, Kenji GM, et al. Extraction technique influences the physico-chemical characteristics and functional properties of edible crickets (Acheta domesticus) protein concentrate. J Food Meas Charact. 2017;11(4):2013–21. https://doi.org/10.1007/s11694-017-9584-4.

Chel-Guerrero L, Perez-Flores V, Betancur-Ancona D, et al. Functional properties of flours and protein isolates from Phaseolus lunatus and Canavalia ensiformis seeds. J Agric Food Chem. 2002;50(3):584–91. https://doi.org/10.1021/jf010778j.

Acknowledgements

Authors would like to thank the QualiTree and Qualisani project for supporting this study.

Funding

The authors are grateful to the QualiTree (DFC n° 10002AU) and Qualisani projects for their technical supporting the study.

Author information

Authors and Affiliations

Contributions

Conceived and designed the experiment study AS, AB, BSRB, ET, CP, OG, IHNB. Performed the study: AS, AB, BSRB, ET, CP, IHNB. Wrote the paper: AS, AB, BSRB, ET, CP, OG, IHNB. All author read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

According to Decree No. 2002-36/PRES/MS/MESSRS establishing the Health Research Ethics Committee of Burkina Faso, this article does not contain studies with animal subjects as experiments with insects or invertebrates are not classified as animal experiments.

Consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Séré, A., Bougma, A., Bazié, B.S.R. et al. Chemical composition, energy and nutritional values, digestibility and functional properties of defatted flour, protein concentrates and isolates from Carbula marginella (Hemiptera: Pentatomidae) and Cirina butyrospermi (Lepidoptera: Saturniidae). BMC Chemistry 15, 46 (2021). https://doi.org/10.1186/s13065-021-00772-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s13065-021-00772-z