Abstract

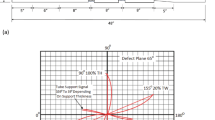

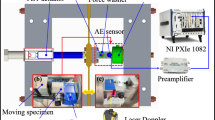

The results of the combined application of ultrasonic and eddy current flaw detection to increase the detectability of surface cracks in welds of small thicknesses are considered. A statistical analysis of the noise parameters generated by the reinforcing beads during eddy current testing is carried out. The useful signal-to-noise ratio was evaluated when identifying transverse cracks of operational origin emerging to the surface in vertical and horizontal butt welds of the steel tanks wall. Welds made by manual arc and semiautomatic submerged arc welding are considered, including the most critical areas of the crossings of these welds. For such welds, the reliability of combined ultrasonic and eddy current testing was evaluated when detecting surface and internal longitudinal and transverse cracks compared with the results of radiographic and magnetic particle testing. The prospects of using a combination of methods in the tanks diagnosis as part of ultrasonic testing to detect cracks in the cross section of butt joints and their crossings and eddy current monitoring to detect surface cracks against the background of weld beads are demonstrated.

Similar content being viewed by others

REFERENCES

Aleshin, N.P., Mogilner, L.Yu., Krysko, N.V., Pridein, O.A., Idrisov, M.T., and Kusyy, A.G., Possibilities for testing welded joints of the walls of steel tanks using ultrasonic and eddy current methods, Russ. J. Nondestr. Test., 2022, vol. 58, no. 8 (in press).

Aleshin, N.P., Fizicheskie metody nerazrushayushchego kontrolya svarnykh soedinenii (Physical Methods of Nondestructive Testing of Welded Joints), Moscow: Mashinostroenie, 2013.

Kretov, E.F., Ul’trazvukovaya defektoskopiya v energomashinostroenii (Ultrasonic Flaw Detection in Power Engineering), St. Petersburg: Sven, 2007.

Aleshin, N.P., Mogilner, L.Yu., Krysko, N.V., Pridein, O.A., and Idrisov, M.T., Features of crack detection during ultrasonic inspection of welded joints of VST walls, Neft. Prom-st, 2022, no. 1, pp. 86–91.

Wright, M., Eddy Current Testing Technology, Waterloo, Canada: Eclipse Sci., 2015.

Zhdanov, A.G., Shchukis, E.G., Lunin, V.P., and Stolyarov, A.A., Algorithms for pre-processing of eddy-current signals when inspecting heat-exchanger pipes of NPP steam generators, Russ. J. Nondestr. Test., 2018, vol. 54, no. 4, pp. 283–293.

Dymkin, G.Ya., Kurkov, A.V., Smorodinskii, Ya.G., and Shevelev, A.V., On the sensitivity of eddy current testing of parts of railway rolling stock, Russ. J. Nondestr. Test., 2019, vol. 55, no. 8, pp. 610–616.

OLIMPUS company website. httml//www//olimpus-ims.com/en. Accessed January 30, 2022.

EddyFi company website. Html Access Mode // Non-Destructive Testing Solutions and Technologies. EddyFi. Accessed January 30, 2022.

NPF Politest company website. https://www.polytest.ru/. Accessed January 30, 2022.

Nishimizu, A., Endo, H., Tooma, M., Kometani, Y., Ouchi, H., Yoshida, I., and Nonaka, Y., Non-destructive examination using a flexible multi-coil eddy current probe for weld surfaces of core internal components of nuclear power plants, Insight: Non-Destr. Test. Cond. Monit., 2012, vol. 54, pp. 134–137.

McNab, A. and Thomson, J., An eddy current array instrument for application on ferritic welds, NDT & E Int., 1995, vol. 28, no. 2, pp. 103–112.

Todorov, E., Nagy, B., Levesque, S., Ames, N., and Na, J., Inspection of laser welds with array eddy current technique, Conf. Rev. Progr. Quant. Nondestr. Eval. (Denver, CO, 2012).

Raude, A., Sirois, M., Lemieux, H., and Crepeau, J., Advances in carbon steel weld inspection using tangential eddy current array, 19th WCNDT (2016).

Aleshin, N.P., Krysko, N.V., Shchipakov, N.A., and Mogilner, L.Yu., Optimization of parameters of mechanized ultrasonic control of extended welds, Nauka Tekhnol. – Truboprovodn. Transp. Nefti Nefteprod., 2020, vol. 10, no. 6, pp. 352–363.

ISO 17643. Non-destructive testing of welds—eddy current examination of welds by complex plane analysis.

Volchenko, V.N., Veroyatnost’ i nadezhnost' otsenki kachestva metalloproduktsii (Likelihood and Reliability of Assessing the Quality of Metal Products), Moscow: Metallurgiya, 1979.

Wright, M., Developing Qualified NDT Procedures & the Technical Justification Process, Waterloo, Canada: Eclipse Sci., 2016.

Ivchenko, G.I. and Medvedev, Yu.N., Vvedenie v matematicheskuyu statistiku: uchebnik (Introduction to Mathematical Statistics: a Textbook) Moscow: Izd. LKI, 2010.

Gourieroux, C. and Monfor, A., Statistics and Econometric Models: Vol. 2, Testing, Confidence Regions, Model Selection and Asymptotic Theory, Cambridge: Cambridge Univ. Press, 1995.

Aleshin, N.P., Krysko, N.V., Kusyy, A.G., Skrynnikov, S.V., and Mogilner, L.Yu., Investigating the detectability of surface volumetric defects in ultrasonic testing with the use of Rayleigh waves generated by an electromagnetic-acoustic transducer, Russ. J. Nondestr. Test., 2021, vol. 57, no. 5, pp. 361–368.

https://reliability.readthedocs.io/en/latest/. Accessed March 21, 2022.

ACKNOWLEDGMENTS

The authors thank Olympus-Moscow and LLC Inzhenernie Tekhnicheskie Sistemy for the equipment provided and assistance in running experiments during the preparation of this article.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Aleshin, N.P., Mogilner, L.Y., Krysko, N.V. et al. Assessing Reliability of Testing Welded Joints of Steel Tank Walls Using Ultrasonic and Eddy Current Methods. Russ J Nondestruct Test 58, 769–778 (2022). https://doi.org/10.1134/S1061830922090030

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830922090030