Abstract

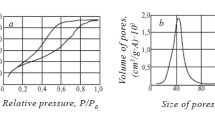

Nickel-molybdenum hydrocracking catalysts based on amorphous silica-aluminas (ASAs) with Si/Al = 0.3–1.5 have been prepared using chemicals and methods available for catalyst plants. The acidic properties of the ASA surface have been investigated by IR spectroscopy of adsorbed CO, and it has been demonstrated that the Si/Al ratio has an effect on the concentration and strength of Brønsted and Lewis acid sites in the ASA. The catalysts have been characterized by low-temperature nitrogen adsorption and transmission electron microscopy, and it was found that the Si/Al ratio in the ASA has a considerable effect on the textural properties of the catalysts and only a slight effect on the particle size of the sulfide active component. The catalysts have been tested in vacuum gas oil hydrocracking in a laboratory-scale high-pressure flow reactor under typical industrial hydrocracking conditions. The highest diesel fraction yield (>60 wt % at 400°C) has been obtained with the catalyst based on the Si/Al = 0.9 ASA, which has the strongest Brønsted acid sites. With the catalysts based on the Si/Al = 0.3 and 1.5 ASAs, the diesel fraction yield is much lower. This may be due to the lower concentration and strength of acid sites in these catalysts and their smaller specific surface area. The NiMo catalyst based on Si/Al ≈ 0.9 ASA is recommended for industrial use in refineries aimed at obtaining the maximum possible yield of low-sulfur, high-cetane, diesel fuels.

Similar content being viewed by others

References

Galkin, V.V., Makhiyanov, V.A., and Levinbuk, M.I., Mater konf. RRTC-2013 (Proc. RRTC-2013 Conf.), Moscow, 2013.

Minderhoud, J.K., van Veen, J.A.R., and Hagan, A.P., Hydrotreatment and Hydrocracking of Oil Fractions, Amsterdam: Elsevier, 1999, pp. 3–30.

Ward, J.W., Fuel Process. Technol., 1993, vol. 35, pp. 55–85.

Dik, P.P., Klimov, O.V., Koryakina, G.I., Leonova, K.A., Pereyma, V.Yu., Budukva, S.V., Gerasimov, E.Yu., and Noskov, A.S., Catal. Today, 2014, vols. 220–222, pp. 124–132.

Parmon, V.N., Mater. I Sankt-Peterburgskogo mezhd. foruma “Innovatsionnye tekhnologii v oblasti polucheniya i primeneniya goryuchikh i smazochnykh materialov” (Proc. I St. Petersburg Int. Forum “Innovative Technologies for the Production and Application of Flammable Materials and Lubricants”), St. Petersburg, 2013, pp. 24–25.

Pashigreva, A.V., Klimov, O.V., and Bukhtiyarova, G.A., Stud. Surf. Sci. Catal., 2010, vol. 175, pp. 109–116.

Schwarz, J.A., Russel, B.G., and Harnsberger, H.F., J. Catal., 1978, vol. 54, pp. 303–317.

Pieta, I.S., Ishaq, M., Wells, R.P.K., and Anderson, J.A., Appl. Catal., A, 2010, vol. 390, pp. 127–134.

Shnel, R., Appl. Catal., 1984, vol. 11, pp. 271–280.

Shnel, R., Appl. Catal., 1984, vol. 12, pp. 181–200.

Plank, C.J. and Drake, L.C., J. Colloid Sci., 1947, vol. 2, pp. 399–412.

Hwang, S., Lee, J., Park, S., Park, D.R., Jung, J. Ch., Lee, S.-B., and Song, I.K., Catal. Lett., 2009, vol. 129, pp. 163–169.

Hensen, E.J.M., Poduval, D.G., Magusin, P.C.M.M., Coumans, A.E., and van Veen, J.A.R., J. Catal., 2010, vol. 269, pp. 201–218.

Ishihara, A., Negura, H., Hashimoto, T., and Nasu, H., Appl. Catal., A, 2010, vol. 388, pp. 68–76.

Corma, A., Martinez, A., Pergher, S., Peratello, S., Perego, C., and Bellusi, G., Appl. Catal., A, 1997, vol. 152, pp. 107–125.

Carati, A., Ferraris, G., Guidotti, M., Moretti, G., Psaro, R., and Rizzo, C., Cataly. Today, 2003, vol. 77, pp. 315–323.

Leydier, F., Chizallet, C., Chaumonnot, A., Digne, M., Soyer, E., Quoineaud, A., Costa, D., and Raybaud, P., J. Catal., 2011, vol. 284, pp. 215–229.

Manton, M.R.S. and Davidtz, J.C., J. Catal., 1979, vol. 60, pp. 156–166.

Bandopadhyay, A.K., Das, J., and Roy, S.K., J. Catal., 1990, vol. 124, pp. 241–246.

US Patent 3974099, 1976.

US Patent 4499197, 1985.

US Patent 7186757, 2007.

US Patent 7323100, 2008.

US Patent 7541310, 2009

US Patent 4711868, 1987.

Leyva, C., Ancheyta, J., Travert, A., Maugé, F., Mariey, L., Ramírez, J., and Rana, M.S., Appl. Catal., A, 2012, vols. 425–426, pp. 1–12.

Leyva, C., Rana, M.S., Trejo, F., and Ancheyta, J., Catal. Today, 2009, vol. 141, pp. 168–175.

WO Patent 2004/043582, 2004.

US Patent 6399530, 2002.

Klimov, O.V., Leonova, K.A., Koryakina, G.I., Gerasimov, E.Yu., Prosvirin, I.P., Cherepanova, S.V., Budukva, S.V., Pereyma, V.Yu., Dik, P.P., Parakhin, O.A., and Noskov, A.S., Catal. Today, 2014, vols. 220–222, pp. 66–77.

RF Patent 2472585, 2013.

Bukhtiyarova, G.A., Klimov, O.V., Pashigreva, A.V., Aleksandrov, P.V., Kashkin, V.N., and Noskov, A.S., Oil Gas J. Russ., 2010, vol. 37, pp. 58–66.

Ivanova, A.S., Korneeva, E.V., Bukhtiyarova, G.A., Nuzhdin, A.L., Budneva, A.A., Prosvirin, I.P., Zaikovskii, V.I., and Noskov, A.S., Kinet. Catal., 2011, vol. 52, pp. 446–458.

Paukshtis, E.A., IK spektroskopiya v geterogennom kislotno-osnovnom katalize (IR Spectroscopy Applied to Heterogeneous Acid-Base Catalysis), Novosibirsk: Nauka, 1992.

Leonova, K.A., Klimov, O.V., Gerasimov, E.Yu., Dik, P.P., Pereyma, V.Yu., Budukva, S.V., and Noskov, A.S., Adsorption, 2013, vol. 19, pp. 723–731.

Eijsbouts, S., van den Oetelaar, L.C.A., and van Puijenbroek, R.R, J. Catal., 2005, vol. 229, pp. 352–364.

Francis, J., Guillon, E., Bats, N., Pichon, C., Corma, A., and Simon, L.J., Appl. Catal., A, 2011, vols. 409–410, pp. 140–147.

Kapustin, V.M. and Rudin, M.G., Khimiya i tekhnologiya pererabotki nefti (Petroleum Refining Chemistry and Technology), Moscow: Khimiya, 2013.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © P.P. Dik, O.V. Klimov, S.V. Budukva, K.A. Leonova, V.Yu. Pereyma, E.Yu. Gerasimov, I.G. Danilova, A.S. Noskov, 2014, published in Kataliz v Promyshlennosti.

Rights and permissions

About this article

Cite this article

Dik, P.P., Klimov, O.V., Budukva, S.V. et al. Silica-alumina based nickel-molybdenum catalysts for vacuum gas oil hydrocracking aimed at a higher diesel fraction yield. Catal. Ind. 6, 231–238 (2014). https://doi.org/10.1134/S2070050414030076

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070050414030076