Abstract

With the widespread application of the computer and microelectronic technology in the industry, digitization becomes the inevitable developing trend of the hydraulic technology. Digitization of the hydraulic components is critical in the digital hydraulic technology. High-speed on-off valves (HSVs) which convert a train of input pulses into the fast and accurate switching between the on and off states belong to widely used basic digital hydraulic elements. In some ways, the characteristics of the HSVs determine the performance of the digital hydraulic systems. This paper discusses the development of HSVs and their applications. First, the HSVs with innovative structures which is classified into direct drive valves and pilot operated valves are discussed, with the emphasis on their performance. Then, an overview of HSVs with intelligent materials is presented with considering of the switching frequency and flow capacity. Finally, the applications of the HSVs are reviewed, including digital hydraulic components with the integration of the HSVs and digital hydraulic systems controlled by the HSVs.

Similar content being viewed by others

1 Introduction

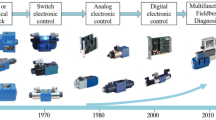

Hydraulic technology which generates, transmits, and controls the power with pressurized liquids has advantages of high power density, large output force and easy linear motion [1]. It plays an irreplaceable role in many fields, such as construction machinery, machine tool industry, mining engineering, and so on [2,3,4]. With the widespread application of the computer and microelectronic technology in the industry, digitization which is essential to the intelligent control becomes the inevitable developing trend of the hydraulic technology. Digital hydraulic technology means that hydraulic components driven by the digital signals are used to control the system output [5].

High-speed on-off valves (HSVs) belong to typical digital hydraulic valves, in which a train of input pulses convert into the fast and accurate switching between the on and off states. They can interface with a computer directly and control the flow by the digital signals flexibly with no need for the digital-to-analog converters [6]. The HSVs have advantages of simple structure, high reliability and high fast response. In addition, when the HSVs working, the orifice is fully opened or fully closed most of the time as the switching time is very short. This feature makes the HSVs work with small throttling loss, high energy efficiency and high robustness against oil contamination. Consequently, HSVs have become the mainstream of the digital valves and development of the HSVs has drawn considerable attention.

The inherent advantages enable the HSVs to be readily applied in the digital hydraulic technology. The HSVs can be applied in two ways: digital hydraulic components with the integration of the HSVs and digital hydraulic systems controlled by the HSVs. In the digital hydraulic technology, digital hydraulic components are obviously necessary to achieve their objects. The integration of the HSVs offers a method for the construction of digital proportional valves, pumps and actuators [7]. Hydraulic systems controlled by the HSVs obviously promise high energy efficiency and control flexibility. Thus the application of the HSVs has become an important research branch in the digital hydraulic technology.

Given their advantages and importance in the digital hydraulic technology, this paper discusses the development of HSVs and their applications. First, the HSVs with innovative structures which is classified into direct drive valves and pilot operated valves are discussed, with the emphasis on their performance. Then, an overview of HSVs with intelligent materials is presented with considering of the switching frequency and flow capacity. Finally, the applications of the HSVs are reviewed, including digital hydraulic components with the integration of the HSVs and digital hydraulic systems controlled by the HSVs.

2 HSV with Innovative Structure

HSVs are the key components in the digital hydraulic technology and their characteristics greatly impact the performance of the digital hydraulic systems. Thus, developing a well-performing HSV with fast switching frequency, large flow and miniature size is critical to the digital hydraulic technology. In a HSV, the on and off states are controlled by the movement of the moving part driven by the electromechanical converter. Valve structure is obviously an important consideration in the development of the HSVs.

2.1 Direct Drive HSV

Figure 1 shows a 3/2 ball valve with a threaded cartridge structure developed by Honglin Machinery in the 1990s [8]. The spin with two balls driven by the solenoid serve as the moving part to alternate the flow path. The armature is restored by the hydraulic pressure instead of spring force so that the fatigue damage of the restoring spring can be avoided and the service life runs up to 2109 cycles according to the durability test. The opening time is 3.5 ms or less and the closing time is 2.5 ms or less with a repeated accuracy of ± 0.05 ms. However, due to impact of the flow forces, the forces acting on the balls are un-balanced and the orifice is limited to a rather small size. The maximum flow rate is 9 L/min at a rated pressure of 20 MPa. To improve the response speed of this valve, Kong et al. replaced the single coil with the parallel coils [9]. When at the same ampere-turns, the opening time reduces from 15 ms to 1.16 ms and the closing time decreases from 1.54 ms to 1.3 ms. Zhang et al. investigated the effect of supply pressure on the switching time of this valve and proposed self-correcting pulse-width modulation control algorithm to counteract the effect [10,11,12]. When the supply pressure increases from 4 MPa to 20 MPa, the switching time variation can be limited within 0.3 ms.

Manhartsgruber designed a 3/2 spool valve with a plate-style armature in 2006 [13]. As shown in Figure 2, with the custom-built accumulators integrated in the valve, the fluid in the chamber at the top and bottom of the spool generate hydraulic springs due to the fluid compressibility. The hydraulic springs and spool mass form a spring-mass system with a natural frequency of 400 Hz. The solenoid with a large circular plate used as the armature conducts the resonant excitation at the natural frequency and the small plate deformation produces the restoring force. The hydraulic connection is switched with the spool vibration and the duty cycle corresponding to the spool vibration bias can be adjusted by the pressure in the chamber at the top of the spool. With resonant excitation, the valve driven by an excitation actuator can work with high energy efficiency by kinetic energy recuperation. However, because of the extreme eddy-current damping, the spool vibration amplitude is confined to 0.5 mm the flow rate is about 30 L/min or less at a pressure drop of 0.5 MPa.

In 2007, Tu et al. provided a self-spinning 3/2 rotary valve [14]. As shown in Figure 3(a), with the helical inlet turbine blades, the flow force acting on the tangential direction of the spool is transformed into the torque and drives the spool spin. It can be seen from Figure 3(b) that when the spool spins, the inlet turbine continuously switch the flow direction between the tank and application. The duty cycle is controlled by the spool axial displacement which determines the orifice area ratio between the two hydraulic paths per rotation. The valve can reach a switching frequency of 84 Hz with a flow rate of 40 L/min at a pressure drop of 0.62 MPa [15]. With the flow force utilization, there is no need of dedicated actuator to spin the spool. This feature leads to a simplified structure. However, due to the rotation speed fluctuation caused by the fluid compressibility and viscosity, it is difficult to control the switching frequency and flow rate accurately [16, 17].

Figure 4 shows a disc-style 3/2 rotary valve proposed by Katz in 2008 [18]. It can be seen from Figure 4(a) that there are two motors needed in the valve: one is used to rotate the valve plate continuously and the other is applied to change the phase angle between the two tiers intermittently. As shown in Figure 4(b), the flow path is alternated with the valve plate rotation and the switching is double the rotation frequency. The duty cycle determined by the phase angle between the two tiers. The valve is able to reach a flow rate of 10 L/min at a pressure drop of 0.5 MPa [19]. The disc-style structure can offer ad-vantages of loose manufacturing tolerance and no centrifugal effect. Whereas, because of the actuator limitation, the maximum switching frequency is only 64 Hz [20].

Gu et al. developed a moving-sleeve type 2/2 poppet valve in 2013 [21]. As shown in Figure 5, to reduce the driving force, a thin-walled sleeve is applied as the moving part to switch the hydraulic connection while the poppet is fixed on the valve body. The valve can achieve an opening time of 2.25 ms and a closing time of 2.15 ms with a flow rate of 60 L/min at a pressure drop of 1 MPa. However, due to the effect of the steady flow force, the relationship between the flow rate and the duty ratio is irregular and nonlinear when the switching frequency is higher than 50 Hz. This disadvantage make it difficult to control the flow rate precisely at a relatively high switching frequency.

In 2016, Messner et al. designed a 2/2 ball valve with a fast actuator derived from the fuel injection technology [22]. As shown in Figure 6, the actuator is borrowed from the samples applied in the common rail injection systems. The ball is utilized to seal the hydraulic path with mechanical contact with the valve seat. To meet the requirements for the hydraulic do-main, a ball type valve seat is designed to reduce the leakage and the actuator is separated from the high pressure chamber. The valve can reach a switching frequency of 1 kHz. However, due to the compact construction, the stroke is limited to 0.05 mm and the flow rate is only 0.2 L/min at a pressure drop of 0.5 MPa.

In 2016, Noergaard et al. developed a 2/2 moving-coil actuated valve shown in Figure 7(a) [23]. The plunger fixed with the coil serve as the moving part, which is driven by the Lorentz force acting on the energized coil in the magnetic field generated by the permanent magnet. When the plunger contacts with the valve seat, the hydraulic path is cut off. A spring is used to keep the valve open normally. Due to the permanent magnet, the actuator can drive the plunger with higher energy efficiency compared to the solenoid [24]. However, the electrical connection related to the coil must be robust and durable because the coil is immersed in the oil with fluctuant high pressure. This leads to a disadvantage of complex structure in the electrical interface. According to the experimental test, the moving-coil actuated valve achieve a switching time of 3 ms with a flow rate of 120 L/min at a pressure drop of 0.18 MPa [25].

To simplify the structure, Madsen et al. designed a moving-magnet actuated valve in 2017 [26]. As shown in Figure 7(b), the restoring spring is needless in this valve. The plunger fixed with the permanent magnet is driven by the magnetic force between the permanent magnet and electromagnet formed by the energized coil. The permanent magnet move with the plunge while the coil remain stationary. Hence, the coil does not sustain the fatigue stress and the complex electrical interface can be omitted. Whereas, there is a disadvantage of long switching time due to the heavy moving part caused by the permanent magnet. The moving-magnet actuated valve has a long switching time of 5.7 ms and the flow rate is 142 L/min at a pressure drop of 0.11 MPa [27]. Moreover, in the two seat valves, there is a common risk of the permanent magnet demagnetization caused by the mechanical impact between the plunger and the valve seat. To solve this problem, the structure of the plunger or valve seat need to be optimized [28].

In 2017, Liu et al. designed a 2/2 poppet valve driven by a voice coil motor [29]. As shown in Figure 8, the valve is com-posed of a voice coil motor and a valve structure. The moving part in the voice coil motor and the poppet are connected with screw threads. The piston and the poppet are impacted with the lock nut to balance the hydraulic pressure at the top of the poppet and reduce the needed driving force. Due to its large orifice diameter, this valve can reach a flow rate of 100 L/min at a supply pressure of 8 MPa and a stroke of 1 mm. Whereas, there is a long delay in the valve. The opening time is about 7 ms and the closing time is about 9 ms. To improve the dynamic performance, the poppet diameter, orifice diameter and cone angle need to be optimized [30].

Figure 9 shows a miniature 2/2 poppet valve with a magnetic ring provided by Yang et al. in 2018 [31]. A ring with magnetic material put in the valve is applied to decrease the reluctance loss. To enhance the magnetic flux, the restoring spring with proper stiffness is mounted on the top of the coil. With the electromagnetic configuration design, the actuator can out-put large driving force with a small size. The valve is able to achieve a switching time of 1.5 ms with a length of 36 mm and a diameter of 12 mm. Whereas, the small size limits the orifice diameter to 0.5 mm and the flow rate is only 0.7 L/min at a pressure drop of 3.5 MPa [32].

Koktavy et al. provided a crank-slider 3/2 spool valve in 2018 [33]. As shown in Figure 10, two spools actuated by the crank-shaft serve as the slider in the crank-slider mechanism. The spool 1 is used to switch the flow path and the switching frequency is controlled by the crank-shaft rotation speed. The spool 2 is used to adjust the duty ratio by changing the phase angle between the two crank-arms. The valve can achieve a 22.7 L/min flow rate at a 0.69 MPa pressure drop with a 120 Hz switching frequency. The crank-slider mechanism can provide an advantage of efficient actuation with non-constant spool speed. In the transition stage, high speed can decrease the throttling loss while in the other stage, low speed can reduce the viscous friction loss. Whereas the crank-slider mechanism brings potential problems of heavy structure and large size.

The summary of the direct drive HSVs with innovative structures is shown in Table 1. Ball valves can only be used in the small flow rate conditions because the forces acting on the ball are unbalanced. Due to the heavy moving part, seat valves are only suitable for the conditions in which the requirement of the response speed is not very high. In the rotary valve, the switching frequency is limited to a low range by the performance of the actuators. Poppet valves and spool valve can be constructed with high switching frequency or large flow rate.

In the direct drive HSVs, the moving part is driven by the electromechanical converter directly. When the design flow increases, the actuator dimension increases significantly while to achieve fast switching frequency, the valve has to be made with light weight and small size. Thus there is a contradiction between high switching frequency and large flow rate. For example, the poppet valve developed by Messner et al. can reach a switching frequency of 1 kHz while the flow rate is only 0.2 L/min [22]. Conversely, the seat valve designed by Noergaard et al. can achieve a flow rate of 142 L/min while the switching time is limited to 5.7 ms [26].

2.2 Pilot Operated HSV

Figure 11 shows a multi-poppet 2/2 valve developed by Winkler et al. in 2010 [34]. It can be seen from Figure 11(a) that the pilot valve is a 3/2 spool valve driven by a solenoid. As shown in Figure 11(b), when the pilot valve controlled by the pulse width modulation, the control pressure above the poppet alternate between the supply pressure and the tank pressure while the pressure under the poppet is always equal to the supply pressure. Driven by the control pressure and the supply pressure, the poppet can connect or disconnect the hydraulic path. Multiple poppets shown in Figure 11(c) are applied to enhance the flow rate. A ring put between the spring and the poppets is used to ensure that the all the poppets move synchronously. The valve can reach a flow rate of 85 L/min at a pressure difference of 0.5 MPa with a switching time of 1 ms. In 2014, Lantela et al. designed a pilot operated miniature 2/2 valve with the same working principle shown in Figure 12 [35]. A 3/2 spool valve is applied as the pilot stage and a 2/2 ball valve is used as the main stage. The ball is driven by the pressure difference between the supply pressure and the tank pressure. The valve can achieve a 1 ms switching time and a 9 L/min flow rate at a 3.5 MPa pressure drop with a volume of 4 cm3.

In 2012, Johnston et al. provided a three-stage 3/2 spool valve [36]. The valve is composed of an actuation module and a main stage. As shown in Figure 13(a), the actuation module can be subdivided into two stage: the servo valve produced by Moog with a model number of E050-899 serve as the first stage and a cylinder actuator with equal areas serve as the second stage. The screwed end of the piston is threaded into the spool in the main stage. As shown in Figure 13(b), the flow path is switched by the spool oscillation driven by the actuation module. To enhance the flow capacity, multiple grooves are machined on the spool and each valve port has four orifices. Sell et al. provided the control strategy of this valve and tested the performance of the valve [37, 38]. The results show that the valve can reach a 0.5 ms switching time and the flow rate is 50 L/min at a pressure drop of 1 MPa.

Figure 14 shows a two-dimensional 3/2 valve proposed by Jia et al. in 2016 [39]. As shown in Figure 14(a), the valve is actuated by a rotary solenoid. The shift fork is applied to drive the spool rotation by amplifying the torque and displacement output by the rotary solenoid. As shown in Figure 14(b), the fluid with high pressure is always directed into the chamber at the right of the spool. A servo spiral mechanism is used to transform the spool rotation angle into the spool displacement along the axis and alternate the hydraulic path by directing the fluid with supply pressure or tank pressure into the chamber at the at left of the spool. The valve can reach a flow rate of 60 L/min at a pressure drop of 3.5 MPa. With the optimal deigns of actuator and valve structure, the switching time reduces from 18 ms to 8 ms [40]. However, the switching time is still relatively long compared to its counterpart.

The summary of the pilot operated HSVs with innovative structures are shown in Table 2. Compared to the direct drive valves listed in Table 1, the pilot operated valves can ease the contradiction between the high flow rate and fast switching frequency. For example, the valve with good performance developed by Winkler et al. can reach a switching time of 1 ms and a flow rate of 85 L/min [34]. In the pilot operated valves, main stage is driven by the hydraulic pressure. Due to the high power density of the hydraulic transmission, the pilot operated valves have a stronger flow capacity than the direct drive valves with similar size. For example, the valve designed by Lantela et al. can achieve a flow rate of 9 L/min with a 4 cm3 volume [35].

3 HSV with Intelligent Material

Intelligent materials can change their shapes or physical properties rapidly by perceiving the external excitation including electric field and magnetic field. This feature provides a possibility for the actuator construction with intelligent materials in the HSVs. This section discusses the HSVs with intelligent materials including their merits and demerits.

Figure 15 shows a 2/2 poppet valve with two multilayered piezoelectric actuator developed by Yokota et al. in 1991 [41]. The slider is utilized to adjust the zero position of the poppet. On both sides of the poppet, two piezoelectric elements are applied to push or pull the poppet directly with a maximum force of 850 N at a voltage of 100 V and the flow path is switched with the poppet movement. The switching frequency can reach 2 kHz and the switching time is less than 0.07 ms. Because there is no displacement amplifier in this valve, the stroke is limited to 0.015 mm. The flow capacity of the valve is not mentioned by the authors. But it can be infer that the flow rate is rather small according to the stroke. Lu et al. designed a 3/2 poppet valve with similar structure in 2002 [42]. With the optimal design of the energizing circuit, this valve can reach a flow rate of 8 L/min at a supply pressure of 10 MPa and a stroke of 0.03 mm. The opening time is about 1.2 ms and the closing time is about 1.7 ms.

Shi et al. designed a 3/2 poppet valve with two giant magnetostrictive actuators in 2003 [43]. As shown in Figure 16, the displacement output by the actuator is 0.035 mm. The poppet and sleeve are both driven by the actuator and the displacement can be amplified to 0.288 mm by utilizing the lever. With the relative motion between the poppet and sleeve, the hydraulic connection switches and the stroke is enlarged to 0.576 mm with an opening time of 1.4 ms and a closing time of 1.8 ms. Although with the design for enlarging the stroke, the flow rate of is still rather small. The valve can achieve a flow rate of 1.24 L/min at a supply pressure of 5 MPa [44, 45].

In 2008, Jiang et al. provided a 2/2 poppet valve with two piezoelectric actuators [46]. As shown in Figure 17, the fluid with load pressure or tank pressure into the chamber is alternately directed into the control chamber with the poppet movement. The difference between the pressure in the control chamber and the load pressure is utilized to help the poppet move and enlarge the stroke. The dampers are applied to stop the poppet. With the help of the hydraulic pressure, the inherent disadvantage of small displacement in the piezoelectric material can be overcome and the valve can work without the displacement amplifier [47]. This leads to a simple structure. The valve can achieve a switching frequency of 250 Hz with a stroke of 0.7 mm and the flow rate is 15 L/min at a supply pressure of 20 MPa.

Mo designed a 2/2 pilot valve with magnetorheological fluid in 2012 [48]. As shown in Figure 18, the magnetorheological fluid has a feature of high viscosity in a strong magnetic field. The pressure above the poppet in the main stage alternate between the supply pressure and the tank pressure when the pilot valve controlled by the pulse width modulation while the pressure under the poppet is always equal to the supply pressure. Due to the pressure difference, the poppet oscillate to switch the hydraulic path. The valve has an advantage of large flow rate due to the relatively large stroke. It can achieve a flow rate of 60 L/min at a supply pressure of 6 MPa and a stroke of 3 mm. However, the large stroke slows down the response speed and the switching time is limited to 9 ms [48].

In 2013, Ma provided a 2/2 poppet valve with a giant magnetostrictive actuator [49]. As shown in Figure 19, with the optimal design of the poppet sectional area, the hydraulic pressures acting on the poppet can be self-balancing. This feature can help to improve the energy efficiency because the hydraulic pressure does not resist the poppet movement. There is no displacement amplifier in this valve. Instead, a poppet with multiple orifices is applied to overcome the disadvantage of small output displacement in the giant magnetostrictive actuator and achieve a relatively high flow rate at a small stroke. The flow rate is about 21 L/min at a supply pressure of 20 MPa and a stroke of 0.05 mm. The opening time is about 1.7 ms and the closing time is about 1.9 ms.

Figure 20 shows a 3/2 poppet valve with shape memory alloy proposed by Qin et al. in 2014 [50]. The two actuators with shape memory are mounted at both side of the valve. The shape memory alloy magnetically controlled by the solenoid and the poppet is directly driven by the force generated by the shape change. With the differential action, the poppet moves along the sleeve at a driven force of 100 N and the hydraulic path is alternated with the poppet movement. Compared to the magnetostrictive material and giant magnetostrictive material, the actuator with shape memory alloy can output a relatively large displacement. Without the displacement amplification, the valve can reach a stroke of 0.8 mm with a switching time of 1 ms and the flow rate is 10 L/min at a pressure drop of 0.5 MPa [51].

The summary of the HSVs with intelligent materials are shown in Table 3. Compared with the HSVs driven by the solenoid, the HSVs with piezoelectric material and giant magnetostrictive material can reach high switching frequency. For example, the valve with piezoelectric material developed by Yokota et al. can reach a switching frequency of 2 kHz [41]. However, the output displacement of the actuator with piezoelectric material and giant magnetostrictive material is rather small. Displacement amplifier or multiple-orifice poppet can enlarge the stroke and flow rate at the expense of response speed and output force. The shape memory alloy can output a relatively large stroke compared to the piezoelectric material and giant magnetostrictive material. Whereas, an external force is needed to restore the deformation and the flow rate is limited by the small output force. The valve with magnetorheological fluid can reach a relatively large flow rate with a simple structure. However, the response speed is slow due to the large stroke. Similarly to the HSVs with innovative structures, HSVs with intelligent materials also have the contradiction between the high switching frequency and large flow rate. Further analysis need to be performed to ease this contradiction.

4 Digital Hydraulic Component with HSV

The HSVs evidently have a disadvantage of discrete output flow while continuous flow is usually needed in the hydraulic systems to control the velocity, displacement or force accurately. Consequently, digital proportional valves are indispensable in the digital hydraulic technology. Obviously, besides the valves, digitization of pumps and actuators is also essential to control the hydraulic systems with digital signal. Integration of the HSV is an effective method for the digital hydraulic component construction and has been put into practice.

4.1 Digital Proportional Valve

In 2014, Paloniitty et al. developed a digital flow control unit with multiple direct drive HSVs [52]. As shown in Figure 21, there are 16 miniature HSVs integrated and the flow rate is determined by the number of open valves. It can reach a flow rate of about 25 L/min at a pressure drop of 3.5 MPa and the switching time is less than 4 ms [53]. To improve the flow rate resolution, a new digital flow control unit with 64 miniature HSVs are provided by Linjama et al. in 2015 [54]. As shown in Figure 22, to enlarge the flow rate, Lantela et al. developed a valve system integrated with 32 miniature pilot operated valves in 2017 [55]. The miniature valve is designed with different flow capacities to achieve different flow rates. This valve system can reach a flow rate of 78 L/min at a pressure drop of 3.5 MPa and the switching time is less than 2 ms. Compared to the traditional proportional valves, the valve system has advantages of smaller size and better fault tolerance. Whereas, due to the rather narrow flow path, the digital flow control unit high rely on the advanced technology, such as plate lamination technology and 3D printing technology.

As shown in Figure 23, Sauer-Danfoss developed a series of proportional multiple valves, in which the HSVs are utilized to form the pilot stage. There are two types of pilot stages adapted to the main valve. In the pilot stage shown in Figure 23(a), four 2/2 HSVs form a hydraulic full-bridge. The pressure in the chambers at both sides of the spool is regulated by the flow rate through the bridge arm which is determined by the duty cycle of the HSVs. In the pilot stage shown in Figure 23(b), two 3/2 HSVs are used to control the pressure in the chamber at both sides of the spool by adjusting the duty cycle, respectively. Then the spool displacement is controlled by the duty cycle of the four HSVs. Parker also produced proportional multiple valves with the same working principle shown in Figure 23(b). When used as the pilot stage, the HSV can control a flow rate which is much larger than its flow capacity. The flow capacity of the proportional multiple valve can reach 500 L/min while the flow rate through the pilot stage is only 0.7 L/min at a switching frequency of higher than 100 Hz. However, this valve is a proportional throttle valve and its flow rate is susceptible to the load change. Extra pressure compensator is needed to control the flow rate precisely.

In 2015, Li et al. proposed a digital Valvistor valve with a single HSV used as the pilot stage shown in Figure 24 [56]. In this valve, the poppet in the main valve is controlled by the displacement-flow feedback and the large main flow is proportional to the small pilot flow. This valve is named as the Valvistor valve because its flow amplification characteristic is very similar to the electronic transistor. At a pressure drop of 3 MPa, the pilot flow is 1.6 L/min with a switching frequency of 100 Hz and the main flow is 80 L/min [57]. The valve has a disadvantage of flow fluctuation due to the discrete flow output by the pilot valve. Further analysis need to be performed to solve the problem. Moreover, this valve is also classified to the proportional throttle valve and the load change has a great effect on its flow rate [58, 59].

4.2 Digital Pump

Virtually variable displacement pumps have been proposed to supply different flow rates with a fixed displacement pump controlled by a HSV [60,61,62]. The flow rate to the load depends on the duty cycle of the HSV. They have an obvious advantage of universality because there are various fixed displacement pump with compact structure and low cost. However, the flow rate to the load is pulsatile due to the discrete value output by the HSV [62]. The flow rate stability highly rely on the switching frequency. High-performance HSV is needed in the virtually variable displacement pumps to achieve a relatively steady flow rate [63]. Moreover, because of the fluid compressibility and throttling, large energy is lost in the transition stage of the HSV [64]. To reduce the energy losses, soft switching approach to provide temporary hydraulic path alternation in the transition stage. As shown in Figure 25, a soft switching mechanism is used to absorb the fluid when the orifice in the HSV is partially opened and release the fluid when the orifice in the HSV is fully opened. Thus, only when the HSV is fully opened, the fluid can flow through the HSV with high efficiency [65, 66]. With the soft switching approach, the energy losses in the transition stage can be reduced by about 66% [67].

Artemis Intelligent Power and Sauer-Danfoss developed an HSV controlled radial piston pump with six cylinders [68]. As shown in Figure 26, it utilizes a radial piston machine which enables and disables cylinders in real time. When in the pump idling state, the low-pressure valves above the cylinders are open and oil moves into and out of the cylinders at low pressure. When in the working state, the low-pressure valve above each cylinder closes as its respective piston reaches bottom-dead-center. This initiates the pumping stroke and the high-pressure valve opens to deliver oil to the external circuit. The pump has advantages of low energy losses, fast response and high-frequency noise elimination [69]. From the idle state, full flow can be achieved within 30 ms independently of working pressure [70]. It can reduce energy losses by approximately 90% in comparison to a similarly sized axial piston pump [71]. Shi et al. investigated the flow rate control in the digital pumps with the similar working principle and provided a radial piston pump with constant flow [72,73,74]. There are five cylinders in the pumps and each cylinder is controlled by one 3/2 HSV. To achieve nearly constant flow rate under a random rotation speed, a controller is utilized to adjust the duty cycle of the HSV based on the rotation speed in real time and a novel optimal fluctuation regulation method is provided to minimize the flow fluctuation [75, 76].

As shown in Figure 27, controlling the swashplate angle with the HSV is another way to construct a digital variable displacement pump, in which the pump displacement is determined by the duty cycle of the HSV [77,78,79]. Zhang et al. designed a controller to achieve constant flow, constant pressure or constant power [80,81,82]. In the controller, according to the swashplate angle and supply pressure, the flow rate and power can be calculated and compared with the desired value with the closed-loop control strategy. Then the control signal is generated and input into the HSV to adjust the duty cycle. To control the large flow rate precisely, Wang et al. provided a control strategy which take advantage of large flow rate in the rotation speed control with variable frequency motor and high accuracy in the swashplate angle control with high-speed on-off valve [83]. This type of pump has been put into industrial practice. Hitachi put a pump with the HSV controlled swashplate into the excavator to improve the energy efficiency and operating performance [84].

4.3 Digital Actuator

Linjama et al. developed a multi-chamber cylinder controlled by the HSVs in 2009 [85]. As shown in Figure 28, there are three chambers in the cylinder and each chamber is connected with two discrete pressure sources. The cylinder can achieve different static and dynamic characteristics by changing the valve combination. For example, the cylinder can output eight discrete forces with different valve combinations. The performance of the multi-chamber cylinder depends on the number of cylinder chambers and supply pressures. Due to the structure limitation, there are at most four chambers in the cylinder. Consequently, increasing the number of supply pressures is the key to improve the performance of the multi-chamber.

Figure 29 shows a stepper cylinder designed by Plöckinger et al. in 2016 [86]. The master cylinder is controlled by a stepper unit. The operation modes including stepper up and stepper down is controlled by the 3/2 HSV V3. In the step up mode, the supply pressure is directed to the stepper unit. The piston in the slave cylinder I moves up when the HSV V1 opens. The fluid flows into the master cylinder from the slave cylinder I and leads to an accurate piston displacement in the master cylinder. When the piston in the slave cylinder I reaches the top position, the HSV V1 closes and the HSV V2 opens. The spring restores the piston in the slave cylinder I to the initial position. At this time, the piston in the master cylinder remain stationary, because the fluid in the bottom chamber of the slave cylinder I is supplied to the top chamber. The working process in the stepper down mode is similar to the stepper up mode. The stepper cylinder with an open loop control can achieve precise motion without displacement sensors.

Similarly to the digital radial piston pumps, as shown in Figure 30, the HSVs are used to control the cylinders in the digital radial piston motors [87]. Each cylinder is operated by two 2/2 HSVs connected to the high pressure and low pressure, respectively. The HSV connected to the low pressure opens as its respective piston reaches the bottom dead center while the HSV connected to the high pressure opens as its respective piston reaches the top dead center. This can drive the crank shaft rotate. Shi et al. replaced the two 2/2 HSVs with one 3/2 HSV and developed a motor with low rotation speed and high output torque [88, 89]. They studied the factors that influence the rotation speed. Constant rotation speed can be achieved by adjusting the duty cycle based on the rotation speed in real time [90,91,92].To improve the energy efficiency, Roemer et al. closes the HSV connected to the low pressure before the piston reaches the top dead center to obtain a high pressure with the closed chamber before the HSV connected to the high pressure opens [93]. Nordas et al. reduced the throttling loss and enhanced the machine efficiency by improving the accuracy and repeatability of the HSV [94].

Digital hydraulic components with HSVs can work with high energy efficiency. For example, compared to a similarly sized axial piston pump, the digital pump controlled by HSVs can reduce energy losses by approximately 90% [71]. In the digital hydraulic components, HSVs are usually used as the control valve which direct a small flow rate to operate the machine and the disadvantage of discrete flow can be overcome. For example, in the digital Valvistor valve, the pilot HSV with a flow rate of 1.6 L/min is able to control the main valve with a flow rate of 80 L/min [57]. The response speed has great impact on the performance of the digital hydraulic components. Thus, compared to the flow rate, the switching frequency gets more attention in the HSVs and become the trend in the future. Fast response and miniature structure can be achieved at the expense of flow rate since the contradiction between high switching frequency and large flow rate cannot be overcome.

5 Digital Hydraulic System Controlled by HSV

Unlike the conventional valve controlled hydraulic systems, which are used for precise control with throttling, digital hydraulic systems have the potential to be more cost-efficient, robust, and less sensitive to contamination. Digital hydraulic system controlled by HSV shows a broad application prospect and has become an important research field (Table 4).

As shown in Figure 31, Linjama et al. developed a separate meter-in and separate meter-out control system [95]. Pulse code modulation is used to control all four flow path independently with parallel connected HSVs. The flow capacities of the HSVs are set according to the binary sequence. Each flow path is controlled by a parallel-connected HSV series with five HSVs, which can provide 25 discrete opening values. The separate meter-in and separate meter-out control system can give freedom to control independently velocity and pressure level of the actuator, which can be utilized in energy saving by minimizing pressure losses [96].

Figure 32 shows a switched inertance hydraulic system provided by Manhartsgruber et al. [97]. It consist of a 2/2 HSV and a check valve. The check valve arranged in the return line is used to prevent the oil from flowing back. When the HSV is opened, the oil with high velocity flows from the pump to the load. When the HSV is closed, the oil drawn by the fluid momentum still flows from the reservoir to the load despite the adverse pressure gradient. Thus the average flow is significantly higher than the supply flow. Compared with conventional valve controlled hydraulic systems, the switched inertance hydraulic system can achieve higher energy efficiency, it has the potential to reach a energy efficiency of 100%.

Figure 33 shows a speed control system for hydraulic motor proposed by Qiu et al. [98]. HSV is used as the pilot valve of the cartridge valve. When the electromagnet is energized, the cartridge valve is opened and the fluid flow to the tank through the cartridge valve. When the electromagnet is de-energized, the cartridge valve is closed and the fluid flow to the tank through the motor. The flow through the motor can be adjusted by changing the duty cycle of the HSV. With the HSV, this system not only achieve high response speed, but also can avoid the overflow.

In the hydraulic systems, the actuators are usually need to be controlled continuously while the output flow of the HSVs is discrete. To overcome the disadvantages of the HSVs, researchers connected the HSVs in parallel or used the HSVs as the pilot valve to control the actuators continuously.

6 Conclusions

With the widespread application of the computer and microelectronic technology in the industry, digitization becomes the inevitable developing trend of the hydraulic technology. Digitization of the hydraulic components is critical in the digital hydraulic technology. High-speed on-off valves which convert a train of input pulses into the fast and accurate switching between the on and off states belong to widely used basic digital hydraulic elements. In some ways, the characteristics of the HSVs determine the performance of the digital hydraulic systems. This paper discusses the development of HSVs and their applications.

Although numerous structures have been developed to improve the performance of the HSVs, there is still a contradiction between high switching frequency and large flow rate, especially in the direct drive HSVs. The pilot operated HSVs can ease this contradiction and achieve a relatively high flow rate with a miniature structure. Compared with the HSVs driven by the solenoid, the HSVs with intelligent materials can reach high switching frequency while the flow rate is rather small due to the tiny stroke, although with the displacement amplifier.

In the digital hydraulic components including digital proportional valves, pumps, and actuators, HSVs are usually used as the control valve which direct a small flow rate to operate the machine and the disadvantage of discrete flow can be overcome. In the hydraulic systems, the actuators are usually need to be controlled continuously while the output flow of the HSVs is discrete. To overcome the disadvantages of the HSVs, researchers connected the HSVs in parallel or used the HSVs as the pilot valve to control the actuators continuously. The response speed has great impact on the performance of the digital hydraulic components and digital hydraulic systems. Thus, compared to the flow rate, the switching frequency gets more attention in the HSVs and become the trend in the future. Fast response and miniature structure can be achieved at the expense of flow rate since the contradiction between high switching frequency and large flow rate cannot be overcome.

References

N D Manring. Hydraulic control systems. John Wiley & Sons, 2005.

J Tao, J Lei, C Liu, et al. Nonlinear static and dynamic stiffness characteristics of support hydraulic system of TBM. Chinese Journal of Mechanical Engineering, 2019, 32: 101.

Y Liu, J Zheng, R Song, et al. Simple push-type wave generating method using digital rotary valve control. Chinese Journal of Mechanical Engineering, 2020, 33: 5.

J Zhang, Y Deng, N Zhang, et al. Vibration performance analysis of a mining vehicle with bounce and pitch tuned hydraulically interconnected suspension. Chinese Journal of Mechanical Engineering, 2019, 32: 5.

M Linjama. Digital fluid power – state of the art. The Twelfth Scandinavian International Conference on Fluid Power, 2011.

B Xu, J Shen, S Liu, et al. Research and development of electro‑hydraulic control valves oriented to industry 4.0: A review. Chinese Journal of Mechanical Engineering, 2020, 33: 29.

B Winkler. Recent advances in digital hydraulic components and applications. The Ninth Workshop on Digital Fluid Power, 2017.

J Yu, X Han, Y Zhang, et al. Application of high speed digital control solenoid valves in the electronic control of diesel engines. Journal of Beijing Institute of Technology, 1994, 14(1): 91–95. (in Chinese)

X Kong, S Li. Dynamic performance of high speed solenoid valve with parallel coils. Chinese Journal of Mechanical Engineering, 2014, 27(4): 816–821.

S Wang, B Zhang, Q Zhong, et al. Study on control performance of pilot high-speed switching valve. Advances in Mechanical Engineering, 2017, 9(7): 1–8.

Q Zhong, B Zhang, H Yang, et al. Performance analysis of a high-speed on/off valve based on an intelligent pulse-width modulation control. Advances in Mechanical Engineering, 2017, 9(11): 1–11.

B Zhang, Q Zhong, J Ma, et al. Self-correcting PWM control for dynamic performance preservation in high speed on/off vale. Mechatronics, 2018, 55: 141–150.

B Manhartsgruber. A hydraulic control valve for PWM actuation at 400 Hz. Power Transmission and Motion Control, 2006: 373–385.

H C Tu, M B Rannow, J D Van de Ven, et al. High speed rotary pulse width modulated on/off valve. 2007 ASME International Mechanical Engineering Congress and Exposition, 2007: IMECE2007-42559.

H C Tu, M B Rannow, M Wang, et al. High speed rotary pulse width modulated on/off valve. Proceedings of the ASME 2009 Dynamic Systems and Control Conference, 2009: DSCC2009-2763.

H C Tu, M B Rannow, M Wang, et al. Design, modeling, and validation of a high-speed rotary pulse-width-modulation on/off hydraulic valve. Journal of Dynamic Systems, Measurement, and Control – Transactions of the ASME, 2012, 134: 061002.

H C Tu. High speed rotary PWM on/off valves for digital control of hydraulic pumps and motors. Minneapolis: University of Minnesota Twin Cities, 2014.

A A Katz. Design of a high speed hydraulic on/off valve. Worcester: Worcester Polytechnic Institute, 2008.

A A Katz, J D Van de Ven. Design of a high-speed on-off valve. Proceedings of the ASME 2009 International Mechanical Engineering Congress & Exposition, 2009: IMECE2009-11189.

J D Van de Ven, A A Katz. Phase-shift high-speed valve for switch-mode control. Journal of Dynamic Systems, Measurement, and Control – Transactions of the ASME, 2011, 133: 011003.

L Gu, L Li, J Chen, et al. Development of a large flow-rate high speed on/off valve for underwater hydraulic ejection system. 2013 Oceans – San Diego, 2013: 1–5.

F Messner, R Scheidl. Development and experimental results of a small fast switching valve derived from fuel injection technology. Proceedings of the Eighth Workshop on Digital Fluid Power, 2016: 9–25.

C Noergaard, M M Bech, D B Roemer, et al. Optimization of moving coil actuators for digital displacement machines. Proceedings of the Eighth Workshop on Digital Fluid Power, 2016: 39–54.

C Noergaard, L Schmidt, M M Bech. A simple and robust sliding mode velocity observer for moving coil actuators in digital hydraulic valves. BATH/ASME 2016 Symposium on Fluid Power and Motion Control, 2016: FPMC2016-1789.

C Noergaard, M M Bech, J H Christensen, et al. Modeling and validation of moving coil actuated valve for digital displacement machines. IEEE Transactions on Industrial Electronics, 2018, 65(11): 8749–8757.

E L Madsen, J M T Jorgensen, C Noergaard, et al. Design optimization of moving magnet actuated valves for digital displacement machines. Proceedings of the ASME/BATH 2017 Symposium on Fluid Power and Motion Control, 2017: FPMC2017-4255.

C Noergaard, E L Madsen, J M T Jorgensen, et al. Test of a novel moving magnet actuated seat valve for digital displacement fluid power machines. IEEE/ASME Transactions on Mechatronics, 2018, 23(5): 2229–2239.

N C Bender, A Plöckinger, P Foschum, et al. Measurements of a novel digital hydraulic valve comprising a cushioning feature. Journal of Dynamic Systems, Measurement, and Control – Transactions of the ASME, 2020, 142: 011001.

X Liu, S Nie, G Li. Dynamic characteristics for the water hydraulic direct-driven high-speed on-off valve. Journal of Beijing University of Technology, 2017, 43(7): 1052–1059. (in Chinese)

X Li, S Nie, H Ji, et al. Dynamic Characteristics for the voice coil motor direct-driven high-speed on-off valve. Chinese Hydraulics & Pneumatics, 2020, (3): 37–44. (in Chinese)

M Yang, J Zhang, B Xu. Experimental study and simulation analysis on electromagnetic characteristics and dynamic response of a new miniature digital valve. Advances in Materials Science and Engineering, 2018: 1–8.

J Zhang, M Yang, B Xu. Design and experimental research of a miniature digital hydraulic valve. Micromachines, 2018, 9(6): 283.

S E Koktavy, A C Yudell, J D Van de Ven. Design of a crank-slider spool valve for switch-mode circuits with experimental validation. Journal of Dynamic Systems, Measurement, and Control – Transactions of the ASME, 2018, 140: 061008.

B Winkler, A Ploeckinger, R Scheidl. A novel piloted fast switching multi poppet valve. International Journal of Fluid Power, 2010, 11(3): 7–14.

T Lantela, J Kajaste, J Kostamo, et al. Pilot operated miniature valve with fast response and high flow capacity. International Journal of Fluid Power, 2014, 15(1): 11–18.

N Johnston, S Kudzma, A R Plummer, et al. A high flow fast switching valve for digital hydraulic systems. The Fifth Workshop on Digital Fluid Power, 2012: 175–187.

N P Sell, D N Johnston, A R Plummer. Control of a fast switching valve for digital hydraulics. The 13th Scandinavian International Conference on Fluid Power, 2013: 497–503.

N P Sell, D Johnston, A R Plummer, et al. Development of a position controlled digital hydraulic valve. Proceedings of the ASME/BATH 2015 Symposium on Fluid Power and Motion Control, 2015: FPMC2015-9514.

W Jia, J Ruan, S Li. Structure parameters optimization and experiments on 2D high-speed on-off valve. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(11): 391–398. (in Chinese)

H Jiang, J Ruan, S Li, et al. Design and experiment of 2D electrohydraulic high-speed on-off valve. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(2): 328–334. (in Chinese)

S Yokota, K Akutu. A fast-acting electro-hydraulic digital transducer: A poppet-type on-off valve using a multilayered piezoelectric device. JSME International Journal. Ser. 2, Fluids Engineering, Heat Transfer, Power, Combustion, Thermophysical Properties, 1991, 34(4): 489–495.

H Lu, C Zhu, S Zeng, et al. Study on the new kind of electro-hydraulic high-speed on-off valve driven by PZT components and its high-powerful and speedy technique. Chinese Journal of Mechanical Engineering, 2002, 38(8): 118–121. (in Chinese)

Y Shi, Y Zhang, C Liu. Design and study of a new kind of high speed on-off valve. China Mechanical Engineering, 2003, 14(21): 1824–1826. (in Chinese)

Y Shi. Study on giant magnetostrictive high speed hydraulic on-off valve. Chinese Hydraulics & Pneumatics, 2003, (1): 36–38. (in Chinese)

Y Shi, C Liu, Y Zhang. Design and study of a new kind of larger flow rate high-speed on-off valve. Journal of Mechanical Engineering, 2004, 40(4): 195–198. (in Chinese)

Y Jiang, X Ouyang, H Yang. Design and simulation of an innovative piezoelectric high speed on-off valve. Fluid Power Transmission and Control, 2008, (6): 16–19. (in Chinese)

X Ouyang, H Yang, Y Jiang, et al. Simulation of the piezoelectric high-speed on/off valve. Chinese Science Bulletin, 2008, 53(17): 2706–2711.

Z Mo. Research of the cartridge type high speed switch valve based on MRF. Kunming: Kunming University of Science and Technology, 2012. (in Chinese)

Z Ma. Structure design and research on hydraulic high speed on-off valve based on GMA. Lanzhou: Lanzhou University of Technology, 2013. (in Chinese)

Y Qin, Z Wu, Z Mo, et al. The simulation analysis of the high speed switch valve control the cartridge valve based on AMEsim. Advanced Materials Research, 2014, 971–973: 827–832.

Y Qin. The design and research of magnetic control of shape memory alloy high-speed on/off valve. Kunming: Kunming University of Science and Technology, 2015. (in Chinese)

M Paloniitty, M Linjama, K Huhtala. Concept of digital microhydraulic valve system utilising lamination technology. The 9th International Fluid Power Conference, 2014: 302–313.

M Paloniitty, M Linjama, K Huhtala. Equal coded digital hydraulic valve system – improving tracking Control with pulse frequency modulation. Procedia Engineering, 2015, 106: 83–91.

M Linjama, M Paloniitty, L Tiainen, et al. Mechatronic design of digital hydraulic micro valve package. Procedia Engineering, 2015, 106: 97–107.

T Lantela, M Pietola. High-flow rate miniature digital valve system. International Journal of Fluid Power, 2017, 18(3): 188–195.

T Li, J Huang, Y Bai, et al. Characteristics of a piloted digital flow valve based on flow amplifier. 2015 International Conference on Fluid Power and Mechatronics, 2015: 200–204.

T Li, J Huang, L Quan, et al. Characteristic test of high-speed on-off solenoid valve. Chinese Hydraulics & Pneumatics, 2015, (8): 30–33. (in Chinese)

X Guo, T Li, J Huang, et al. Characteristic analysis of the digital pilot flow control valve. Hydromechatronics Engineering, 2016, 44(6): 25–29.

J Huang, X Guo, T Li, et al. Analyses of characteristic s of a PWM digital flow valve. China Mechanical Engineering, 2016, 27(5): 680–684.

P Y Li, C Y Li, T R Chase. Software enabled variable displacement pumps. 2005 ASME International Mechanical Engineering Congress and Exposition, 2005: IMECE2005-81376.

M B Rannow, H C Tu, P Y Li, et al. Software enabled variable displacement pumps – experimental studies. 2006 ASME International Mechanical Engineering Congress and Exposition, 2006: IMECE2006-14973.

H C Tu, M B Rannow, M Wang, et al. High-speed 4-way rotary on/off valve for virtually variable displacement pump/motor applications. Proceedings of the ASME 2011 Dynamic Systems and Control Conference, 2011: DSCC2011-6109.

M B Rannow, P Y Li. Soft switching approach to reducing transition losses in an on/off hydraulic valve. Journal of Dynamic Systems, Measurement, and Control – Transactions of the ASME, 2012, 134: 064501.

M A Batdorff, J H Lumkes. Virtually variable displacement hydraulic pump including compressability and switching losses. 2006 ASME International Mechanical Engineering Congress and Exposition, 2006: IMECE2006-14838.

B K Beckstrand, J D Van de Ven. Experimental validation of a soft switch for a virtually variable displacement pump. Proceedings of the ASME/BATH 2014 Symposium on Fluid Power & Motion Control, 2014: FPMC2014-7857.

J D Van de Ven. Soft switch lock-release mechanism for a switch-mode hydraulic pump circuit. Journal of Dynamic Systems, Measurement, and Control – Transactions of the ASME, 2014, 136: 031003.

B K Beckstrand, J D Van de Ven. Design and validation of a soft switch for a virtually variable displacement pump. Journal of Dynamic Systems, Measurement, and Control – Transactions of the ASME, 2018, 140: 061006.

M Ehsan, W H S Rampen, S H Salter. Modeling of digital-displacement pump-motors and their application as hydraulic drives for nonuniform loads. Journal of Dynamic Systems, Measurement, and Control – Transactions of the ASME, 2000, 122(1): 210–215.

C Williamson, N Manring. A more accurate definition of mechanical and volumetric efficiencies for digital displacement pumps. Proceedings of the ASME/BATH 2019 Symposium on Fluid Power and Motion Control, 2019: FPMC2019-1668.

G S Payne, A E Kiprakis, M Ehsan, et al. Efficiency and dynamic performance of digital displacement hydraulic transmission in tidal current energy converters. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2007, 221(2): 207–218.

J J Budden, C Williamson. Danfoss digital displacement excavator: Test results and analysis. Proceedings of the ASME/BATH 2019 Symposium on Fluid Power and Motion Control, 2019: FPMC2019-1669.

L Qi. Research on radial piston constant flow pump with digital distribution under random low speed driving. Shanghai: Shanghai Jiao Tong University, 2016. (in Chinese)

L Qi, G Shi, L Yu. Research on radial piston constant flow pump with digital distribution under random low speed driving. Mechatronics, 2016, (6): 8–12. (in Chinese)

H Lu, L Yu, G Shi. Application of optimal pulsation valve control theory in low speed five plunger radial digital pump. Mechatronics, 2019, (6): 48–55. (in Chinese)

G Shi, L Yu, L Qi. Simulation of radial piston constant flow pump with digital distribution under random low speed driving. The Eighth Workshop on Digital Fluid Power, 2016: 55–67.

L Yu, L Qi. Optimal fluctuation regulation method in low-speed digital piston pump. Journal of Dynamic Systems, Measurement, and Control – Transactions of the ASME, 2019, 141: 111011.

B Dong. Research on controller of axial piston pump based on numerical control. Guizhou: Guizhou University, 2009. (in Chinese)

M Su. Simulation research on control of the axial piston pump with high speed on-off solenoid valve. Machine Tool & Hydraulics, 2012, 40(23): 25–28. (in Chinese)

S Cen, Z Wu, X Wang, et al. Research on digital variable displacement pumps based on high-speed on/off valve. China Mechanical Engineering, 2012, 23(6): 671–675. (in Chinese)

Q Deng, B Zhang, H Yang. Study on the electronic servo control variable displacement pump through co-simulation. Hydraulics Pneumatics & Seals, 2015, (1): 27–30. (in Chinese)

Q Deng. Study on the key technology of closed-loop electrical control and hydraulic pump and its embedded control system. Hangzhou: Zhejiang University, 2015. (in Chinese)

B Zhang, C Hong, Q Zhong, et al. A pilot control method for a variable displacement axial piston pump using switching technology. The Eighth Workshop on Digital Fluid Power, 2016: 107–119.

H Wang. Research on compound control system based on swashplate axial piston pump. Kunming: Kunming University of Science and Technology, 2015. (in Chinese)

B Yan. Research on the piston pumps using high-speed on-off valve with phase shift of PWM control method. Fuzhou: Fuzhou University, 2015. (in Chinese)

M Linjama, H Vihtanen, A Sipola, et al. Secondary controlled multi-chamber hydraulic cylinder. The 11th Scandinavian International Conference on Fluid Power, 2009.

A Plöckinger, C Gradl, R Scheidl. High accuracy sensorless hydraulic stepping actuator. The Eighth Workshop on Digital Fluid Power, 2016: 177–186.

K J Merrill, M A Holland, J Lumkes. Efficiency analysis of a digital pump/motor as compared to a valve plate design. Proceedings of 7th International Fluid Power Conference, 2010: 313–324.

Q Meng, G Shi, J Pan. A new type of low speed high torque hydraulic motor using digital distribution and speed adjusting. Machine Tool & Hydraulics, 2008, 36(10): 1–3. (in Chinese)

Q Meng. Research on the digital distribution and speed adjusting mechanism of low speed high torque hydraulic motor. Shanghai: Shanghai Jiao Tong University, 2009. (in Chinese)

J Pan, G Shi. Distribution characteristics of hydraulic motor with digital distribution. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(10): 203–208. (in Chinese)

J Pan, G Shi. Modeling and implementation of hydraulic motor with digital distribution and speed adjusting mechanism. Journal of Shanghai Jiao Tong University, 2011, 45(11): 1607–1612. (in Chinese)

J Pan. Research on characteristics of low-speed-high-torque hydraulic motor with digital distribution and speed adjusting mechanism. Shanghai: Shanghai Jiao Tong University, 2011. (in Chinese)

D B Roemer, M M Bech, P Johansen, et al. Optimum design of a moving coil actuator for fast-switching valves in digital hydraulic pumps and motors. IEEE/ASME Transactions on Mechatronics, 2015, 20(6): 2761–2770.

S Nordas, M K Ebbesen, T O Andersen. Analysis of requirements for valve accuracy and repeatability in high efficiency digital displacement motors. Proceedings of the BATH/ASME 2018 Symposium on Fluid Power and Motion Control, 2018: FPMC2018-8908.

M Linjama, M Vilenius. Energy-efficient motion control of a digital hydraulic joint actuator. Proceedings of the 6th JFPS International Symposium on Fluid Power, 2005: 640–645.

M Linjama, A Laamanen, M Vilenius. Is it time for digital hydraulics? The Eighth Scandinavian International Conference on Fluid Power, 2003: 347–366.

B Manhartsgruber, G Mikota, R Scheidl. Modelling of a switching control hydraulic system. Mathematical and Computer Modelling of Dynamical Systems, 2005, 11(3): 329–344.

T Qiu, X He, S Yang, et al. Study on speed control system for hydraulic motor based on a high-speed on /off valve. Machine Tool and Hydraulics, 2018, 46(1): 80–86.

Acknowledgements

Not applicable.

Funding

Supported by Key Technologies Research and Development Program of China (Grant No. 2019YFB2004502), National Natural Science Foundation of China (Grant Nos. 51805350, 51775362), and Postdoctoral Science Foundation of China (Grant No. 2019M651073).

Author information

Authors and Affiliations

Contributions

HW organized the materials and wrote the manuscript. ZC and JH collected the materials. LQ was in charge of the whole project. BZ helped to organize the materials. All authors read and approved the final manuscript.

Authors’ Information

He Wang, born in 1986, is currently an associate professor at Key Laboratory of Advanced Transducers and Intelligent Control System, Ministry of Education, Taiyuan University of Technology, China. His research interests include the hydraulic components and systems.

Zhen Chen, born in 1995, is currently a master candidate at Key Laboratory of Advanced Transducers and Intelligent Control System, Ministry of Education, Taiyuan University of Technology, China. His research interest is Hydraulic valves.

Jiahai Huang, born in 1979, is currently a professor at Key Laboratory of Advanced Transducers and Intelligent Control System, Ministry of Education, Taiyuan University of Technology, China. His research interests is electro-hydraulic proportional control technology.

Long Quan, born in 1959, is currently a professor at Key Laboratory of Advanced Transducers and Intelligent Control System, Ministry of Education, Taiyuan University of Technology, China. His research interests include fluid power transmission and control.

Bin Zhao, born in 1981, is currently an associate professor at Key Laboratory of Advanced Transducers and Intelligent Control System, Ministry of Education, Taiyuan University of Technology, China. His research interests include the hydraulic components.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing financial interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, H., Chen, Z., Huang, J. et al. Development of High-Speed On–Off Valves and Their Applications. Chin. J. Mech. Eng. 35, 67 (2022). https://doi.org/10.1186/s10033-022-00720-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1186/s10033-022-00720-5