Abstract

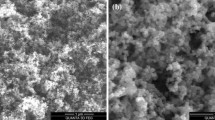

In this study Al5083–Al2O3–TiO2 hybrid surface nanocomposite was successfully prepared by friction stir processing (FSP). The effects of different combination of rotational and travel speed of tool were investigated. The samples were characterized by optical and scanning electron microscopy (SEM), microhardness and undergone tensile and wear tests. Based on the maximum tensile strength and hardness value, optimum rotational speed of 710 rpm and travel speed of 20 mm/min was achieved. The microhardness and tensile strength of the as-received alloy and specimens having optimum surface nanocomposite were about 80 Hv, 285 MPa, 140 Hv and 375 MPa, respectively. Surface nanocomposites showed significantly lower friction coefficients and wear rates than those obtained for substrate. Based on scanning electron microscopy tests, abrasive wear as dominant wear mechanism was detected.

Similar content being viewed by others

References

Kok, M., J. Mater. Process. Technol., 2005, vol. 161, p. 381.

Sahin, Y., Kok, M., and Celik, H., J. Mater. Process. Technol., 2002, vol. 128, p. 280.

Iwai, Y., Honda, T., Miyajima, T., et al., Compos. Sci. Technol., 2000, vol. 60, p. 1781.

Kiourtsidis, G.E. and Skolianos, S.M., Wear, 2002, vol. 253, p. 946.

Mishra, R., Ma, Z.Y., and Charit, I., Mater. Sci. Eng., A, 2003, vol. 341, p. 307.

Cavaliere, P., Composites, Part A, 2005, vol. 36, p. 1657.

Mishra, R.S. and Ma, Z.Y., Mater. Sci. Eng., R, 2005, vol. 50, p. 1.

Mahmoud, E.R.I., Takahashi, M., Shibayanagi, T., and Ikeuchi, K., Wear, 2010, vol. 268, p. 1111.

Lee, C.J., Huang, J.C., and Hsieh, P.J., Scr. Mater., 2006, vol. 54, p. 1415.

Arora, H.S., Singh, H., and Dhindaw, B.K., Int. J. Adv. Manuf. Technol., 2012, vol. 61, p. 1043.

Nascimento, F., Santos, T., Vilaca, P., et al., Mater. Sci. Eng., A, 2009, vol. 506, p. 16.

Wang, Y. and Mishra, R.S., Mater. Sci. Eng., A, 2007, vol. 463, p. 245.

Darras, B.M., Khraisheh, M.K., Abu-Farha, F.K., and Omar, M.A., J. Mater. Process. Technol., 2007, vol. 191, p. 77.

Sua, J.Q., Nelson, T.W., and Sterling, C.J., Mater. Sci. Eng., A, 2005, vol. 405, p. 277.

Ma, Z.Y., Mishra, R.S., and Mahoney, M.W., Acta Mater., 2002, vol. 50, p. 4419.

Hassan, K.A.A., Norman, A.F., Price, D.A., and Prangnell, P.B., Acta Mater., 2003, vol. 51, p. 1923.

McNelley, T.R., Swaminathan, S., and Su, J.Q., Scr. Mater., 2008, vol. 58, p. 349.

Kumar, S., Arch. Civ. Mech. Eng., 2016, vol. 16, no. 3, p. 473.

Khodabakhshi, F., Simchi, A., Kokabi, A.H., et al., Mater. Sci. Eng., A, 2014, vol. 605, p. 108.

Ma, Z.Y., Sharma, S.R., Mishra, R.S., and Manohey, M.W., Mater. Sci. Forum, 2003, vols. 426–432, p. 2891.

Hu, C.M., Lai, C.M., Du, X.H., et al., Scr. Mater., 2008, vol. 59, p. 1163.

Liu, Q., Ke, L., Liu, F., Huang, C., and Xing, L., Mater. Des., 2013, vol. 45, p. 343.

Liu, Z.Y., Xiao, B.L., Wang, W.G., and Ma, Z.Y., Mater. Sci. Technol., 2014, vol. 30, no. 7, p. 649.

Patel, V.V., Badheka, V., and Kumar, A., Metallogr., Microstruct., Anal., 2016, vol. 5, no. 4, p. 278.

Soleymani, S., Abdollah-zadeh, A., and Alidokht, S.A., Wear, 2012, vols. 278–279, p. 41.

Shafiei-Zarghani, A., Kashani-Bozorg, S.F., and Zarei-Hanzaki, A., Wear, 2011, vol. 270, p. 403.

Shahi, A., Heydarzadeh Sohi, M., Ahmadkhaniha, D., and Ghambari, M., Int. J. Adv. Manuf. Technol., 2014, vol. 75, p. 1331.

Faraji, G., Dastani, O., and Akbari Mousavi, S.A., J. Mater. Eng. Perform., 2011, vol. 20, p. 1583.

Ahmadifard, S., Kazemi, Sh., and Heidarpour, A., J. Mater.: Des. Appl. doi: 10.1177/1464420715623977

Li, Y., Murr, L.E., and McClure, J.C., Mater. Sci. Eng., A, 1999, vol. 271, p. 213.

Murr, L.E., Mater. Res. Innovations, 1998, vol. 2, p. 150.

Kwon, Y.J., Shigematsu, I., and Saito, Y., Scr. Mater., 2003, vol. 49, p. 785.

Humphreys, F.J. and Hatherly, M., Recrystallization and Related Annealing Phenomena, Oxford: Elsevier, 2004.

Feng, A.H. and Ma, Z.Y., Acta Mater., 2009, vol. 57, p. 4248.

Humphreys, F.J., Prangnell, P.B., and Priestner, R., Curr. Opin. Solid State Mater. Sci., 2001, vol. 5, p. 15.

Yadav, D. and Bauri, R., Mater. Sci. Eng., A, 2011, vol. 528, p. 1326.

Shahraki, S., Khorasani, S., Abdibehnagh, R., et al., Metall. Mater. Trans. B, 2013, vol. 44, p. 1546.

Yuvaraj, N. and Aravindan, S., J. Mater. Res. Technol., 2015, vol. 154, p. 13.

Kumar, S., Sarma, V.S., and Murty, B.S., Mater. Sci. Eng., A, 2007, vol. 465, p. 160.

Zahmatkesh, B. and Enayati, M.H., Mater. Sci. Eng., A, 2010, vol. 527, p. 6734.

Sarmadi, H., Kokabi, A.H., and Seyed Reihani, S.M., Wear, 2013, vol. 304, p. 1.

Shafei-Zarghani, Z.A., Kashani-Bozorg, S.F., and Zarei-Hanzaki, A., Mater. Sci. Eng., A, 2009, vol. 500, p. 84.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Heidarpour, A., Ahmadifard, S. & Kazemi, S. On the Al5083–Al2O3–TiO2 Hybrid Surface Nanocomposite Produced by Friction Stir Processing. Prot Met Phys Chem Surf 54, 409–415 (2018). https://doi.org/10.1134/S2070205118030279

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205118030279