Abstract

This paper presents the results of experimental studies of the modes of formation of nanosized structures on the surface of a silicon substrate by the method of focused ion beams (FIB). The regularities of the effect of the ion beam current, accelerating voltage, and radiation dose on the surface morphology of nanoscale structures are determined. The modes under which the effects of implantation swelling (structure height up to 3 nm) and etching (structure depth up to 8 nm) manifest themselves are determined. The average roughness of the resulting structures varies from 0.13 to 0.24 nm. The results can be used in the development of technology for manufacturing instrument structures in nanoelectronics and nanophotonics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 INTRODUCTION

In relation to the trend towards a decrease in the lateral dimensions of elements of nanoelectronics and nanophotonics, the urgency of mastering new methods for local modification of the surface of substrates and structures with nanoscale resolution is increasing. One of the promising methods for the formation of nanosized structures is the use of focused ion beams (FIB), which is used for maskless etching, deposition, and surface modification during the formation of nanosized structures in micro- and nanoelectronic technology [1–9]. The method is based on the interaction of accelerated ions with the substrate surface, as a result of which various processes occur on the surface and in the near-surface layer: ion implantation, formation of a damaged layer, material sputtering, etc. The minimum diameter of an ion beam in the FIB method can reach 7 nm, which opens up wide-ranging possibilities for using it to form nanosized structures of nanoelectronic and nanophotonic elements. The papers [2, 10–14] present the results of studies of regularities in the processes of nanoscale modification of the substrate surface under the action of a focused ion beam; however, the regions of low currents and accelerating voltages used in the formation of nanometer-scale structures used in modern nanoelectronic device structures remain poorly studied. The aim of this paper is to study the regularities of the effect of FIB modes to provide nanoscale modification of the silicon substrate surface. To this end, experimental studies of the effect of the ion beam current, accelerating voltage, and dose on the morphology of structures formed in the near-surface region of the silicon surface were carried out.

2 EXPERIMENTAL

Experimental studies were carried out using a scanning electron microscope (SEM) Nova NanoLab 600 with an ion column (FEI, the Netherlands). KDB-0.001 (100) silicon substrates were used after preliminary chemical cleaning in acetone and isopropyl alcohol at a temperature of 70°C for 10 min and exposure to an aqueous solution of HF (10%) for 30 s. To form structures with a size of 5 × 5 μm, using the built-in tools of the SEM control program, a template was formed, according to which the surface of the substrates was treated with a focused ion beam. The calculation of the dose for a point effect of an ion beam, taking into account the nonuniformity of the effect, is given in [15]. In our case, the ion beam exposure overlap was 50% and the exposure time at the point was 1 µs. This makes it possible to use the following ratio when assessing the radiation dose:

where D is the dose (nC/µm2), I is the ion beam current (nA), t is the total time of exposure to the ion beam according to the template (s), \(S\) is the template area (µm2), dt is the time of exposure to the ion beam at point (s), N is the number of points in the template, n is the number of passes of the ion beam along the template, \({{S}_{{{\text{beam}}}}}\) is the beam area (µm2), and π/4 is the coefficient that takes into account the filling density of the ion beam effects in the template.

During the experimental studies, the FIB modes were selected to ensure the same dose, including the minimum one, taking into account the features of the SEM control program, according to which for different accelerating voltages, due to different apertures, it was not possible to set the same ion beam current. Table 1 shows the modes under which experimental studies were carried out.

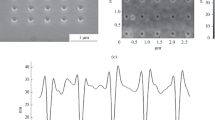

The morphology of the resulting structures was studied by atomic force microscopy (AFM) at the Ntegra Vita probe nanolaboratory (ZAO NT-MDT, Russia). Figure 1 shows the typical AFM scans, which were used to measure the depth and average roughness of the inner region of the formed structures.

The depth of the structure was determined as the difference between the average heights in the center of the formed structure and the surface outside the structure, which were determined from histograms. The average roughness was measured using the built-in tools of the AFM control program in the inner region of the structures over an area of 4 × 4 μm2.

3 RESULTS AND DISCUSSION

The analysis showed that at low doses and currents of the ion beam, the volume of the near-surface region treated with the ion beam increases (Figs. 1c, 1d), which can be explained by the effect of radiational pore formation (implantation swelling), in which ions are introduced into the near-surface layer, but their energy is not sufficient to sputter the substrate atoms. In this case, the crystal structure of the near-surface layer is disturbed, amorphization occurs, and its volume increases [13].

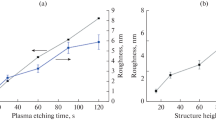

Figure 2 shows the dependences of the depth and average roughness of the obtained structures on the ion beam current at various doses. The positive values of the structure depth at low ion beam currents and exposure doses make it possible to determine the FIB modes under which implantation swelling occurs. These modes correspond to relatively high values of the average roughness, which is due to the high porosity of the surface of the formed structures.

Analysis of the dependence of the depth of the obtained structures at 10 keV (Fig. 2a) shows that implantation swelling occurs at an ion beam current of 0.3 pA. With a further increase in the ion beam current, the energy of the ions increases, the process of material removal begins to predominate, and the depth of the structures increases. The average roughness (Fig. 2b) decreases with a slight increase in the ion beam current, which is explained by an increase in the flux density of ions affecting the surface and the rate of material removal. With a further increase in the ion beam current, the roughness slightly increases, which is related to the overlapping of the areas of exposure of the ion beam and its broadening due to the Coulomb interaction.

With an increase in the accelerating voltage up to 20 keV (Fig. 2c), the nature of the dependences does not change. A decrease in the implantation swelling can be noted, which is related to the increase in the ion energy and sputtering coefficient. The average roughness (Fig. 2d) at 20 keV and exposure dose of 1 pC/µm2 with an increase in the ion beam current decreases and goes into saturation, which is probably caused by the effect of implantation swelling and an insufficient number of ions to bleed the unevenness of the initial surface relief. At an exposure dose of 6 pC/µm2 and low currents, the roughness decreases, and with an increase in the ion beam current, the dependence enters saturation, since at low currents the ion energy is sufficient to remove the initial relief, and at high currents, serious damage to the surface still does not occur. At an exposure dose of 20 pC/µm2 and a current of 0.7 pA, the initial surface relief is leveled, and with an increase in the ion beam current, the roughness increases due to the uneven distribution of the ion beam.

With an increase in the accelerating voltage up to 30 keV (Fig. 2e), at a dose of 1 pC/µm2, implantation swelling occurs over the entire range of ion beam currents used. With an increase in the exposure dose and ion beam current, the depth of structures increases, which is explained by an increase in the number and energy of ions. The average roughness at an accelerating voltage of 30 keV (Fig. 2f) and a dose of 1 pC/µm2 is lower than at accelerating voltages and decreases with increasing ion beam current. In this case, the developed relief is determined by the effect of implantation swelling, which weakens as the current increases to 30 pA. At doses of 6 and 20 pC/µm2, there is no implantation swelling; at a low current, the surface has a low average roughness due to the etching of the initial relief. The nature of the dependences with increasing current is sufficiently smooth, probably due to the complex influence of the overlapping of the ion impact regions and the broadening of the ion beam width due to the Coulomb interaction.

Figure 3 shows the dependences of the depth of the formed structures and the average roughness on the accelerating voltage. In Fig. 3a the nature of the dependence for the ion beam exposure dose of 1 pC/μm2 reflects the presence of implantation swelling: an increase in the height of the structures with an increase in the accelerating voltage is observed. In this case, the ion beam current was the minimum possible for each accelerating voltage based on the apertures installed in the Nova NanoLab 600 SEM (Table 1). As the dose increases, the spraying of the material begins to predominate. For a dose of 20 pC/µm2 at a current of 0.3 pA and an accelerating voltage of 10 keV, implantation swelling is observed; with an increase in the accelerating voltage, the energy of the ion flux density increases, due to which the material sputtering process begins to dominate. The dependence of the average roughness (Fig. 3b) decreases monotonically at a dose of 1 pC/µm2, which can be explained by the etching of the original relief. At 30 keV, the ion beam current is 1 pA (Table 1), which corresponds to a decrease in the number of ions and the etching rate. With an increase in the dose, the dependences of the average roughness decrease faster and become saturated due to uniform etching.

Dependence of the depth and average roughness of the formed structures on the accelerating voltage: (a, b) at minimum currents for accelerating voltages of 10, 20, 30 keV; (c, d) at average currents for accelerating voltages of 10, 20, 30 keV; (e, f) at maximum currents for accelerating voltages of 10, 20, 30 keV.

With an increase in the ion beam currents to average values (Table 1, Fig. 3c), the depth of the resulting structures first decreases and then increases, which can be explained by the effect of implantation swelling at a low accelerating voltage, similar to the minimum ion beam current (Fig. 3a). At an accelerating voltage of 30 keV, the depth of the structures begins to decrease due to the introduction of a larger number of ions into the near-surface layer and, as a result, a decrease in the etching rate. The average roughness (Fig. 3d) at low doses first decreases and then increases, which is related to the etching of the surface relief and the subsequent influence of the uneven effect of the ion beam. At a dose of 20 pC/µm2, as the accelerating voltage increases, the roughness first does not change and then decreases, which is related to the increase in the number of implanted ions and a decrease in the etching rate.

With an increase in the ion beam currents to the maximum values taken for the study (Table 1), at a dose of 1 pC/µm2, implantation swelling is observed (Fig. 3e). With an increase in the exposure dose, the depth of the structures first decreases, which can be explained by an increase in the energy of the ions and, as a consequence, an increase in the number of knocked out atoms by one ion, and then increases, due to the active introduction of gallium ions in the near-surface layer of silicon. The average roughness for low doses decreases, probably due to the small etching depth related to the increase in the ion energy and leveling of the relief. For a dose of 20 pC/µm2, the roughness first decreases due to the etching of the relief, and then begins to grow due to the high current and the uneven effect of the ion beam on the surface.

Figure 4 shows the dependences of the depth of the formed structures and the average roughness on the dose of ion exposure. The dependence at an accelerating voltage of 10 keV (Fig. 4a) and an ion beam current of 0.3 pA reflects an increase in the height of structures due to implantation swelling with an increasing dose. As the current increases, the ion energy increases, the sputtering process begins to predominate, and the depth of the formed structures increases. The average roughness (Fig. 4b) at a current of 0.3 pA and a low dose first increases, which can be explained by implantation swelling similarly to Fig. 3b, and decreases with the increasing dose due to relief etching. As the ion beam current increases, the total value of the roughness becomes smaller, while the dependences first decrease due to relief etching, and then increase due to the uneven effect of the ion beam.

At an accelerating voltage of 20 keV (Fig. 4c), at an ion beam current of 0.7 pA, implantation swelling manifests itself to a lesser extent than at 0.3 pA and 10 keV, which is explained by the increase in the ion energy, and etching begins to predominate. With an increase in the ion beam current, the depth of the formed structures increases similarly to the dependences for 10 keV (Fig. 4a). The average roughness (Fig. 4d) on all dependences first decreases due to relief etching, and then increases due to the uneven effect of the ion beam.

At an accelerating voltage of 30 keV (Fig. 4e), the ion beam dose is 1 pC/µm2 and at all currents of the ion beam, implantation swelling begins. With increasing current, this effect decreases due to the increase in the ion flux density. As the dose increases, the depth of the resulting structures increases monotonically. The average roughness (Fig. 4f) initially tends to decrease, and with a further increase in the dose, it increases similarly to the structures formed at 10 and 20 keV (Figs. 4b, 4d).

CONCLUSIONS

As a result of the study carried out, the possibility of forming structures with a depth of the order of a few nanometers with a low roughness was shown. The regularities of the influence of the implantation dose, current, and accelerating voltage of the ion beam on the morphology of the Si surface are determined. The boundary modes of the transition from implantation swelling to etching are studied. Due to the overlap of the FIB etching regions and the broadening of the ion beam due to the increase in the ion flux density at high doses, an increase in roughness is observed. The results obtained can be used in the development of technology for manufacturing instrument structures in nanoelectronics and nanophotonics.

REFERENCES

Luchinin, V.V., Nanotekhnologii: fizika, protsessy, diagnostika, pribory (Nanotechnologies: Physics, Processes, Diagnostics, Devices), Moscow: Fizmatlit, 2006.

Nanotekhnologii v mikroelektronike (Nanotechnologies in Microelectronics), Ageev, O.A. and Konoplev, B.G., Eds., Moscow: Nauka, 2019.

Komarov, F.F., Novikov, A.P., and Shiryaev, S.Yu., Defekty struktury v ionno-implantirovannom kremnii (Structural Defects in Ion-Implanted Silicon), Minsk: Universitetskoe, 1990.

Salvati, E., Brandt, L.R., Papadaki, C., Zhang, H., Mousavi, S.M., Wermeille, D., and Korsunsky, A.M., Nanoscale structural damage due to focused ion beam milling of silicon with Ga ions, Mater. Lett., 2018, vol. 213, pp. 346–349.

Lunt, A.J.G. and Korsunsky, A.M., A review of micro-scale focused ion beam milling and digital image correlation analysis for residual stress evaluation and error estimation, Surf. Coat. Technol., 2015, vol. 283, pp. 373–388.

Wang, Y.-C., Xie, D.-G., Ning, X.-H., and Shan, Z.-W., Thermal treatment-induced ductile-tobrittle transition of submicron-sized Si pillars fabricated by focused ion beam, Appl. Phys. Lett., 2015, vol. 106, no. 8, p. 081905.

Korsunsky, A.M., Guénolé, J., Salvati, E., Sui, T., Mousavi, M., Prakash, A., and Bitzek, E., Quantifying eigenstrain distributions induced by focused ion beam damage in silicon, Mater. Lett., 2016, vol. 185, pp. 47–49.

Schöngrundner, R., Treml, R., Antretter, T., Kozic, D., Ecker, W., Kiener, D., and Brunner, R., Critical assessment of the determination of residual stress profiles in thin films by means of the ion beam layer removal method, Thin Solid Films, 2014, vol. 564, p. 321.

Salvati, E., Sui, T., Lunt, A.J.G., and Korsunsky, A.M., The effect of eigenstrain induced by ion beam damage on the apparent strain relief in FIB-DIC residual stress evaluation, JMADE, 2016, vol. 9, pp. 649–658.

Baxter, F., Garner, A., Topping, M., Hulme, H., and Preuss, M., Phase stability of zirconium oxide FI LMS during focused ion beam milling, J. Nucl. Mater., 2018, vol. 504, pp. 176–180.

Lisitsyn, S.A., Kolomiytsev, A.S., Il’in, O.I., Il’ina, M.V., Konoplev, B.G., Bykov, A.V., and Ageev, O.A., Study of ion beam including deposition modes of platinum nanosized structures using by focused ion beams, Russ. Microelectron., 2017, vol. 46, no. 7, pp. 468–473.

Ageev, O.A., Vnukova, A.V., Gromov, A.L., Il’in, O.I., Kolomiitsev, A.S., Konoplev, B.G., and Lisitsyn, S.A., Analysis of modes of nanoscale profiling during ion-stimulated deposition of W and Pt using the method of focused ion beams, Nanotechnol. Russ., 2014, vol. 9, nos. 3–4, pp. 145–150.

Lisitsyn, S.A., Balakirev, S.V., Avilov, V.I., Kolomiitsev, A.S., Klimin, V.S., Solodovnik, M.S., Konoplev, B.G., and Ageev, O.A., Study of nanoscale profiling modes of GaAs epitaxial structures by focused ion beams, Nanotechnol. Russ., 2018, vol. 13, nos. 1–2, pp. 26–33.

Kots, I.N., Kolomiitsev, A.S., Lisitsyn, S.A., Polyakova, V.V., Klimin, V.S., and Ageev, O.A., Studying the regimes of silicon surface profiling by focused ion beams, Russ. Microelectron., 2019, vol. 48, no. 2, pp. 72–79.

Mitrofanov, M.I., Voznyuk, G.V., Rodin, S.N., Lundin, W.V., Evtikhiev, V.P., Tsatsulnikov, A.F., and Kaliteevski, M.A., Calculation of the Ga+ FIB ion dose distribution by SEM image, Semiconductors, 2020, vol. 54, no. 12, pp. 1682–1684.

Funding

This study was supported by the Russian Science Foundation (grant no. 20-69-46076).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access. This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kots, I.N., Polyakova, V.V., Morozova, Y.V. et al. Nanosized Modification of the Silicon Surface by the Method of Focused Ion Beams. Russ Microelectron 51, 126–133 (2022). https://doi.org/10.1134/S1063739722030076

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063739722030076