Abstract

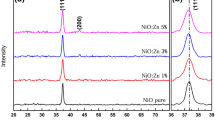

The spray pneumatic method has been successfully employed for the preparation of polycrystalline NiO-doped ZnO thin films. The effect of NiO content (0, 1, 2, 3, and 6 at %) is studied on structural, optical, and electrical properties of NiO-doped ZnO thin films. The thin films were successfully deposited on a glass substrate at 450°C using the organic solar heater. XRD patterns of NiO-doped ZnO thin films indicate that the obtained ZnO thin films are polycrystalline with (100), (002), and (101) highest peaks of ZnO phase. However, α-Ni(OH)2 and β-Ni(OH)2 were observed at 6 and 3 at % NiO, respectively. The crystal structure was improved for doped thin films, the crystallite size decreased by increasing the NiO content up to 6 at % NiO. All thin films have a high optical transmission in the visible region of about 85%. The optical band gap energy decreased from 3.26 eV for 0% to 3.34 eV for 1 at %, and further decreased to 3.27 eV for 6 at % NiO. The thin film deposited with 3 at % NiO has the lowest value of Urbach energy of 0.091 eV. The electrical conductivity of the NiO-doped ZnO films increased greatly from 0.016 (Ω cm)–1 for 0% NiO to 0.042 (Ω cm)–1 for 3 at % NiO. It can be noted that the deposited film after 3 at % NiO is a p-type semiconductor.

Similar content being viewed by others

REFERENCES

M. N. Suma, M. V. N. Prasad, V. Gaddam, K. Rajanna, and M. M. Nayak, J. Pure Appl. Ind. Phys. 9, 1 (2019).

D. Selvakumar, R. Vasudevan, and R. Jayavel, Mater. Today: Proc. 5, 14468 (2018).

R. Vinodkumar, J. Varghese, J. Varghese, S. K. Saji, and N. V. Unnikrishnan, Optik 174, 274 (2018).

M. Hjiri, M. S. Aida, O. M. Lemine, and L. El Mir, Mater. Sci. Semicond. Proc. 89, 149 (2019).

Y. Adachi, N. Saito, I. Sakaguchi, and T. T. Suzuki, Thin Solid Films 685, 238 (2019).

Y. Hou and A. H. Jayatissa, Prog. Nat. Sci.: Mater. Int. 27, 435 (2017).

M. E. I. Ahmed, F. Taghizadeh, F. D. Auret, W. E. Meyer, and J. M. Nel, Mater. Sci. Semicond. Proc. 101, 82 (2019).

D. Nithyaa Sree, S. P. M. Deborrah, C. Gopinathan, and S. S. R. Inbanathan, Appl. Surf. Sci. 494, 116 (2019).

A. Bouaine, A. Bourebia, H. Guendouz, and Z. Riane, Optik 166, 317 (2018).

P. Kumar, H. K. Malik, A. Ghosh, R. Thangavel, and K. Asokan, J. Alloys Compd. 768, 323 (2018).

F. Basharata, U. A. Ranab, M. Shahida, and M. Serwar, RSC Adv. 5, 86713 (2015).

K. H. Young, L. Wang, S. Yan, X. Liao, T. Meng, H. Shen, and W. C. Mays, Batteries 3, 6 (2017).

G. S. Kumar, L. Xuejin, Y. Du, Y. Geng, and X. Hong, J. Alloys Compd. 798, 467 (2019).

K. Kandpal and N. Gupta, J. Mater. Sci.: Mater. Electron. 28, 16013 (2017).

M. R. Islam, M. Rahman, S. F. U. Farhad, and J. Podder, Surf. Interfaces 16, 120 (2019).

Y. P. Santos, E. Valença, R. Machado, and M. A. Macêdo, Mater. Sci. Semicond. Proc. 86, 43 (2018).

S. Benramache, B. Benhaoua, N. Khechai, and F. Chabane, Mater. Tech. 100, 573 (2012).

Y. Aoun, M. Marrakchi, S. Benramache, B. Benhaoua, S. Lakel, and A. Cheraf, Mater. Res. 2, e20170681 (2018).

ACKNOWLEDGMENTS

The authors wish to thank the editors of the J. Physics of the Solid State for a critical reading of the manuscript and valuable comments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Aoun, Y., Meneceur, R., Benramache, S. et al. Sprayed NiO-Doped p-Type Transparent ZnO Thin Films Suitable for Gas-Sensing Devices. Phys. Solid State 62, 131–136 (2020). https://doi.org/10.1134/S1063783420010060

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783420010060