Abstract

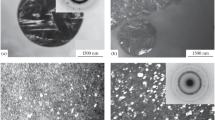

A complex study of the structure of Ti50Ni25Cu25 alloy obtained in the initial amorphous state by rapid quenching (melt spinning) have been performed for the first time. The investigations are carried out by methods of neutron diffraction, X-ray diffraction, transmission electron microscopy, scanning electron microscopy, and electron microdiffraction. It is found that the topological and composition short-range atomic order, corresponding to three superstructure types (B2, L21, and L12), is formed within localized nanodomains (up to 1 nm) in amorphous Ti50Ni25Cu25 alloy upon solidification. It is also demonstrated for the first time that the alloy has an amorphous–crystal structure, which contains (along with individual microspherulites that underwent thermoelastic martensitic transformation B2 ↔ B19) nanocrystalline ensembles with the B2, L21, or L12 structure up to 10 nm in size, which are localized in the amorphous matrix.

Similar content being viewed by others

REFERENCES

Rapidly Quenched Metals, Ed. by S. Steeb and H. Warlimont (Elsevier, Amsterdam, 1985).

I. B. Kekalo, Atomic Structure of Amorphous Alloys and Its Evolution (Ucheba MISIS, Moscow, 2006) [in Russian].

A. M. Glezer and I. E. Permyakova, Nanocrystals Quenched from Melt (Fizmatlit, Moscow, 2012) [in Russian].

V. G. Pushin, S. B. Volkova, and N. M. Matveeva, Fiz. Met. Metalloved. 83 (3), 68 (1997).

V. G. Pushin, S. B. Volkova, and N. M. Matveeva, Fiz. Met. Metalloved. 83 (3), 78 (1997).

V. G. Pushin, S. B. Volkova, and N. M. Matveeva, Fiz. Met. Metalloved. 83 (4), 155 (1997).

V. G. Pushin, S. B. Volkova, N. M. Matveeva, et al., Fiz. Met. Metalloved. 83 (6), 149 (1997).

V. G. Pushin, S. B. Volkova, N. M. Matveeva, et al., Fiz. Met. Metalloved. 83 (6), 157 (1997).

V. G. Pushin, S. B. Volkova, N. M. Matveeva, et al., Fiz. Met. Metalloved. 84 (4), 172 (1997).

N. M. Matveeva, V. G. Pushin, A. V. Shelyakov, et al., Fiz. Met. Metalloved. 83 (6), 82 (1997).

E. Cesari, J. Van Humbeek, V. Kolomytsev, et al., J. Phys. IV. France 5, 197 (1997).

A. V. Pushin, N. I. Kourov, A. A. Popov, and V. G. Pushin, Materialovedenie 187 (10), 24 (2012).

A. V. Pushin, A. A. Popov, and V. G. Pushin, Fiz. Met. Metalloved. 113 (3), 299 (2012).

A. V. Pushin, A. A. Popov, and V. G. Pushin, Fiz. Met. Metalloved. 114 (6), 753 (2013).

A. V. Pushin, A. A. Popov, and V. G. Pushin, Mater. Sci. Forum 738–739, 321 (2013).

A. V. Shelykov, S. G. Larin, V. P. Ivanov, et al., J. Phys. IV, France 11, 547 (2001).

S. F. Dubinin, V. D. Parkhomenko, V. G. Pushin, and S. G. Teploukhov, Fiz. Met. Metalloved. 89 (1), 70 (2000).

V. D. Parkhomenko, S. F. Dubinin, V. G. Pushin, and S. G. Teploukhov, Vopr. At. Nauki Tekh., No. 4, 28 (2001).

B. A. Aleksashin, V. V. Kondrat’ev, A. V. Korolev, et al., Fiz. Met. Metalloved. 110 (6), 608 (2010).

V. G. Pushin, V. V. Stolyarov, R. Z. Valiev, et al., Ann. Chim. Sci. Mat. 27 (3), 77 (2002).

V. G. Pushin, N. I. Kourov, T. E. Kuntsevich, et al., Phys. Met. Metallogr. 94 (Suppl. 1), S107 (2002).

Heusler Alloys: Properties, Growth, Applications, Ed. by C. Felser (Springer International Publishing, 2016).

N. N. Kuranova, A. V. Pushin, A. N. Uksusnikov, et al., Tech. Phys. 62 (8), 1189 (2017).

A. V. Pushin, V. G. Pushin, T. E. Kuntsevich, et al., Tech. Phys. 62 (12), 1843 (2017).

ACKNOWLEDGMENTS

Electron microscopy studies were performed using equipment of the Collaborative Access Center of the Institute of Metal Physics (Ural Branch, Russian Academy of Sciences).

Funding

This study was performed within government contract no. AAAA-A18-118020190116-6 (“Structure”) and the Joint Laboratory of the Ural State University and the Mikheev Institute of Metal Physics (Ural Branch, Russian Academy of Sciences).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Yu. Sin’kov

Rights and permissions

About this article

Cite this article

Pushin, V.G., Pushin, A.V. & Kuranova, N.N. Specific Features of the Atomic Structure of Ti50Ni25Cu25 Alloy Rapidly Quenched from Melt. Crystallogr. Rep. 65, 12–17 (2020). https://doi.org/10.1134/S1063774519060154

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063774519060154