Abstract

Rare-earth ion doped, silica glass, optical fibre amplifiers have transformed the world by enabling high speed communications and the Internet. Fibre lasers, based on rare-earth ion doped silica glass optical fibres, achieve high optical powers and are exploited in machining, sensing and medical surgery. However, the chemical structure of silica glass fibres limits the wavelength of laser operation to < 2.5 µm, which excludes the mid-infrared longer wavelength range of 3–50 µm. Rare-earth ion doping of fluoride glasses enables manufacture of fibre lasers up to a limiting 3.92 µm wavelength, but the fluoride glass chemical structure again prevents operation at longer wavelengths. Optical fibre lasers that are constructed from different rare-earth ion doped chalcogenide glass fibres will potentially operate across the 4–10 µm wavelength range, where suitable high-power lasers currently do not exist. We present a short review here of our recent work in achieving first time, continuous wave, mid-infrared fibre lasing beyond 5 μm wavelength in Ce3+-doped selenide chalcogenide fibre. We place this disruptive breakthrough into the wider fibre laser context, and also present the unprecedented advances in new cross-sector applications that will be enabled by mid-infrared fibre lasers in the 4–10 µm wavelength range. To surpass the few mW power output of the Ce3+-doped chalcogenide glass fibre lasing achieved to date, the glass quality of the doped chalcogenide fibres must now be improved, similar to the challenges originally facing the first glass fibre lasers based on silica.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Rare-earth ion-doped, silica glass, optical fibre lasers are related to rare-earth ion fibre optical amplifiers that provide light amplification without lasing. Fibre optical amplifiers have transformed the world by enabling high speed telecommunications, the Internet and social media [1]. A fibre laser is a laser in which the active gain medium, i.e. the lasing cavity, is a glass fibre of maximum diameter of a few hundred μm and the glass is doped with active (i.e. fluorescent ≡ photoluminescent) trivalent rare-earth ions such as erbium III (Er3+), ytterbium III (Yb3+), neodymium III (Nd3+) and cerium III (Ce3+). The elements, from which these ions derive, are members of the Lanthanide Series in the Periodic Table. Fibre lasers based on rare-earth ion doped silica glass optical fibres have achieved high optical powers (currently in excess of 100 kW [2]) and are exploited in machining, sensing and medical surgery (e.g. [3]).

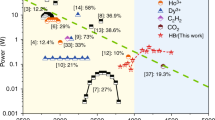

The first glass fibre laser was reported in 1961 by Snitzer [4] (see Fig. 1). It was based on doping Nd3+ into the core glass of an optical fibre. The core glass was a multicomponent silicate glass, a so-called ‘barium crown’ glass: 59SiO2–25BaO–15K2O–1Sb2O3 weight (wt)%, doped with 2 Nd2O3 wt%. This core oxide glass was concentrically surrounded by an undoped optical cladding glass which was a soda–lime–silica glass (~ 25Na2O–10CaO–65SiO2 wt%); the doped core glass and surrounding cladding glass together formed a multimode fibre [4]. Two fibre geometries were made, one of core diameter: 304 μm and the other of core diameter: 32 μm. The core and cladding glass refractive index at the operating wavelength was 1.54 and 1.52, respectively, giving each fibre a numerical aperture (NA) of 0.25, and a light half acceptance angle of ~ 14° [4].

This first fibre lasing report [4] did not present a numerical value for optical transmission of the active fibre. Later in 1991 [5], Snitzer, in referring back to that work, observed that to make the first fibre laser, in 1961 [4], the ‘small’ 500 g glass melts utilised were not of high optical quality. Therefore, it can be concluded that the first glass fibre laser was achieved in fibre whose optical transmission was poor. Moreover, Snitzer revealed [5] that the cladding glass of the first fibre lasers was there to surround the light-carrying core glass primarily to minimise unwanted light deviation and loss out of the core glass. He stated that the mechanism of this light loss was due to the presence of unwanted striae (short scale inhomogeneities of differing refractive index glass) inside the core glass which scattered and/or deviated the light out of the fibre core [5]. Striae are caused by incomplete mixing of the constituents during glass melting, leaving not only compositional variations in the glass but also density variations, and hence refractive index variation. Snitzer generally observed in his 1991 book preface [5] that, although laser emission had by that time, in1991, been made to occur in most rare-earth ions and ‘thousands’ of different glass host compositions, only a handful had become commercially significant. Figure 1 shows that the first visible fibre laser was due to Farries et al. [6] operating in a silica glass fibre doped with samarium ions (Sm3+) at 650 nm. Also, the first single-mode glass fibre laser, from Mears et al. [7], is shown.

The strong ≡Si–O– network chemical bonding of silica glass underpins its excellent physicochemical properties which make it the most robust of all inorganic glasses. The glass transition (Tg) is high (~ 1050 °C) so undoped silica glass fibres are the transmission medium of choice in extreme temperature and hostile environments. All inorganic glasses usually fail from Griffith flaws at the glass surface [8] that can be caused by hard dust dropping from the atmosphere, and so the surface of silica glass fibres is protected in a primary polymeric coating or a metallic coating.

The phonon energy of silica glass (concerted vibrations of the silica glass network that can add to resonantly de-activate the rare-earth ion excited state) is high (~ 1000 cm−1) due to the strong chemical bonding and low reduced mass of the vibrating atoms; so the excited states of rare-earth ions doped into silica glass are resonantly, multiphonon deactivated thus limiting the laser operating wavelength of silica glass optical fibre to < 2.5 µm wavelength. This excludes achieving fibre lasing in the mid-infrared (MIR) wavelength range when using a silica host glass, as now explained. Note that the MIR wavelength range is defined by the International Organisation for Standardisation (ISO) and British Standards Institution (BSI) as 3–50 µm [9] (MIR spectral range is also named Infrared-C radiation [9]).

Rare-earth ion doping of the lower phonon energy, more weakly chemically bonded with greater reduced-mass ions, fluoride glasses, like ZBLAN (ZrF4–BaF2–LaF3–AlF3–NaF) and indium fluoride (InF3)-based glasses, has enabled manufacture of rare-earth ion doped fluoride glass fibre lasers, but only up to a laser operating wavelength of 3.92 µm [10] (Fig. 1). Again, the high phonon energy of fluoride glasses prevents longer wavelength operation. This had created the so-called ‘4 micron barrier’; thus, fibre laser operation at 4 µm wavelength and beyond had stalled for a number of years.

On the other hand, optical fibre lasers that are constructed of chalcogenide glass have much lower phonon energies, down to 200 cm−1. So, rare-earth ion doped chalcogenide glasses will potentially operate in the 4–10 µm wavelength range, where high-power fibre lasers currently still do not exist. We review here, and put into the wider fibre laser context, our recent work in achieving for the first time continuous wave (cw) mid-infrared fibre lasing beyond 5 μm wavelength in Ce3+-doped selenide chalcogenide fibre [11] (Sect. 2). The cross-sector new applications of mid-infrared fibre lasers that will be enabled in the near future will be discussed (Sect. 3).

There are many challenges to developing a practical, high-power mid-infrared fibre laser and the glass quality issues are similar to those challenges that faced silica-based optical fibre lasers in the 1960s, as described by Snitzer [5] and above.

2 Short review of MIR fibre lasers based on direct emission

2.1 Background

Reports on direct emission, rare-earth ion (RE3+) doped mid-infrared fibre lasers were limited to below 4 μm emission in fluoride glass hosts, until our demonstration of the new chalcogenide fibre laser in 2021 [11]. For instance, MIR fibre lasing at 3.78 μm was reported [12], using dual-wavelength pumping, of an Er3+-doped ZBLAN fluoride fibre at room temperature. Lasing in the wavelength range of 2.8–3.9 μm was demonstrated by several authors in Ho3+ or Dy3+-doped ZBLAN fluoride fibres (e.g. [13]-first to achieve 3.90 μm fibre lasing). In 2018, room temperature cw lasing at 3.92 µm was observed in Ho3+-doped fluoro-indate glass fibre [10] (see Fig. 1), and photoluminescence at 4.2 µm in a Dy3+-doped fluoro-indate glass fibre [14]. But this meant it took 23 years to extend the room temperature lasing wavelength in fluoride glass fibres from 3.90 µm (1995) [13] to 3.92 µm (2018) [10] (see Fig. 1) enabled by the lower phonon energy (509 cm−1 [15]) fluoro-indate glass hosts compared to fluoro-zirconate glass hosts (see Fig. 1). However, a phonon energy of 509 cm−1 is still too high for laser operation beyond 4 μm [16,17,18], so lower phonon energy glass hosts than fluoro-indate glasses are essential.

Chalcogenide glasses with phonon energies down to 200 cm−1 are prime candidates [18, 19]. Chalcogenide glasses are composed of sulfide, selenide and tellurides (Chalcogen Group XVI of the new Periodic Table, except oxygen) in combination with Group XIV and XV elements like arsenic (As), germanium (Ge) and antimony (Sb). Sulfide, selenide and tellurides are more polarisable atomic species than fluoride or oxide glasses, and exhibit large linear refractive indices, hence large absorption and emission cross sections of doped in RE3+, leading to short, active laser devices.

Figure 2a shows that the calculated intrinsic non-radiative transition rate of rare-earth ions in selenide chalcogenide glasses across the mid-infrared spectral region is many orders of magnitude lower than that of fluoride glasses, and other glass families, due to the very low phonon energy of the selenide chalcogenide glasses [20,21,22,23].

Calculated dependence of the intrinsic multiphonon relaxation rate on the energy gap: a in 2–10 μm region for glass families redrawn from [21] with data in (b) added, and b for bulk Ge–As–Ga–Se chalcogenide glasses calculated in [20] from data presented by us [23] and others [22]; the black plot indicates the line of best fit

The low phonon energy of the selenide chalcogenide glasses is due to their weak chemical bonding, coupled with greater reduced mass of the matrix atoms, leading to the lower vibrational frequency of the glass-matrix chemical bonds. Hence also, the selenide chalcogenide glasses exhibit mid-infrared transparency to longer wavelengths compared to silica and other glasses, as shown by the Szigeti equation (Eq. 1) for a simple oscillator [24]:

where λ is the wavelength of the vibrational mode of the chemical bond; m is the geometric mean of the two vibrating atomic masses connected by the chemical bond; f is the bond force constant, which is related to chemical bond strength.

From Eq. 1, the weaker chemical bonds of the selenide chalcogenide glasses, such as Ge–Se bonds, combined with the larger relative atomic masses of Ge and Se, give rise to longer wavelength vibrational absorption of the chalcogenide glasses compared to silica glass. This manifests as increased MIR transparency and lower phonon energy of chalcogenide glasses, with respect to silica glass.

Figure 3 shows this transparency of a selenide chalcogenide glass and also depicts mid-infrared emission (i.e. photoluminescence) to occur almost right across the 3–10 μm wavelength range of a selection of rare-earth ions doped in bulk selenide chalcogenide glasses, as reported by Sanghera et al. [25].

Dy3+, Pr3+, Er3+, Tm3+ or Tb3+,-doped chalcogenide Ge–As–Ga–Se bulk glasses: mid-infrared emissions in the 2–9 μm atmospheric window. (Adapted from [25].)

However, Eq. 1 shows that the tautological consequence of the benefit of longer mid-infrared wavelength transparency is the inevitable weaker chemical bonding of chalcogenide glasses compared to silica and other glasses. The weaker chemical bonding gives:

-

1.

increased likelihood of glass devitrification during processing, such as during fibre drawing;

-

2.

lower glass transition (Tg) temperatures and lower processing temperatures;

-

3.

weaker mechanical properties: Young’s modulus ~ 1/5 × silica [26]; Vicker’s Hardness ~ 2 GPa [27] (cf. window-glass: 5.5 GPa),

-

4.

greater chemical interactivity.

Yet, chalcogenide glass fibres manufactured in our laboratory are sufficiently robust for handling and development. They are exceptionally stable in both liquid water and water vapour at ambient, and not oxidised in air < Tg, beyond a nanolayer [28] (like silicon (Si) cf. [29]). Our in-house manufactured plastic-coated and uncoated chalcogenide glass fibres of > 2 years’ old stored at ambient retained a respectable Ultimate Fracture Stress median of ~ 80 MPa [30] and maintained optical transmission > 7 years. We reported As-free chalcogenide fibres to seed and support growth of human cells in growth (water (H2O)-based) media for ≥ 14 days [31]. High optical damage thresholds have been reported: e.g. 10.2 W through 200 mm (90.6% transmission) of As-S small core fibre at 2 μm wavelength: power density = 12.2 MW/cm2 [32].

In addition, chalcogenide glasses:

-

1.

exhibit large optical nonlinearities (~ 103 × silica glass [33]) for exploitation as supercontinuum fibre sources [34] for broadband sensing;

-

2.

solubilise RE3+ and we have demonstrated long wavelength photoluminescence (PL) and fibre lasing [11, 35].

Right now the manufacture of new supporting technologies of mid-infrared fibre components is needed, viz.: fibre Bragg gratings (FBG), fibre-splicing, fibre-couplers and antireflection at the fibre ends.

The theoretical minimum mid-infrared optical loss of the chalcogenide host glass fibre is 10 dB/km [36]. The actual lowest (record loss) achieved of the host glass type composition, suitable for solubilising RE3+ [11], was reported by us in collaboration with the Churbanov Group as: 84 dB/km at 6.6 μm wavelength; this low loss was achieved by means of glass purification using glass gettering and distillation [37]. However, such low optical loss RE3+-doped chalcogenide optical fibre has not yet been reported; this is a similar position to the challenges facing the early silicate glass fibre lasers, as indicated by Snitzer in [4, 5] (see Sect. 1). The reason why purer, better optical quality RE3+-doped chalcogenide glass is required for drawing to low optical loss fibre is to increase the fibre laser gain and so realise powerful fibre MIR lasing. Thus, it is important now to explore extending the wavelength capability of fibre lasers as far as possible into the MIR spectral region by perfecting the manufacture of doped chalcogenide glass fibres for efficient mid-infrared fibre lasing. Such advances will lead to new sensing applications (see Sect. 3) and may generate new physics.

2.2 Prior work

2.2.1 Modelling

Modelling and design has played an important role in the development of mid-infrared fibre lasers. This has been particularly evident in the case of chalcogenide glass-based fibre lasers that have the potential to operate efficiently well beyond the 4 μm wavelength socalled barrier. In predicting this characteristic of chalcogenide glasses, modelling was the key element which motivated the experimental research and stimulated an enormous effort which, over the last decade, has been invested into developing suitable host glasses and discovering the mid-infrared photoluminescent behaviour of the lanthanide ion (RE3+) dopants. Early PL studies on RE3+-doped bulk chalcogenide glasses gave an initial strong indication of the lasing potential of RE3+-doped chalcogenide glass [22]. This evidence alone, however, was not sufficient to back up the claim that chalcogenide glass fibres can be turned into efficient lasers operating in the MIR wavelength range. The missing bit of this puzzle was provided by modelling results published first in 2007 by Quimby et al. [38]. In [38], the Authors demonstrated by modelling that an output power > 0.5 W could be possible from a dysprosium(III) ion doped chalcogenide glass fibre pumped at 1710 nm with 4 W input power. The authors in [38] also showed that critical to an efficient operation of such a fibre laser is the trapping of the idler signal at 3500 nm within the cavity using high reflectivity mirrors and the reduction of the fibre loss below 5 dB/m. The results presented in [38] stimulated the direction of experimental research for the decade to come and also provided the justification of such effort and strong stimulus for intensification of experimental work aiming at chalcogenide glass composition practical development. A caveat is that other types of intrinsic loss, following on from the semiconductor nature of chalcogenide glasses [35], have not yet been addressed in any modelling study. Following [38], also other authors started to study numerically the properties of rare-earth ion doped, chalcogenide glass, fibre-based lasers considering other lanthanide ions besides dysprosium III, i.e. praseodymium III, terbium III, neodymium III and cerium III. Of all these candidates, the theoretical studies showed terbium III and cerium III as the most promising candidates for the realisation of MIR fibre lasers based on chalcogenide glass and operating at wavelengths exceeding 4 μm. These predictions were later confirmed by the experimental results. A fairly recent review of modelling activities within the area of chalcogenide glass fibre lasers can be found in [39].

2.2.2 Experimentally, in the laboratory

It should be noted that CVD (chemical vapour deposition) of chalcogenide glass optical preforms is impossible due to the differing vapour pressures of the many components (at least two British EPSRC grants, awarded to others, have been devoted to this and failed). Instead, in prior work leading up to achieving the record MIR fibre lasing [11], our Group invented and then developed glass (melt) extrusion and co-extrusion methods to make chalcogenide glass optical fibre preforms (e.g. see [40, 41]). The extrusion approach has now been adopted for manufacturing non-silica glass by the Groups of Ole Bang of DTU in Denmark, IR-FlexINC in the USA, Heike Ebendorff-Heidepriem at Adelaide University in Australia, and at the University of Torino, Italy, and beyond. Our extrusion, cane drawing and fibre drawing were improved during 1994–2010 firstly of undoped fibre, and then of rare-earth ion doped fibre since 2010.

At first chalcogenide glass host compositions were developed to successfully solubilise RE3+ without the glass devitrifying nor the glass melt attacking the silica ampoule containment (Ph.D. Thesis Z. Q. Tang, University of Nottingham, 2012). HRTEM SAED (high-resolution transmission electron microscopy, selected area electron diffraction) was used to investigate whether there was any unwanted crystallisation in rare-earth ion doped chalcogenide glasses. This revealed [42] an isolated sighting of [Dy] and [O] in the vicinity of a nanocrystal of Ga2Se3 in a circa 3000 ppmw (parts per million parts by weight) Dy3+-doped Ge–As–Ga–Se chalcogenide glass. A mechanism to explain this observation was inferred of Dy III scavenging adventitious oxide in the chalcogenide glass melt. Furthermore, the lattice registry between Dy2O3 and Ga2Se3 provides a rationale for how Dy2O3 could nucleate a Ga2Se3 nanocrystal. FtIR (Fourier transform Infrared) spectroscopy showed increased light scattering of a 3000 ppmw Dy3+-doped Ge–As–Ga–Se chalcogenide glass compared with undetectable light scattering in 500–800 ppmw Dy3+-doped Ge–As–Ga–Se chalcogenide glasses. This result suggests that our chosen RE3+ dopant level of 500 ppmw which was used to demonstrate fibre lasing beyond 5 μm wavelength [11] could be assumed to be free from this unwanted scattering mechanism. Increasing the RE3+ dopant level beyond 500 ppmw for greater fibre laser output power would require greater dissolution of the RE3+ in the selenide chalcogenide glass host and this in turn would demand purer glass hosts free from, or with a minimal amount of, adventitious oxide, hydroxide and water.

The local environment of Dy3+ in a Ge–As–Ga–Se glass host was investigated for additions as DyCl3 or Dy foil doped in at 0–3000 ppmw in [43] as follows. EXAFS (Extended X-ray Absorption Fine Structure) demonstrated that the glasses doped with Dy foil, or < 1000 ppmw Dy3+ added as DyCl3, contained Dy ions that were fully incorporated into the glass network and were coordinated by 7–8 Se atoms. However, when the DyCl3 dopant was present in concentrations of ≥ 1000 ppmw Dy3+, then the Dy3+ local environment in the glass host was dominated by Dy–Cl bonds. Furthermore, the Dy–Cl environments were nanocrystalline, retaining a chemical order beyond the first coordination shell. XRD (X-ray diffraction) and FtIR results indicated that the presence of α-Ga2Se3 crystallites in the glass, and the increased optical scattering in the fibres, were both related to the presence of DyCl3 crystallites [42].

After optimising the Ge–As–Ga–Se host glass composition and rare-earth ion doping level, next, small core fibre was developed using novel extrusion to produce the correct geometry fibre preforms, and fibre-drawing, and cane-drawing, hardware and skills were further developed.

In [35], we presented a summary of our photoluminescence studies of Dy3+, Sm3+, Tb3+, Pr3+ in large and small core fibre format carried out between 2010 and 2021. As part of this we reported 1 mW incoherent, mid-infrared light output from Pr3+-doped unstructured fibre [44] and mid-infrared optical amplification in Pr3+doped fibre [45].

Having achieved the fibre lasing beyond 5 μm in Ce3+-doped fibre [11], we are now working on improving glass quality to increase the power output from Ce3+-doped mid-infrared chalcogenide glass fibre lasers; the current laser maximum mid-infrared power emission is a few mW in our laboratories. In addition, we are working on novel approaches to studying ESA (Excited State Absorption), of rare-earth ions in chalcogenide glass hosts; ESA potentially depletes RE3+ excited states.

2.3 Achieving the first mid-infrared fibre laser operating beyond the so called 4 micron wavelength barrier

Bulk rare-earth ion doped chalcogenide glass lasing was first announced in 2020 and 2021 [46, 47] and we announced the first-in-the-world chalcogenide glass fibre, cw, room temperature lasing at 5.2 microns in 2021 [11]; this latter work has been replicated by only one other international group (RAS, Nizhny-Novgorod) (e.g. [48]). To achieve the first mid-infrared fibre laser operating beyond the 4 μm wavelength barrier, we initially investigated in-band pumping, at 4.15 μm wavelength, of Ce3+ doped into selenide chalcogenide glass in an unstructured fibre format, SIF (step index fibre), polished bulk glass and particulate glass geometries [49]. Mid-infrared PL spanning 3.40–5.80 μm wavelength was observed, corresponding to the 2F5/2 ← 2F7/2 electronic emission transition due to Ce3+ [11, 49] (Fig. 4).

a Mid-infrared absorption spectrum of 500 ppmw (parts per million by weight) Ce3+-doped Ge15As21Ga1Se63 atomic% (at.%) bulk core glass, and b Ce3+ electronic energy level diagram overlaid with the 4.15 μm QCL (Quantum Cascade Laser) pump output and the 5.14 μm Ce3+ emission [11]

Room temperature emission and MIR absorption spectra together enabled interpretation of the manifold energies of the first excited state and there is potential for occupied upper Stark levels in the ground state at room temperature [50]. Both ‘τrad’ (photoluminescent lifetime) and ‘trise’ (rise time through 10–90% of maximum PL intensity) were determined. For the particulate glass at 4.60 μm wavelength, the best decay fit comprised a primary, and perhaps secondary, lifetime for particulate glass of 3.5 ms, and 1.2 ms, and PL rise time of 3.9 ms [49].

These PL measurements in [49] were in support of our report of cw fibre lasing beyond 5 μm at room temperature [11] in a small core Ce3+-doped selenide chalcogenide SIF (step index fibre) (Fig. 5) of core: Ge–As–Ga–Se chalcogenide glass, doped with 500 ppmw of cerium (III), employing in-band pumping by means of a 4.15 μm QCL (quantum cascade laser). The lasing fibre was short: 64 mm, with a calculated numerical aperture of 0.48 at the lasing wavelengths [11]. The core was Ge15As21Ga1Se63 atomic % (at.%) glass, doped with the 500 ppmw Ce, and of core diameter: 9 μm (Fig. 5); the cladding was Ge21Sb10Se69 at.% and the fibre outer diameter was 190 μm [11]. As pump power was increased, continuous wave lasing corresponding to the 2F5/2 ← 2F7/2, emission of Ce3+ occurred at 5.14 μm, 5.17 μm and 5.28 μm (Fig. 6) [11].

SEM (scanning electron microscope) images of the cleaved end of the SIF (step index fibre) (code: F130RERC), samples of which exhibited fibre lasing (see Figs. 6, 7) with core // cladding = nominally Ge15As21Ga1Se63 atomic% (at.%) glass, doped with 500 parts per million by weight (ppmw) Ce // Ge21Sb10Se69 at.% [11]. a SIF with some debris arrowed and b SIF core // cladding interface [11]

Cavity emission intensity versus the 4.15 μm QCL pumping power, of the SIF (step index fibre) (code: F130RERC) of core // cladding = Ge15As21Ga1Se63 at.% glass, doped with 500 ppmw Ce // Ge21Sb10Se69 at.% [11]

The area under the cavity emission peaks from Fig. 6 [11] was plotted, versus the 4.15 μm QCL pumping power between 0 and 616 mW (Fig. 7, [11], of the SIF (step index fibre) (code: F130RERC) demonstrating a threshold to lasing of 86 mW [11].

Area under the cavity emission peaks from Fig. 6 plotted here, versus the 4.15 μm QCL pumping power between 0 and 616 mW, of the SIF (step index fibre) (code: F130RERC) of core // cladding = Ge15As21Ga1Se63 at.% glass, doped with 500 ppmw Ce // Ge21Sb10Se69 at.% [11]. The threshold pump power for lasing was 86 mW

We are now achieving ~ 2.5 mW output power, with 600 mW QCL direct pumping at 4.15 μm wavelength, giving ~ 0.4% efficiency for this in-band pumping. We anticipate that with improvements in fibre quality, including lowering fibre background loss to < 0.5 dB/m and hydride absorption to ≤ 1.5 dB/m, will lead to > 5% efficiency. This would open up the possibility of pulsed mid-infrared fibre lasing, with potential for direct seeding of mid-infrared supercontinuum broadband output to achieve all-fibre molecular sensing (see Sect. 3).

3 Prospective cross-sector, disruptive applications of MIR fibre lasers

Our recent demonstration of first-in-the-world, cw fibre lasing beyond 4 μm wavelength in rare-earth ion (RE3+)-doped chalcogenide glass fibre [11] opens up the promise of new application fields. Such brand new mid-infrared fibre lasers, operating beyond 4 μm wavelength, will enable unprecedented advances in sensing of molecular solids, liquids and gases, and also in machining, cutting and welding of soft organic materials.

The 3–15 µm wavelength range in the mid-infrared is the so-called ‘fingerprint’ spectral region where molecules have characteristic vibrational absorptions. These enable direct molecular sensing with high selectivity and high specificity. Gas, liquid and solid molecular moieties, for instance, complex biological molecules, such as amides in proteins and DNA (deoxyribonucleic acid), absorb mid-infrared light in this range [51]. We, along with others, are investigating their molecular signatures on mid-infrared light for their potential application in in-vitro medical diagnosis. Beyond that, a mid-infrared fibreoptic laser system would enable such diagnoses to be carried out in-vivo as a new kind of mid-infrared endoscopy and hence shorten diagnosis time and obviate the need for excision-biopsies [52].

Noteworthy is that the Earth’s atmosphere has the highest transmission in the mid-infrared range, for free-space communications and LIDAR (Light Detection And Ranging)-based sensors. The James Webb space telescope collecting mid-infrared light is ‘seeing’ further back than ever before into the Universe, for instance, 4000 billion years (NASA on-line photographs July 2022) and is able to pick up the signature of carbon dioxide on an exoplanet 700 million light years’ distant (https://www.youtube.com/watch?v=u3ilmdsNmLA, consulted Oct. 2023). The molecular signature of life, as we know it, would be detectable.

There is a crucial difference between the currently available near-infrared spectral sensors and the mid-infrared spectral sensors to be developed. Thus, in the mid-infrared the fundamental molecular vibrational fingerprint region (~ 3–15 μm wavelength) exhibits extinction coefficients around 100,000 × larger than the extinction coefficients of the near-infrared vibrational absorption bands [24]. This is the key reason why mid-infrared fibreoptic molecular sensing will newly enable high contrast, highly sensitive, highly specific, highly accurate, quantitative spectral sensing of molecular species.

MIR fibre lasers offer excellent beam quality of bright, spatially and temporally coherent light, routable in MIR fibre optics for applications such as narrow-band sensing, new medical laser wavelengths, and pulsed seeding of MIR-supercontinua for MIR broadband sensing such as in clinical diagnostics [34, 53, 54]. The new powerful MIR fibre lasers will impact world research with cross-sector disruptive impacts in: healthcare (disease diagnostics), defence/security and environmental monitoring. Our vision is to establish MIR fibreoptic sources that are robust, functionally designed, flexible, safe, compact and cost-effective, for cross-sector disruptive impact in: (a) molecular spectral sensing at the point of need in healthcare (disease screening and diagnostics at the bedside), defence and security (detecting explosives/narcotics/toxins in the field; anti-collision) and environment (field detection of pollutants); (b) MIR machining and welding of soft (molecular) materials, for instance, for fibre laser resonant medical surgery and in polymer additive and subtractive manufacture.

Data Availability Statement

This manuscript has associated data in a data repository. [Authors’ comment: Data sets generated during the current study are available from the corresponding author on reasonable request].

References

P.C. Becker, N.A. Olsson, J.R. Simpson, Erbium-Doped Fiber Amplifiers: Fundamentals and Technology, Preface by E Snitzer (Academic Press, London, 1999)

M. Zervas, Bright future for fibre lasers? Laser Systems: Europe (2019)

R. Sarrafi, J. Jia, J. Zhang, M. Mendes, Laser Processing: Advances in Cutting with Ultrahigh-Power Fiber Lasers. Laser Focus World, September 20 (2022)

E. Snitzer, Optical MASER action of Nd3+ in a barium crown glass. Phys. Rev. Lett. 7(12), 444–446 (1961)

P.W. France, Optical Fibre Lasers and Amplifiers, Preface by E Snitzer (Blackie CRC Press, Boca Raton, 1991)

M.C. Farries, P.R. Morkel, J.E. Townsend, A samarium doped visible glass laser operating at: 651 nm, in Conference on Lasers and Electro-Optics ed. by D. Pinnow, P. Moulton. Volume 7 of OSA Technical Digest (Optica Publishing Group, 1988), paper CPD5. https://opg.optica.org/abstract.cfm?URI=CLEO-1988-CPD5

R.J. Mears, L. Reekie, S.B. Poole, D.N. Payne, Neodymium-doped silica single-mode fibre lasers. Electron. Lett. 21(17), 738–740 (1985). https://doi.org/10.1049/el:19850521

A.A. Griffith, The theory of rupture, in Proceedings of the International Congress on Applied Mechanics (1924), pp. 56–63

ISO 20473:2007, Optics and Photonics, Spectral bands. This standard was last reviewed and confirmed in 2021. Therefore this version remains current

F. Maes, V. Fortin, S. Poulain, M. Poulain, J.-Y. Carrée, M. Bernier, R. Vallée, Room-temperature fibre laser at 3.92 μm. Optica 5, 761–764 (2018)

J.J. Nunes, Ł Sojka, R.W. Crane, D. Furniss, Z.Q. Tang, D. Mabwa, B. Xiao, T.M. Benson, M.C. Farries, N. Kalfagiannis, E. Barney, S. Phang, A.B. Seddon, S. Sujecki, Room temperature mid-infrared fiber lasing beyond 5 µm in chalcogenide glass small-core step index fiber. Opt. Lett. 46(15), 3504–3507 (2021)

O. Henderson-Sapir, S.D. Jackson, D.J. Ottaway, Versatile and widely tunable mid-infrared erbium doped ZBLAN fibre laser. Opt. Lett. 41, 1676–1679 (2016)

J. Schneider, Fluoride fibre laser operating at 3.9 μm. Electron. Lett. 31, 1250–1251 (1995)

M.R. Majewski, R.I. Woodward, J.-Y. Carreé, S. Poulain, M. Poulain, S.D. Jackson, Emission beyond 4 μm and mid-infrared lasing in a dysprosium-doped indium fluoride (InF3) fibre. Opt. Lett. 43(8), 1926–1929 (2018)

R.M. Almeida, J.C. Pereira, Y. Messaddeq, M.A. Aegerter, Vibrational spectra and structure of fluoroindate glasses. J. Non-Cryst. Solids 161, 105–108 (1993)

S.D. Jackson, Towards high-power mid-infrared emission from a fibre laser. Nat. Photonics 6, 423–431 (2012)

Z. Wang, B. Zhang, J. Liu, Y. Song, H. Zhang, Review: recent developments in mid-infrared fiber lasers: status and challenges. Opt. Laser Technol. 132, 106497 (2020)

A.B. Seddon, Z. Tang, D. Furniss, S. Sujecki, T.M. Benson, Progress in rare-earth-doped mid-infrared fibre lasers. Opt. Express 18(25), 26704–26719 (2010)

A.B. Seddon, Chalcogenide glasses: their preparation, properties and applications. J. Non-Cryst. Solids 184, 44–50 (1995)

Ł Sójka, Z.Q. Tang, D. Furniss, H. Sakr, Y. Fang, E. Beres-Pawlick, T.M. Benson, A.B. Seddon, S. Sujecki, Mid-infrared emission in Tb3+-doped selenide glass fibre. J. Opt. Soc. Am. B 34(3), A70–A79 (2017)

G. Fuxi, Optical and Spectroscopic Properties of Glass (Springer, Berlin, 1992)

L.B. Shaw, B. Cole, P.A. Thielen, J.S. Sanghera, I.D. Aggarwal, Mid-wave IR and long-wave IR laser potential of rare-earth doped chalcogenide glass fibre. IEEE J. Quantum Electron. 37, 1127–1137 (2001)

H. Sakr, D. Furniss, Z. Tang, L. Sójka, N.A. Moneim, E. Barney, S. Sujecki, T.M. Benson, A.B. Seddon, Superior photoluminescence (PL) of Pr3+–In, compared to Pr3+–Ga, selenide-chalcogenide bulk glasses and PL of optically-clad fibre. Opt. Express 22, 21236–21252 (2014)

P.W. France, M.G. Drexhage, J.M. Parker, M.W. Moore, S.F. Carter, J.V. Wright, Fluoride Glass Optical Fibres (Blackie, London, 1990)

J.S. Sanghera, L.B. Shaw, I.D. Aggarwal, Chalcogenide glass-fibre-based mid-IR sources and applications. IEEE J. Sel. Top. Quantum Electron. 15(1), 114–119 (2009)

Personal communication to A B Seddon from J S Sanghera. NRL, USA

J.-P. Guin, T. Rouxel, J.-C. Sangleboeuf, I. Melscoet, J. Lucas, J. Guin, Hardness, toughness, and scratchability of germanium–selenium chalcogenide glasses. J. Am. Ceram. Soc. 85, 1545–1552 (2002)

P. Lucas, A.A. Wilhelm, M. Videa, C. Boussard-Plédel, B. Bureau, Chemical stability of chalcogenide infrared glass fibres. Corros. Sci. 50, 2047–2052 (2008)

M. Morita, T. Ohmi, E. Hasegawa, M. Kawakami, M. Ohwada, Growth of native oxide on a silicon surface. J. Appl. Phys. 68(3), 1272–1281 (1990)

Research Project Reports Aniruddh Shah (2010) and Almunthir Abdullatif (2007), Faculty of Engineering, University of Nottingham, UK

D. Mabwa, T. Kubiena, H. Parnell, R. Su, D. Furniss, Z. Tang, R. Leach, T.M. Benson, C.A. Scotchford, A.B. Seddon, Evaluating the cytotoxicity of Ge–Sb–Se chalcogenide glass optical fibres on 3T3 mouse fibroblasts. RSC Adv. 11, 8682–8693 (2021)

A. Sincore, J. Cook, F. Tan, A. El Halawany, A. Riggins, L. Shah, A.F. Abouraddy, M.C. Richardson, K.L. Schepler, High power 2053 nm transmission through single-mode chalcogenide fibre. ATu5A.5 OSA Laser Congress 2017 (ASSL, LAC) OSA (2017)

A. Zackery, S.R. Elliott, Optical Nonlinearities in Chalcogenide Glasses and their Applications. Springer Series in Optical Sciences, vol. 135 (Springer, New York, 2007)

C.R. Petersen, U. Møller, I. Kubat, B. Zhou, S. Dupont, J. Ramsay, T. Benson, S. Sujecki, N. Abdel-Moneim, Z. Tang, D. Furniss, A. Seddon, O. Bang, Mid-infrared supercontinuum covering the 1.4–13.3 μm molecular fingerprint region using ultra-high NA chalcogenide step-index fibre. Nat. Photonics 8, 830–834 (2014)

A.B. Seddon, Ł Sojka, M. Shen, Z. Tang, D. Furniss, E. Barney, H. Sakr, D. Jayasuriya, H. Parnell, J. Butterworth, R. Crane, J. Nunes, D. Mabwa, M. Farries, S. Phang, T.M. Benson, S. Sujecki, Breaking through the wavelength barrier: the state-of-play on rare-earth ion, mid-infrared fibre lasers for the 4–9 μm wavelength region, in Mid-Infrared Photonics. ed. by S. Jackson, R. Vallee, M. Bernier (Elsevier, Amsterdam, 2021)

J.S. Sanghera, V.Q. Nguyen, P.C. Pureza, R.E. Miklos, F.H. Kung, I.D. Aggarwal, Fabrication of long lengths of low loss transmitting As40S60−xSex glass fibres. J. Lightwave Technol. 14(5), 743–748 (1996)

Z. Tang, V.S. Shiryaev, D. Furniss, L. Sojka, S. Sujecki, T.M. Benson, A.B. Seddon, M.F. Churbanov, Low loss Ge–As–Se chalcogenide glass fiber, fabricated using extruded preform, for mid-infrared photonics. Opt. Mater. Express 5(8), 1722–1737 (2015)

R.S. Quimby, L.B. Shaw, J.S. Sangher, I.D. Aggrawal, Modeling of cascade lasing in Dy: chalcogenide glass fiber laser with efficient output at 4.5 mm. IEEE Photonics Technol. Lett. 20, 123–125 (2008)

S. Sujecki, Ł Sojka, A.B. Seddon, T.M. Benson, E. Barney, M.C. Falconi, F. Prudenzano, M. Marciniak, H. Baghdasaryan, P. Peterka, S. Taccheo, Comparative modeling of infrared fiber lasers. MDPI Photonics 5, 48 (2018)

D. Furniss, A.B. Seddon, Extrusion of gallium lanthanum sulfide glasses for fiberoptic preforms. J. Mater. Sci. Lett. 17, 1541–1542 (1998)

S.D. Savage, C.A. Miller, D. Furniss, A.B. Seddon, Extrusion of chalcogenide glass preforms and drawing to multimode optical fibers. J. Non-Cryst. Solids 354(29), 3418–3427 (2008)

Z. Tang, D. Furniss, M. Fay, N. Neate, Y. Cheng, E. Barney, L. Sojka, S. SlawoMIR, T. Benson, A.B. Seddon, First identification of rare earth oxide nucleation in chalcogenide glasses and implications for fabrication of mid-infrared active fibres. J. Am. Ceram. Soc. 97(2), 432–441 (2014)

E.R. Barney, Z. Tang, A. Seddon, D. Furniss, S. Sujecki, T. Benson, N. Neate, D. Gianolio, The local environment of Dy3+ in selenium-rich chalcogenide glasses. R. Soc. Chem. Adv. 4(80), 42364–42371 (2014)

L. Sojka, Z. Tang, D. Jayasuriya, M. Shen, J. Nunes, D. Furniss, M. Farries, T.M. Benson, A.B. Seddon, S. Sujecki, Milliwatt-level spontaneous emission across the 3.5–8 μm spectral region from Pr3+ doped selenide chalcogenide fiber pumped with a laser diode. Appl. Sci. 10(539), 11 (2020). https://doi.org/10.3390/app1002053

M. Shen, D. Furniss, M. Farries, D. Jayasuriya, Z. Tang, L. Sojka, S. Sujecki, T.M. Benson, A.B. Seddon, Experimental observation of gain in a resonantly pumped Pr3+-doped chalcogenide glass mid-infrared fibre amplifier notwithstanding the signal excited-state absorption. Sci. Rep. Nat. Res. 9, 11426 (2019). https://doi.org/10.1038/s41598-019-47432-w

M.F. Churbanov, B.I. Denker, B.I. Galagan, V.V. Koltashev, V.G. Plotnichenko, M.V. Sukhanov, S.E. Sverchkov, A.P. Velmuzhov, First demonstration of ~ 5 μm laser action in terbium-doped selenide glass. Appl. Phys. B 126, 117 (2020)

M.F. Churbanov, B.I. Denker, B.I. Galagan, V.V. Koltashev, V.G. Plotnichenko, G.E. Snopatin, M.V. Sukhanov, S.E. Sverchkov, A.P. Velmuzhov, Laser potential of Pr3+ doped chalcogenide glass in 5–6 μm spectral range. J. Non-Cryst. Solids 559, 120592 (2021)

P. Fjodorow, M.P. Frolov, S.O. Leonov, B.I. Denker, B.I. Galagan, S.E. Sverchkov, V.V. Koltashev, V.G. Plotnichenko, M.V. Sukhanov, A.P. Velmuzhov, Mid-infrared laser performance of Ce3+-doped selenide glass. Opt. Express 29(17), 27674–27682 (2021). https://doi.org/10.1364/OE.433828

J.J. Nunes, R.W. Crane, Z.Q. Tang, Ł Sójka, N. Kalfagiannis, D. Furniss, M.C. Farries, T.M. Benson, S. Sujecki, A.B. Seddon, Mid-infrared photoluminescence in Ce3+ doped selenide-chalcogenide glass and fiber. Opt. Mater. 137, 113543–113553 (2023). https://doi.org/10.1016/j.optmat.2023.113543

M.J. Weber, Optical spectra of Ce3+ and Ce3+-sensitized fluorescence in YAlO3. J. Appl. Phys. 44(7), 3205–3208 (1973). https://doi.org/10.1063/1.1662735

M. Diem, S. Boydston-White, L. Chiriboga, Infrared spectroscopy of cells and tissues: shining light onto a novel subject. Appl. Spectrosc. 53(4), 148–161 (1999)

A.B. Seddon, A prospective for new mid-infrared medical endoscopy using chalcogenide glasses. Int. J. Appl. Glass Sci. 2(3), 177–191 (2011)

A.B. Seddon, B. Napier, I. Lindsay, S. Lamrini, P.M. Moselund, N. Stone, O. Bang, M. Farries, Prospective on using fibre mid-infrared supercontinuum laser sources for in vivo spectral discrimination of disease (minireview). Analyst 143, 5874–5887 (2018). https://doi.org/10.1039/C8AN01396A

A.B. Seddon, Mid-Infrared (MIR) optical sensing, in Springer Handbook on Glass, ed by J. Musgraves, D.J. Hu, L. Calvez (2019)

Acknowledgements

Joel Nunes acknowledges with gratitude his ‘Thematic PhD Studentship’ funded by the UK Engineering and Physical Sciences Research Council (EPSRC, ref. EP/N50970X/1). David Furniss was supported by EPRSC through Projects: (i) COOL (COld-cOntainer processing for long-wavelength mid-infrared fibreoptics, (EP/P013708/1) and SHAPE (Ceramic SHaping: extrusion of glAss Preforms for new fibres in hEalthcare) (EP/T010762/1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Seddon, A.B., Farries, M.C., Nunes, J.J. et al. Short review and prospective: chalcogenide glass mid-infrared fibre lasers. Eur. Phys. J. Plus 139, 142 (2024). https://doi.org/10.1140/epjp/s13360-023-04841-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-023-04841-1