Abstract

The starch in waste bread (WB) from industrial sandwich production was directly converted to ethanol by an amylolytic, ethanologenic thermophile (Parageobacillus thermoglucosidasius strain TM333) under 5 different simultaneous saccharification and fermentation (SSF) regimes. Crude α-amylase from TM333 was used alone or in the presence of amyloglucosidase (AMG), a starch monomerizing enzyme used in industry, with/without prior gelatinisation/liquefaction treatments and P. thermoglucosidasius TM333 fermentation compared with Saccharomyces cerevisiae as a control. Results suggest that TM333 can ferment WB using SSF with yields of 94–100% of theoretical (based on all sugars in WB) in 48 h without the need for AMG addition or any form of heat pre-treatment. This indicates that TM333 can transport and ferment all of the malto-oligosaccharides generated by its α-amylase. In the yeast control experiments, addition of AMG together with the crude α-amylase was necessary for full fermentation over the same time period. This suggests that industrial fermentation of WB starch to bio-ethanol or other products using an enhanced amylolytic P. thermoglucosidasius strain could offer significant cost savings compared to alternatives requiring enzyme supplementation.

Similar content being viewed by others

Introduction

The global economy is in a process of transition away from the use of fossil carbon as a source of energy and chemicals towards the use of renewable energy and carbon sources. Depending on the sector, this may result in complete decarbonisation, but there will still be a requirement for carbon-based precursors in industry and where complete decarbonisation of the energy sector is impractical. In these instances, ensuring that the carbon originates from renewable plant-based/algal resources is critical to balance the inevitable end-of-life carbon emissions, and mitigate against the potential for global warming.

Microbial fermentation is well established as an effective way to produce useful molecules from plant-derived carbohydrates but, with low and intermediate value products, the cost of the carbon feedstock makes up a large proportion of the process cost [32, 33, 49, 61] and can render a process non-viable. The use of lignocellulose-derived carbohydrates for bio-ethanol production is a classic example where, despite much progress in cost-reduction, this is still not competitive with using starch as the source of carbohydrate [49], despite the fact that starch comprises only a small proportion of the plant biomass. Notwithstanding, the combination of metabolic and protein engineering enables us to consider producing new compounds to supplant fossil carbon-derived chemicals and also to consider different production hosts based on their process properties, including their ability to grow on cheaper substrates such as those found in food-waste.

In the UK, bread is one of the most wasted foods with bread wastes of up to 1.2 million tons annually [37]. A recent report showed that over 11.5 billion sandwiches are typically consumed in the UK annually when home and industrially produced sandwiches are combined [6, 18] and, prior to the Covid 19 pandemic, the sandwich industry was growing at a steady rate of 2% or 80 million sandwiches each year [29]. The waste bread (WB, primarily the heels/crusts) generated from sandwich production has also increased with an estimated 24 million slices of bread thrown away annually by UK households, while the sandwich industries discard about 17% of the total bread that enters the factory [57]. Most of this ends up in anaerobic digestion, or in animal feed formulations as a low value feed [57]. Bread contains 50–75% starch, 10–15% protein and 0.3 to 5% sugars [12] and is potentially an ideal low-cost fermentation substrate. Starch is generally comprised of 20–30% amylose and 70–80% amylopectin, and several studies have demonstrated the conversion of bread to bioethanol after high temperature gelatinisation, liquefaction and saccharification with combinations of industrial enzymes [16, 27, 28, 38, 46]. Conversion of WB into other compounds like lactic acid [43, 52], Omega-3 rich oil [56], baker’s yeast [4], biohydrogen [13], enzyme production [39] and aromatic compounds [10] has also been reported. Industrial scale fermentation of surplus bread into alcoholic beverage has also been demonstrated through the traditional starch to ethanol bioprocess in the UK and Sweden [54, 57]. However, the conventional starch fermentation bioprocess is still not very economical, due largely to the cost of the high temperature gelatinization and the multiple enzymes needed for conversion to glucose for organisms such as Saccharomyces cerevisiae to ferment, as it cannot directly utilize starch or its oligosaccharides [7, 19,20,21, 30, 40, 48, 62] with the exception of maltose. Various pH and temperature adjustments required during gelatinization, enzymatic liquefaction and pre-saccharification also add to the cost.

Parageobacillus thermoglucosidasisus NCIMB 11,955 encodes an α-amylase and maltose transporter in its genome and is naturally amylolytic. Recent genome sequence analysis suggests that it can also secrete a neopullulanase and probably transports branched malto-oligosaccharides, providing it with the complete arsenal of enzymatic activities to break down starch [31]. It has been engineered to create a homoethanologenic strain TM242 and its amylolytic capabilities have been enhanced by incorporation of a second amylase gene, derived from G. stearothermophilus into its genome, creating strain TM333 [2, 3, 8].

Using bio-ethanol production as an example, together with various pre-processing scenarios from traditional pretreatment to “self-sufficient” simultaneous saccharification and fermentation (SSF), in this study we have explored the potential of P. thermoglucosidasius TM333 to use WB as a fermentation substrate with S. cerevisiae as a comparator. Simultaneous saccharification and fermentation, in which polymeric/oligomeric substrates are hydrolysed and fermented at the same time [35, 44], can reduce total processing time (by removing the need for a separate saccharification step), reduce overflow metabolism which can occur when cells are grown in high concentrations of easily metabolized sugars, and allow transport and intracellular metabolism of oligomeric carbohydrates as they are produced, which is an advantageous features of Parageobacillus/Geobacillus spp. In “self-sufficient” SSF the enzymes added during the fermentation actually derive from the same organism as used in the fermentation process, so do not require extensive purification.

Materials and methods

Materials

Un-used heels from sandwich manufacture were obtained from Greencore, UK, dried at 40 °C in an oven for 24 h (to 91.5% oven dry solids) and stored in sealed bags. Pullulanase (PULL, E2412) and amyloglucosidase (AMG, A7095) were sourced from Sigma Aldrich UK, while P. thermoglucosidasius TM333, a thermophilic ethanologen derived from P. thermoglucosidasius TM242 [8] and incorporating an additional amyS gene from G. stearothermophilus DSM22 expressed from the ldh promoter was obtained from ReBio Ltd (Guildford, UK), formerly TMO Renewables. S. cerevisiae strain S228C was obtained from Dr A. Wheals, University of Bath. All other chemical reagents and carbohydrate standards for HPLC were analytical grade (> 99% purity) and purchased from Sigma Aldrich.

Compositional analysis of WB

Carbohydrate compositional analysis of the WB was carried out following acid hydrolysis [53]. Oven dried bread was first milled to a powder in a coffee grinder. Triplicate samples (0.1 g, to 0.3 g) of the milled bread were hydrolyzed with 3 ml of 72% w/w H2SO4 in a 100 ml capped Durham bottle and incubated (Harrow Scientific LTD, UK) at 35 °C for 1 h with shaking at 100 rpm. Then the samples were diluted with 84 ml of Milli-Q water and autoclaved at 121 °C for 60 min, cooled to room temperature, and neutralized with calcium carbonate powder to pH 6–7. The samples were filtered through a 0.22 μm nylon membrane filter (Phenomenex) and stored at −20 °C prior to analysis by HPLC. A sugar recovery test was used to compensate for sugar loss/decomposition due to acid hydrolysis [53], while compensation for the moisture content was considered during calculations. Estimation of the original amount of starch before hydrolysis was made by multiplying the measured amount of glucose by 0.901. Errors represent ± the standard deviation of 3 independent samples.

Αlpha-amylase and pullulanase production by TM333

A fresh inoculum of P. thermoglucosidasius TM333 was prepared from a -80 °C vial grown for 24 h on tryptone soya agar plates (TSA: 15 g casein peptone, 5 g soy peptone, 5 g sodium chloride and 15 g agar per liter). This was used to inoculate 50 mL of 2SPY medium (16 g soy peptone, 8 g yeast extract, and 5 g sodium chloride per liter), pH 7 in a 250 ml baffled flask and incubated aerobically at 60 °C with shaking at 250 rpm in an Innova 44 shaking incubator (New Brunswick Scientific Ltd, St Albans, UK) until the OD600 reached 7–8 (3-4 h). This culture was used at 2% inoculum to inoculate a 1% (w/w) soluble starch (or 1% (w/w) sterile WB) suspension prepared in 2SPY media. The media was either buffered with a combination of 1 M stock solutions of MOPS, BIS–TRIS and HEPES buffers (32.8 mM final concentration of each) or unbuffered and incubated at 60 °C, 250 rpm for 17 h. After fermentation, samples were centrifuged at 3200×g, 4 °C and 15 min, and the supernatant analyzed and used as the source of crude ɑ-amylase and pullulanase in all the SSF experiments.

Αlpha-amylase and neopullulanase analysis

Crude α-amylase in the supernatant of TM333 was analyzed by the DNS method [5]. A 1% solution of soluble starch in citrate phosphate buffer of various pH was used as substrate, and 0.5 ml of diluted crude enzyme and 0.5 ml of the substrate in capped glass tubes were assayed in triplicate at various temperatures (35–100 °C) and pH (5.5–8.0) for 10 min. The reactions were stopped by the addition of 3mls of dinitrosalicylic acid (DNS) solution (10.6 g of 3, 5-Dinitrosalicylic acid, 19.8 g of NaOH, 306 g of sodium potassium tartrate, 4 g of phenol, 8.3 g sodium metabisulfite and 1416 mL distilled water) and boiled in a water bath for 5 min. The samples were cooled in water (4 °C), and 10 ml of distilled water was added to each tube, mixed by vortexing and the absorbance measured in a spectrophotometer (Jenway 6305) at 575 nm. Standard solutions of maltose were prepared in the same buffer and used to calculate the enzyme activity. In control reactions just the substrate was incubated, with the enzyme added after the addition of DNS. Spectrophotometer blanks contained reagents and DNS solution only. One unit of alpha-amylase activity is the amount of enzyme that released reducing sugars equivalent to 1 µmole of maltose per minute under the assay conditions. Neopullulanase activity was measured according to Duffner et al. [14]. A 1% pullulan solution in citrate phosphate buffer pH 7 was used as substrate. The reaction, including controls and blanks, was the same as that for α-amylase except that 1% pullulan was used as substrate, with maltose as standard. One unit of neopullulanase activity is the amount of enzyme that released reducing sugars equivalent to 1µmole of maltose per minute under the assay conditions. Errors represent ± the standard deviation of three independent assays made on a single biological sample.

SSF ethanol fermentation by P. thermoglucosidasius TM333 and Saccharomyces cerevisiae from WB

The standard process for industrial bioethanol production from starchy biomass involves: (1) gelatinization at 100 °C, pH 6.5 in the presence of a thermostable amylase (typically 15 min), (2) liquefaction at 85 °C, pH 6.5 with further amylase addition (typically 60 min), (3) saccharification (typically 3 h) at 60 °C, pH 5.5, after the addition of amyloglucosidase (and pullulanase, if the economics allow), (4) yeast fermentation at 35 °C, pH 5.5 Therefore, this regime provided the starting point for the current SSF analysis using WB. The dried WB was initially milled in a blender (Kitchen Perfected Table Blender with Grinder, Lloytron, UK), wrapped in aluminum foil and sterilized dry in an autoclave at 121 °C, 15 min to eliminate microbial contaminants. The powdered bread was adjusted to 3.6% (w/w) dry solids with 2SPY media for bacterial fermentations or with YP media (15 g/L yeast extract and 8 g/l peptone) for yeast fermentations in 500 ml sterile Durham bottles.

Five SSF strategies were investigated, with strategies 1 to 5 involving a gradual simplification of the process. Strategies 1 and 2 involved gelatinization (100 °C, pH7.0) and liquefaction processes (85 °C, pH 7.0) in the presence of TM333 α-amylase (crude culture supernatant) prior to SSF. Strategy 3 involved only gelatinization before SSF, while 4 and 5 involved no pretreatment but addition of crude TM333 α-amylase with (SSF4) or without (SSF 5) commercial AMG supplementation. After each treatment/process the pH was adjusted to 5.5 prior to yeast fermentation, using 5 M H3PO4. No further pH adjustment was made for TM333 fermentations as the final pH remained between 6.85 and 7.0, but MOPS, BIS–TRIS and HEPES buffers were added as described in “Αlpha-amylase and pullulanase production by TM333” section for every TM333 fermentation. The inoculum of P. thermoglucosidasius TM333 was prepared as described for amylase production (“Αlpha-amylase and pullulanase production by TM333” section), but after the 24 h plate cultures, a further liquid culture was prepared by inoculating a loopful of the TSA plate culture into 50 ml 2SPY media in a 250 ml flask and incubated at 60 °C, with shaking at 200 rpm for 4 h (OD600 of 7–8).

Yeast inoculum was prepared from a −80 °C glycerol stock spread on a YPD agar plate (10 g yeast extract, 20 g peptone, 20 g glucose and 15 g/l agar), and grown for 24 h at 35 °C, then a loopful from the plate was used to inoculate 50 ml of liquid YPD in a 250 ml baffled shake flask and grown at 35 °C with shaking at 180 rpm. After 24 h, the yeast culture was diluted to an OD600 of 18 with sterile distilled water for use as inoculum for SSF fermentations. Inoculation of yeast or bacteria was at a ratio of 1:10 (v/v) inoculum: bread media in a 15-mL screw-capped tube containing 10 ml of a WB media and 5 drops of antifoam, added to minimize foaming, according to the experimental options listed below (taking into account the dilution factor, actual fermentations were at 3.0% w/w dry WB solids). In SSF 1 to 5, S cerevisiae was incubated at 35 °C and 180 rpm, while TM333 fermentations were at 60 °C with shaking at 250 rpm in triplicate for 24–92 h. A sterile needle plugged with sterile cotton wool for CO2 pressure removal was used to pierce the caps of the tubes and left in place during the fermentations [47]. Tubes were sacrificed periodically, centrifuged at 3200×g for 15 min at 4 °C, and the supernatant filtered through a 0.2 µm nylon membrane, then stored at − 20 °C for subsequent HPLC analysis. All experiments were carried out in triplicate without supplementation with Ca2+; a requisite for most calcium ion dependent α-amylases. Errors represent ± standard deviation of the 3 biological replicates.

The maximum and experimental theoretical ethanol yields were calculated as follows:

SSF strategies

In SSF 1, milled bread was gelatinized at 100 °C together with 100 ml crude TM333 α-amylase per kg of bread in a 500 ml Durham capped bottle for 15 min in a shaking water bath. The starch in the bread was then liquefied by incubation with a further 100 ml of crude α-amylase per kg of bread at 85 °C for 1 h at 150 rpm in a shaking water bath (Grant OLS 200, Grant instruments, Cambridge, UK) with occasional manual mixing (vigorous shaking of the bread suspension) before SSF. During the subsequent SSF, amyloglucosidase and pullulanase (both at 0.65% v/w of bread) were added together with a 10% (v/v) inoculum.

During pre-treatment, 2 ml samples were centrifuged at 3200×g, 4 °C for 15 min, the supernatant filtered through 0.2 µm nylon filters and analyzed for total sugars (monomeric and polymeric) using the NREL method [53]. Fermentation samples were also analyzed by HPLC for sugars, ethanol and other metabolites as described below.

SSF 2 differed from SSF 1 by the omission of pullulanase during the fermentation. This allowed assessment of the use of AMG alone for the breakdown of the starch oligosaccharides generated by the α-amylase pretreatment. SSF 3 was effectively the same as SSF 2 but with the omission of the separate liquefaction and saccharification steps; however, α-amylase was added during the fermentation. After gelatinization the sample was cooled then inoculated with a 10% (v/v) inoculum of TM333 or yeast and 0.65% (v/w) of AMG plus 100 ml/kg of α-amylase before fermentation. The total α-amylase added was the same as in SSF 1 and 2. SSF 4 was the same as SSF 3 but omitted the gelatinization stage (200 ml of α-amylase + AMG was added during SSF), while SSF 5 was the same as SSF 4 but omitted the amyloglucosidase from the SSF. Thus, complete fermentation depended on activities generated by S. cerevisiae or P. thermoglucosidasius to degrade the dextrins generated by the α-amylase (200 ml crude enzyme per kg of WB, equivalent to 42,850 IU amylase/kg of bread).

Analysis of sugars, oligosaccharides and metabolites by HPLC

After each treatment step or fermentation, samples were taken and centrifuged at 3200×g for 15 min. The supernatants were filtered through 0.2 µm nylon filter (Phenomenex Inc, Torrance, CA) prior to analysis. High Pressure Liquid Chromatography (Agilent HPLC 1200, Agilent Technologies, Santa Clara, CA) was used to analyze all samples using NREL methods [53]. For oligomeric sugar determinations, acid hydrolysis of the samples was carried out by adding 0.035 mL of 72% w/w H2SO4 to 1.0 mL of the filtered sample and autoclaving at 121°C for 60 min. The autoclaved samples were cooled slowly to room temperature before addition of calcium carbonate powder to neutralize the samples [53]. The samples were filtered as described earlier and analysed by HPLC. Fermentation samples were also filtered and analyzed for sugars, ethanol, and other metabolic products. Analytes were separated on a Phenomenex Rezex RHM Monosaccharide H + (8%) column (300 m × 7.8 mm, Phenomenex Inc, Torrance, CA) at 65 °C with 5 mM H2SO4 as the mobile phase at a flow rate of 0.6 mL/min. Detection was either by refractive index or UV absorbance (215 nm). The difference between the amount of sugars after and before acid hydrolysis was assumed to represent oligomeric/polymeric soluble sugars after correction for sugar recovery under acid hydrolysis conditions [53]. Preparations of pure compounds of > 99% (glucose, maltose, arabinose, xylose, glycerol and ethanol) were used as standards for quantification.

Results and discussions

Compositional analysis of waste sandwich bread

The compositions of the WB used in this study are shown in Table 1. This accords with [45] who reported that WB contained 68.9% starch. Sanchez et al. [52] and [12] also reported that bread contains between 55.3 and 83.3% glucose equivalents. The moisture content of the mixed bread, made up of a combination of 22 different types of wholemeal and white bread, was 35% ± 13.5. After oven drying at 45 °C for 24 h, the moisture content was reduced to 8.5% ± 0.8 (w/w) to prevent spoilage during storage. The total carbohydrate content of the mixed WB (Table 1) was 70.58% starch (all of the glucose was assumed to derive from starch) with a small amount of arabinoxylan (2.26%) derived mainly from the wholemeal variety. The parent strain of TM333 can ferment hemicellulose-derived sugars (such as xylose and arabinose) and associated short chain oligosaccharides but does not encode a secreted xylanase or arabinanase [31].

Alpha-amylase and neopullulanase production by TM333

The crude α-amylase secreted by TM333 into the culture supernatant after 17 h of fermentation had a maximum activity of 428.5 U/ml at pH 7 and 85 °C but retained some activity at pH 5.5 and 35 °C (yeast fermentation condition), and also at the P. thermoglucosidasius TM333 optimal fermentation conditions of pH7 and 60 °C (Table 2). Malhotra et al. [34] reported that maximum Ca+-independent α-amylase production by thermophilic B. thermooleovorans NP54, using a 2% inoculum was between 12 and 16 h, similar to the 17 h optimum fermentation time reported here.

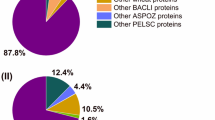

Endoamylases are known to produce various chain lengths of linear and branched oligosaccharides from starch by acting on α-1–4, or α-1–6 glucose linkages [23]. In addition to α-amylase, low levels of neopullulanase activity (1.35 to 1.79 U/ml) were also measured in the culture supernatant produced either from soluble starch or WB at 18 h to 24 h (Fig. 1). Neopullulanase and pullulanase are known to increase the hydrolysis of starch by α-amylase, especially via the removal of α 1–6 branching or cleavage of dextrin to form panose, but they are expensive enzymes that are produced in low titers and are rarely added to starch hydrolysis for economic reasons. The use of pullulanases can reduce the requirement for glucoamylase by ~ 50% and can reduce the total reaction time of industrial starch conversion. A higher neopullulanase titre was produced on WB (1.79 U/ml) than on soluble starch (1.35 U/ml), suggesting that this might be a cheaper substrate for both α-amylase and neopullulanase production compared with purified soluble starch. The presence of protein, various vitamins and minerals in WB compared with purified soluble starch might have resulted in better enzyme production from WB. A DHSS [11] report on the nutritional aspects of bread and flour established that UK breads contain between 8 to 9% protein, several essential amino acids, fats and fatty acids, minerals, vitamins and trace elements which might enhance microbial growth and enzyme production.

WB processing for SSF 1 to 5

Figure 2 shows the sugar composition of the WB in media without pretreatment, after gelatinization and after both gelatinization and liquefaction in SPY media; the same treatments done in YP media gave virtually identical results. The untreated WB suspended in media shows the presence of soluble malto-oligosaccharides and maltose with trace amounts of glucose (glucose < 0.5 g/l, maltose 3.6 to 3.9 g/l, malto-oligosaccharides 8.7–9.2 g/l) due to the presence of partially hydrolyzed starch. The low levels of glucose and maltose after 1 h of liquefaction suggest that TM333 α-amylase is not a maltogenic α-amylase. Van Zyl et al. [60], showed that α-amylases hydrolyze the internal α-1,4-bonds of starch amylose and amylopectin randomly, leading to the production of maltodextrins with a length of 10 to 20 glucose residues as major products, as well as smaller amounts of maltose and free glucose. These dextrins are known to be water soluble [23, 59]. In a control experiment (results not shown), WB without autoclave treatment was processed in the same way, in the presence of 0.2% (w/v) sodium azide to reduce microbial growth. The sugar profiles were similar to those in Fig. 2 indicating that the autoclave treatment did not contribute to starch hydrolysis in the WB.

SSF1: SSF of gelatinized and liquefied WB with amyloglucosidase + pullulanase.

Fermentation results for SSF 1 with amyloglucosidase and pullulanase included in the process are shown in Fig. 3. As described, the bread samples had been pre-gelatinized and liquefied with α-amylase from TM333 to yield mainly maltodextrins (Fig. 2). While AMG is important for the generation of glucose from straight chain malto-oligosaccharides, pullulanase attacks the 1,6 linkages, debranching the dextrins and also prevents the reverse reaction of glucose condensation to maltose or isomaltose, a process known to be catalysed by amyloglucosidase [36, 50]. The fermentation results show that complete fermentation of the WB was possible with yeast or TM333 at yields of > 98% of the maximum theoretical from all WB carbohydrates. Thus, the malto-oligosaccharides in the pretreated bread (Fig. 2) were being rapidly converted to maltose or glucose by the amyloglucosidase and/or pullulanase in combination with the remaining crude TM333 α-amylase under both sets of culture conditions.

SSF 2: SSF of gelatinized and liquefied WB with amyloglucosidase added during fermentation

In SSF 2 the debranching pullulanase was omitted from the SSF, but otherwise the conditions were the same as SSF 1. Fermentation results (Fig. 4) show that this SSF generated similarly high yields (> 98% of theoretical) for both yeast and TM333, indicating that the combination of TM333 α-amylase and AMG alone was sufficient to hydrolyse all of the malto-oligosaccharides to maltose or glucose, even at the sub-optimal temperature of 35 °C and pH5.5, with a fermentation profile similar to that in SSF 1. The α 1,6 debranching activities of AMG appeared to be sufficient to obviate the need for pullulanase, although it is not clear whether the low neopullulanase activity in the crude amylase might have been beneficial.

SSF 3: SSF of gelatinized WB with amyloglucosidase added during fermentation

SSF 3 differed from 1 and 2 by not going through a liquefaction process after the initial gelatinization. The compositions of the SSF3 media prior to fermentation (Figs. 1 and 2) suggested that much of the initial α-amylase activity occurred during gelatinization, mainly producing malto-oligosaccharides with a small amount of maltose and less than 0.5% of glucose. Fermentation results (Fig. 5 and Table 2) showed that both TM333 and yeast fully fermented this media with yields of > 98% of theoretical. This shows that, with the quantities of α-amylase added, there was no need for liquefaction and pre-saccharification before fermentation when the crude enzyme of TM333 was added for both yeast and TM333 fermentations. However, TM333 fermentation was slower than seen in SSF 1 and 2 and there was a transient increase in glucose accumulation in the media, suggesting that the amyloglucosidase activity exceeded the capacity of cells to grow on the resulting glucose.

SSF 4; SSF of untreated WB with crude α-amylase and amyloglucosidase added during fermentation

Given that some maltose and free glucose was present in the autoclaved breadcrumbs, this should allow initial growth of both organisms while supplemented enzymes hydrolyse the oligosaccharides and any residual unhydrolysed starch. Therefore, in SSF 4 untreated WB without gelatinization or liquefaction was used as the substrate and α-amylase and amyloglucosidase were added to the fermentation media (Fig. 6). Both yeast and TM333 were still able to fully ferment the WB in 24-48 h with > 98% of the maximum theoretical yield with comparable results to SSF 1 to 3. The fermentation profile for TM333 was similar to that of SSF 3, with a spike of glucose at 24 h.

The ability to degrade the residual non-hydrolysed starch within 24 h shows that the synergistic activity of the α-amylase and amyloglucosidase, even under the unfavorable conditions of 35 °C and pH5.5 was high, and that the autoclaved, but otherwise particulate starch was accessible to the TM333 amylase. It is, therefore, surprising that TM333 grew marginally more slowly under these conditions than in SSF 2. Given that there was glucose accumulating after 24 h, this suggests that intermediates in the breakdown of the polymeric starch were actually reducing the rate of growth, possibly by directly or indirectly (via regulation) affecting the glucose transporter. Given that Parageobacillus spp are known to be capable of transporting complex oligosaccharides this could be an example of evolutionary adaptation leading to impairment of growth under an artificial abundance of monosaccharide. Nevertheless, the cost savings in removing a pre-hydrolysis step and using a one-pot SSF should outweigh any marginal reduction in productivity. Furthermore, this effect might be resolved by optimising the balance of enzyme activity and nutrient uptake rate of the cells. The only comparative work on SSF of WB was by [45, 46], whereby a commercial enzyme cocktail (α-amylase and amyloglucosidase plus a protease) were used in combination with several types of pretreatment including heat, microwave, ultrasound (Table 3), but yields were still lower than those from our current work with only crude α-amylase.

SSF 5: SSF of untreated WB with TM333 α-amylase alone

As the TM333 α-amylase was clearly capable of degradation of the polymeric starch from WB, potentially down to maltose and branched limit dextrins the effect of a simple SSF on the autoclaved WB was examined in SSF 5. The lack of the saccharifying and 1,6-debranching amyloglucosidase was expected to reduce the amount of carbohydrate available for the yeast fermentation, but production of a neopullulanase by TM333 suggested that it should be able to import the product panose for further degradation. Given the results from SSF 4, the yeast fermentation in the presence of α-amylase alone was surprisingly poor (Fig. 7A), with less than 30% of the ethanol production seen in SSF 1 and 2. While this is more than can be accounted for by the maltose and glucose present in the untreated bread, suggesting that some maltose or glucose had been generated by the α-amylase, this is clearly fairly limited, with the saccharifying AMG being critical for good yeast SSF on WB. This is consistent with reports that maltose and glucose are minor products from the action of α-amylase on starch, [19, 21]. However, Fig. 7B shows that WB was fully fermented by TM333 in SSF with a native (actually a mixture or native and recombinant from the closely related G. stearothermophilus) α-amylase, with a very similar profile to that which was observed in SSF 4, suggesting that AMG had minimal contribution to the latter. The yield of ethanol using TM333 in this SSF was 94–96% of theoretical (14.24 g/l ethanol) based on the total sugars in WB, and seemingly even higher after 72-92 h fermentation (Table 3). With S. cerevisiae, however, the SSF with α-amylase alone gave a maximum ethanol yield of 26.8% of theoretical (3.74 g/l) based on total carbohydrate (Fig. 7A), with no increase at longer fermentation times (Table 3). The profile of the SSF 5 fermentation with TM333 was very similar to that of SSF 4 with a transient increase in glucose concentration after 24 h despite the lower ethanol production rate. The similarity suggests this was not the result of AMG activity but potentially the result of transglycosylation activity involving malto-oligosaccharides or neopullulanase activity, again suggesting that oligosaccharides were being metabolised in preference to glucose. Fermentation of other oligosaccharides by TM242, the parent strain of TM333 has been reported, including mannobiose and mannotriose from Palm kernel cake mannan [47], and also xylo-oligosaccharides and cellobiose [8, 31] with the help of its oligosaccharide active transport systems. Any regulatory effects of oligosaccharide utilization over monosaccharide uptake can potentially be modified through mutation.

Comparison with previous studies

As far as we are aware, the only previous reports of WB SSF is the work of Pietrazak and Kawa-Ragieska et al. [45, 46] using SSF after various pretreatments and supplementing with commercial α-amylase, protease and amyloglucosidase. In some cases, cellulases, pentosanases and β-glucanases were also added to improve yields (Table 3). When adjusted to a common scale, these studies produced yields of 333–425 g ethanol per kg of WB [45, 46], with the highest yield only obtained by employing pre-liquefaction, in comparison with 437–447 g/kg produced by simple SSF with TM333 at 48 h and 72 h respectively in the current study.

The work of Pietrazak and Kawa-Ragieska et al. [45, 46] showed that initial high temperature gelatinization was beneficial for obtaining good ethanol yields, but this was less obvious in the current study. Two major starch transformations take place during the bread baking and storage process: firstly, crystalline starch is converted largely to its amorphous form during baking, while secondly during storage for > 2 days, the amylopectin units become more crystalline through retrogradation [25]. These two reactions are known to present a starchy material that normally requires high temperature gelatinization to be completely accessible to α-amylase. Additionally, amylose interacts with lipids to form complexes that are difficult for α-amylases to access and requires a liquefaction/melting temperature of around 105–116 °C [17, 22, 25] to improve accessibility, while amylose crystals are much more thermostable and melt at 150 °C [15]. Though fermentation was slightly faster in our experiments when gelatinization and liquefaction pre-treatment was incorporated, the yields without any treatment were comparable and not significantly different at P ≤ 0.05.

The SSF yields of ethanol obtained using the TM333 α-amylase, whether using P thermoglucosidasius or yeast (in combination with AMG) were higher in the current study than in previous reports (Table 3). Although this study used a lower bread concentration, Torabi et al. [58] showed that over a range of 9–16% (w/v), the concentration of WB did not affect the sugar and subsequent ethanol fermentation yields. Experimentally, it is difficult to demonstrate a P thermoglucosidasius SSF using higher concentrations of substrate without setting up a process of continuous ethanol removal, because ethanol toxicity starts to be observed above 2% (v/v). So, to confirm that the observations made using TM333 α-amylase hold true at higher loadings, SSF3 with yeast was repeated at WB loadings up to 25% (w/w).

Ethanol and glycerol yields after 24 h increased linearly over the waste bread concentrations tested (Fig. 8). The linearity (R2 = 0.989 for ethanol and 0.999 for glycerol) of the profiles indicates that there was no observed loss of enzyme performance or yeast fermentation inhibition as the waste bread concentrations increased from 3 to 27.5% during gelatinisation and from 2.5 to 25% during SSF ethanol production. The only notable effect of high substrate concentrations was that the concentration of glucose and maltose measured after gelatinization, reached a plateau at 15% (w/w) WB (Table 4). Glycerol production during yeast fermentation (Fig. 8) is a reaction to stress and acts as osmotic stabilizer for the yeast cells against high ethanol and acid concentrations produced during fermentation [51], but it diverts sugar away from ethanol production. The glycerol levels are consistent with those reported by [16] from 20% waste bread (43 g/kg of waste bread).

With 25% (w/w) WB as substrate SSF3 produced approximately 11% (w/v) ethanol, equivalent to 440 g/kg WB, higher than virtually all previous reports and similar to that produced after liquefaction of the WB using α-amylase, amyloglucosidase and a protease [46]. This is also close to the yields obtained with both yeast and TM333 at lower substrate loadings. A possible explanation for these very high yields is that the crude α-amylase preparation from TM333 also contained a low activity of neopullulanase. Neopullulanase is a starch trimming enzyme with α-1–4 activity and some α-1–6 activity enabling conversion of highly branched amylopectin to the 3-sugar compound panose [24, 26] for direct transport into P. thermoglucosidasius or further hydrolysis by AMG for uptake into yeast. Indeed, Takata et al. have shown that neopullulanase can catalyse hydrolysis of α-(1–4)-glucosidic linkage, hydrolysis of α-(1–6)-glucosidic linkage, transglycosylation to form α-(1–4)-glucosidic linkage, and transglycosylation to form α-(1–6)-glucosidic linkages [55] and may be able to covert liquefied starch to malto-oligosaccharides without the presence of an α-amylase or amyloglucosidase.

It is notable that the disruption of the neopullulanase gene, susA, in Bacteroides thetaiotaomicron was found to reduce its rate of growth on starch by about 30% [9]. It is therefore possible that there was incomplete starch hydrolysis in most of the previous works shown in Table 3 due to the lack of a starch debranching enzyme. Interestingly, Novozymes [42] have recently launched an enzyme mixture (Spirizyme T) that contains both amyloglucosidase and pullulanase, with reported increase in both sugar and ethanol yields from starch. In a review on the use of pullulanases as debranching enzymes, Nisha and Satyanarayana [41] stated that the addition of pullulanase in starch hydrolysis would allow a reduction of glucoamylase usage by approximately 50% and reduce the total reaction time of an industrial starch conversion process. The possibility of using thermostable amylopullulanases in an economic one-step starch liquefaction and saccharification process, which replaces amylolytic enzymes thus resulting in the overall reduction in the cost of sugar production was also mentioned [41].

Conclusions

A novel bioprocess, based on a self-sufficient simultaneous saccharification and fermentation of waste bread, using an amylolytic ethanologenic thermophile, Parageobacillus thermoglucosidasius TM333, to both generate the amylolytic enzyme cocktail and also carry out the fermentation, has been demonstrated. High ethanol yields (94–100% of the maximum theoretical based on all the carbohydrates in WB) were possible because TM333 can transport oligomeric sugars allowing it to ferment malto-oligosaccharides without the need for a starch monomerising enzyme. In addition, the production of both an amylase and a small amount of the debranching enzyme neopullulanase in the TM333 growth medium probably contributed to efficient substrate utilisation. Increasing the production of the native neopullulanase by recombinant methods would probably improve the fermentation rate. Unlike in previous studies, initial high temperature gelatinization of the starch in waste bread was not essential for the TM333 amylase to work. This, and dispensing with the need for an amyloglucosidase hydrolysis step, will significantly save on operational cost. Given that the amylase + neopullulanase cocktail is produced by P. thermoglucosidasius TM333 it may be sufficient to grow an inoculum on starch/WB and use a high (5–10%) inoculation rate for the main culture for this process to operate successfully. Alternatively, cell separation and enzyme concentration across a pair of cross-flow membranes might be necessary and would afford a greater degree of control.

The ability of the TM333 amylase cocktail to work at a wide range of pH and temperatures (35–100 °C) enabled demonstration of efficient mesophilic and thermophilic SSF of the starch in waste bread into ethanol, indicating that it may also have a wide application in several applications outside the biofuel industry. To the best of our knowledge, this is the first time it has been demonstrated that oligosaccharides (malto-oligosaccharides/malto-dextrins) generated by alpha-amylase catalysis of starch from WB during SSF can be effectively converted to ethanol by thermophilic bacteria at very high yields without the need for starch monomerising enzyme (amyloglucosidase).

Availability of data and materials

All data generated or analysed during this study are included in this published article. Parageobacilllus thermoglucosidasius TM333 is the property of ReBio Ltd.

References

Acanski M, Pastor K, Razmovski R, Vucurovic V, Psodoro D. Bioethanol production from waste bread samples made from mixtures of wheat and buckwheat flours. J Proc En Agric. 2014;18:40–3.

Atkinson A, Cripps R, Eley K, Rudd B, Todd M. Thermophilic micro-organisms for ethanol production. 2011. US Patent number US8021865B2.

Atkinson A, Cripps R, Eley K, Rudd B, Todd M. Thermophilic micro-organisms for ethanol production. 2014. US Patent number US8852906. Available at: https://patents.justia.com/patent/8852906. Accessed 10 Apr 20.

Benabda O, Kasmib M, Kachouri F, Hamdi M. Valorization of the powdered bread waste hydrolysate as growth medium for baker yeast. Food Bioprod Proc. 2018;109:1–8.

Bernfeld P. Amylases: alpha and beta methods. Enzymol. 1955;1:149–58.

British Sandwich Association (BSA). How many sandwiches do we eat? 2017. www.britishsandwichweek.com/index.php/facts-figures/3-how-many-sandwiches-do-we-eat. Accessed on 23 May 18.

Cinelli BA, Castilho LR, Freire DMG, Castro AM. A brief review on the emerging technology of ethanol production by cold hydrolysis of raw starch. Fuel. 2015;150:721–9.

Cripps RE, Eley K, Leak DJ, Rudd B, Taylor M, Todd M, Boakes S, Martin S, Atkinson T. Metabolic engineering of Geobacillus thermoglucosidasius for high yield ethanol production. Metab Eng. 2009;11:398–408.

D’elia JN, Salyers AA. Con an α-glucosidase to growth of Bacteroides thetaiotaomicron on starch. J Bacteriol. 1996;178:7173–9.

Daigle P, Gélinas P, Leblanc D, Morin A. Production of aroma compounds by Geotrichum candidum on waste breadcrumb. Food Microbiol. 1999;16:517–22.

Department of Health and Social Security (DHSS) UK Nutritional aspects of bread and flour. Report of the Panel on Bread. Flour and other Cereal Products Committee on Medical Aspects of Food Policy. Report 23 on Health and Social Subjects 1981 Accessed on 30/06/22. https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/743803/Nutritional_Aspects_of_Bread_and_Flour__1981_.pdf.

Dewettinck K, Van Bockstaele F, Kuhne B, Van de Welle D, Courtens TM, Gellynck X. Nutritional value of bread: influence of processing, food interaction and consumer perception. J Cereal Sci. 2008;8:243–57.

Doi T, Matsumoto H, Abe J, Morita S. Feasibility study on the application of rhizosphere microflora of rice for the biohydrogen production from wasted bread. Int J Hydrog Energy. 2009;34:1735–43.

Duffner F, Bertoldo C, Andersen JT, Wagner K, Antranikian G. A New Thermoactive Pullulanase from Desulfurococcus mucosus: Cloning, Sequencing, Purification, and Characterization of the Recombinant Enzyme after Expression in Bacillus subtilis. J Bacteriol. 2000;182:6331–8.

Eberstein K, Hoepcke R, Kieve G, Konieczny-Janda G, Stute R. DSC-Untersuchungen Stärke Teil I Möglichkeiten thermoanalytischer methoden zur stärkecharakterisierung. Starch. 1980;32:397–404.

Ebrahimi F, Khanahamdi M, Roodpeyma S, Taherzadeh MJ. Ethanol production from bread residues. Biomass Bioen. 2008;32:333–7.

Eliasson AC. Interactions between starch and lipids studied by DSC. Thermochim Acta. 1994;246:343–56.

Espinoza-Orias N, Azapagic A. Understanding the impact on climate change of convenience food: Carbon footprint of sandwiches. Sust Prod Consumpt. 2018;15:1–15.

Favaro L, Jooste T, Basaglia M, Rose SH, Saayman M, Görgens JF, Casella S, van Zyl WH. Designing industrial yeasts for the consolidated bioprocessing of starchy biomass to ethanol. Bioengineered. 2013;4:97–102.

Fukuda H, Kondo A, Tamalampudi S. Bioenergy: sustainable fuels from biomass by yeast and fungal whole-cell biocatalysts. Biochem Eng J. 2009;44:2–12.

Gibreel A, Sandercock JR, Lan J, Goonewardene LA, Zijlstra RT, Curtis JM, Bressler DC. Fermentation of barley by using Saccharomyces cerevisiae: examination of barley as a feedstock for bioethanol production and value-added products. Appl Environ Microbiol. 2009;75:1363–72.

Gudmundsson M, Eliasson AC. Some physical properties of barley starches from cultivars differing in amylose content. J Cereal Sci. 1992;16:95–105.

Gupta R, Gigras P, Mohapatra H, Goswami VK, Chauhan B. Microbial α-amylases: a biotechnological perspective. Proc Biochem. 2003;38:1599–616.

Hii SL, Tan JS, Ling TC, Ariff AB. Pullulanase: Role in Starch Hydrolysis and Potential Industrial Applications. Enzy Res. 2012. https://doi.org/10.1155/2012/921362.

Hug-Iten S, Escher F, Conde-Petit B. Structural properties of starch in bread and bread model systems: Influence of an Antistaling α-Amylase. Cereal Chem. 2001;78:421–8.

Hussein AH, Lisowska BK, Leak DJ. The genus Geobacillus and their biotechnological potential. Adv Appl Microbiol. 2015;92:1–48.

Kawa-Rygielska J, Pietrzak W. Utilization of waste bread for ethanol production. Food Sci Technol Qual. 2011;6:105–18.

Kawa-Rygielska J, Pietrzak W, Czubaszek A. Characterization of fermentation of waste wheat–rye bread mashes with the addition of complex enzymatic preparations. Biomass Bioen. 2012;44:17–22.

Knight S. How the sandwich consumed Britain. 2017 https://www.theguardian.com/news/2017/nov/24/how-the-sandwich-consumed-britain. Accessed 18 Feb 2018.

Li M, Kim JW, Peeples TL. Kinetic enhancement of starch bioconversion in thermoseparating aqueous two-phase reactor systems. Biochem Eng J. 2002;11:25–32.

Lisowska BK. Genomic analysis and metabolic modelling of Geobacillus thermoglucosidasius NCIMB 11955. 2016 http://opus.bath.ac.uk/51242/1/ThesisBeataLisowska.pdf. Accessed 2 June 18.

Lynd LR, Laser MS, Brandsby D, Dale BE, Davison B, Hamilton R, Himmel M, Keller M, McMillan JD, Sheehan J, Wyman CE. How biotech can transform biofuels. Nat Biotechnol. 2008;26:169–72.

Lynd LR, Wyman CE, Gerngross TU. Biocommodity Engineering. Biotechnol Prog. 1999;15:777–93.

Malhotra S, Noorwez M, Satyanarayana T. Production and partial characterization of thermostable and calcium-independent α-amylase of an extreme thermophile Bacillus thermooleovorans NP54 R. Letts Appl Microbiol. 2000;31:378–84.

Marulanda AR, Gutierrez CDB, Alzate CAC. Thermochemical, biological, biochemical, and hybrid conversion methods of bio-derived molecules into renewable fuels. In: Hosseini M, editor. Advanced Bioprocessing for Alternative Fuels, Biobased Chemicals, and Bioproducts. Cambridge: Woodhead Publishing; 2019. p. 59–81.

Melikoglu M. Production of sustainable alternatives to petrochemicals and fuels using waste bread as a raw material. PhD thesis. 2008 https://ethos.bl.uk/OrderDetails.do?uin=uk.bl.ethos.488783

Melikoglu M, Webb C. Use of waste bread to produce fermentation products. In: Webb C, Kosseva MR, editors. Food industry wastes; assessment and recuperation of commodities. Amsterdam: Elsevier Science Publishers; 2013. p. 63–74.

Melikoglu M, Lin CSK, Webb C. Kinetic studies on the multi-enzyme solution produced via solid state fermentation of waste bread by Aspergillus awamori. Biochem Eng J. 2013;80:76–82.

Nakamura Y, Kobayashi F, Ohnaga M, Sawada T. Alcohol fermentation of starch by a genetic recombinant yeast having glucoamylase activity. Biotechnol Bioeng. 1997;53:21–5.

Nisha M, Satyanarayana T. Characteristics, protein engineering and applications of microbial thermostable pullulanases and pullulan hydrolases. Appl Microbiol Biotechnol. 2016;100:5661–79.

Novozymes. Novozymes launches advanced enzymes to increase ethanol yields and plant profits. Bioenergy Trade News. 2017. https://www.novozymes.com/en/news/news-archive/2017/02/novozymes-launches-advanced-enzymes-to-increase-ethanol-yields-and-plant-profits. Accessed 18 Sep 2018.

Oda Y, Park BS, Moon KH, Tonomura K. Recycling of bakery wastes using an amylolytic lactic acid bacterium. Bioresour Technol. 1997;60:101–6.

Oliva JM, Ballesteros M, Olsson L. Comparison of SHF and SSF processes from steam-exploded wheat straw for ethanol production by xylose-fermenting and robust glucose-fermenting Saccharomyces cerevisiae strains. Biotechnol Bioeng. 2008;100:1122–31.

Pietrzak W, Kawa-Rygielska J. Ethanol fermentation of waste bread using granular starch hydrolyzing enzyme: Effect of raw material pretreatment. Fuel. 2014;134:250–6.

Pietrzak W, Kawa-Rygielska J. Simultaneous saccharification and ethanol fermentation of waste wheat–rye bread at very high solids loading: effect of enzymatic liquefaction conditions. Fuel. 2015;147:236–42.

Presecki AV, Blazevic ZF, Vasic-Racki DV. Complete starch hydrolysis by the synergistic action of amylase and glucoamylase: impact of calcium ions. Bioproc Biosyst Eng. 2013;36:1555–62.

Raita M, Ibenegbu C, Champreda V, Leak DJ. Production of ethanol by thermophilic oligosaccharide utilising Geobacillus thermoglucosidasius TM242 using palm kernel cake as a renewable feedstock. Biomass Bioenergy. 2016;95:45–54.

Reddy LVA, Reddy OVS, Basappa SC. Potentiality of yeasts in the direct conversion of starchy materials to ethanol and its relevance in the new millennium. In; T. Satyanarayana, G. Kunze (eds.), Yeast Biotechnology: Diversity and Applications, Springer Science, 2009; 515–545.

Rosales-Calderon O, Arantes V. A review on commercial-scale high-value products that can be produced alongside cellulosic ethanol. Biotechnol Biofuels. 2019;12:240.

Roy I, Gupta MN. Hydrolysis of starch by a mixture of glucoamylase and pullulanase entrapped individually in calcium alginate beads. Enz Microb Technol. 2004;34:26–32.

Sakwa L, Cripwell RA, Rose SH, Viljoen-Bloom M. Consolidated bioprocessing of raw starch with Saccharomyces cerevisiae strains expressing fungal alpha-amylase and glucoamylase combinations. FEMS Yeast Res. 2018;18:1–10.

Sánchez C, Serrano L, Llano-Ponte R, Labidi J. Bread residues conversion into lactic acid by alkaline hydrothermal treatments. Chem Eng J. 2014;250:326–30.

Sluiter AD, Hames BR, Ruiz RO, Scarlata CJ, Sluiter JB, Templeton DW. Determination of sugars, byproducts, and degradation products in liquid fraction process samples. Laboratory analytical procedure (LAP) NREL/TP510e42623, 2008 National Renewable Energy Laboratory, Golden, Colorado, USA.

ST1 Biofuels. Advanced fuels from waste. 2020. https://www.st1.com/about-st1/company-information/areas-operations/advanced-fuels-waste. Accessed 11 Apr 2020.

Takata H, Kuriki T, Okada S, Takesada Y, Lizuka M, Noshi M, Imanaka T. Action of Neopullulanase: Neopullulanase catalyzes both hydrolysis and transglycosylation at α (1–4) and α-(1–6)- glucosidic linkages. J Biol Chem. 1992;267:18447–52.

Thyagarajan T, Puri M, Vongsvivut J, Barrow CJ. Evaluation of breadcrumbs as a potential carbon source for the growth of Thraustochytrid species for oil and omega-3 production. Nutrients. 2014;6:2104–14.

Toast Ale. https://www.toastale.com/bread-waste/. Accessed 01 Apr 20.

Torabi S, Satari B, Hassan-Beygi SR. Process optimization for dilute acid and enzymatic hydrolysis of waste wheat bread and its effect on aflatoxin fate and ethanol production. Biomass Convers Biorefin. 2021;11:2617–25.

Van der Maarel MJEC, van der Veen B, Uitdehaag JCM, Leemhuis H, Dijkhuizen L. Properties and applications starch-converting enzymes of the α-amylase family. J Biotechnol. 2002;94:137–55.

Van Zyl WH, Bloom M, Viktor MJ. Engineering yeasts for raw starch conversion. Appl Microbiol Biotechnol. 2012;95:1377–88.

Warner E, Moriarty K, Lewis J, Milbrandt A, Schwab A. 2015 Bioenergy market report. NREL, Golden, USA. 2017. Accessed on 02 July 22. https://www.nrel.gov/docs/fy17osti/66995.pdf.

Xu QS, Yan YS, Feng JX. Efficient hydrolysis of raw starch and ethanol fermentation: a novel raw starch-digesting glucoamylase from Penicillium oxalicum. Biotechnol Biofuels. 2016;9:216–33.

Acknowledgements

The authors acknowledge Greencore, UK for supplying the sandwich WB and providing background data. ReBio Ltd, Guildford, UK are thanked for providing Parageobacillus thermoglucosidasius TM333 used in the fermentations.

Funding

The authors thank FoodWasteNet, a BBSRC Network in Industrial Biotechnology and Bioenergy, for funding, and Greencore UK for provision of materials.

Author information

Authors and Affiliations

Contributions

CI planned and executed the experimental work, wrote the first manuscript draft and prepared the figures and tables. DL raised the funding, supervised the project and finalised the manuscript. Both authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for Publication

Not applicable.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Ibenegbu, C.C., Leak, D.J. Simultaneous saccharification and ethanologenic fermentation (SSF) of waste bread by an amylolytic Parageobacillus thermoglucosidasius strain TM333. Microb Cell Fact 21, 251 (2022). https://doi.org/10.1186/s12934-022-01971-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12934-022-01971-6