Abstract

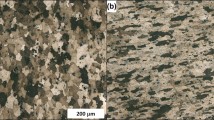

In recent years, surface mechanical attrition treatment (SMAT) operations have drawn the researchers attention in terms of the impact of this operation on wear resistance, hardness and creation of residual stresses. In this study, the effect of SMAT operation time on microstructure, residual stress, hardness and wear resistance was investigated. For this purpose, the specimens were subjected to SMAT at three times of 10, 15 and 20 min and compared with the As-received specimen (specimen without SMAT). XRD has been used to measure grain size and residual stress, SEM to check the microstructure, the hardness, wear resistance and roughness of the specimens were also measured. The results showed that the grain size decreases due to SMAT operation, so that the grain size decreasees from 139.2 nm in the As-received specimen to 93.2, 72.6 and 34.9 nm in the SMAT specimens with times of 10, 15 and 20 minutes, respectively. Also, residual stress is created due to compressive force and microstrain as a result of SMAT operation, which is 158, 170 and 234 MPa for 10, 15 and 20 min SMAT specimens, respectively. As a result of SMAT operation, the hardness and wear resistance of the specimens increase, which is due to the fact that the fine grains, nanocrystalline of their grains and many microstrains created. Studies have shown that hardness and wear resistance increase by 36, 45, 62% and 16, 27, 36% at SMAT times of 10, 15 and 20 min, respectively, compared to the As-received specimen. Examination of the wear mechanism indicates that the wear mechanism in the As-received specimen is strong adhesive and tribochemical wear, which in SMAT specimens decreases due to the increase in hardness of the adhesive wear. Also, by performing SMAT operation, the specimen roughness increases.

Similar content being viewed by others

REFERENCES

Fisher, P.A., Metall. Rev., 2013, vol. 23, no. 1, p. 269.

Polmear, I.J., Met. Sci. J., 1994, vol. 10, no. 1, p. 1.

Zhou, H., Mater. Rev., 2003, vol. 17, no. 11, p. 16.

Duan, M., Luo, L., and Liu, Y., J. Alloys Compd., 2020, vol. 823, p. 153691.

Song, G.L. and Atrens, A., Adv. Eng. Mater., 2003, vol. 5, p. 837.

Wang, B.J., Wang, S.D., Xu, D.K., and Han, E.H., J. Mater. Sci. Technol., 2017, vol. 33, p. 1075.

Kojima, Y., Mater. Sci. Forum, 2000, vol. 350, p. 3.

Zhao, X.H., Zhao, Y.J., and Liu, Y., Metals, 2017, vol. 7, p. 1.

Liu, W.C., Wu, G.H., Zhai, C.Q., Ding, W.J., and Korsunsky, A.M., Int. J. Plast., 2013, vol. 49, p. 16.

Zhang, J., et al., J. Magnesium Alloys, 2021, vol. 9, p. 1187.

Zhang, J., Zhao, X., Meng, D., et al., Int. J. Miner., Metall. Mater., 2022, vol. 29, p. 1413. https://doi.org/10.1007/s12613-022-2414-7

Zhao, J., Xia, W., Li, N., and Li, F.L., Trans. Nonferrous Met. Soc. China, 2014, vol. 24, p. 441.

Tang, L.L., Zhao, Y.H., Islamgaliev, R.K., Valiev, R.Z., and Zhu, Y.T., J. Alloys Compd., 2017, vol. 721, p. 577.

Liu, C., et al., J. Alloys Compd., 2019, vol. 770, p. 500.

Dong, Z., Wang, F., Qian, D., Yin, F., Wang, H., Wang, X., Hu, S., and Chi, J., Metals, 2022, vol. 12, no. 3, p. 424.

Liu, Y., Jin, B., and Lu, J., Mater. Sci. Eng., A, 2015, vol. 636, p. 446.

Wei, Y.H., Liu, B.S., Hou, L.F., et al., J. Alloys Compd., 2008, vol. 452, no. 2, p. 336.

Gao, J.C., Wang, Q., and Gao, Z.Y., J. Funct. Mater., 2010, vol. 41, no. 5, p. 741.

Haghighi, O., Amini, K., and Gharavi, F., Prot. Met. Phys. Chem. Surf., 2020, vol. 56, p. 164.

Lai, H.H., Cheng, H.C., Lee, C.Y., Lin, C.M., and Wu, W., J. Mater. Process. Technol., 2020, vol. 284, p.116747.

Wen, Y., Wu, Y., Hua, L., Xie, L., Wang, L., Zhang, L.-C., and Lu, W., Mater. Des., 2021, vol. 206, p. 109760.

Soleimany, J., et al., Phys. Met. Metallogr., 2019, vol. 120, p. 888.

Mokarian, B., Amini, K., Ghayour, H., and Gharavi, F., Trans. IMF, 2019, vol. 97, no. 3, p. 121.

Chen, G., Fu, Y., Cui, Y., Gao, J., Guo, X., Gao, H., Wu, S., Lu, J., Lin, Q., and Shi, S., Int. J. Fatigue, 2019, vol. 127, p. 461.

Bagherifard, S., Hickey, D.J., Fintová, S., Pastorek, F., Fernandez-Pariente, I., Bandini, M., et al., Acta Biomater., 2018, vol. 66, p. 93.

Funding

This work was supported by regular institutional funding, and no additional grants were obtained.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Ali Kazemi, Heidari, A., Amini, K. et al. The Effect of Surface Mechanical Attrition Treatment Time on Microstructure and Mechanical Properties of AZ31 Mg Alloy. Prot Met Phys Chem Surf 59, 453–460 (2023). https://doi.org/10.1134/S2070205123700508

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205123700508