Abstract

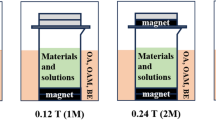

In quest to find a non-contact self-assembly synthesis of magnetic materials, magnetic field assisted chemical reactions have attracted enormous research attention. In this study, the influence of static magnetic field on structure, self-assembly, and magnetic and microwave absorption properties of CoNi alloy has been reported. By applying the magnetic field, the obtained CoNi nanochains own uniform size and superior magnetic and microwave absorption performance. Results demonstrated that properties of CoNi depend on their shape and morphology, as the shape of particle varied, the value of saturation magnetization (Ms) gradually increased. In addition, the CoNi nanochains synthesized under magnetic field achieved the minimum reflection loss (RL) of − 38 dB with a sample thickness of 3 mm. This improved microwave absorption performance can be attributed to conduction loss, eddy current loss, and interchain multiple reflections of microwaves. Therefore, it is convincing that magnetic fields can greatly influence the properties of CoNi by varying shape and morphology. This study provides a new route for designing novel heterostructure materials under the static magnetic field, which can be used not only in microwave absorption devices but also in other practical applications.

Similar content being viewed by others

References

N. Gao, W.-P. Li, W.-S. Wang, D.-P. Liu, Y.-M. Cui, L. Guo, G.-S. Wang, A.C.S. Appl, Mater. Interfaces 12, 14416 (2020)

S. Wang, X. Huang, W. Zhang, Appl. Phys. A 127, 742 (2021)

N. Yousefi, X. Sun, X. Lin, X. Shen, J. Jia, B. Zhang, B. Tang, M. Chan, J. Kim, Adv. Mater. 26, 5480 (2014)

J. Feng, Y. Zong, Y. Sun, Y. Zhang, X. Yang, G. Long, Y. Wang, X. Li, X. Zheng, Chem. Eng. J. 345, 441 (2018)

X. Chen, Z. Jia, A. Feng, B. Wang, X. Tong, C. Zhang, G. Wu, J. Colloid Interface Sci. 553, 465–474 (2019)

A. Hassan, M.A. Aslam, M. Bilal, M.S. Khan, S. ur Rehman, K. Ma, J. Wang, Z. Sheng, Ceram. Int. 47, 20706 (2021)

R. Ahmed, R. Si, S. ur Rehman, Results Phys. 20, 103623 (2021)

D. Lan, M. Qin, R. Yang, S. Chen, H. Wu, Y. Fan, Q. Fu, F. Zhang, J. Colloid Interface Sci. 533, 481 (2019)

H.T. Yudistira, K. Kananda, Eur. Phys. J. Plus 136, 603 (2021)

S. ur Rehman, J. Liu, Z. Fang, J. Wang, R. Ahmed, C. Wang, H. Bi, ACS Appl. Nano Mater. 2, 4451 (2019)

J. Yu, S. Pan, L. Cheng, Y. Liu, L. Huang, Appl. Phys. A 126, 348 (2020)

H. Xu, X. Yin, M. Zhu, M. Han, Z. Hou, X. Li, L. Zhang, L. Cheng, A.C.S. Appl, Mater. Interfaces 9, 6332 (2017)

P.H. Zhou, L.J. Deng, J.L. Xie, D.F. Liang, J. Alloys Compd. 448, 303 (2008)

H.-Y. Wang, X.-B. Sun, S.-H. Yang, P.-Y. Zhao, X.-J. Zhang, G.-S. Wang, Y. Huang, Nano-Micro Lett. 13, 206 (2021)

X. Guo, Z. Bai, B. Zhao, R. Zhang, J. Chen, J. Mater. Sci. Mater. Electron. 27, 8408 (2016)

H. Li, J. Liao, Y. Feng, S. Yu, X. Zhang, Z. Jin, Mater. Lett. 67, 346 (2012)

S. ur Rehman, J. Liu, R. Ahmed, H. Bi, J. Saudi Chem. Soc. 23, 385 (2019)

Q. Liu, Q. Cao, X. Zhao, H. Bi, C. Wang, D.S. Wu, R. Che, A.C.S. Appl, Mater. Interfaces 7, 4233 (2015)

Q. Xu, Z.-J. Wang, Y.-G. Wang, H.-Y. Sun, J. Magn. Magn. Mater. 419, 166 (2016)

H. Li, J. Liao, Y. Feng, S. Yu, X. Zhang, Z. Jin, CrystEngComm 14, 2974 (2012)

Q. Liu, X. Xu, W. Xia, R. Che, C. Chen, Q. Cao, J. He, Nanoscale 7, 1736 (2015)

D. Min, W. Zhou, Y. Qing, F. Luo, D. Zhu, J. Electron. Mater. 46, 4903 (2017)

S.M. Neumayer, L. Tao, A. O’Hara, J. Brehm, M. Si, P.-Y. Liao, T. Feng, S.V. Kalinin, D.Y. Peide, S.T. Pantelides, Phys. Rev. Appl. 13, 64063 (2020)

S. ur Rehman, R. Ahmed, K. Ma, S. Xu, T. Tao, M.A. Aslam, M. Amir, J. Wang. Eng. Sci. 13, 71 (2020)

L.C. Dong, Y.B. Zhong, S. Zhe, T.Y. Zheng, H. Wang, RSC Adv. 6, 21037 (2016)

P. Fu, X. Huan, J. Luo, S. Ren, X. Jia, X. Yang, A.C.S. Appl, Nano Mater. 3, 9340 (2020)

S. ur Rehman, R. Ahmed, J. Liu, J. Wang, M. Sun, Z. Fang, M.A. Aslam, P.C. Morais, C. Wang, H. Bi, Part. Part. Syst. Charact. 36, 1900047 (2019)

S. ur Rehman, J. Wang, Q. Luo, M. Sun, L. Jiang, Q. Han, J. Liu, H. Bi, Chem. Eng. J. 373, 122 (2019)

M.A. Aslam, W. Ding, S. ur Rehman, A. Hassan, Y. Bian, Q. Liu, Z. Sheng, Appl. Surf. Sci. 543, 148785 (2021)

A. Hassan, W. Ding, M.A. Aslam, Y. Bian, Q. Liu, Z. Sheng, J. Mater. Res. Technol. 9, 12869 (2020)

M.A. Aslam, K. Hu, W. Ding, A. Hassan, Y. Bian, K. Qiu, Q. Liu, Z. Sheng, Ceram. Int. 47(19), 27496–27502 (2021)

H. Peng, Z. Xiong, Z. Gan, C. Liu, Y. Xie, Compos. Part B Eng. 224, 109170 (2021)

H.-Y. Wang, X. Sun, G.-S. Wang, J. Mater. Chem. A 9, 24571 (2021)

Y.-L. Wang, S.-H. Yang, H.-Y. Wang, G.-S. Wang, X.-B. Sun, P.-G. Yin, Carbon N. Y. 167, 485 (2020)

S. ur Rehman, M. Sun, M. Xu, J. Liu, R. Ahmed, M. Adnan-Aslam, R. Ali-Ahmad, H. Bi, J. Colloid Interface Sci. 574, 87 (2020)

Acknowledgements

The authors acknowledge the financial support from the National Key Research and Development Project (2020YFA0210703), the National Natural Science Foundation of China (No. U2032159, U2032158, and 62005292), and supported by the Alliance of International Science Organizations, (ANSO-VF-2021-03), Development Program of Anhui Province (No. 202103a05020013, 202104a05020036), The Major Scientific and Technological Special Project of Anhui Province (202103a05020192).

Author information

Authors and Affiliations

Corresponding authors

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Aslam, M.A., Ahsen, R., Uddin, W. et al. Tailoring the morphology of CoNi alloy by static magnetic field for electromagnetic wave absorption. Eur. Phys. J. Plus 137, 480 (2022). https://doi.org/10.1140/epjp/s13360-022-02680-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-022-02680-0