Abstract

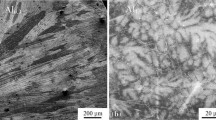

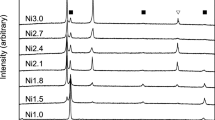

Al-xCu alloys (x = 5 wt.%, 15 wt.%, 33 wt.%, and 40 wt.%) were solidified at atmospheric pressure (AP) and at high pressure of 3 GPa (3 GPa). The microstructural evolution was studied, and it shows that the amount of eutectic Al2Cu phase is suppressed in the Al-xCu samples solidified under high pressure compared to the samples solidified under ambient conditions. In addition, the secondary dendritic arm spacing in the Al-15Cu and Al-33Cu alloy decreases when solidified under high pressure. The strain rate sensitivity (m) and activation volume (V*) were calculated from the nanoindentation experiments, and the results show that m increases while V* decreases for the hypoeutectic Al-5Cu and Al-15Cu alloys solidified at 3 GPa. Both m and V* decrease for the eutectic alloy (Al-33Cu), and for the hypereutectic composition (Al-40Cu), m decreases, whereas V* increases when solidified under high pressure. The results suggest that both the strength and plasticity for the hypoeutectic compositions increase simultaneously, while the plasticity decrease in the eutectic composition solidified under high pressure. On the other hand, for the hypereutectic Al-40Cu alloy solidified under 3 GPa, both the strength and plasticity decrease.

Similar content being viewed by others

References

W.F. Guo, Y.P. Yi, S.Q. Huang, X.C. Mao, J. Fang, H.L. He, and B. Hu, Mater. Charact. 160, 110094 (2020).

L. Gao, X. Ou, S. Ni, K. Li, Y. Du, and M. Song, Mater. Sci. Eng. A. 762, 138091 (2019).

Y.H. Gao, L.F. Cao, J. Kuang, J.Y. Zhang, G. Liu, and J. Sun, J. Alloys. Compd. 822, 153629 (2020).

X.L. Wen, B. Chen, Z. Chen, X. Lin, H.O. Yang, N. Kang, Q.Z. Wang, W.L. Wang, and W.D. Huang, Mater. Sci. Eng. A. 847, 143290 (2022).

N.D. Alexopoulos, Z. Velonaki, C.I. Stergiou, and S.K. Kourkoulis, Mater. Sci. Eng. A. 700, 457 (2017).

T.X. Zheng, B.F. Zhou, J. Wang, S.S. Shuai, Y.B. Zhong, W.L. Ren, Z.M. Ren, F. Debray, and E. Beaugnon, Mater. Sci. Eng. A. 733, 170 (2018).

P. Wang, C. Gammer, F. Brenne, K.G. Prashanth, R.G. Mendes, M.H. Rümmeli, T. Gemming, J. Eckert, and S. Scudino, Mater. Sci. Eng. A. 711, 562 (2018).

Y. Zhang, F. L. Li, Z. Luo, Y. L. Zhao, W. Xia, and W.W. Zhang, Trans. Nonferrous. Met. Soc. China (English. Ed). 26, 2296 (2016).

A.K. Dahle, K. Nogita, J.W. Zindel, S.D. McDonald, and L.M. Hogan, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 32, 949 (2001).

B.I. Jung, C.H. Jung, T.K. Han, and Y.H. Kim, J. Mater. Process. Technol. 111, 69 (2001).

X. Liu, P. Ma, Y. D. Ji, Z. J. Wei, C.J. Suo, P.C. Ji, X.R. Shi, Z.S. Yu, and K. G. Prashanth, J. Mater. Res. Technol. 9, 2983 (2020).

Z.J. Wei, P. Ma, H.W. Wang, C.M. Zou, S. Scudino, K.K. Song, K.G. Prashanth, W. Jiang, and J. Eckert, Mater. Des. 65, 387 (2015).

Y. Fujinaga, Jpn. J. Appl. Phys. 42, 5215 (2003).

Y. Fujinaga and Y. Syono, High. Press. Res. 15, 233 (1997).

J.C. Jie, C.M. Zou, E. Brosh, H.W. Wang, Z.J. Wei, and T.J. Li, J. Alloys. Compd. 578, 394 (2013).

J.J. Sobczak, L. Drenchev, and R. Asthana, Int. J. Cast. Met. Res. 25, 1 (2012).

X. Tong, D.C. Zhang, K. Wang, J.G. Lin, Y.Y. Liu, Z.M. Shi, Y.C. Li, J.X. Lin, and C.E. Wen, Mater. Sci. Eng. A. 733, 9 (2018).

X.H. Wang, Z. Ran, Z.J. Wei, C.M. Zou, H.W. Wang, J. Gouchi, and Y. Uwatoko, J. Alloys. Compd. 742, 670 (2018).

P. Ma, C.M. Zou, H.W. Wang, S. Scudino, B.G. Fu, Z.J. Wei, U. Kühn, and J. Eckert, J. Alloys. Compd. 586, 639 (2014).

X.P. Lin, Y. Kuo, L. Wang, J. Ye, C. Zhang, L. Wang, and K.Y. Guo, Trans. Nonferrous. Met. Soc. China. (English. Ed). 31, 1587 (2021).

P. Ma, Z.J. Wei, Y.D. Jia, C.M. Zou, S. Scudino, K.G. Prashanth, Z.S. Yu, S.L. Yang, C.G. Li, and J. Eckert, J. Alloys. Compd. 688, 88 (2016).

W.H. Li, K. Shin, C.G. Lee, B.C. Wei, T.H. Zhang, and Y.Z. He, Mater. Sci. Eng. A. 478, 371 (2008).

H. Wu, F. Xu, J.Y. Ren, X.D. Lan, Y. Yin, L.X. Liang, M. Song Y. Liu, J. Li, Q.X. Li, and W.D. Huang, Trans. Nonferrous. Met. Soc. China. (English. Ed). 31, 1758 (2021).

E. Liu, H. Wang, G. Xiao, G. Yuan, and X. Shu, Ceram. Int. 41, 12939 (2015).

Z.H. Jiang, H.Z. Zhang, C.D. Gu, Q. Jiang, and J.S. Lian, J. Appl. Phys. 104, 053505 (2008).

H.Z. Zhang, Z.H. Jiang, and Y.H. Qiang, Mater. Sci. Eng. A. 517, 316 (2009).

J.J. Hu, S. Han, G.X. Sun, S.C. Sun, Z.H. Jiang, G.Y. Wang, and J.S. Lian, Mater. Sci. Eng. A. 618, 621 (2014).

D.C.C. Magalhães, A.M. Kliauga, and V.L. Sordi, Trans. Nonferrous. Met. Soc. China. (English. Ed). 31, 595 (2021).

Y. Jiang, J.J. Hu, Z.H. Jiang, J.S. Lian, and C.E. Wen, Mater. Sci. Eng. A. 712, 341 (2018).

H.W. Wang, D.D. Zhu, C.M. Zou, and Z.J. Wei, Mater. Des. 34, 488 (2012).

T. Maity, K.G. Prashanth, Balci, J.T. Kim, T. Schöberl, Z. Wang, and J. Eckert, Int. J. Plast. 109, 121 (2018).

Y. Ma, G.J. Peng, Y.H. Feng, T.H. Zhang, and J. Non, Cryst. Solids. 465, 8 (2017).

T. Maity, K.G. Prashanth Balçi, Z. Wang, Y.D. Jia, and J. Eckert, Compos. Part. B: Eng. 150, 7 (2018).

R. B. Figueiredo, S. Sabbaghianrad, A. Giwa, J.R. Greer, and T.G. Langdon, Acta. Mater. 122, 322 (2017).

C.L. Wang, Y.H. Lai, J.C. Huang, and T.G. Nieh, Scr. Mater. 62, 175 (2010).

H. Li, Y. Liang, L. Zhao, J. Hu, S. Han, and J. Lian, J. Alloys. Compd. 709, 566 (2017).

T. Maity, B. Roy, and J. Das, Acta. Mater. 97, 170 (2015).

Q. Wei, S. Cheng, K.T. Ramesh, and E. Ma, Mater. Sci. Eng. A. 381, 71 (2004).

N. Makuch, Trans. Nonferrous. Met. Soc. China. (English. Ed). 31, 764 (2021).

Acknowledgements

This work was supported by the State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology (No. AWJ-22M05), the National Natural Science Foundation of China (No. 51971123), the Innovation Program of Shanghai Municipal Education Commission (No. 2021-01-07-00-09-E00114), the financial support from Program 173 (No. 2020-JCIQ-ZD-186-01), and the Space Utilization System of China Manned Space Engineering (No. KJZ-YY-NCL08).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, P., Zhang, Z., Liu, X. et al. Microstructure and Nanoindentation Creep Behavior of Binary Al-Cu Alloy Synthesized at High Pressure. JOM 75, 176–183 (2023). https://doi.org/10.1007/s11837-022-05545-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05545-0