Abstract

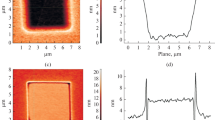

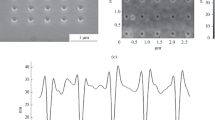

The aim of this paper is to study the modes and determine the patterns of plasma-chemical processing in a fluoride plasma of a silicon surface locally modified with gallium ions. Experimental and theoretical studies of the interaction of the surface of silicon wafers with focused ion beams (FIB) and fluoride plasma are carried out. The general regularities of the influence of the FIB and plasma-chemical etching (PCE) modes on the etching rate, surface roughness, and the angle of inclination of the structure walls are determined, and the manifestation of activation and masking effects during the PCE of a silicon surface locally modified by FIB is established. It is found that, in the case of the masking effect, the selectivity is 195.26, and the rate of formation of structures by the combination of FIB and PCE methods is 3.23 nm/s.

Similar content being viewed by others

REFERENCES

Giannuzzi, L.A. and Stevie, F.A., Introduction to Focused Ion Beams: Instrumentation, Theory, Techniques and Practice, New York: Springer, 2004, p. 357.

Luchinin, V.V., Nanotekhnologii: fizika, protsessy, diagnostika, pribory (Nanotechnologies: Physics, Processes, Diagnostics, Devices), Moscow: Fizmatlit, 2006.

Nanotekhnologii v mikroelektronike (Nanotechnologies in Microelectronics), Ageev, O.A. and Konoplev, B.G., Eds., Moscow: Nauka, 2019.

Bhushan, B., Springer Handbook of Nanotechnology, New York: Springer, 2010, 3rd ed., no. 1964.

Colligon, J.S., Energetic condensation processes, properties, and products, J. Vac. Sci. Technol. A, 1995, vol. 13, no. 3, pp. 1649–1657.

Vakulov, Z., Khakhulin, D., Geldash, A., Tominov, R.V., Klimin, V.S., Smirnov, V.A., and Ageev, O.A., Impact of laser pulse repetition frequency on nucleation and growth of LiBbO3 thin films, J. Adv. Dielectr., 2021, no. 2160019.

Vakulov, Z., Geldash, A., Khakhulin, D., Il’ina, M.V., Il’in, O.I., Klimin, V.S., Dzhuplin, V.N., Konoplev, B.G., He, Z., and Ageev, O.A., Piezoelectric energy harvester based on LiNbO3 thin films, Materials, 2020, vol. 13, no. 18, p. 3984.

Vakulov, Z., Khakhulin, D., Zamburg, E., Mikhaylichenko, A., Smirnov, V.S., Tominov, R.V., Klimin, V.A., and Ageev, O.A., Towards scalable large-area pulsed laser deposition, Materials, 2021, vol. 14, no. 17, p. 3984.

Salvati, E., Brandt, L.R., Papadaki, C., Zhang, H., Mousavi, S.M., Wermeille, D., and Korsunsky, A.M., Nanoscale structural damage due to focused ion beam milling of silicon with Ga ions, Mater. Lett., 2018, vol. 213, pp. 346–349.

Korsunsky, A.M., Guénolé, J., Salvati, E., Sui, T., Mousavi, M., Prakash, A., and Bitzek, E., Quantifying eigenstrain distributions induced by focused ion beam damage in silicon, Mater. Lett., 2016, vol. 185, pp. 47–49.

Kots, I.N., Kolomiitsev, A.S., Lisitsyn, S.A., Polyakova, V.V., Klimin, V.S., and Ageev, O.A., Studying the regimes of silicon surface profiling by focused ion beams, Russ. Microelectron., 2019, vol. 48, no. 2, pp. 72–79.

Lisitsyn, S.A., Balakirev, S.V., Avilov, V.I., Kolomiytsev, A.S., Klimin, V.S., Solodovnik, M.S., Konoplev, B.G., and Ageev, O.A., Study of nanoscale profiling modes of GaAs epitaxial structures by focused ion beams, Nanotechnol. Russ., 2018, vol. 13, nos. 1–2, pp. 26–33.

Park, H. and Kim, H.J., Theoretical analysis of Si2H6 adsorption on hydrogenated silicon surfaces for fast deposition using intermediate pressure SiH4 capacitively coupled plasma, Coatings, 2021, vol. 11, no. 9, p. 1041.

Yong-Hyun, K., Ji-Ho, C., Jong-Sik, K., Jong-Bae, P., Dae-Chul, K., and Young-Woo, K., Comprehensive data collection device for plasma equipment intelligence studies, Coatings, 2021, vol. 11, no. 9, p. 1025.

Zeze, D., Forrest, R., Carey, J., Cox, D., Robertson, I., and Weiss, B., Ion etching of quartz and pyrex for microelectronic application, J. Appl. Phys., 2002, vol. 92, pp. 3624–3629.

Winkler, T., Kirchhoff, V., and Goedicke, K., Requirements of new pulse power-supplies regarding reactive sputtering processes and adjustment of layer properties, Presentation at European Workshop on Pulsed Plasma Surface Technologies, Dresden, Germany, 2002.

Han, C.F., Lin, C.C., and Lin, J.F., Applications of energy flux and numerical analyses to the plasma etching of silicon deep trench isolation (DTI) structures, Precis. Eng., 2021, vol. 71, pp. 141–152.

Alvarez, H.S., Cioldin, F.H., Silva, A.R., Espínola, L.C.J., Vaz, A.R., and Diniz, J.A., Silicon micro-channel definition via ICP-RIE plasma etching process using different aluminum hardmasks, J. Microelectromech. Syst., 2021, vol. 30, no. 9459194, pp. 668–674.

Gusmão Cacho, M.G., Benotmane, K., Pimenta-Barros, P., Tiron, R., and Possémé, N., Selective plasma etching of silicon-containing high chi block copolymer for directed self-assembly (DSA) application, J. Vacuum Sci. Technol. B, 2021, vol. 39, no. 41, p. 042801.

Choi, J.H., Yoon, J., Jung, Y., Im, W.B., and Kim, H.-J., Analysis of plasma etching resistance for commercial quartz glasses used in semiconductor apparatus in fluorocarbon plasma, Mater. Chem. Phys., 2021, vol. 2721, p. 125015.

Solovetskii, D.I., Mechanisms of plasma-chemical etching of materials, in Entsiklopediya nizkotemperaturnoi plazmy (Encyclopedia of Low Temperature Plasma), Moscow: Nauka, 2000, vol. 3.

Orlikovskii, A.A. and Slovetskii, D.I., Problems of plasma-chemical etching in microelectronics, Mikroelektronika, 1987, vol. 16, no. 6, p. 497.

Kots, I.N., Klimin, V.S., Polyakova, V.V., Vakulov, Z.E., and Ageev, O.A., Masking coating formation by the focused ion beams method for plasma chemical treatment, J. Phys.: Conf. Ser., 2018, vol. 1124, no. 8, p. 081035.

Komarov, F.F., Novikov, A.P., and Shiryaev, S.Yu., Defekty struktury v ionno-implantirovannom kremnii (Structural Defects in Ion-Implanted Silicon), Minsk: Universitetskoe, 1990.

Amirov, I.I. and Shumilov, A.S., Profile evolution of silicon nanostructures in argon-plasma sputtering, J. Surf. Invest.: X-ray, Synchrotron Neutron Tech., 2020, vol. 14, no. 5, pp. 935–943.

Funding

This study was supported by the Russian Science Foundation (grant no. 20-69-46076). The results were obtained using the infrastructure of the Scientific and Educational Center “Nanotechnologies” of the Southern Federal University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Klimin, V.S., Morozova, Y.V., Kots, I.N. et al. Formation of Nanosized Structures on the Silicon Surface by a Combination of Focused Ion Beam Methods and Plasma-Chemical Etching. Russ Microelectron 51, 236–242 (2022). https://doi.org/10.1134/S1063739722030064

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063739722030064