Abstract

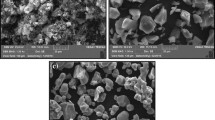

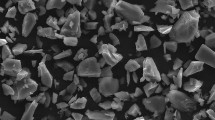

AA6082–TiO2 surface composites are prepared by friction stir processing (FSP). Fabricating defect-free surface composite with uniform particle distribution by FSP is a challenging task. In this study, TiO2 particle-reinforced AA6082 alloy surface composites were fabricated using different FSP parameters to find the optimum tool rotation speeds and traverse speeds. This investigation was carried out with optical microscopy and was found that TiO2 reinforcement particles are disintegrated and distributed homogenously by the stirring action of the tool, which also forges the plasticized material. The hardness profile was obtained using Vickers microhardness test across the thermomechanically affected zone and welded zone and found that the retreating side had more hardness. The tensile test was also performed to identify the change in the strength due to the surface composite.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Mishraa RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50:1–78

Salih OS, Ou H, Sun W, McCartney DG (2015) A review of friction stir welding of aluminium matrix composites. Mater Des 86:61–71

Ma ZY (2008) Friction stir processing technology: a review. Metall Mater Trans A 39(3):642–658

Jana A, Siddhalingeshwar IG, Mitra R (2013) Effect of homogeneity of particle distribution on tensile crack propagation in mushy state rolled in situ Al–4.5Cu–5TiB2 particulate composite. Mater Sci Eng, A 575:104–110

Peddavarapu S, Raghuraman S, Bharathi RJ et al (2017) Micro structural investigation on friction stir welded Al–4.5Cu–5TiB2 Composite. Trans Indian Inst Met 70:703

Herbert MA, Sarkar C, Mitra R, Chakraborty M (2007) Microstructural evolution, hardness, and alligatoring in the mushy state rolled cast Al-4.5Cu alloy and In-Situ Al4.5Cu-5TiB2 Composite. Metall Mater Trans A 38(9):2110–2126

Sundaram NS, Murugan N (2010) Tensile behavior of dissimilar friction stir welded joints of aluminium alloys. Mater Des 31:4184–4193

Palanivel R, Laubscher RF, Dinaharan I, Murugan N (2016) Tensile strength prediction of dissimilar friction stir-welded AA6351–AA5083 using artificial neural network technique. J Brazillian Soc Mech Sci Eng 38(6):1647–1657

Cavaliere P (2013) Friction stir welding of Al alloys: analysis of processing parameters affecting mechanical behavior. Procedia CIRP 11:139–144

Gandraa J, Pereirab D, Mirandab RM, Vilaçac P (2013) Influence of process parameters in the friction surfacing of AA 6082-T6 over AA 2024-T3. Procedia CIRP 7:341–346

Adamowski J, Gambaro C, Lertora E, Ponte M, Szkodo M (2007) Analysis of FSW welds made of aluminium alloy AW6082-T6. Arch Mater Sci Eng 28(8):453–460

Raja AR, Yusufzai MZK, Vashista M (2016) Characterization of advancing and retreating weld of friction stir welding of aluminium. ICAMM

Zheng Q, Feng X, Shen Y, Huang G, Zhao P (2016) Dissimilar friction stir welding of 6061 Al to 316 stainless steel using Zn as a filler metal. J Alloy Compd 686:693–701

Huang Y, Wang Y, Wan L, Liu H, Shen J, dos Santos JF, Zhou L, Feng J (2016) Material-flow behavior during friction-stir welding of 6082-T6 aluminum alloy. Int J Adv Manuf Technol 87:1115–1123

Fonda R, Reynolds A, Feng CR, Knipling K, Rowenhorst D (2013) Material flow in friction stir welds. Metall Mater Trans A 44(1):337–344

Adamowski J, Szkodo M (2007) Friction stir welds (FSW) of aluminium alloy AW6082-T6. J Achievements Mater Manufacturing Eng 20

Asensio-Lozano J, Suárez-Peña B, Voort GFV (2014) Effect of processing steps on the mechanical properties and surface appearance of 6063 aluminium extruded products. Materials 7:4224–4242

Sharma V, Prakash U, Kumar BVM (2015) Surface composites by friction stir processing: a review. J Mater Process Technol 224:117–134

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sandar, D., Chatterjee, R., Bharathi, R.J., Sreehari, P. (2019). Investigation on the Microstructure and Mechanical Properties of AA6082/TiO2 Surface Composites Produced by Friction Stir Processing. In: Lakshminarayanan, A., Idapalapati, S., Vasudevan, M. (eds) Advances in Materials and Metallurgy. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-1780-4_3

Download citation

DOI: https://doi.org/10.1007/978-981-13-1780-4_3

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-1779-8

Online ISBN: 978-981-13-1780-4

eBook Packages: EngineeringEngineering (R0)