Abstract

In parallel with the development of novel materials, such as cellulose nanofibers (CNFs), their effects on aquatic organisms should be evaluated. In ecotoxicity testing, concentration measurements are important to obtain accurate exposure concentrations; however, few studies have measured the concentration and dispersion state of CNFs in test solutions. Therefore, we evaluated the applicability of enzymatic and phenol–sulfuric acid methods for CNF quantification in ecotoxicity testing. In the enzymatic method, CNF content was determined by quantifying the d-glucose produced from the CNFs using cellulase with a glucose assay kit. Three types of cellulases were purchased, and impurities such as d-glucose were identified and removed. The differences in CNF degradation efficiency among the cellulases were evaluated, and a cellulase suitable for CNF degradation was selected. In the phenol–sulfuric acid method, a microplate-based method was employed to handle a large number of samples. We demonstrated that both the enzymatic and phenol–sulfuric acid methods could quantify CNFs in media for ecotoxicity testing. The enzymatic method was able to measure lower CNF concentrations (~ 1 mg/L) than the phenol–sulfuric acid method (~ 10 mg/L) and had less interference with CNF quantification by algae and non-cellulosic polysaccharides.

Similar content being viewed by others

Introduction

Cellulose nanofibers (CNFs) are plant-derived nanomaterials that contribute to a sustainable society. Owing to their unique properties, including thixotropy, high mechanical strength, elastic modulus, gas barrier properties, viscosity, and low thermal expansion, various applications have been proposed, such as structural and packaging materials, filters, coatings, foods, and cosmetics [1,2,3]. As the production and use of CNFs expand, the amount of runoff into the environment and exposure to aquatic organisms are expected to increase. Therefore, the effects of CNFs on aquatic organisms should be evaluated in conjunction with their development.

Recently, ecotoxicity assessments of CNFs in aquatic organisms have been conducted [4,5,6,7,8,9,10]. However, few studies have measured the concentration and dispersion states of CNFs in test solutions. According to the Organisation for Economic Co-operation and Development (OECD) test guidelines and guidance documents [11,12,13,14], it is recommended to analyze the test concentrations at the beginning and end of the test if the concentrations are unlikely to remain within 80–120% of the nominal values. Because CNFs tend to agglomerate and sediment owing to their interaction with the components of the culture media [5, 7, 15], CNF concentration measurements are particularly important for obtaining accurate exposure concentrations and conducting proper testing. For ecotoxicity testing, it is necessary to measure CNFs at concentrations in the order of 1–100 mg/L [4,5,6,7,8,9,10]. Because algae, which contain cellulose as the major component of their cell walls, are used in ecotoxicity studies as test subjects for algal growth inhibition tests or as food for Daphnia magna in D. magna reproduction tests, their contribution to CNF measurements must be considered. Furthermore, an easy and less expensive method is required to measure multiple samples.

Previously, we reported a method for the quantitative analysis of CNFs via enzymatic degradation [16]. Cellulose is enzymatically degraded into d-glucose through the cooperative action of glycoside hydrolases. Celluloses are depolymerized into cellooligosaccharides by endo-β-1,4-glucanases [17]. In addition, reducing and non-reducing end-specific cellobiohydrolases release cellobioses from the reducing and non-reducing ends of cellulose, respectively. The cellooligosaccharides and cellobiose produced are then degraded to d-glucose by β-glucosidases. In addition to these glycoside hydrolases, other enzymes, such as lytic polysaccharide monooxygenases, are also involved in the degradation of cellulose [18]. The amount of cellulose, including CNFs, can be determined by quantifying d-glucose produced from cellulose using cellulase, which is a complex mixture including endo-β-1,4-glucanases, cellobiohydrolases, and β-glucosidases. Using a glucose assay kit to measure the glucose produced from CNFs, the amount of CNFs can be measured using a plate reader.

Another easy and inexpensive method applicable to CNF quantification is the phenol–sulfuric acid method, which is a colorimetric method widely used to determine total saccharides [19, 20]. Microplate-based phenol–sulfuric acid methods have also been developed to handle large numbers of samples and reduce the use of hazardous chemicals [21,22,23,24,25]. The amount of CNFs can also be measured using a plate reader [25].

In this study, our aim was to evaluate the applicability of enzymatic and phenol–sulfuric acid methods for CNF quantification in CNF ecotoxicity testing. Our previous studies have shown that CNFs dispersed in pure water can be quantified by both the enzymatic and phenol–sulfuric acid methods [16, 25]. However, the solutions in ecotoxicity tests contain media components and organisms (and their food and excretions), which may interfere with the determination of CNFs. In addition, the optimal procedure for the determination of CNFs by enzymatic methods has not been well studied. In this study, three types of cellulases were purchased, and impurities such as d-glucose were identified and removed. The differences in CNF degradation efficiency among the cellulases were evaluated, and a cellulase suitable for CNF degradation was selected. We then evaluated whether CNFs could be quantified in the media used in the ecotoxicity tests. In addition, to evaluate the interference of algae and non-cellulosic polysaccharides with CNF quantification, we examined whether d-glucose was produced from algae and non-cellulosic polysaccharides by cellulase treatment. Similarly, using the phenol–sulfuric acid method, we evaluated whether CNFs could be quantified in the media used in the ecotoxicity tests. To evaluate the interference of algae with CNF quantification, we investigated the glucose-equivalent concentration of algae, which was measured using the phenol–sulfuric acid method. Based on these results, the advantages and disadvantages of the enzymatic and phenol–sulfuric acid methods for CNF quantification in CNF ecotoxicity testing are discussed.

Materials and methods

Materials

CNFs produced by the mechanical fibrillation of bleached hardwood kraft pulp (BHKP) and bleached softwood kraft pulp (BSKP) were provided by the Daio Paper Corporation (Tokyo, Japan). Both BHKP- and BSKP-CNFs had a typical width and length of 20–100 nm and > 1 μm, respectively. The 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO)-oxidized CNFs (TEMPO-CNFs) were provided by Nippon Paper Industries Co., Ltd. (Tokyo, Japan). TEMPO-CNFs had a sodium carboxylate content of 1.3–1.6 mmol/g and a typical width and length of 3–4 nm and 0.1–1 μm, respectively.

The US Environmental Protection Agency (USEPA) moderately hard water [26], slightly modified by adding 4.8 μg/L sodium selenite and 2 μg/L vitamin B12, which is used as the culture medium for D. magna, was prepared as described previously [27]. The OECD culture medium used for the algal growth inhibition tests [11] was purchased from FUJIFILM Wako Pure Chemical Corp. (Osaka, Japan). Both media contained ions such as Na+, K+, Ca2+, Mg2+, Cl−, and SO42−.

CNF dispersions at a concentration of 1 g/L were prepared by mixing as-obtained CNFs (10–30 g/L) with ultrapure water, USEPA moderately hard water, or OECD medium using an ultrasonic mixer (PR-1, Thinky Corporation, Tokyo, Japan) at 300 rpm for 3 min for BHKP- and BSKP-CNFs and a planetary centrifugal mixer (ARE 310, Thinky Corporation, Tokyo, Japan) at 1500 rpm for 30 min for TEMPO-CNFs. CNF dispersions at each concentration were prepared by dilution and manual shaking (repeated inversion).

Enzymatic method for quantitative CNF measurement

Removal of impurities in cellulase

Commercial cellulases contain not only cellulose degradation-related enzymes but also other low-molecular-weight compounds, such as d-glucose. Because the contamination of d-glucose on cellulase can affect the quantification of cellulose, the contaminated d-glucose was removed by ultrafiltration. Three types of cellulases were purchased: cellulase enzyme blend Cellic CTec2 (SAE0020, Sigma-Aldrich, St. Louis, MO, USA), cellulase from Trichoderma sp. (C0615, Sigma-Aldrich), and cellulase from Aspergillus niger (C0057, Tokyo Chemical Industry, Tokyo, Japan). First, 0.2 g of cellulases were dissolved in 10 mL of 50 mM sodium acetate buffer (pH 5.0), and insoluble matter was removed by centrifugation (10,000g, 10 min at 4 ℃). Then, 8 mL of each cellulase solution was concentrated to approximately 0.5 mL using a 10-kDa cutoff ultrafiltration unit (Vivaspin Turbo 15, Sartorius, Germany), and 7.5 mL of sodium 50 mM acetate buffer (pH 5.0) was added to each concentrated cellulase solution. The concentration and dilution procedures were repeated five times to remove d-glucose and other low-molecular-weight compounds from the cellulases. At each step, the d-glucose concentrations in the cellulases were measured using a LabAssay Glucose kit (638–50,971, FUJIFILM Wako Pure Chemical Corp.). Protein concentrations in cellulases were measured by UV absorbance (280 nm) using a NanoDrop spectrophotometer (Thermo Fisher Scientific, Waltham, MA, USA).

Differences in degradation efficiency according to cellulase type

BHKP-, BSKP-, and TEMPO-CNFs were degraded using purified cellulases, as described below.

A 100-μL reaction mixture containing 2.5 g/L CNFs, 20 mM sodium acetate buffer (pH 5.0), and 0.02 mg/mL cellulase (Cellic CTec2, Trichoderma sp. cellulase, or A. niger cellulase) was incubated at 50 ℃ for 4 h. After the reaction, the mixture was centrifuged at 1000g for 5 min, and the concentration of d-glucose produced in the supernatant was measured using a LabAssay Glucose kit.

Degradation efficiency with reaction time

BSKP- and TEMPO-CNFs were degraded using purified Cellic CTec2, and the concentration of d-glucose produced was measured chronologically, as described below.

First, 100 μL of reaction mixture containing 50 mg/L CNFs, 20 mM sodium acetate buffer (pH 5.0), and 0.02 mg/mL Cellic CTec2 was incubated at 50 ℃ for 2, 4, 6, or 24 h. After the reaction, the reaction mixture was incubated at 98 ℃ for 10 min to terminate the reaction. The concentration of the d-glucose produced was determined using a Glucose Colorimetric/Fluorometric Assay Kit (K606-100; BioVision, Waltham, MA, USA).

Quantification of CNFs in the ecotoxicity testing media

We evaluated whether CNFs could be quantified in the media used in the ecotoxicity tests. BSKP- and TEMPO-CNFs were degraded using purified Cellic CTec2 in ultrapure water, USEPA moderately hard water, or OECD medium, as described below.

First, 94 μL of CNF dispersion (0, 0.78, 1.56, 3.12, 6.25, 12.5, 25, and 50 mg/L) in ultrapure water, USEPA moderately hard water, or OECD medium, prepared by dilution and manual shaking, was mixed with 4 μL of 500 mM sodium acetate buffer and 2 μL of 1 mg/mL Cellic CTec2 and incubated at 50 ℃ for 20 h. After incubation, the d-glucose concentration was determined using a Glucose Colorimetric/Fluorometric Assay Kit.

Investigation of d-glucose production from algae by cellulase treatment

To evaluate the interference of algae with CNF quantification using cellulase, we investigated d-glucose production from algae by cellulase treatment. Raphidocelis subcapitata (NIES-35, National Institute for Environmental Studies in Japan), which was used for the algal growth inhibition tests, and Chlorella vulgaris (Recenttec Corp., Tokyo, Japan), which was used as food for D. magna in the D. magna reproduction test, were degraded using purified Cellic CTec2. Ninety-four μL of algal dispersion (0, 2.81 × 108, 5.63 × 108, 1.13 × 109, and 2.25 × 109 cells/L in OECD medium for R. subcapitata; 0, 2.5 × 109, 5.0 × 109, 1.0 × 1010, and 2.0 × 1010 cells/L in USEPA moderately hard water for C. vulgaris) was measured using the same method as the CNF quantification described in the previous section. The biomass concentration of R. subcapitata was set to correspond to the concentration of algae grown in 72-h algal growth inhibition tests (the order of 1 × 109 cells/L [11]). In contrast, the biomass concentration of C. vulgaris was deliberately set higher than what is typically used as food for D. magna in the D. magna reproduction test (5 × 108 cells/L [27]). This was done because it was difficult to detect a low concentration of C. vulgaris in a preliminary evaluation.

Investigation of d-glucose production from non-cellulosic polysaccharides by cellulase treatment

To evaluate the influence of non-cellulosic polysaccharides, which are potentially derived from living organisms, on the quantification of CNFs using cellulase, we examined whether d-glucose is produced from non-cellulosic polysaccharides, including xylan (monosaccharide composition: xylose and glucuronic acid, main chain glycosidic linkage: β-1,4), (1,3)(1,4)-β-glucan (monosaccharide composition: glucose, main chain glycosidic linkage: β-1,4 and β-1,3), starch (monosaccharide composition: glucose, main chain glycosidic linkage: α-1,4 and α-1,6), curdlan (monosaccharide composition: glucose, main chain glycosidic linkage: β-1,3), glucomannan (monosaccharide composition: glucose and mannose, main chain glycosidic linkage: β-1,4), or xyloglucan, by cellulase treatment.

A 20-μL reaction mixture containing 50 mM sodium acetate buffer (pH 5.0), 0.5 mg/mL purified Cellic CTec2, and 0.5 mg/mL polysaccharide: BSKP-CNFs, beech wood xylan (Sigma-Aldrich), barley (1,3)(1,4)-β-glucan (Megazyme, Wicklow, Ireland), tamarind seed xyloglucan (Megazyme), potato starch (FUJIFILM Wako Pure Chemical Corp.), curdlan from Alcaligenes faecalis (Megazyme), or konjac glucomannan (Megazyme), was incubated at 50 ℃ for 20 h. After the reaction, the d-glucose concentrations of the reaction products were measured using a LabAssay Glucose kit. Cellic CTec2-treated polysaccharides were analyzed by thin-layer chromatography (TLC) using a silica gel-coated glass TLC plate (Merck, Darmstadt, Germany), developing solvent (2-propanol: acetic acid: water = 4:1:1), and coloring reagent (ethanol: p-anisaldehyde: acetic acid: sulfuric acid = 96:2.6:1:3.6).

Phenol–sulfuric acid method for quantitative CNF measurement

Quantification of CNFs in the ecotoxicity testing media

We evaluated whether CNFs could be quantified in the media for ecotoxicity tests using the microplate-based phenol–sulfuric acid method. BSKP- and TEMPO-CNFs in ultrapure water, USEPA moderately hard water, or OECD medium were measured using the microplate-based phenol–sulfuric acid method described in our previous study [25]. Namely, 30 μL of CNF dispersion (0, 12.5, 25, 50, and 100 mg/L) in ultrapure water, USEPA moderately hard water, or OECD medium was added to each well of a 96-well flat-bottom microplate (1-1601-06, Violamo, AS ONE, Osaka, Japan), followed by 150 μL of concentrated sulfuric acid (96.0–98.0%, super special grade, FUJIFILM Wako Pure Chemical Corp.). The microplate was heated at 90 °C and shaken at 600 rpm for 15 min in a thermomixer (ThermoMixer® C, Eppendorf, Hamburg, Germany) and then cooled to room temperature using a block bath (CDB-105, AS ONE) at 4 °C for 2.5 min. The microplate was ultrasonicated for 10 s to remove air bubbles and read on a plate reader (SpectraMax ABS Plus®, Molecular Devices, San Jose, CA, USA) at an absorbance of 490 nm to obtain the background absorbance before the color reaction with phenol. Then, 30 μL of 5% phenol solution (guaranteed reagent, FUJIFILM Wako Pure Chemical Corp.) was added to each well of the microplate, and the mixture was shaken at 600 rpm for 5 min at 25 °C in a thermomixer. After allowing the plate to rest for 60 min, it was read again on a plate reader to obtain the absorbance after the reaction with phenol. The absorbance due to the color reaction with phenol was obtained from the difference in absorbance before and after the phenol reaction. The d(+)-glucose (guaranteed reagent, FUJIFILM Wako Pure Chemical Corp.) was measured in the same manner to obtain glucose-equivalent concentrations. Outliers were removed based on the modified Thompson’s tau test (95% confidence level).

Investigation of glucose-equivalent concentration of algae measured by the phenol–sulfuric acid method

To evaluate the interference of algae with CNF quantification, we investigated the glucose-equivalent concentration of algae, which was measured using the phenol–sulfuric acid method. R. subcapitata in OECD medium (0, 2.81 × 108, 5.63 × 108, 1.13 × 109, and 2.25 × 109 cells/L) and C. vulgaris in USEPA moderately hard water (0, 1.25 × 1010, 2.5 × 1010, 5.0 × 1010, and 1.0 × 1011 cells/L) were measured using the same method as the CNF quantification described in the previous section. The biomass concentration of C. vulgaris was deliberately set higher than what is typically used as food for D. magna in the D. magna reproduction test (5 × 108 cells/L [27]) because it was difficult to detect the low concentration of C. vulgaris in a preliminary evaluation.

Results and discussion

Enzymatic method for quantitative CNF measurement

Removal of impurities in cellulase

Before ultrafiltration, A. niger cellulase and Cellic CTec2 contained high levels of d-glucose. In contrast, Trichoderma sp. cellulase contained less d-glucose. After five cycles of ultrafiltration, the concentrations of d-glucose in A. niger cellulase, Cellic CTec2, and Trichoderma sp. cellulase decreased to less than 0.04 mg/mL (Fig. 1). After purification, the amount of glucose in Cellic CTec2 and Trichoderma sp. cellulase was almost the same, whereas that in A. niger cellulase was slightly higher. However, the glucose concentration of cellulases could be reduced to the extent that it did not affect the subsequent quantitative CNF experiments (below the detection limit of the glucose assay kit).

Differences in degradation efficiency according to cellulase type

The BHKP-, BSKP-, and TEMPO-CNFs were degraded using the purified cellulases: Cellic CTec2, Trichoderma sp. cellulase, and A. niger cellulase (Fig. 2). Among these cellulases, Cellic CTec2 produced d-glucose more efficiently than the others, indicating that Cellic CTec2 is suitable for the degradation and quantification of CNFs under our assay conditions. The d-glucose production efficiency of TEMPO-CNFs was much lower than that of BHKP- and BSKP-CNFs, suggesting that the oxidation of cellulose negatively affects the degradation of cellulases and/or determination of the d-glucose concentration.

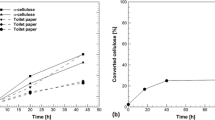

Degradation efficiency with reaction time

Figure 3 shows the relationship between the reaction time and the concentration of d-glucose produced from BSKP- and TEMPO-CNFs using purified Cellic CTec2. The d-glucose concentration increased during the first 6 h of the reaction and hardly increased after 6 h. This result indicates that 20 h was sufficient to degrade the CNFs. After 20 h, BSKP-CNFs were almost completely degraded into d-glucose. Approximately 46 mg/L of d-glucose was produced from 50 mg/L of BSKP-CNFs (Fig. 3). This result is reasonable because BSKP contains hemicellulose. In contrast, because some glucopyranosyl residues were oxidized in TEMPO-CNFs, only 25 mg/L d-glucose was produced from 50 mg/L TEMPO-CNFs. In addition, it is possible that the TEMPO-mediated oxidization of cellulose interferes with cellulose degradation by cellulases. We confirmed that pH 5.0–5.5 was suitable for the activity of purified Cellic CTec2, and 0.05 mg/mL of cellulase was sufficient for the degradation of CNFs (data not shown).

Quantification of CNFs in the ecotoxicity testing media

We evaluated whether CNFs could be quantified in the media for ecotoxicity tests using an enzymatic method. Both the BSKP- and TEMPO-CNFs were quantitatively detectable in ultrapure water (Fig. 4a), USEPA moderately hard water (Fig. 4b), and OECD medium (Fig. 4c). The d-glucose production efficiency of BSKP-CNFs in USEPA moderately hard water and OECD medium was almost the same as that in ultrapure water. In contrast, the d-glucose production efficiency of TEMPO-CNFs in USEPA moderately hard water and OECD medium was lower than that in ultrapure water, and USEPA moderately hard water negatively affected the quantification of TEMPO-CNFs. We speculate that the ions present in the media affected the conditions of the TEMPO-CNFs [28, 29] and the decomposition efficiency by cellulase.

The standard deviation (σ) of the glucose concentration of the blank sample (0 mg/L of CNFs) was 0.02–0.08 mg/L (n = 6 for each medium). From these values and the slopes of the graphs (a) in Fig. 4, the detection limits (DL) calculated using the formula DL = 3.3σ/a [30] were 0.09–0.3 mg/L for BSKP-CNFs and 0.2–0.6 mg/L for TEMPO-CNFs. In Fig. 4, we used a simple linear approximation; however, a curvilinear approximation may be more appropriate because the response tends to decrease slightly at higher concentrations.

Investigation of d-glucose production from algae by cellulase treatment

To evaluate the interference of algae with CNF quantification using cellulase, we investigated d-glucose production from algae by cellulase treatment (Fig. 5). The amount of d-glucose produced per algal cell (i.e., the slope of the graph) was 2.4 × 10–10 mg/cell for R. subcapitata (Fig. 5a) and 8.4 × 10–11 mg/cell for C. vulgaris (Fig. 5b). Typically, in a 72-h algal growth inhibition test, the biomass concentration of R. subcapitata increases to the order of 1 × 109 cells/L [11], which corresponds to ~ 0.2 mg/L of d-glucose according to the result in Fig. 5a. This glucose concentration was near the lower end of the typical concentration range for CNFs in ecotoxicity studies (on the order of 1–100 mg/L [4,5,6,7,8,9,10]). Therefore, the interference of R. subcapitata with CNF quantification should be considered when measuring low CNF concentrations. In contrast, the biomass concentration of C. vulgaris as food for D. magna is 5 × 108 cells/L in the D. magna reproduction test [27], which corresponds to ~ 0.04 mg/L of d-glucose according to the result in Fig. 5b. This glucose concentration was well below the typical range of CNF concentrations in ecotoxicity studies. Therefore, the interference of C. vulgaris with CNF quantification was negligible.

Investigation of d-glucose production from non-cellulosic polysaccharides by cellulase treatment

In addition to cellulose, some polysaccharides also contain glucose residues. For example, xyloglucan, which is found in plant cell walls and seeds, has β-1,4-glucan as the main chain, and α-1,6-linked d-xylopyranosyl side chains are attached to the main chain glucopyranosyl residues. In addition to d-xylose, other saccharides, such as d-galactose and l-fucose, are attached to the side chains of xyloglucan. To evaluate the interference of non-cellulosic polysaccharides with CNF quantification using cellulase, we investigated d-glucose production from non-cellulosic polysaccharides by cellulase treatment. No considerable amount of d-glucose was produced from xylan, xyloglucan, or starch after cellulase treatment (Fig. 6a). Upon cellulase treatment, xylan and xyloglucan were degraded into d-xylose and xyloglucan oligosaccharides, respectively (Fig. 6b). In contrast, d-glucose was produced by cellulase from (1,3)(1,4)-β-glucan, curdlan, and glucomannan, suggesting that Cellic CTec2 has hydrolytic activity toward these polysaccharides. In particular, because (1,3)(1,4)-β-glucan is structurally similar to cellulose, it could not be distinguished from cellulose in this experimental method.

Degradation of non-cellulosic polysaccharides using cellulase. BSKP-CNFs, xylan, (1,3)(1,4)-β-glucan, xyloglucan, starch, curdlan, and glucomannan were treated with Cellic CTec2 for 20 h. After the treatment, the reaction products were analyzed using a glucose concentration assay kit (a) and TLC (b)

Phenol–sulfuric acid method for quantitative CNF measurement

Quantification of CNFs in the ecotoxicity testing media

We evaluated whether CNFs could be quantified in the media for ecotoxicity tests using the phenol–sulfuric acid method. Both the BSKP- and TEMPO-CNFs were quantitatively detectable in ultrapure water (Fig. 7a), USEPA moderately hard water (Fig. 7b), and OECD medium (Fig. 7c). The glucose-equivalent concentration per CNF concentration (i.e., the slope of the graph) for BSKP-CNFs was 1.1–1.2. This result is considered reasonable, given that the ratio of the molar mass of glucose (180 g/mol) to the molar mass of the glucose residue in cellulose (162 g/mol) is 1.1. In contrast, the glucose-equivalent concentration per CNF concentration for TEMPO-CNFs was 0.70–0.78. This result is also considered reasonable, given that the TEMPO-CNFs had a sodium carboxylate content of 1.3–1.6 mmol/g. Additionally, approximately 1/4 of the TEMPO-CNFs was composed of glucuronic acid residues, which have low reactivity in the phenol–sulfuric acid method [31, 32].

The standard deviation (σ) of the glucose-equivalent concentration of the blank sample (0 mg/L of CNFs) was 1.1–1.8 mg/L. From these values and the slopes of the graphs (a) in Fig. 7, the detection limits (DL) calculated using the formula DL = 3.3σ/a [30] were 3–6 mg/L for BSKP-CNFs and 5–8 mg/L for TEMPO-CNFs.

Investigation of glucose-equivalent concentration of algae measured by the phenol–sulfuric acid method

To evaluate the interference of algae with CNF quantification, we investigated the glucose-equivalent concentration of algae using the phenol–sulfuric acid method (Fig. 8). The glucose-equivalent concentration per algal concentration (i.e., the slope of the graph) was 5.6 × 10–9 mg/cell for R. subcapitata (Fig. 8a) and 9.1 × 10–10 mg/cell for C. vulgaris (Fig. 8b). These values were more than 10 times higher than those of the enzymatic method (the slope of the graphs in Fig. 5), indicating that the phenol–sulfuric acid method is more responsive to algae than the enzymatic method. This result is reasonable because the enzymatic method measures cellulose specifically and depends on the accessibility of cellulase to cellulose, whereas the phenol–sulfuric acid method measures all polysaccharides.

The dry weight of the algae per cell is not constant, but assuming 2 × 10–8–4 × 10–8 mg/cell [11], the percentage of glucose-equivalent mass was calculated as 14–28% (= 5.6 × 10–9 divided by 2 × 10–8–4 × 10–8) for R. subcapitata and 2–5% (= 9.1 × 10–10 divided by 2 × 10–8–4 × 10–8) for C. vulgaris, which is consistent with the range of reported values for cellulose content in algae [33].

Typically, in a 72-h algal growth inhibition test, the biomass concentration of R. subcapitata increases to the order of 1 × 109 cells/L [11], which corresponds to ~ 6 mg/L of d-glucose, as shown in Fig. 8a. This algae-derived glucose-equivalent concentration can interfere with the quantification of CNFs using the phenol–sulfuric acid method. In contrast, the biomass concentration of C. vulgaris as food for D. magna is 5 × 108 cells/L in the D. magna reproduction test [27], which corresponds to ~ 0.5 mg/L of d-glucose according to the result in Fig. 8b. This algae-derived glucose-equivalent concentration was below the detection limit of the phenol–sulfuric acid method and, therefore, is not likely to interfere with CNF determination using the phenol–sulfuric acid method.

Comparison of enzymatic and phenol–sulfuric acid methods

Table 1 summarizes the advantages and disadvantages of the enzymatic and phenol–sulfuric acid methods for CNF quantification. The lower limit of the measurable concentration was ~ 1 mg/L for the enzymatic method and ~ 10 mg/L for the phenol–sulfuric acid method; therefore, the enzymatic method can measure lower concentrations. However, the phenol–sulfuric acid method requires less time for the measurements. The phenol–sulfuric acid method also requires the use of deleterious substances, such as phenol and sulfuric acid. In contrast, the enzymatic method requires a glucose assay kit, which is somewhat costly. Compared to the phenol–sulfuric acid method, the enzymatic method showed less interference with CNF quantification by algae and non-cellulosic polysaccharides.

Thus, both methods have advantages and disadvantages. For CNF ecotoxicity testing, it is necessary to measure CNFs at concentrations in the order of 1–100 mg/L [4,5,6,7,8,9,10]. Therefore, we recommend using the phenol–sulfuric acid method when measuring CNF concentrations higher than several tens of mg/L and the enzymatic method when measuring CNF concentrations lower than several tens of mg/L.

Conclusions

We evaluated the applicability of enzymatic and phenol-sulfuric acid methods as easy and inexpensive CNF quantification methods for ecotoxicity testing. In the enzymatic method, the CNF content was determined by quantifying the d-glucose produced from the CNFs using cellulase. Commercially available cellulases were found to contain d-glucose, but ultrafiltration adequately removed the d-glucose. Among the three cellulases (Cellic CTec2, Trichoderma sp. cellulase, and A. niger cellulase), Cellic CTec2 was suitable for the degradation and quantification of CNFs. We demonstrated that both the enzymatic and phenol-sulfuric acid methods could quantify CNFs in media for ecotoxicity testing (USEPA moderately hard water and OECD medium), which contain ions such as Na+, K+, Ca2+, Mg2+, Cl−, and SO42−. The enzymatic method was able to measure lower CNF concentrations (~1 mg/L) than the phenol-sulfuric acid method (~10 mg/L) and had less interference with CNF quantification by algae and non-cellulosic polysaccharides. However, the phenol-sulfuric acid method requires less time for measurement, and the enzymatic method requires a glucose assay kit, which is costly. Therefore, we recommend using the phenol-sulfuric acid method when measuring CNF concentrations higher than several tens of mg/L and the enzymatic method when measuring CNF concentrations lower than several tens of mg/L. Both methods would be useful not only for the determination of CNFs in ecotoxicity studies but also for the determination of other celluloses in other media. Because the enzymatic method has a high specificity for measuring cellulose, it is considered useful for quantifying cellulose in the presence of organic substances and most polysaccharides.

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Abbreviations

- CNF:

-

Cellulose nanofiber

- OECD:

-

Organisation for Economic Co-operation and Development

- BHKP:

-

Bleached hardwood kraft pulp

- BSKP:

-

Bleached softwood kraft pulp

- TEMPO:

-

2,2,6,6-Tetramethylpiperidine-1-oxyl

- TEMPO-CNF:

-

2,2,6,6-Tetramethylpiperidine-1-oxyl radical-oxidized cellulose nanofiber

- USEPA:

-

US Environmental Protection Agency

- TLC:

-

Thin-layer chromatography

- DL:

-

Detection limit

References

Sharma A, Thakur M, Bhattacharya M, Mandal T, Goswami S (2019) Commercial application of cellulose nano-composites—a review. Biotechnol Rep (Amst) 21:e00316

Barhoum A, Li H, Chen M, Cheng L, Yang W, Dufresne A (2019) Emerging applications of cellulose nanofibers. In: Barhoum A, Bechelany M, Makhlouf A (eds) Handbook of nanofibers. Springer, Cham, pp 1131–1156

Cherian RM, Tharayil A, Varghese RT, Antony T, Kargarzadeh H, Chirayil CJ, Thomas S (2022) A review on the emerging applications of nano-cellulose as advanced coatings. Carbohydr Polym 282:119123

Vartiainen J, Pöhler T, Sirola K, Pylkkänen L, Alenius H, Hokkinen J, Tapper U, Lahtinen P, Kapanen A, Putkisto K, Hiekkataipale P, Eronen P, Ruokolainen J, Laukkanen A (2011) Health and environmental safety aspects of friction grinding and spray drying of microfibrillated cellulose. Cellulose 18:775–786

Pereira MM, Mouton L, Yéprémian C, Couté A, Lo J, Marconcini JM, Ladeira LO, Raposo NR, Brandão HM, Brayner R (2014) Ecotoxicological effects of carbon nanotubes and cellulose nanofibers in Chlorella vulgaris. J Nanobiotechnol 12:15

Munk M, Brandão HM, Nowak S, Mouton L, Gern JC, Guimaraes AS, Yéprémian C, Couté A, Raposo NR, Marconcini JM, Brayner R (2015) Direct and indirect toxic effects of cotton-derived cellulose nanofibres on filamentous green algae. Ecotoxicol Environ Saf 122:399–405

Harper BJ, Clendaniel A, Sinche F, Way D, Hughes M, Schardt J, Simonsen J, Stefaniak AB, Harper SL (2016) Impacts of chemical modification on the toxicity of diverse nanocellulose materials to developing zebrafish. Cellulose (Lond) 23:1763–1775

Ong KJ, Shatkin JA, Nelson K, Ede JD, Retsina T (2017) Establishing the safety of novel bio-based cellulose nanomaterials for commercialization. NanoImpact 6:19–29

Ogonowski M, Edlund U, Gorokhova E, Linde M, Ek K, Liewenborg B, Könnecke O, Navarro JRG, Breitholtz M (2018) Multi-level toxicity assessment of engineered cellulose nanofibrils in Daphnia magna. Nanotoxicology 12:509–521

Wang Z, Song L, Ye N, Yu Q, Zhai Y, Zhang F, Vijver MG, Peijnenburg WJGM (2020) Oxidative stress actuated by cellulose nanocrystals and nanofibrils in aquatic organisms of different trophic levels. NanoImpact 17:100211

Organisation for Economic Co-operation and Development (OECD) (2021) OECD guidelines for the testing of chemicals, Test No. 201: Freshwater alga and cyanobacteria, growth inhibition test. https://www.oecd-ilibrary.org/environment/test-no-201-alga-growth-inhibition-test_9789264069923-en. Accessed 29 November 2023

Organisation for Economic Co-operation and Development (OECD) (2004) OECD guidelines for the testing of chemicals, Test No. 202: Daphnia sp. acute immobilisation test. https://www.oecd-ilibrary.org/environment/test-no-202-daphnia-sp-acute-immobilisation-test_9789264069947-en. Accessed 29 November 2023

Organisation for Economic Co-operation and Development (OECD) (2019) Guidance document on aquatic toxicity testing of difficult substances and mixtures, OECD Series on Testing and Assessment No. 23, second ed. https://www.oecd-ilibrary.org/environment/guidance-document-on-aquatic-toxicity-testing-of-difficult-substances-and-mixtures_0ed2f88e-en. Accessed 29 November 2023

Organisation for Economic Co-operation and Development (OECD) (2021) Guidance document on aquatic and sediment toxicological testing of nanomaterials, OECD Series on Testing and Assessment No. 317. https://one.oecd.org/document/env/jm/mono(2020)8/en/pdf. Accessed 29 November 2023

Sone A, Saito T, Isogai A (2016) Preparation of aqueous dispersions of TEMPO-oxidized cellulose nanofibrils with various metal counterions and their super deodorant performances. ACS Macro Lett 5:1402–1405

Ogura I, Matsuzawa T, Takata M (2020) Examples of detection and quantification of cellulose nanofibers (in Japanese). https://riss.aist.go.jp/results-and-dissemin/776/. Accessed 29 November 2023

Biely P, Vrsanská M, Claeyssens M (1991) The endo-1,4-β-glucanase I from Trichoderma reesei. Action on β-1,4-oligomers and polymers derived from d-glucose and d-xylose. Eur J Biochem 200:157–163

Jagadeeswaran G, Gainey L, Prade R, Mort AJ (2016) A family of AA9 lytic polysaccharide monooxygenases in Aspergillus nidulans is differentially regulated by multiple substrates and at least one is active on cellulose and xyloglucan. Appl Microbiol Biotechnol 100:4535–4547

DuBois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Hodge JE, Hofreiter BT (1962) Determination of reducing sugars and carbohydrates. In: Whistler RL, Wolfrom ML (eds) Methods in carbohydrate chemistry. Academic Press, New York, pp 380–394

Masuko T, Minami A, Iwasaki N, Majima T, Nishimura S, Lee YC (2005) Carbohydrate analysis by a phenol–sulfuric acid method in microplate format. Anal Biochem 339:69–72

Wang Y, Jing Y, Leng F, Wang S, Wang F, Zhuang Y, Liu X, Wang X, Ma X (2017) Establishment and application of a method for rapid determination of total sugar content based on colorimetric microplate. Sugar Tech 19:424–431

Li Y, Mehta R, Messing J (2018) A new high-throughput assay for determining soluble sugar in sorghum internode-extracted juice. Planta 248:785–793

Kondo M, Mulianda R, Matamura M, Shibata T, Mishima T, Jayanegara A, Isono N (2021) Validation of a phenol-sulfuric acid method in a microplate format for the quantification of soluble sugars in ruminant feeds. Anim Sci J 92:e13530

Ogura I, Sugiyama M, Tai R, Mano H, Matsuzawa T (2023) Optimization of microplate-based phenol-sulfuric acid method and application to the multi-sample measurements of cellulose nanofibers. Anal Biochem 681:115329

US Environmental Protection Agency (USEPA) (2002) Short-term methods for estimating the chronic toxicity of effluents and receiving waters to fresh organisms, fourth ed., EPA-821-R-02–013. https://www.epa.gov/sites/default/files/2015-08/documents/short-term-chronic-freshwater-wet-manual_2002.pdf. Accessed 29 November 2023

Mano H, Shinohara N, Peters A, Garman E, Middleton E, Schlekat C, Naito W (2022) Variation in chronic nickel toxicity to Daphnia magna among Japanese river waters and performance evaluation of bioavailability models in predicting the toxicity. Environ Sci Pollut Res Int 29:27664–27676

Saito T, Isogai A (2005) Ion-exchange behavior of carboxylate groups in fibrous cellulose oxidized by the TEMPO-mediated system. Carbohydr Polym 61:183–190

Tai R, Ogura I, Okazaki T, Iizumi Y, Mano H (2024) Acute toxicity tests of TEMPO-oxidized cellulose nanofiber using Daphnia magna and Oryzias latipes. Cellulose 31:2207–2220

Currie LA (1968) Limits for qualitative detection and quantitative determination. Application to radiochemistry. Anal Chem 40:586–593

Noyes A, Godavarti R, Titchener-Hooker N, Coffman J, Mukhopadhyay T (2014) Quantitative high throughput analytics to support polysaccharide production process development. Vaccine 32:2819–2828

Yue F, Zhang J, Xu J, Niu T, Lü X, Liu M (2022) Effects of monosaccharide composition on quantitative analysis of total sugar content by phenol–sulfuric acid method. Front Nutr 9:963318

Zanchetta E, Damergi E, Patel B, Borgmeyer T, Pick H, Pulgarin A, Ludwig C (2021) Algal cellulose, production and potential use in plastics: challenges and opportunities. Algal Res 56:102288

Acknowledgements

Not applicable.

Funding

This study was based on results obtained from a project, JPNP20009, commissioned by the New Energy and Industrial Technology Development Organization (NEDO).

Author information

Authors and Affiliations

Contributions

TM: conceptualization, performing the experiments, data analysis, interpretation of the data, discussion of the results, drafting the manuscript, writing—review and editing. RT: conceptualization, discussion of the results, writing—review and editing. HM: conceptualization, discussion of the results, writing—review and editing. IO: conceptualization, design of the work, performing the experiments, data analysis, interpretation of the data, discussion of the results, drafting the manuscript, writing—review and editing, project administration. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Matsuzawa, T., Tai, R., Mano, H. et al. Applicability of enzymatic and phenol–sulfuric acid methods for determination of cellulose nanofibers in ecotoxicity testing. J Wood Sci 70, 17 (2024). https://doi.org/10.1186/s10086-024-02131-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s10086-024-02131-7