Abstract

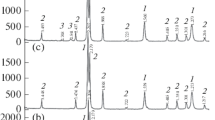

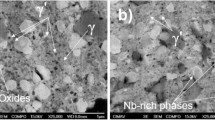

The microstructure and phase composition of the Mo-Si alloy doped with Sc, Y or Nd were investigated. The methods of X-ray diffraction analysis (XRD), electron microscopy, and electron probe microanalysis (EPMA) were used to determine the main phase components and their volume fractions as well as to assess the speciation and interphase distributions of doping rare earth elements (REE). It was shown that, when introducing up to 3.0 at % Si, Y, or Nd into the Mo–15.3 at % Si hypoeutectic alloy, the structure intrinsic to naturally occurring (in situ) composites was formed. This structure was composed of an α-Mo based solid solution and a strengthening silicide phase including Mo3Si and the particles of complex composition enriched in REE. Doping additives contributed significantly to the microstructure dispersity and modified the morphology of particles of both the metallic and silicide phases, and increased the Moss/Mo3Si volume ratio. The microhardness of structural components was determined and the parameters of lattice elementary cells of the main phases were evaluated for the REE-doped alloys under study. The observed regularities of their variations generally conformed to the conclusions about the influence of REE on the structural-phase state of the Mo-Si hypoeutectic composites.

Similar content being viewed by others

References

Karpov, M.I., Svetlov, I.L., and Popova, O.I., Heat-resistant materials based on niobium and molybdenum, in Novye materialy: perspektivnye tekhnologii metallurgii (New Materials: Advanced Technologies in Metallurgy), Moscow: Vseross. Inst. Aviats. Mater., 2014, p. 17.

Kablov, E.N., Svetlov, I.L., and Efimochkin, I.Yu., High-temperature Nb–Si composites, Vestn. Mosk. Gos. Tekh. Univ. im. N.E. Baumana, Ser. Mashinostr., 2011, suppl. 2, pp. 164–173.

Svetlov, I.L., Abuzin, Yu.A., Babich, B.N., et al., High-temperature niobium composites reinforced with niobium silicides, Zh. Funkts. Mater., 2007, vol. 1, no. 2, pp. 48–53.

Jackson, M.R., Bewlay, B.P., Rowe, R.G., Skelly, D.W., and Lipsitt, H.A., High-temperature refractory metalintermetallic composites, JOM, 1996, vol. 48, no. 1, pp. 39–44.

Bewlay, B.P., Jackson, M.R., Zhao, J.-C., and Subramanian, P.R., A review of very-high-temperature Nb–silicide-based composites, Metall. Mater. Trans. A, 2003, vol. 34, pp. 2043–2052.

Chen, Y., Hammerschmidt, T., Pettifor, D.G., Shang, J.-X., and Zhang, Y., Influence of vibrational entropy on structure stability of Nb–Si and Mo–Si systems at elevated temperatures, Acta Mater., 2009, vol. 57, pp. 2657–2664.

Okamoto, H., Nb–Si (niobium–silicon), J. Phase Equilib. Diffus., 2005, vol. 26, no. 6, p. 649.

Gokhale, A.B. and Abbaschian, G.J., The Mo–Si (molybdenum–silicon) system, J. Phase Equilib., 1991, vol. 12, no. 4, pp. 493–498.

Chen, H., Ma, Q., Shao, X., Ma, J., Wang, C., and Huang, B., Microstructure, mechanical properties and oxidation resistance of Mo5Si3–Al2O3 composite, Mater. Sci. Eng., A, 2014, vol. 592, pp. 12–18.

Vasudevan, A.K. and Petrovic, J., A comparative overview of molybdenum disilicide composites, Mater. Sci. Eng., A, 1992, vol. 155, pp. 1–17.

Ingemarsson, L., Hellström, K., Johansson, L.G., Svensson, J.E., and Halvarsson, M., Oxidation behavior of a Mo(Si, Al)2 based composite at 1500°C, Intermetallics, 2011, vol. 19, pp. 1319–1329.

Ashby, M.F., Blunt, F.J., and Bannister, M., Flow characteristics of highly constrained metal wires, Acta Metall., 1989, vol. 37, pp. 1847–1857.

Rosales, I. and Schneibel, J.H., Stoichiometry and mechanical properties of Mo3Si, Intermetallics, 2000, vol. 8, pp. 885–889.

Mousa, M., Wanderka, N., Timpel, M., Singh, S., Krüger, M., Heilmaier, M., and Banhart, J., Modification of Mo–Si alloy microstructure by small additions of Zr, Ultramicroscopy, 2011, vol. 111, pp. 706–710.

Jehanno, P., Saage, M., Boning, M., Kestler, H., Freudenberger, J., and Drawin, S., Assessment of the high temperature deformation behavior of molybdenum silicide alloys, Mater. Sci. Eng., A, 2007, vol. 463, pp. 216–223.

Krüger, M., Jain, P., Kumar, K.S., and Heilmaier, M., Correlation between microstructure and properties of fine-grained Mo–Mo3Si–Mo5SiB2 alloys, Intermetallics, 2014, vol. 8, pp. 10–18.

Larionov, A.V., Udoeva, L.Yu., Chumarev, V.M., and Mansurova, A.N., Thermodynamic simulation of phase formation in the Mo–Si alloys doped with yttrium, Butlerovskie Soobshch., 2015, vol. 43, no. 9, pp. 84–88.

Larionov, A.V., Udoeva, L.Yu., and Chumarev, V.M., Thermodynamic simulation of phase formation in the Mo–Si, alloys doped with scandium or neodymium, Butlerovskie Soobshch., 2015, vol. 43, no. 9, pp. 89–96.

Mansurova, A.N., Larionov, A.V., Tyushnyakov, S.N., and Marshuk, L.A., Phase composition and microstructure of Mo–Si alloys, obtained under nonequilibrium crystallization, Butlerovskie Soobshch., 2015, vol. 43, no. 9, pp. 97–101.

Northcott, L., Molybdenum, London: Butterworths, 1956.

Samsonov, G.V., Dvorina, L.A., and Rud’, B.M., Silicidy (Silicides), Moscow: Metallurgiya, 1979.

Kotur, B.YA. and Bodak, O.I., Triple systems of Sc–Mo–Si and Sc–Mo–Ge at 1070K, Metally, 1988, no. 4, pp. 189–192.

Bodak, O.I., Gorelenko, Yu.K., Yarovets, V.I., and Kolozdra, R.V., Crystalline structure and magnetic properties of R2Mo3Si4 compounds (R–Y, Tb, Dy, Ho, Er, Tm), Neorg. Mater., 1984, vol. 20, no. 5, pp. 853–855.

Kablov, E.N., Ospennikova, O.G., and Vershkov, A.V., Rare metals and rare earth elements are the materials for modern and prospective high technologies, Tr. Vseross. Nauchno-Issled. Inst. Aviats. Mater., 2013, no. 2. http://viam-works.ru/ru/articles?art_id=9.

Stringer, J., The reactive element effect in high-temperature corrosion, Mater. Sci. Eng., A, 1989, vol. 120, pp. 129–137.

Udoeva, L.Yu, Chumarev, V.M., Leontev, L.I., and Sel’menskikh, N.I., Structural-phase state of the Nb–Si eutectic alloys doped by yttrium and scandium, Tsvetn. Met., 2014, no. 8, pp. 59–65.

Chumarev, V.M., Leont’ev, L.I., Udoeva, L.Yu., Sel’menskikh, N.I., Gulyaeva, R.I., Zhidovinova, S.V., and Larionov, A.V., Effect of boron and yttrium on the phase composition and the microstructure of natural Nb–Si composites, Russ. Metall. (Engl. Transl.), 2014, vol. 2014, no. 9, pp. 688–696.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © L.Yu. Udoeva, V.M. Chumarev, A.V. Larionov, S.V. Zhidovinova, S.N. Tyushnyakov, 2017, published in Perspektivnye Materialy, 2017, No. 7, pp. 24–33.

Rights and permissions

About this article

Cite this article

Udoeva, L.Y., Chumarev, V.M., Larionov, A.V. et al. Influence of Rare Earth Elements on the Structural-Phase State of Mo–Si–X (X = Sc, Y, Nd) in situ Composites. Inorg. Mater. Appl. Res. 9, 257–263 (2018). https://doi.org/10.1134/S2075113318020296

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113318020296