Abstract

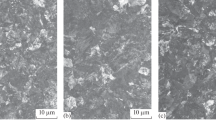

A layer by layer analysis of rails, differentially hardened in various modes, has been carried out using transmission electron microscopy on various scale levels. It has been shown that the differential hardening of rails is accompanied by the formation of a morphologically different structure, which is formed according to the diffusion mechanism of γ-α transformation and consisting of plate perlite grains, free ferrite grains, and grains of a ferrite-carbide mixture. The gradient character of modifications of structure, phase composition, and dislocation substructure parameters along the cross section of rail head has been established. It has been revealed that the interfaces between globular cementite particles and the matrix are the most dangerous stress concentrators.

Similar content being viewed by others

References

V. E. Gromov, V. A. Berdyshev, E. V. Kozlov, et al., Gradient Structure-Phase States in Rail Steel (Nedra Commun., Moscow, 2000) [in Russian].

Topical Problem of Rails Manufacturing, Ed. by V. E. Gromov, et al. (Izd. Siberian State Industrial Univ., Novokuznetsk, 2001) [in Russian].

A. I. Borts, E. A. Shur, V. A. Reikhart, S. V. Khlyst, and A. V. Gontar’, Rail Producing Development Trends in Russia. www.rusnauka.com/17-AVSN-2012/Economics/9-112679.doc.htm

Ren An-chao, Ji Yu, Zhou Gui-feng, et al., “Hot deformation behavior of V-microalloys steel,” J. Iron Steel Res. Int. 17(8), 55–60 (2010).

I. V. Volkov, V. E. Gromov, Yu. F. Ivanov, and V. A. Grishunin, The Way to Rise Fatigue Strength of Rail Steel by Electron-Beam Processing (Inter-Kuzbass, Novokuznetsk, 2013) [in Russian].

R. O. Olivares, C. I. Garsia, A. DeArdo, et al., “Advanced metallurgical alloy design and thermomechanical processing for rails steels for North American heavy haul use,” Wear 271, 364–373 (2011).

P. B. Hirsch, A. Howie, R. B. Nicholson, D. W. Pashley, and M. J. Whelan, Electron Microscopy of Thin Crystals (Krieger Publ., Melbourne, 1977).

K. W. Andrews, D. J. Dyson, and S. R. Keown, Interpretetion of Electron Diffraction Patterns (Adam Hilger Ltd., London, 1971).

L. M. Utevskii, Diffraction Electron Microscopy in Metal Science (Metallurgiya, Moscow, 1973) [in Russian].

Yu. F. Ivanov, V. V. Kovalenko, E. V. Kozlov, and V. E. Gromov, Gradient Structure-Phase States in Steels (Nauka, Novosibirsk, 2006) [in Russian].

V. V. Kovalenko, E. V. Kozlov, Yu. F. Ivanov, and V. E. Gromov, Physical Nature of Gradient Structure-Phase States Formation and Evolution in Steels and Alloys (LLC Poligraf, Novokuznetsk, 2009) [in Russian].

V. E. Panin, V. A. Likhachev, and Yu. V. Grinyaev, Structure Levels of Solids Deformation (Nauka, Novosibirsk, 1985) [in Russian].

V. E. Panin, Yu. V. Grinyaev, P. V. Makarov, et al., Physical Mezomechanics and Computer Simulation for Materials (Nauka, Novosibirsk, 1995), Vol. 1 [in Russian].

V. V. Rybin, Great Plastic Deformations and Metals Fracture (Metallurgiya, Moscow, 1986) [in Russian].

J. D. Eshelby, “Elastic inclusions and inhomogeneities,” in Progress in Solid Mechanics, Ed. by I. N. Snedolow (1961), Vol. 2.

V. M. Finkel’, Physical Foundation of Fracture Deceleration (Metallurgiya, Moscow, 1977) [in Russian].

N. A. Koneva and E. V. Kozlov, “Nature of substructural strengthening,” Izv. Vyssh. Uchebn. Zaved. Fiz., No. 8, 3–14 (1982).

V. I. Vladimirov, Physical Theory of Strength and Plasticity. Point Defects. Strengthening and Recovery (Leningrad Polytech. Inst., Leningrad, 1975) [in Russian].

M. A. Shtremel’, Strength of Alloys, Part 1: Lattice Defects (National University of Science and Technology “MISIS”, Moscow, 1999) [in Russian].

Yu. F. Ivanov, E. V. Kornet, E. V. Kozlov, and V. E. Gromov, Hardened Constructional Steel: Structure and Strengthening Mechanisms (Izd. Siberian State Industrial Univ., Novokuznetsk, 2010) [in Russian].

V. E. Gromov, E. V. Kozlov, V. I. Bazaikin, Yu. F. Ivanov, et al., Physics and Mechanics of Drawing and Volumetric Stamping (Nedra, Moscow, 1997) [in Russian].

N. A. Koneva, E. V. Kozlov, L. I. Trishkina, and D. V. Lychagin, “Long-range stress fields, flexion-torsion of crystalline lattice and stages of plastic deformation. Measurement methods and results,” in Proc. Int. Conf. New Methods in Deformed Solid Physics and Mechanics (National Research Tomsk State Univ., Tomsk, 1990), pp. 83–93 [in Russian].

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.E. Gromov, K.V. Morozov, Yu.F. Ivanov, K.V. Volkov, S.V. Konovalov, 2014, published in Rossiiskie Nanotekhnologii, 2014, Vol. 9, Nos. 5–6.

Rights and permissions

About this article

Cite this article

Gromov, V.E., Morozov, K.V., Ivanov, Y.F. et al. Formation of gradients of structure, phase composition, and dislocation substructure in differentially hardened rails. Nanotechnol Russia 9, 288–292 (2014). https://doi.org/10.1134/S1995078014030045

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1995078014030045