Abstract

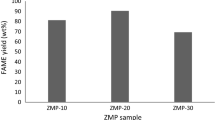

Catalytic membrane reactors, as a promising novel technology, are widely recommended for carrying out heterogeneous reactions. If the reactant feed is forced to flow through the pores of a membrane, which has been impregnated with a convenient catalyst, the intense contact provides high catalytic activity with negligible resistance to diffusive mass transport. The synthesis of a fatty ester (ethylhexanoic ester) by esterification was developed by the Factorial Design and Response Surface Methodology (FDRSM). Selection of factors was based on the operating conditions that have a significant influence on the esterification process, namely temperature, molar ratio of ethanol to fatty acid, and internal surface area of membrane pores. Experimental results indicated that the optimum conditions (under which the conversion achieved 99.7%) were as follows: temperature of 30°C, molar ratio of 5: 1, and internal membrane area of 252450 cm2. It can be concluded that the factorial design is an important tool to reduce time and to facilitate reaching optimum reaction conditions.

Similar content being viewed by others

References

Teplyakov, V.V., Pisarev, G.I., Magsumov, M.I., Tsodikov, M.V., Zhu, W., and Kapteijn, F., Catal. Today, 2006, vol. 118, nos. 1–2, pp. 7–11.

Dittmeyer, R., Svajda, K., and Reif, M., Top. Catal., 2004, vol. 29, nos. 1–2, pp. 3–27.

Miachon, S. and Dalmon, J.-A., Top. Catal., 2004, vol. 29, nos. 1–2, pp. 59–65.

Wang, H., Cong, Y., and Yang, W., Catal. Today, 2003, vol. 82, nos. 1–4, pp. 157–166.

Tsodikov, M.V., Laguntsov, N.I., Magsumov, M.I., Spiridonov, P.V., Bukhtenko, O.V., Zhdanova, T.N., and Teplyakov, V.V., Russ. Chem. Bull., 2004, vol. 53, no. 12, pp. 2723–2729.

El-Zanati, E. and Abdallah, H., Int. J. Emerging Trends Eng. Dev., 2012, vol. 5, no. 2, pp. 505–521.

El-Zanati, E., Ritchie, S.M., Abdallah, H., Ettouny, R., and El-Rifai, M.A., Int. J. Chem. React. Eng., 2011, vol. 9, no. 1. doi 10.1515/1542-6580.2518.

Ajmera, S.K., Delattre, C., Schmidt, M.A., and Jensen, K.F., J. Catal., 2002, vol. 209, no. 2, pp. 401–412.

Albo, S.E., Broadbelt, L.J., and Snurr, R.Q., AIChE J., 2006, vol. 52, no. 11, pp. 3679–3687.

Westermann, T., Kopriwa, N., Schröder, A., and Melin, T., Chem. Eng. Sci., 2010, vol. 65, no. 5, pp. 1609–1615.

Westermann, T. and Melin, T., Chem. Eng. Process, 2009, vol. 48, no. 1, pp. 17–28.

Berchmans, H.J. and Hirata, S., Bioresour. Technol., 2008, vol. 99, no. 6, pp. 1716–1721.

Lee, J.-S. and Saka, S., Bioresour. Technol., 2010, vol. 101, no. 19, pp. 7191–7200.

Haas, M.J., McAloon, A.J., Yee, W.C., and Foglia, T.A., Bioresour. Technol., 2006, vol. 97, no. 4, pp. 671–678.

Liu, Y., Lotero, E., and Goodwin, J.G.Jr., J. Mol. Catal. A: Chem., 2006, vol. 245, nos. 1–2, pp. 132–140.

Liu, Y., Yan, Y., Hu, F., Yao, A., Wang, Z., and Wei, F., AIChE J., 2010, vol. 56, no. 6, pp. 1659–1665.

Westermann, T., Kretzschmar, E., Pitsch, F., and Melin, T., Chem. Eng. J., 2009, vol. 155, nos. 1–2, pp. 371–379.

Shah, T.N. and Ritchie, S.M.C., Appl. Catal., A, 2005, vol. 296, no. 1, pp. 12–20.

Shah, T.N., Goodwin, J.C., and Ritchie, S.M.C., J. Membr. Sci., 2005, vol. 251, nos. 1–2, pp. 81–89.

Vicente, G., Martinez, M., and Aracil, J., Bioresour. Technol., 2007, vol. 98, no. 9, pp. 1724–1733.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

El-Zanati, E., Abdallah, H. Esterification of ethyl hexanoic acid using flow-through catalytic membrane reactor. Catal. Ind. 7, 91–97 (2015). https://doi.org/10.1134/S2070050415020038

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070050415020038