Abstract

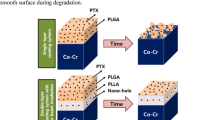

In search for a drug-containing material when creating polymer-free drug-eluting stents, an analysis of the available literature is carried out. It is shown that one of the promising materials for this purpose is mesoporous silicon (the cross-sectional pore diameter is 2–50 nm), which has high biocompatibility and biodegradability. The main requirements for the porous silicon coating as a drug carrier of metal intravascular stents are formulated. The results of experimental studies are presented, including those performed by the authors, showing the possibility of continuous silicon coating application up to 0.6 μm thick on the stents by magnetron sputtering or plasma-immersion ion implantation and deposition (PIII@D). These methods provide high coating adhesion to the stent material and allow coating both on the external and internal stent surfaces.

Similar content being viewed by others

REFERENCES

Barquera, S., Pedroza-Tobias, A., Medina, C., et al., Global overview of the epidemiology of atherosclerotic cardiovascular disease, Arch. Med. Res., 2015, vol. 46, no. 5, pp. 328–338.

Bonsignore, G., A decade of evolution in stent design, Proc. Int. Conf. on Shape Memory and Superelastic Technologies (SMST–2003), Pelton, A.R. and Duerig, T., Eds., Materials Park, OH: ASM Int., 2004, pp. 519–528.

Simard, T., Hibbert, B., Ramirez, F.D., Froeschl, M., et al., The evolution of coronary stents: a brief review, Can. J. Cardiol., 2014, vol. 30, pp. 35–45.

Meier, B., Use and abuse of coronary stenting, Hosp. Chron., 2006, vol. 1, suppl. 1, pp. 99–103.

Kalra, A., Rehman, H., Khera, S., Thyagarajan, B., et al., New-generation coronary stents: current data and future directions, Curr. Atheroscler. Rep., 2017, vol. 19, p. 14. https://doi.org/10.1007/s11883-017-0654-1

Wu, T. and McCarthy, S., Coronary arterial drug-eluting stent: from structure to clinical, in Coronary Artery Diseases, Chaikovsky, I. and Sydorova, N., Eds., London: InTechOpen, 2012, chap. 10.

Steffel, J., Eberli, F.R., Luscher, T.F., and Tanner, F.C., Drug-eluting stents—What should be improved? Ann Med., 2008, vol. 40, no. 4, pp. 242–252.

Abizaid, A. and Costa, J.R., New drug-eluting stents: an overview on biodegradable and polymer-free next-generation stent systems, Circ.: Cardiovasc. Interventions, 2010, vol. 3, pp. 384–393.

Nakazawa, G., Finn, A.V., Joner, M., et al., Delayed arterial healing and increased late stent thrombosis at culprit sites after drug-eluting stent placement for acute myocardial infarction patients: an autopsy study, Circulation, 2008, vol. 118, pp. 1138–1145.

Virmani, R., Farb, A., Guagliumi, G., and Kolodgie, F.D., Drug-eluting stents: caution and concerns for long-term outcome, Coron. Artery Dis., 2004, vol. 15, pp. 313–318.

Hezi‑Yamit, A., Sullivan, C., Wong, J., et al., Impact of polymer hydrophilicity on biocompatibility: implication for DES polymer design, J. Biomed. Mater. Res., Part A, 2009, vol. 90, pp. 133–141.

Middleton, J.C. and Tipton, A.J., Synthetic biodegradable polymers as orthopedic devices, Biomaterials, 2000, vol. 21, pp. 2335–2346.

Diletti, R., Serruys, P.W., Farooq, V., et al., ABSORB II randomized controlled trial: a clinical evaluation to compare the safety, efficacy, and performance of the Absorb everolimus-eluting bioresorbable vascular scaffold system against the XIENCE everolimus-eluting coronary stent system in the treatment of subjects with ischemic heart disease caused by de novo native coronary artery lesions: rationale and study design, Am. Heart J., 2012, vol. 164, pp. 654–663.

Heublein, B., Rohde, R., Kaese, V., et al., Biocorrosion of magnesium alloys: a new principle in cardiovascular implant technology? Heart, 2003, vol. 89, pp. 651–656.

Waksman, R., Biodegradable stents: They do their job and disappear, J. Invasive Cardiol., 2006, vol. 18, no. 2, pp. 70–74.

Moravej, M., Purnama, A., Fiset, M., Couet, J., and Mantovani, D., Electroformed pure iron as a new biomaterial for degradable stents: in vitro degradation and preliminary cell viability studies, Acta Biomater., 2010, vol. 6, pp. 1843–1851.

Dave, V., Falotico, R., Li, Ch., Nguyen, T.M., Parker, T.L., and Zhao, D.Z., RF Patent 2526885, 2014.

Shanley, J.F., US Patent 6 241 762, 2001.

Byrne, R.A., Iijima, R., Mehilli, J., et al., Durability of antirestenotic efficacy in drug-eluting stents with and without permanent polymer, J. Am. Coll. Cardiol.: Cardiovasc. Interventions, 2009, vol. 2, pp. 291–299.

Moore, P., Barlis, P., Spiro, J., et al., A randomized optical coherence tomography study of coronary stent strut coverage and luminal protrusion with rapamycineluting stents, J. Am. Coll. Cardiol.: Cardiovasc. Interventions, 2009, vol. 2, pp. 437–444.

Kollum, M., Farb, A., Schreiber, R., et al., Particle debris from a nanoporous stent coating obscures potential antiproliferative effects of tacrolimus-eluting stents in a porcine model of restenosis, Catheter Cardiovasc. Interventions, 2005, vol. 64, pp. 85–90.

Wieneke, H., Dirsch, O., Sawitowski, T., et al., Synergistic effects of a novel nanoporous stent coating and tacrolimus on intima proliferation in rabbits, Catheterization Cardiovasc. Interventions, 2003, vol. 60, pp. 399–407.

Rajtar, A., Kaluza, G.L., Yang, Q., et al., Hydroxyapatite-coated cardiovascular stents, EuroIntervention, 2006, vol. 2, pp. 113–115.

Costa, J.R., Abizaid, Al., Costa, R., et al., Preliminary results of the hydroxyapatite nonpolymer-based sirolimus-eluting stent for the treatment of single de novo coronary lesions a first-in-human analysis of a third-generation drug-eluting stent system, J. Am. Coll. Cardiol.: Cardiovasc. Interventions, 2008, vol. 1, pp. 545–551.

Costa, J.R., Jr., Abizaid, A., Costa, R., et al., 1-Year results of the hydroxyapatite polymer-free sirolimus-eluting stent for the treatment of single de novo coronary lesions: the VESTASYNC I trial, J. Am. Coll. Cardiol.: Cardiovasc. Interventions, 2009, vol. 2, pp. 422–427.

Mougeri, U.O.G., Beklemyshev, V.I., Makhonin, I.I., et al., RF Patent 2448741, 2012.

Tang, C.J., Wang, G.X., Shen, Y., et al., A study on surface endothelialization of plasma coated intravascular stents, Surf. Coat. Technol., 2010, vol. 204, pp. 1487–1492.

Loya, M.C., Brammer, K.S., Choi, Ch., et al., Plasmainduced nanopillars on bare metal coronary stent surface for enhanced endothelialization, Acta Biomater., 2010, vol. 6, pp. 4589–4595.

Liu, C.L., Chu, P.K., Lin, G.Q., and Qi, M., Anti-corrosion characteristics of nitride-coated AISI 316L stainless steel coronary stents, Surf. Coat. Technol., 2006, vol. 201, no. 6, pp. 2802–2806.

Huang, N., Leng, Y.X., Yang, P., et al., Surface modification of coronary artery stent by Ti–O/Ti–N complex film coating prepared with plasma immersion ion implantation and deposition, Nucl. Instrum. Methods Phys. Res., Sect. B, 2006, vol. 242, nos. 1–2, pp. 18–21.

Herman, R.A., Rybnikar, A., Resch, A., Märkl, B., Alt, E., Stemberger, A., and Schömig, A., Thrombogenicity of stainless steel coronary stents with a completely gold coated surface, J. Am. Coll. Cardiol., 1998, vol. 31, suppl. 2.

Edelman, E., Seifert, P., Groothuis, A., Morss, A., Bornstein, D., and Rogers, C., Gold-coated NIR stents in porcine coronary arteries, Circulation, 2001, vol. 103, no. 3, pp. 429–434.

Bolz, A. and Schaldach, M., Artificial heart valves: improved blood compatibility by PECVD a-SiC:H coating, Artif. Organs, 1990, vol. 14, no. 4, pp. 260–269.

Monnink, S.H., van Boven, A.J., Peels, H.O., Tigchelaar, I., de Kam, P.J., Crijns, H.J., and van Oeveren, W., Silicon-carbide coated coronary stents have low platelet and leukocyte adhesion during platelet activation, J. Invest. Med., 1999, vol. 47, no. 6, pp. 304–310.

Kalnins, U., Erglis, A., Dinne, I., Kumsars, I., and Jegere, S., Clinical outcomes of silicon carbide coated stents in patients with coronary artery disease, Med. Sci. Monit., 2002, vol. 8, no. 2, pp. 116–120.

Gutensohn, K., Beythien, C., Bau, J., Fenner, T., Grewe, P., Koester, R., et al., In vitro analyses of diamond-like carbon coated stents. Reduction of metal ion release, platelet activation, and thrombogenicity, Thromb. Res., 2000, vol. 99, no. 6, pp. 577–585.

Kim, J.H., Shin, J.H., Shin, D.H., et al., Comparison of diamond-like carbon-coated nitinol stents with or without polyethylene glycol grafting and uncoated nitinol stents in a canine iliac artery model, Br. J. Radiol., 2011, vol. 84, no. 999, pp. 210–215.

Cuong, N.K., Tahara, M., Yamauchi, N., and Sone, T., Diamond-like carbon films deposited on polymers by plasma-enhanced chemical vapor deposition, Surf. Coat. Technol., 2003, vol. 174, pp. 1024–1028.

Leu, M.S., Chen, S.Y., Chang, J.J., Chao, L.G., and Lin, W., Diamond-like coatings prepared by the filtered cathodic arc technique for minting application, Surf. Coat. Technol., 2004, vol. 177, pp. 566–572.

Sui, J.H., Cai, W., and Zhao, L.C., Surface modification of NiTi alloys using diamond-like carbon (DLC) fabricated by plasma immersion ion implantation and deposition (PIIID), Nucl. Instrum. Methods Phys. Res.,Sect. B, 2006, vol. 248, no. 1, pp. 67–70.

Macionczyk, F., Gerold, B., and Thull, R., Repassivating tantalum/tantalum oxide surface modification on stainless steel implants, Surf. Coat. Technol., 2001, vol. 142, pp. 1084–1087.

Windecker, S., Mayer, I., De Pasquale, G., et al., Stent coating with titanium-nitride-oxide for reduction of neointimal hyperplasia, Circulation, 2001, vol. 104, pp. 928–933.

Windecker, S., Simon, R., Lins, M., et al., Randomized comparison of a titanium-nitride-oxide-coated stent with a stainless steel stent for coronary revascularization: the tinox trial, Circulation, 2005, vol. 111, pp. 2617–2622.

Pareta, R.A., Nimmy, M., Yokogawa, Y., and Harikrishna, V., Pulsed laser deposition of hydroxyapatite on nanostructured titanium towards drug eluting implants, Mater. Sci. Eng., C, 2013, vol. 33, pp. 2899–2904.

Arruebo, M., Drug delivery from structured porous inorganic materials, WIREs Nanomed.Nanobiotechnol., 2012, vol. 4, pp. 16–30.

Ksenofontova, O.I., Vasin, A.V., Egorov, V.V., et al., Porous silicon and its application in biology and medicine, Tech. Phys., 2014, vol. 59, no. 1, pp. 66–77.

Properties of Porous Silicon, Canham, L., Ed., London: Inst. Electr. Eng., 1997.

Foraker, A.B., Walczak, R.J., Cohen, M.H., et al., Microfabricated porous silicon particles enhance paracellular delivery of insulinacross intestinal Caco-2 cell monolayers, Pharmacol. Res., 2003, vol. 20, pp. 110–116.

Zimin, S.P., Porous silicon—material with new properties, Sorosovskii Obraz. Zh., 2004, vol. 8, no. 1, pp. 101–107.

Anglin, E.J., Cheng, L., Freeman, W.R., and Sailor, M.J., Porous silicon in drug delivery devices and materials, Adv. Drug. Delivery Rev., 2008, vol. 60, pp. 1266–1277.

Tasciotti, E., Plant, K., Bhavane, R., et al., Nanoporous silicon particles as a multistage delivery system for imaging and therapeutic applications, Nat. Nanotechnol., 2008, vol. 3, pp. 151–157.

Gu, L., Park, J.H., Duong, K.H., Ruoslahti, E., and Sailor, M.J., Magnetic luminescent porous silicon microparticles for localized delivery of molecular drug payloads, Small, 2010, vol. 6, pp. 2546–2552.

Haidary, S.M., Córcoles, E.P., and Ali, N.K., Nanoporous silicon as drug delivery systems for cancer therapies, J. Nanomater., 2012, vol. 2012, art. ID 830503.

Postnov, V.N., Naumysheva, E.B., Korolev, D.V., and Galagudza, M.M., Nano-sized carriers for drug delivery, Biotekhnosfera, 2013, vol. 6, no. 30, pp. 16–27.

Polkovnikova, Yu.A., The use of porous silicon as a prospective carrier of medical drugs, Vestn. Voronezh. Gos. Univ., Ser.: Khim., Biol., Farm., 2017, no. 4, pp. 124–129.

Yurakov, Yu.A., Lenshin, A.S., and Seredin, P.V., Poluchenie poristogo kremniya (Formation of Porous Silicon), Voronezh: Voronezh. Gos. Univ., 2014.

Lenshin, A.S., Kashkarov, V.M., and Seredin, P.V., RF Patent 2572128, 2015.

Yuzova, V.A., Levitsky, A.A., and Harlashin, P.A., Advances in porous silicon technology and research, Zh. Sib. Fed. Univ.,Ser.: Tekh. Tekhnol., 2011, vol. 1, no. 4, pp. 92–112.

Shevchenko, V.Ya., Kiselev, O.I., and Sokolov, V.N., Issledovaniya, tekhnologiya i ispol’zovanie nanoporistykh nositelei lekarstv v meditsine (Research, Technology, and Use of Nanoporous Drug Carriers in Medicine), St. Petersburg: Khimizdat, 2015.

Laaksonen, T., Santos, H., Vihola, H., et al., Failure of MTT as a toxicity testing agent for mesoporous silicon microparticles, Chem. Res. Toxicol., 2007, vol. 20, pp. 1913–1918.

Shtansky, D.V., Gloushankova, N.A., Sheveiko, A.N., et al., Si-doped multifunctional bioactive nanostructured films, Surf. Coat. Technol., 2010, vol. 205, pp. 728–739.

Shie, M.-Y., Ding, S.-J., and Chang, H.-C., The role of silicon in osteoblast-like cell proliferation and apoptosis, Acta Biomater., 2011, vol. 7, pp. 2604–2614.

Qian, S. and Liu, X., Effect of Si-incorporation on hydrophilicity and bioactivity of titania film, Surf. Coat. Technol., 2013, vol. 229, pp. 156–161.

Cao, H. and Liu, X., Activating titanium oxide coatings for orthopedic implants, Surf. Coat. Technol., 2013, vol. 233, pp. 57–64.

Lotkov, A.I., Kashin, O.A., Kudryavtseva, Yu.A., et al., Interaction of human endothelial cells and nickeltitanium materials modified with silicon ions, AIP Conf. Proc., 2015, vol. 1683, art. ID 020126.

Velichko, R.V., Gusev, E.Yu., Gamaleev, V.A., Mikhno, A.S., and Bychkova, A.S., PECVD analysis of nano- and polycrystalline silicon films, Fundam. Issled., 2012, no. 11, pp. 1176–1179.

Strunin, V.I., Baranova, L.V., and Khudaibergenov, G.Zh., RF Patent 2165476, 2001.

Aston, R. and Canham, L.T., US Patent 7186267, 2007.

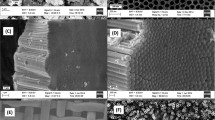

Meisner, S.N. and Lotkov, A.I., Surface morphology and elemental composition of Si coatings deposited on NiTi substrates in different magnetron sputtering modes, Izv. Vyssh. Uchebn. Zaved., Fiz., 2009, 52, no. 12-2, pp. 85–88.

Kashin, O.A., Lotkov, A.I., Kudryashov, A.N., et al., Structural phase states in nickel-titanium surface layers doped with silicon by plasma immersion ion implantation, AIP Conf. Proc., 2015, vol. 1683, art. ID 020078.

Lotkov, A.I., Kashin, O.A., Borisov, D.P., et al., Effect of plasma immersion ion beam processing on the structurephase state and the properties of the surface layers in titanium nickelide samples, Russ. Metall. (Engl. Transl.), 2017, vol. 4, pp. 250–254.

Kashin, O.A., Lotkov, A.I., Borisov, D.P., et al., Plasma immersion ion implantation for surface treatment of complex branched structures, AIP Conf. Proc., 2016, vol. 1783, art. ID 020082.

Lotkov, A.I., Kashin, O.A., Kudryashov, A.N., and Krukovsky, K.V., Structure and properties of self-expanding intravascular NiTi stents doped with Si ions, Mater. Today Proc., 2017, vol. 4, pp. 4647–4651.

Borisov, D.P., Slabodchikov, V.A. and Kuznetsov, V.M., Plasma source based on an unbalanced magnetron sputtering system, IOP Conf. Ser.: J. Phys., 2017, vol. 830, art. ID 012057.

Borisov, D.P., Detistov, K.N., Korotaev, A.D., et al., SPRUT vacuum plasma technological complex for creating the new nanocomposite materials and hardening surfaces structures, Zavod. Lab.,Diagn. Mater., 2010, vol. 76, no. 12, pp. 32–36.

Funding

The work was carried out as part of the Program of Fundamental Scientific Research of the State Academies of Sciences of the Russian Federation for 2013–2020, project III.23.2.2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by A. Kolemesin

Rights and permissions

About this article

Cite this article

Kashin, O.A., Krukovskii, K.V. & Lotkov, A.I. Potential and Capabilities of Porous Silicon as a Material for Intravascular Drug-Eluting Stents: Brief Summary. Inorg. Mater. Appl. Res. 11, 287–296 (2020). https://doi.org/10.1134/S2075113320020161

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113320020161