Abstract—The paper presents results of the industrial implementation of hot plastic deformation and thermal treatment schemes for the production of rolled sheet products based on cold-resistant steel with yield strength not lower that 315–750 MPa for the Arctic. On the basis of the studies performed, a set of scientific and technological techniques has been developed for various technological processes (thermomechanical treatment followed by accelerated cooling, quenching from the rolling heating, and separate furnace heating with high-temperature tempering). The developed complex method provides the formation of a structure having an acceptable heterogeneity and anisotropy level corresponding to different morphological and crystallographic parameters throughout the entire thickness of rolled products up to 100 mm based on low-alloy steels with a yield strength not lower than 315–460 MPa and up to 60 mm based on economically alloyed steels with a yield strength not lower than 500–750 MPa. The structure of sheet products is presented that provides guaranteed characteristics of strength, cold resistance (impact energy KV at a testing temperature ranging from –60 to –80°C, critical ductile-to-brittle transition temperature Tkb, and nil ductility temperature NDT), and crack resistance according to a CTOD criterion in a low-temperature range to meet the requirements of the RMRS “Rules for the Classification and Construction of Ships” for steel with the Arc40 index.

Similar content being viewed by others

Notes

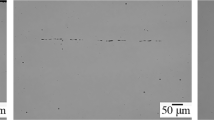

Technological violations can lead to an increase in the value of anisotropy coefficient Ka inherent in the ferritic-bainitic structure. The value of coefficient Ka calculated according to a certified technique developed at JSC Tiksomet characterizes the presence and prominence of the prevailing orientation of structural components.

REFERENCES

Sych, O.V. Scientific and technological bases for creation of cold-resistant steel with a guaranteed yield strength of 315–750 MPa for the Arctic. Part 1: Principles of alloying and requirements for sheet metal structure, Vopr. Materialoved., 2018, no. 3 (95), pp. 22–47.

Gorynin, I.V., Rybin, V.V., Malyshevskii, V.A., and Khlusova, E.I., Alloying principles, phase transformations, structure and properties of low-temperature weldable shipbuilding steels, Met. Sci. Heat Treat., 2007, vol. 49, nos. 1–2, pp. 3–9.

Gorynin, I.V., Rybin, V.V., Malyshevskii, V.A., and Khlusova, E.I., Cold-resistant steels for technical means for development of the Arctic shelf, Vopr. Materialoved., 2009, no. 3 (59), pp. 108–126.

Kazakov, A.A. and Kiselev, D.V., Modern methods for quality assessment of the structure of metals based on panoramic studies using the Thixomet image analyzer, in Perspektivnye materialy: Uchebnoe posobie (Advanced Materials: Manual), Tolyatti: Tol’yat. Gos. Univ., 2013, vol. 5.

Kazakov, A.A., Kazakova, E.I., Kiselev, D.V., and Motovilina, G.D., Development of methods for evaluation of the microstructural heterogeneity of tubular steels, Chern. Met., 2009, no. 12, pp. 12–15.

Gorelik, S.S., Dobatkin, S.V., and Kaputkina, L.M., Rekristallizatsiya metallov i splavov (Recrystallization of Metals and Alloys), Moscow: Mosk. Inst. Stali Splavov, 2005.

Rybin, V.V., Bol’shie plasticheskie deformatsii i razrushenie metallov (Large Plastic Deformations and Destruction of Metals), Moscow: Metallurgiya, 1986.

Kodzhaspirov, G.E., Rudskoi, A.I., and Rybin, V.V., Fizicheskie osnovy i resurso-sberegayushchie tekhnologii izgotovleniya izdelii plasticheskim deformirovaniem (Physical Basis and Resource-Saving Technologies of Product Manufacture by Plastic Deformation), St. Petersburg: Nauka, 2006.

Khasterkamp, F., Khulka, K., Matrosov, Yu.I., Morozov, Yu.D., Efron, L.I., Stolyarov, V.I., and Chevskaya, O.N., Niobiisoderzhashchie nizkolegirovannye stali (Niobium-Containing Low-Alloyed Steels), Moscow: Intermet Inzhiniring, 1999.

Rybin, V.V., Rubtsov, A.S., and Kodzhaspirov, G.E., Structure transmutations in steel during rolling with different degree and graininess of deformation, Fiz. Met. Metalloved., 1984, vol. 58, no. 4, pp. 774–781.

Brown, E.L. and De Ardo, A.J., On the origin of equiaxed austenite grains that result from the hot rolling of steel, Metall. Trans. A, 1981, vol. 12, pp. 39–47.

Sych, O.V., Kruglova, A.A., Schastlivtsev, V.M., Tabatchikova, T.I., and Yakovleva, I.L., Effect of vanadium on the precipitation strengthening upon tempering of a high-strength pipe steel with different initial structure, Phys. Met. Metallogr., 2016, vol. 117, no. 12, pp. 1270–1280.

Kruglova, A.A., Legostaev, Yu.L., and Khlusova, E.I., Study of Temperature-stain modes of dynamic recrystallization of AB-1 steel, Sudostr. Prom-st’, 1988, no. 8, pp. 12–16.

Bianchi, J.G. and Karialainen, L.P., Modeling of dynamic and meta-dynamic recrystallization during bar rolling of a medium carbon spring steel, J. Mater. Process. Technol., 2005, vol. 160, pp. 267–277.

Olasolo, M., Uranga, P., Rodriguez-Ibabe, J. M., and López, B., Effect of austenite microstructure and cooling rate on transformation characteristics in a low carbon Nb–V microalloyed steel, Mater. Sci. Eng., A, 2011, vol. 528, pp. 2559–2569.

Miao, C.L., Shang, C.J., Zhang, G.D., and Subramanian, S.V., Recrystallization and strain accumulation behaviors of high Nb-bearing line pipe steel in plate and strip rolling, Mater. Sci. Eng., A, 2010, vol. 527, pp. 4985–4992.

Pereda, B., Fernández, A.I., and López, B., Effect of Mo on dynamic recrystallization behavior on Nb–Mo micro-alloyed steels, ISIJ Int., 2007, vol. 47, no. 6, pp. 860–868.

Fernández, A.I., Uranga, P., López, B., and Rodrigues-Ibabe, J.M. Dynamic recrystallization behavior covering a wide austenite grain size range in Nb and Nb–Ti microalloyed steels, Mater. Sci. Eng., A, 2001, vol. 361, pp. 367–376.

Hodgson, P.D., Zahiri, S.H., and Whale, J.J., The static and meta-dynamic recrystallization behavior of an X60 Nb microalloyed steel, ISIJ Int., 2004, vol. 44, no. 7, pp. 1224–1229.

Dehgan-Manshadi, A., Barnett, M., and Hodgson, P., Hot deformation and recrystallization of austenitic stainless steel: Part 1. Dynamic recrystallization, Met. Mater. Trans. A, 2008, vol. 39, pp. 1359–1370.

Morito, S., Saito, H., Ogawa, T., Furuhara, T., and Maki, T., Effect of austenite grain size on the morphology and crystallography of lath martensite in low carbon steels, ISIJ Int., 2005, vol. 45, no. 1, pp. 91–94.

Zisman, A.A., Khlusova, E.I., and Soshina, T.V., Recrystallization of 09CrNi2MD steel austenite in hot rolling by relaxation of tensions, Vopr. Materialoved., 2012, no. 2 (70), pp. 16–28.

Soshina, T.V., Zisman, A.A., and Khlusova, E.I., The effect of microalloying by niobium on recrystallization processes in austenite of low-carbon alloyed steels, Vopr. Materialoved., 2013, no. 1 (73), pp. 31–36.

Chastukhin, A.V., Ringinen, D.A., Khadeev, G.E., and Efron, L.I., Kinetics of the static recrystallization of austenite in niobium-microalloyed pipe steels, Metallurgist, 2016, vol. 59, nos. 11–12, pp. 1180–1187.

Chastukhin, A.V., Ringinen, D.A., Efron, L.I., Astaf’ev, D.S., and Golovin, S.V., Development of austenite structuring models to improve the strategies of pipe steel hot rolling, Probl. Chern. Metall. Materialoved., 2016, no. 3, pp. 39–53.

Orlov, V.V., Principles of controlled formation of nanosized structural elements in pipe steels upon significant plastic deformations, Inorg. Mater.: Appl. Res., 2012, vol. 3, no. 6, pp. 466–474.

Kruglova, A.A., Orlov, V.V., Sych, O.V., and Khlusova, E.I., Improvement of chemical composition and production regimes for manufacture of K65–K70 (X80–X90) strip based on simulation, Metallurgist, 2013, vol. 57, nos. 1–2, pp. 113–122.

Sych, O.V., Khlusova, E.I., Golosienko, S.A., Orlov, V.V., Mileikovskii, A.B., Galkin, V.V., Denisov, S.V., Stekanov, P.A., and Malakhov, N.V., RF Patent 2465346, Byull. Izobret., 2012, no. 30.

Korotovskaya, S.V., Orlov, V.V., and Khlusova, E.I., Control of structure formation during thermomechanical treatment of shipbuilding and pipe steels of unified chemical composition, Metallurgist, 2014, vol. 58, nos. 5–6, pp. 406–414.

Khlusova, E.I., Orlov, V.V., and Mikhailov, M.S., Formation of thick-plate low-carbon steel structure at thermomechanical treatment, Deform. Razrushenie Mater., 2007, no. 6, pp. 18–24.

Schastlivtsev, V.M., Tabatchikova, T.I., Yakovleva, I.L., Del’gado Reina, S.Y., Golosienko, S.A., Pazilova, U.A., and Khlusova, E.I., Effect of thermomechanical treatment on the resistance of low-carbon low-alloy steel to brittle fracture, Phys. Met. Metallogr., 2015, vol. 116, no. 2, pp. 189–199.

Khlusova, E.I., Golosienko, S.A., Motovilina, G.D., and Pazilova, U.A., Influence of doping on the structure and properties of high-strength cold-resistant steel after thermal and thermomechanical processing, Vopr. Materialoved., 2007, no. 1 (49), pp. 20–31.

Golosienko, S.A., Motovilina, G.D., and Khlusova, E.I., Influence of the structure formed during quenching on the properties of high-strength cold-resistant steel after tempering, Vopr. Materialoved., 2008, no. 1 (53), pp. 33–46.

Zisman, A.A., Soshina, T.V., and Khlusova, E.I., Maps of structure changes in austenite of low carbon steel 09CrNi2MoCuV during hot deformation and their use to improve industrial technologies, Inorg. Mater.: Appl. Res., 2014, vol. 5, no. 6, pp. 570–577.

Pazilova, U.A., Khlusova, E.I., and Kniaziuk, T.V., Influence of hot plastic deformation modes on the structure and properties of quenched hot rolled economically alloyed high-strength steel, Inorg. Mater.: Appl. Res., 2018, vol. 9, no. 6, pp. 1051–1059.

Golubeva, M.V., Sych, O.V., Khlusova, E.I., Motovilina, G.D., Sviatysheva, E.V., Rogozhkin, S.V., and Lukyanchuk, A.A., Structure changes of high-strength economically alloyed steel 09KhGN2MD (09CrMnNi2MoCu) in tempering, Inorg. Mater.: Appl. Res., 2018, vol. 9, no. 6, pp. 997–1005.

Khlusova, E.I. and Semicheva, T.G., Forming of austenite and ferrite grain under thermal treatment: structural heredity, in Materialy dlya sudostroeniya i morskoi tekhniki (Materials for Ship Building and Marine Equipment), St. Petersburg: Professional, 2009, vol. 1, pp. 83–100.

Golubeva, M.V., Sych, O.V., Khlusova, E.I., and Motovilina, G.D., Mechanical properties and destruction nature of new economical-alloyed cold-resistant steel with guaranteed strength category 690 MPa, Aviats. Mater. Tekhnol., 2017, no. 4 (49), pp. 19–24.

Janjušević, Z., Gulišija, Z., Mihailović, M., and Patarić, A., The investigation of applicability of the Hollomon–Jaffe equation on tempering the HSLA steel, Chem. Ind. Chem. Eng. Q., 2009, vol. 15, no. 3, pp. 131–136.

Jaffe, L. and Gordon, E., Temperability of steels, Trans. Am. Soc. Met., 1957, vol. 49, pp. 359–371.

Hollomon, J. and Jaffe, L., Time-temperature relations in tempering steel, Met. Technol., 1945, vol. 12, pp. 223–249.

Sych, O.V., Golubeva, M.V., and Khlusova, E.I., Development of cold-resistant welded steel of strength category 690 MPa for heavy-duty equipment operated in arctic conditions, Tyazh. Mashinostr., 2018, no. 4, pp. 17–25.

Gusev, M.A., Il’in, A.V., and Larionov, A.V., Certification of shipbuilding materials for Arctic ships, Sudostroenie, 2014, no. 5 (816), pp. 39–43.

Sych, O.V., Khlusova, E.I., Pazilova, U.A., and Yashina, E.A., The structure and properties of zone of thermal influence of low-alloyed cold-resistant steels for application in Arctic, Vopr. Materialoved., 2018, no. 2 (94), pp. 30–51.

Sych, O.V., Golubeva, M.V., and Khlusova, E.I., The structure and properties of welded joints from high-strength cold-resistant 09KhGN2MD steel obtained by electric arc and laser welding, Tyazh. Mashinostr., 2018, nos. 7–8, pp. 23–32.

Sych, O.V., Khlusova, E.I., Golubeva, M.V., Gusev, M.A., Yashina, E.A., Denisov, S.V., Gorshkov, S.N., Steka-nov, P.A., Avramenko, V.A., and Mychak, M.N., Development and introduction of production technologies of cold-resistant rolled metal for icebreakers, marine and service equipment for the Arctic, Materialy mezhdunarodnoi konferentsii i vystavki po osvoeniyu nefti i gaza Rossiiskoi Arktiki i kontinental’nogo shel’fa stran SNG (RAO/CIS Offshore), Sankt-Peterburg, 12–15 sen-tyabrya 2017 g. (Proc. Int. Conf. and Exhibition for Oil and Gas Resources Development of the Russian Arctic and Continental Shelf of CIS Countries (RAO/CIS Offshore), St. Petersburg, September 12–15, 2017), St. Petersburg, 2017, pp. 31–33.

ACKNOWLEDGMENTS

Studies of the anisotropy coefficient for ferrite-bainitic structure Ka calculated according to a certified method of JSC Tiksomet, were carried out in collaboration with Dr. Sci. (Eng.) A.A. Kazakov and Cand. Sci (Eng) P.V. Kovalev (St. Petersburg Polytechnic University).

Fine structure studies were performed in conjunction with Cand. Sci. (Eng). G.D. Motovilina and M.S. Mikhailov (National Research Center Kurchatov Institute—Central Research Institute of Structural Materials Prometey); the EBSD analysis was carried out jointly with Cand. Sci. (Chem) S.N. Petrov and E.A. Vasilyeva (National Research Center Kurchatov Institute—Central Research Institute of Structural Materials Prometey).

Funding

The work was partly supported within the scope of the project “Arctic Steel” according to state contract with the Ministry of Industry and Тrade of the Russian Federation no. 16411.1810190019.09.003 of October 20, 2016.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Polyakov

Rights and permissions

About this article

Cite this article

Sych, O.V. Scientific and Technological Bases for Developing Cold-Resistant Steel with a Guaranteed Yield Strength of 315–750 MPa for Arctic Conditions: Part 2. Manufacturing Technology, Structure, Properties, and Serviceability of Sheet Products. Inorg. Mater. Appl. Res. 10, 1282–1300 (2019). https://doi.org/10.1134/S2075113319060261

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113319060261