Abstract

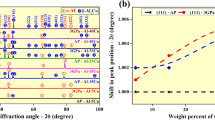

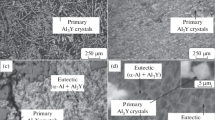

Using the microindentation, X-ray diffraction, optical microscopy, and electron microscopy methods, the microstructure and bulk physical and mechanical properties (hardness, reduced elastic modulus, plasticity index, elastic recovery parameter) of two samples of the Al90Gd10 binary hypereutectic alloy (hereinafter, formula indices correspond to at %) are studied. The first sample is obtained by rapid cooling of the melt at a rate of 1000 degree/s at a high pressure of 10 GPa; the hardening temperature is 1800 K. The second sample is obtained by pressing the original sample with a high pressure of 5 GPa without melting. Compared to the intial sample, the microstructure of both samples is crushed and compacted. The structure of the initial sample is comprised of two equilibrium phases of α-Al and Al3Gd. In the sample prepared without melting, a phase with composition Gd55Al45 is found in addition to the α-Al and Al3Gd phases; in the sample prepared with melting, a phase with composition Al92Gd8 is found. Features of the structure morphology and changes in the phase composition of the samples prepared under high pressure lead to changes in the physical and mechanical properties of the studied alloy.

Similar content being viewed by others

Notes

The comparison is carried out without consideration of the detected Gd55Al45 phase.

REFERENCES

I. Inoue, Prog. Mater. Sci. 43, 365 (1998).

State Diagrams of Binary Metallic Systems, Ed. by N. P. Lyakishev (Mashinostroenie, Moscow, 1996), Vol. 1 [in Russian].

O. J. C. Runnals and R. R. Boucher, J. Less-Common Met. 13, 431 (1967).

I. Pop, N. Dihoiu, M. Coldea, and C. Hagan, J. Less-Common Met. 64, 63 (1979).

S. V. Golubev and V. I. Kononenko, Rasplavy 6, 100 (1991).

V. Sidorov, O. Gornov, V. Bykov, L. Son, R. Ryltsev, S. Uporov, V. Shevchenko, V. Kononenko, K. Shunyaev, N. Ilynykh, G. Moiseev, T. Kulikova, and D. Sordelet, Mater. Sci. Eng. 449, 586 (2007).

S. V. Golubev and V. I. Kononenko, Rasplavy 2, 35 (1988).

I. G. Brodova, P. S. Popel’, N. M. Barbin, and N. A. Vatolin, Melts as the Basis for the Formation of the Structure and Properties of Aluminum Alloys (Yekaterinburg, UrO RAN, 2005).

G. E. Abrosimova and A. S. Aronin, Phys. Solid State 59, 2248 (2017).

S. V. Popova, O. A. Sazanova, V. V. Brazhkin, N. V. Kalyaeva, M. B. Kondrin, and A. G. Lyapin, Phys. Solid State 48, 2177 (2006).

E. V. Dedyaeva, T. K. Akopyan, A. G. Pedalko, G. V. Ta-lanova, G. I. Zabarev, A. D. Izotov, A. N. Suchkov, V. T. Fedotov, and L. I. Shorneva, Inorg. Mater. 52, 1077 (2016).

R. Xu, Mater. Lett. 59, 2718 (2005).

S.-W. He, Liu Yuanqing, and S. Guo, Heat Treatm. Met. 34 (11), 47 (2009).

V. O. Esin, A. S. Krivonosova, I. Zh. Sattybaev, T. G. Fedorova, and V. A. Sazonova, Phys. Met. Metallogr. 107, 588 (2009).

V. V. Brazhkin, Doctoral (Phys.-Math.) Dissertation (Moscow, 1996).

Yu. A. Khokhlova, D. A. Ishchenko, and M. A. Khokhlov, Tekh. Diagn. Nerazr. Kontrol’, No. 1, 30 (2017).

W. C. Oliver and G. M. Pharr, J. Mater. Res. 7, 1564 (1992).

ACKNOWLEDGMENTS

The authors express their sincere gratitude to V.I. Lad’yanov, Dr. Sci. (Phys.–Math.), and A.V. Vakhrushev, Dr. Sci. (Phys.–Math.), for valuable advices given in the course of study, as well as to I.K. Averkiev for his assistance in performing the elemental analysis of the samples.

Funding

This study was supported in part by the Russian Science Foundation (grant no. 22-22-00674). Electron microscopic studies and measurements of physical and mechanical properties were performed using the equipment of Center for Collective Use Center for Physical and Physicochemical Methods of Analysis and for Studying Properties and Characteristics of Surfaces, Nanostructures, Materials and Products at the Udmurt Federal Research Center, Ural Branch, Russian Academy of Sciences (Izhevsk, Russia). Samples under high pressure were prepared in the Institute for High Pressure Physics, Russian Academy of Sciences (Troitsk, Moscow, Russia).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by O. Kadkin

Rights and permissions

About this article

Cite this article

Menshikova, S.G., Shushkov, A.A. & Brazhkin, V.V. Microstructure and Physical and Mechanical Properties of the Al90Gd10 Binary Alloy after Barothermal Treatment. Phys. Solid State 64, 204–209 (2022). https://doi.org/10.1134/S1063783422050055

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783422050055