Abstract

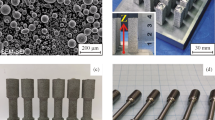

The results of the research works on the development, study, and approbation of promising heatresistant REE-containing intermetallic alloys based on ortho- and gamma-titanium aluminides (Ti2AlNb, TiAl) performed at the All-Russian Scientific Research Institute of Aviation Materials (VIAM) for solving the current problems of aircraft engine construction within the implementation of the complex scientific direction 7.1 “Intermetallic Alloys Based on Titanium” (“Strategic Directions of the Development of Materials and Technologies of Their Processing for the Period until 2030”) [1] are presented. The energy-efficient technological regimes of vacuum arc melting of ingots made of ortho and gamma alloys and having a homogeneous chemical composition and structure are developed; it is shown that the introduction of gadolinium microadditives in the amount of 0.05–0.2 at % into the studied alloys gives a significant modifying effect and forms a finely lamellar structure in ingots, which is favorable from the point of view of the combination of heat-resistant and performance properties. The structural changes and the combination of mechanical characteristics of new VIT5 ortho alloy depending on the heat treatment regimes are studied.

Similar content being viewed by others

References

Kablov, E.N., Innovative developments of the All-Russian Scientific Research Institute of Aviation Materials within the project “Strategic development of materials and technologies of their recycling until 2030,” Aviats. Mater. Tekhnol., 2015, no. 1, pp. 3–33.

Kablov, E.N., Aviation material science: results and prospects, Vestn. Ross. Akad. Nauk, 2002, vol. 72, no. 1, pp. 3–12.

Kablov, E.N., Developments of the All-Russian Scientific Research Institute of Aviation Materials for gas turbine engines and installations, Kryl’ya Rodiny, 2010, no. 4, pp. 3–33.

Kablov, E.N., Materials and chemical technologies for aircraft engineering, Herald Russ. Acad. Sci., 2012, vol. 82, no. 3, pp. 158–167.

Il’in, A.A., Kolachev, B.A., and Pol’kin, I.S., Titanovye splavy. Sostavy, struktury, svoistva: Spravochnik (Titanium Alloys: Composition, Structure, and Properties. Handbook), Moscow: Vseross. Inst. Legkikh Splavov, Mosk. Aviats. Tekhnol. Inst., 2009.

Nochovnaya, N.A., Panin, P.V., Kochetkov, A.S., and Bokov, K.A., Modern refractory alloys based on titanium gamma-aluminide: Prospects of development and application, Met. Sci. Heat Treat., 2014, vol. 56, no. 7, pp. 364–367.

Kothari, K., Radhakrishnan, R., and Wereley, N.M., Advances in gamma titanium aluminides and their manufacturing techniques, Progr. Aerospace Sci., 2012, vol. 55, pp. 1–16.

Imaev, V.M., Imaev, R.M., and Oleneva, T.I., The modern state of research and prospective development of intermetallide γ-TiAl alloy technologies, Pis’ma Mater., 2011, vol. 1, pp. 25–31.

Kablov, E.N., Lomberg, B.S., and Ospennikova, O.G., Creation of modern heat-resistant materials and production technologies for aircraft engine building, Kryl’ya Rodiny, 2012, nos. 3–4, pp. 34–38.

Kashapov, O.S., Novak, A.V., Nochovnaya, N.A., and Pavlova, T.V., Status, problems, and prospects for creation of heat-resistant titanium alloys for GTE parts, Tr. Vses. Nauchno-Issled. Inst. Aviats. Mater., 2013, no. 3, art. 2. http://www.viam-works.ru. Accessed March 4, 2016.

Kablov, E.N., Strategic development of the materials and technologies for their recycling until 2030, Aviats. Mater. Tekhnol., 2012, suppl., pp. 7–17.

Nochovnaya, N.A., Alekseev, E.B., Yasinskii, K.K., and Kochetkov, A.S., The specifics of melting and production of ingots of intermetallic titanium alloys with higher content of niobium, Vestn. Mosk. Gos. Tekh. Univ. im. N.E. Baumana, Ser. Mashinostr., 2011, suppl. 2, pp. 53–59.

Nochovnaya, N.A., Skvortsov, S.V., Anishchuk, D.S., Alekseev, E.B., Panin, P.V., and Umarova, O.Z., Testing of experimental heat-resistant alloy based on Ti2AlNb intermetallic compound, Titan, 2013, no. 4, pp. 33–38.

Kablov, D.E., Panin, P.V., Shiryaev, A.A., and Nochovnaya, N.A. Use of the vacuum arc furnace ALD VAR L200 for smelting ingots of heat-resistant alloys based on titanium aluminides, Aviats. Mater. Tekhnol., 2014, no. 2, pp. 27–33.

Nochovnaya, N.A., Panin, P.V., Alekseev, E.B., and Novak, A.V., Analysis of the formation of the structural-phase state of alloys based on titanium ortho-and gamma-aluminides during thermomechanical treatment, Vestn. Ross. Fonda Fundam. Issled., 2015, no. 1 (85), pp. 18–26.

Panin, P., Nochovnaya, N., Alexeev, E., and Kablov, D., On the problem of low-temperature ductility improvement of Ti–Al and Ti–Al–Nb based alloys, Proc. Int. Symp. on Gamma TiAl Alloys (ISGTA’14), San Diego, 2014.

Lin, J.P., et al., Development of high temperature TiAl alloys, Proc. 12th World Conf. on Titanium, Beijing, 2012, vol. 2, pp. 1357–1362.

Chen, Y., et al., Microstructure and fracture toughness of a β-phase containing TiAl alloy, Intermetallics, 2011, vol. 19, pp. 1405–1410.

Wang, Y., et al., Microstructure of cast γ-TiAl based alloy solidified from β phase region, Trans. Nonferrous Met. Soc. China, 2011, vol. 21, pp. 215–222.

Alekseev, E.B., Nochovnaya, N.A., Skvortsov, S.V., Panin, P.V., and Umarova, O.Z., Analysis of technological parameters of deformation of experimental heat-resistant alloy based on Ti2AlNb intermetallide, Titan, 2014, no. 2, pp. 36–41.

Alekseev, E.B., Nochovnaya, N.A., and Panin, P.V., Analysis of the structure and phase composition of experimental heat-resistant alloy based on deformed Ti2AlNb intermetallide, Titan, 2014, no. 4, pp. 12–17.

Alekseev, E.B., Nochovnaya, N.A., Ivanov, V.I., Panin, P.V., and Novak, A.V., Influence of aluminum on phase composition and thermomechanical regime of isothermal forging of VTI-4 intermetallic alloy, Tekhnol. Legkikh Splavov, 2015, no. 1, pp. 57–61.

Alekseev, E.B., Nochovnaya, N.A., Panin, P.V., and Novak, A.V., Technological plasticity, structure, and phase composition of the experimental titanium orthoalloy containing 13% (by weight) of aluminum, Tr. Vses. Nauchno-Issled. Inst. Aviats. Mater., 2015, no. 12, pp. 61–71. http://www.viam-works.ru. Accessed March 4, 2016.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © E.N. Kablov, N.A. Nochovnaya, P.V. Panin, E.B. Alekseev, A.V. Novak, 2017, published in Materialovedenie, 2017, No. 3, pp. 3–10.

Rights and permissions

About this article

Cite this article

Kablov, E.N., Nochovnaya, N.A., Panin, P.V. et al. Study of the structure and properties of heat-resistant alloys based on titanium aluminides with gadolinium microadditives. Inorg. Mater. Appl. Res. 8, 634–641 (2017). https://doi.org/10.1134/S2075113317040116

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113317040116